Elastic non-slip mat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

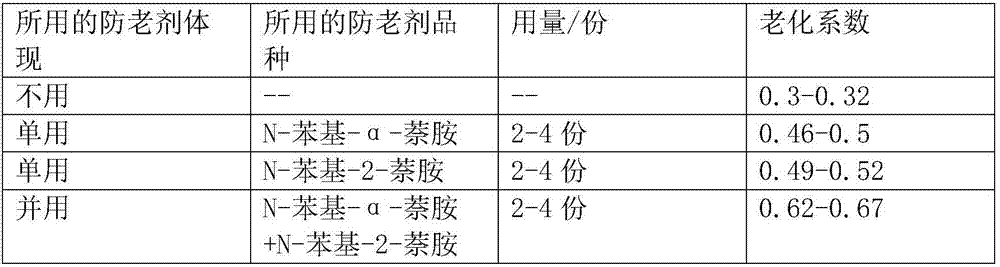

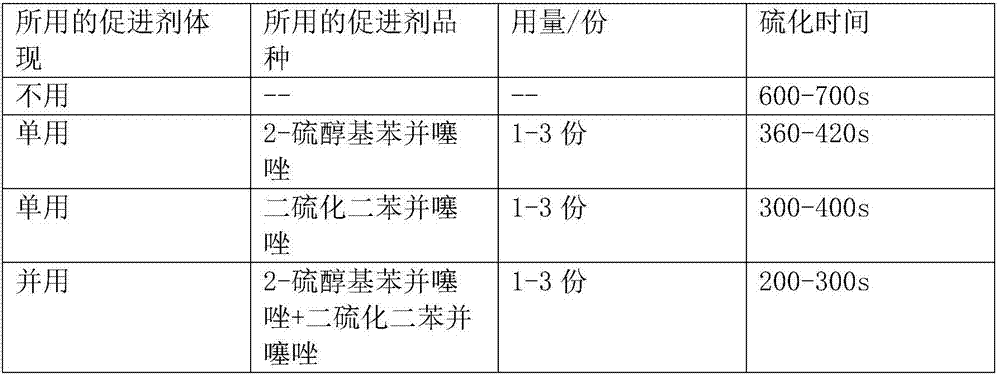

Method used

Image

Examples

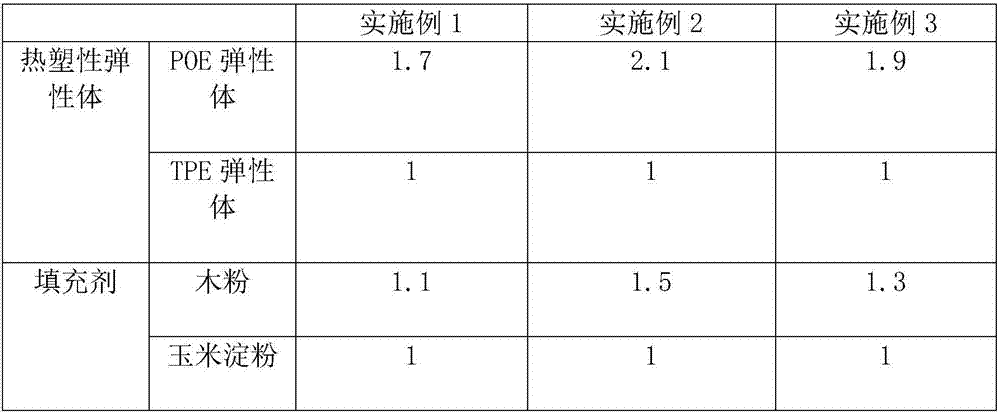

Embodiment 1

[0028] The elastic non-slip floor mat of this embodiment is prepared from the following components by weight: 28 parts of thermoplastic elastomer, 32 parts of EVA, 30 parts of polyethylene, 24 parts of filler, 4 parts of anti-aging agent and 3 parts of accelerator; wherein, The thermoplastic elastomer is mixed with POE elastomer and TPE elastomer with a mass ratio of 1.7:1, and the filler is mixed with wood flour and corn starch with a mass ratio of 1.1:1, and the wood flour is made of wood with a particle size of 50 mesh Flour, corn starch with a particle size of 5.5 μm is selected; the anti-aging agent is a mixture of N-phenyl-α-naphthylamine and N-phenyl-2-naphthylamine, and the accelerator is preferably 2-mercaptobenzothiazole and dibenzothiazole disulfide mixture.

Embodiment 2

[0030] The elastic non-slip floor mat of this embodiment is prepared from the following components by weight: 28 parts of thermoplastic elastomer, 32 parts of EVA, 30 parts of polyethylene, 24 parts of filler, 4 parts of anti-aging agent and 3 parts of accelerator; wherein, The thermoplastic elastomer is mixed with POE elastomer and TPE elastomer with a mass ratio of 2.1:1, and the filler is mixed with wood flour and corn starch with a mass ratio of 1.5:1, and the wood flour is selected from wood with a particle size of 50 mesh. Flour, corn starch with a particle size of 5.5 μm is selected; the anti-aging agent is a mixture of N-phenyl-α-naphthylamine and N-phenyl-2-naphthylamine, and the accelerator is preferably 2-mercaptobenzothiazole and dibenzothiazole disulfide mixture.

Embodiment 3

[0032] The elastic non-slip floor mat of this embodiment is prepared from the following components by weight: 28 parts of thermoplastic elastomer, 32 parts of EVA, 30 parts of polyethylene, 24 parts of filler, 4 parts of anti-aging agent and 3 parts of accelerator; wherein, The thermoplastic elastomer is mixed with POE elastomer and TPE elastomer with a mass ratio of 1.9:1, and the filler is mixed with wood flour and corn starch with a mass ratio of 1.3:1, and the wood flour is made of wood with a particle size of 50 mesh Flour, corn starch with a particle size of 5.5 μm is selected; the anti-aging agent is a mixture of N-phenyl-α-naphthylamine and N-phenyl-2-naphthylamine, and the accelerator is preferably 2-mercaptobenzothiazole and dibenzothiazole disulfide mixture.

[0033] The following table 3 is a comparison table of the mass ratio of each component in the thermoplastic elastomer and the filler in Examples 1-3:

[0034]

[0035] Each sample of the elastic non-slip f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com