Graphene composite antibacterial master batch and preparation method thereof

A graphene composite, antibacterial masterbatch technology, applied in the field of graphene, can solve the problems of poor antibacterial effect, serious pollution of the method of graphene antibacterial particles, etc., achieves good antibacterial effect, improves dispersion effect, and reduces the effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

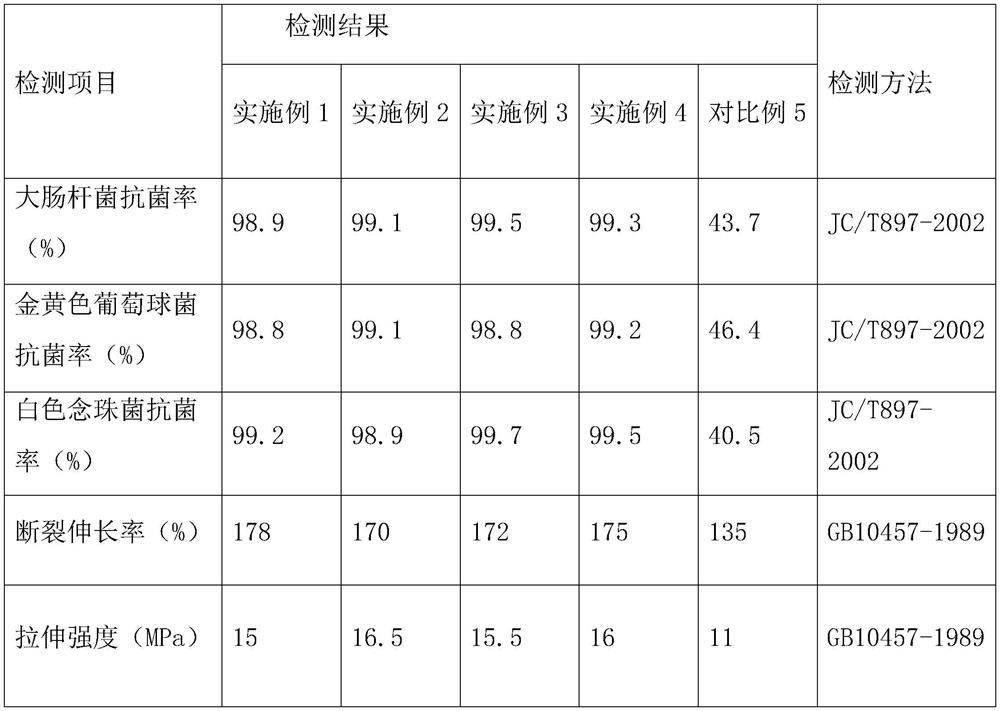

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of the composite antibacterial masterbatch of graphene and resin, comprises the following steps:

[0030] a. Dissolving copper acetate in a propylene glycol solution to obtain a copper acetate propylene glycol solution with a copper acetate concentration of 0.4 to 0.8 mol / L; cooling, centrifuging, and filtering, taking the filter residue for cleaning and vacuum drying to obtain nano cuprous oxide powder;

[0031] b. After dissolving stearic acid, add glucose under stirring condition, then add dropwise silver acetate solution, and continue stirring for 3-5 hours to obtain deep red nano-silver sol, add the cuprous oxide powder obtained in step a, and continue stirring for 1-5 hours 2h, centrifugal separation, after the obtained precipitate is cleaned, add graphene and deionized water, after mixing, use spray drying to obtain a graphene composite antibacterial agent;

[0032] c. Stir the resin masterbatch, graphene compos...

Embodiment 1

[0049] Embodiment 1 adopts the inventive method to prepare graphene composite polyethylene antibacterial fresh-keeping film

[0050] The specific operation steps are as follows:

[0051] 1. Add an appropriate amount of copper acetate to the propylene glycol solution, stir well to completely dissolve the copper acetate, and prepare a 0.7mol / L copper acetate propylene glycol solution;

[0052] 2. Add the above prepared solution into a stainless steel reactor with tetrafluoroethylene lining, seal it, then place it in a constant temperature oil bath heating device, and heat it at a constant temperature of 130°C to fully react copper acetate and propylene glycol for 4 hours;

[0053] 3. After the reaction solution is cooled, centrifugally filter, and the filter residue is repeatedly washed with deionized water and dried in vacuum to obtain nano-cuprous oxide powder;

[0054] 4. Take 1.00g of stearic acid, add 1.00g of ammonia water and 100.00mL of distilled water, and stir in a ma...

Embodiment 2

[0062] Embodiment 2 adopts the inventive method to prepare graphene composite polyethylene antibacterial fresh-keeping film

[0063] The difference from Example 1 is that the solvent concentration in the copper acetate propylene glycol solution is 0.6mol / L, the oil bath heating temperature is 120°C, the mass of glucose is 7.00g, the mass of stearic acid is 1.00g, silver acetate is 2.50g, and cuprous oxide is 2.00g; Grind the composite antibacterial agent powder to an average particle size of 6 μm; when preparing polyethylene composite masterbatch, the weight percentage of raw materials is 97.0% polyethylene masterbatch, 2.9% graphene composite antibacterial agent, and 0.1% high-carbon alkanes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com