Waterproof PU leather and preparation method thereof

A leather and hydrophobic agent technology, applied in the field of artificial leather, can solve the problems of poor waterproof effect of PU leather, achieve uniform waterproof effect, ensure waterproof performance, and reduce the possibility of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

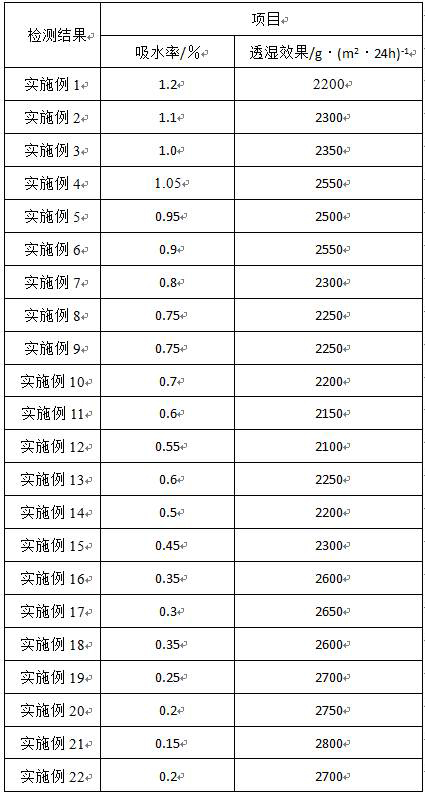

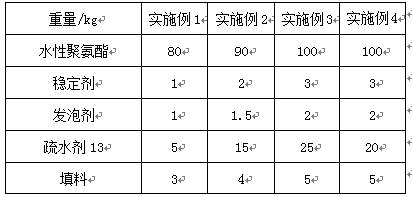

Examples

preparation example 1

[0044] Take 1 kg of methyltriethoxysilane as the modification solution 1.

preparation example 2-7

[0046] Take methyltriethoxysilane, pentaerythritol stearate, silane coupling agent, and dimethylolpropionic acid respectively, the specific quality of which is shown in Table 1, stir and mix, and prepare modification liquid 2-7.

[0047] Components of modifying solution in preparation example 2-7 of table 1

[0048]

[0049] Hydrophobic agent preparation example

preparation example 8-10

[0051] Weigh anhydrous ethanol, deionized water, nano-silica and modified solution 1 respectively, see Table 2 for the specific quality, first stir and mix nano-silica, anhydrous ethanol, and nano-silica at 20kHz for 30s , stand still for 30s, circulate 3 times to obtain an intermediate solution, then add modified solution 1 to the intermediate solution, and continue to stir to obtain an intermediate product, and use absolute ethanol to centrifuge and wash the intermediate product, pour the supernatant, and keep the lower layer of precipitation , and place the precipitate in an oven for drying to obtain modified nano silicon dioxide 1-3 as hydrophobic agent 1-3.

[0052] Each component ratio in table 2 preparation example 8-10

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com