Preparation method of TPU/POE alloy

An alloy and temperature control technology, which is applied in the field of TPU/POE alloy preparation, can solve problems such as performance loss, delay of TPU reaction process, poor dispersion effect, etc., to avoid performance decline, improve thermal stability, and improve dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

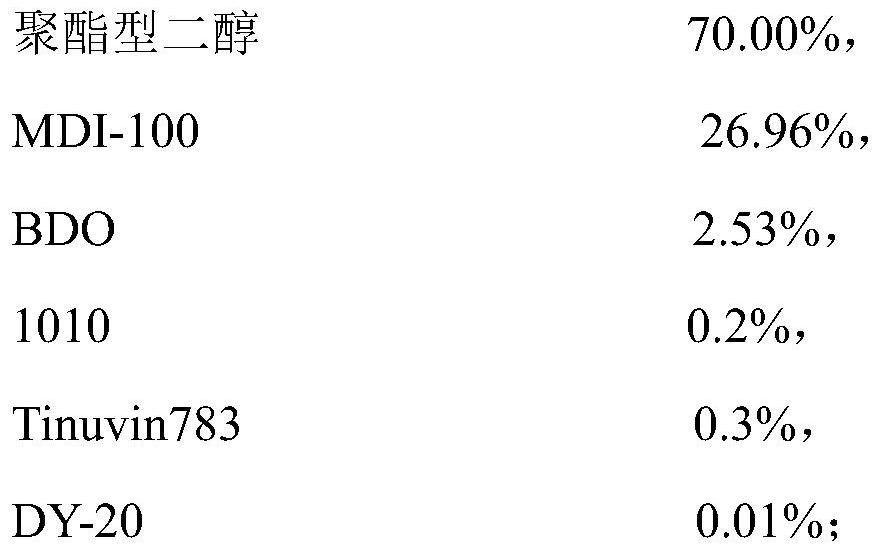

[0029] The composition of raw materials is as follows:

[0030]

[0031] The polyester diol is PE-4010 produced by Shandong Yinuowei Polyurethane Co., Ltd.;

[0032] The NCO / OH value of the raw material system was 0.96.

[0033] The preparation method is as follows:

[0034] (1) Mix and heat polyester diol, MDI-100, BDO, 1010, DY-20, and Tinuvin 783 to 145°C, mix well, and inject into the first-stage screw extruder, and the first-stage screw extruder The exit temperature is controlled at 120-190°C, the screw speed is controlled at 180rpm, and after shear blending and melting reaction, OH-capped TPU is obtained;

[0035] (2) The first section of the screw extruder is connected to the second section of the screw extruder, the screw blocks of the second section of the screw extruder are composed of shear blocks, and the end of the second section of the screw extruder is equipped with a counter-rotating block, the OH-capped TPU continues to be passed into the second stage of...

Embodiment 2

[0037] The composition of raw materials is as follows:

[0038]

[0039] The polyester diol is PE-4020 produced by Shandong Yinuowei Polyurethane Co., Ltd.;

[0040] The NCO / OH value of the raw material system was 0.97.

[0041] The preparation method is as follows:

[0042] (1) Mix and heat polyester diol, MDI-100, BDO, 1010, DY-20, and Tinuvin 783 to 145°C, mix well, and inject into the first-stage screw extruder, and the first-stage screw extruder The exit temperature is controlled at 120-190°C, the screw speed is controlled at 180rpm, and after shear blending and melting reaction, OH-capped TPU is obtained;

[0043] (2) The first section of the screw extruder is connected to the second section of the screw extruder, the screw blocks of the second section of the screw extruder are composed of shear blocks, and the end of the second section of the screw extruder is equipped with a counter-rotating block, the OH-capped TPU continues to be passed into the second stage of...

Embodiment 3

[0045] The composition of raw materials is as follows:

[0046]

[0047] The polyester diol is PE-4030 produced by Shandong Yinuowei Polyurethane Co., Ltd.;

[0048] The NCO / OH value of the raw material system was 0.99.

[0049] The preparation method is as follows:

[0050](1) Mix and heat polyester diol, MDI-100, BDO, 1010, DY-20, and Tinuvin 783 to 145°C, mix well, and inject into the first-stage screw extruder, and the first-stage screw extruder The exit temperature is controlled at 120-190°C, the screw speed is controlled at 180rpm, and after shear blending and melting reaction, OH-capped TPU is obtained;

[0051] (2) The first section of the screw extruder is connected to the second section of the screw extruder, the screw blocks of the second section of the screw extruder are composed of shear blocks, and the end of the second section of the screw extruder is equipped with a counter-rotating block, the OH-capped TPU continues to be passed into the second stage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com