Flame-retardant polypropylene with light specific gravity and impact resistance and preparation method thereof

A flame-retardant polypropylene and impact-resistant technology, applied in the field of polypropylene, can solve problems such as the failure of reactive flame retardants, and achieve the effects of improving dispersion effect, low cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

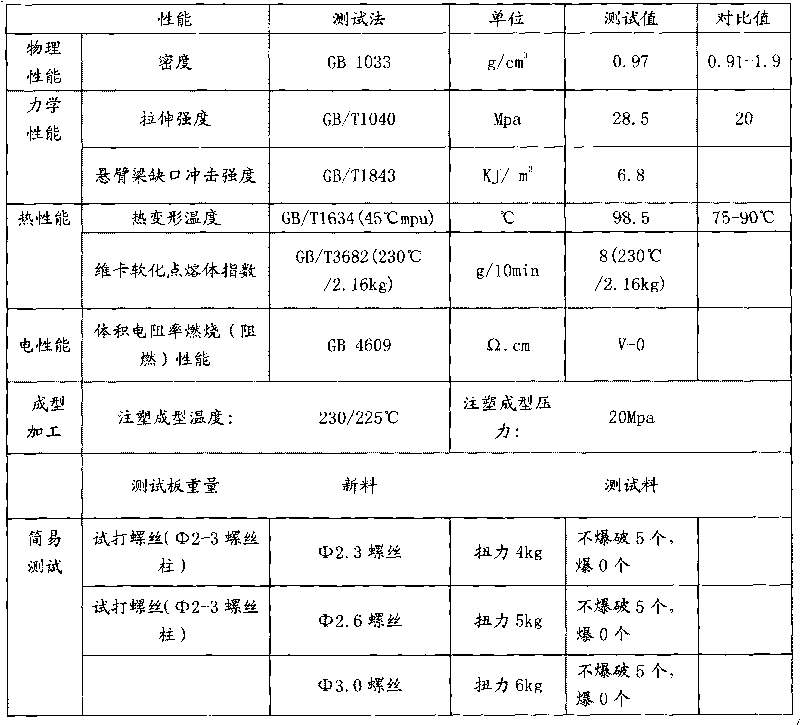

[0055] A flame-retardant polypropylene with light specific gravity and impact resistance; including the following substances in weight percentage: 70% polypropylene, 6% trichloroethyl phosphate, 6% antimony oxide, 6% POE, 10% nano-scale kaolin, antioxidant Agent (2,6-tertiary butyl-4-methylphenol) 0.5%, antioxidant adjuvant (didodecanol ester) 0.5%, hexenyl bisstearamide 1%.

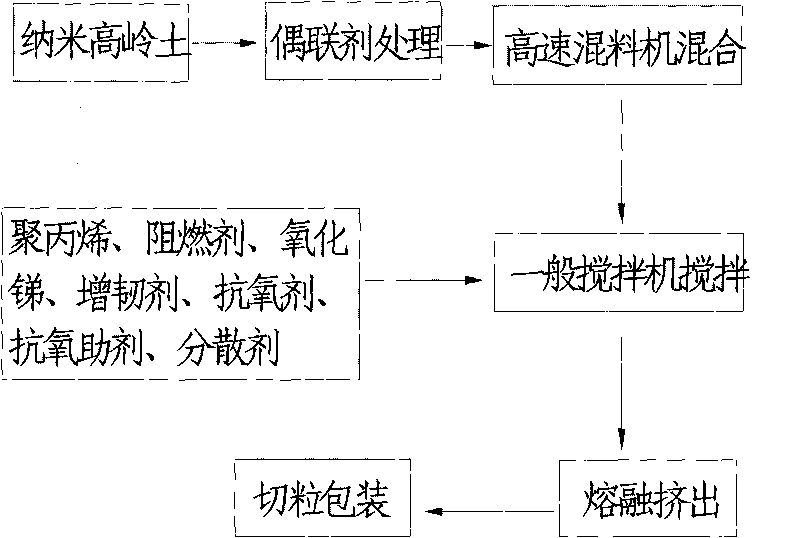

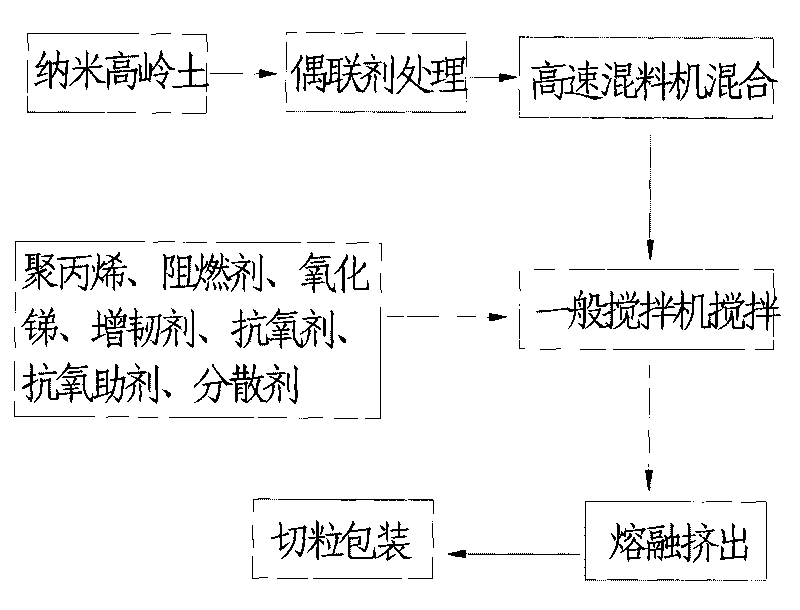

[0056] The method for the above-mentioned light specific gravity, impact-resistant flame-retardant polypropylene, the preparation steps are as follows:

[0057] A, the above-mentioned amount of nano kaolin and coupling agent are processed and mixed, placed in a high-speed mixer and mixed evenly;

[0058] B. Mix the above-mentioned amount of polypropylene, trichloroethyl phosphate, antimony oxide, toughening agent, antioxidant, antioxidant auxiliary agent, hexenyl bis stearamide with nano-scale kaolin and coupling The agent is stirred in a mixer;

[0059] C. Melt extrusion, the pressure is 20MPa, and the ...

Embodiment 2

[0062] A flame-retardant polypropylene with light specific gravity and impact resistance; including the following substances in weight percentage: 75% polypropylene, 10% trichloroethyl phosphate, 3% antimony oxide, 5% POE, 7.5% nano-scale kaolin, antioxidant Agent (bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide) 0.1%, antioxidant adjuvant (mixture of ditetradecyl alcohol ester and dioctadecyl alcohol ester) 0.3%, hexyl Alkenyl bisstearamide 0.1%.

[0063] The preparation method is the same as in Example 1.

Embodiment 3

[0065] A flame-retardant polypropylene with light specific gravity and impact resistance; including the following substances in weight percentage: 70% polypropylene, 6% trichloroethyl phosphate, 8% antimony oxide, 5% POE, 10% nano-scale kaolin, antioxidant Agent (tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) 0.5%, antioxidant adjuvant (tri(dodecyl alcohol) ester) 0.1%, hexene Base bis stearamide 0.4%.

[0066] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com