High-strength and anti-crack concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of high-strength crack-resistant concrete and its preparation, can solve problems such as poor crack resistance of concrete, and achieve the effects of enhanced strength and crack resistance, excellent self-healing, crack resistance and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

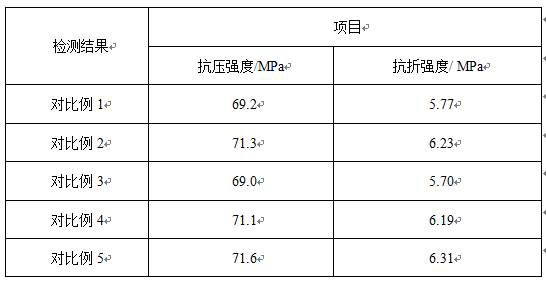

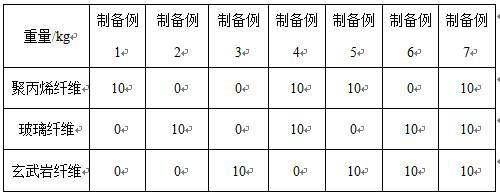

Examples

preparation example 1-7

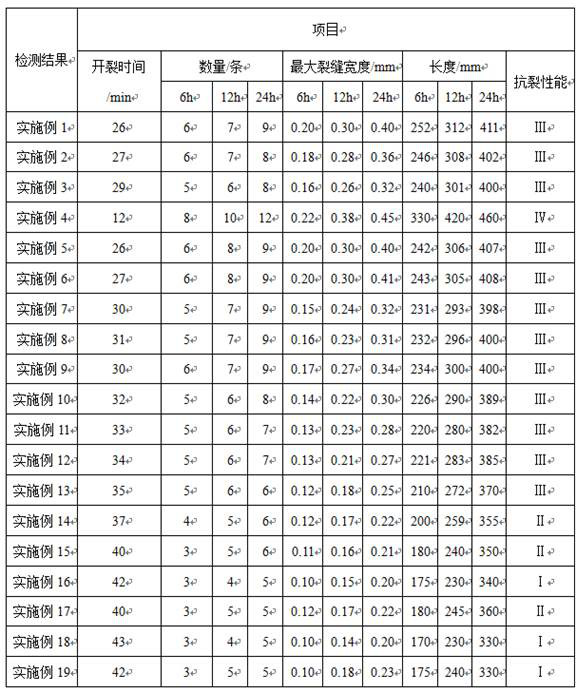

[0043] In the preparation examples 1-7, polypropylene fibers, glass fibers and basalt fibers were used to prepare fibers 1-7, and the components between polypropylene fibers, glass fibers and basalt fibers are specifically shown in Table 1

[0044] The composition of table 1 preparation example 1-7 fiber

[0045]

[0046] Preparation example of urea-formaldehyde resin prepolymer aqueous solution

preparation example 8

[0048] Weigh 10kg urea, 20kg formaldehyde, and 1kg triethanolamine respectively, stir and mix to prepare a mixed solution, add ammonia water with a mass concentration of 10% to the mixed solution, adjust the pH of the mixed solution to 8, and adjust the temperature to 70°C React at constant temperature for 2 hours to obtain aqueous solution 1 of urea-formaldehyde resin prepolymer.

preparation example 9

[0050] The difference from Preparation Example 8 is that: 15kg of urea, 25kg of formaldehyde, and 1.5kg of triethanolamine were weighed to prepare urea-formaldehyde resin prepolymer aqueous solution 2, and the rest of the preparation conditions were the same as those of Preparation Example 8 with uniform preparation environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com