Special polypropylene reinforcing material for water pump and preparation method thereof

A polypropylene reinforced, polypropylene technology, applied in the polymer field, can solve the problems of strict requirements on the physical properties of finished products, the water pressure resistance, the strength is difficult to meet the requirements, the strength of the weld line is weak, etc., to improve the burst pressure and pressure point time. , The effect of improving the strength of the weld line and improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

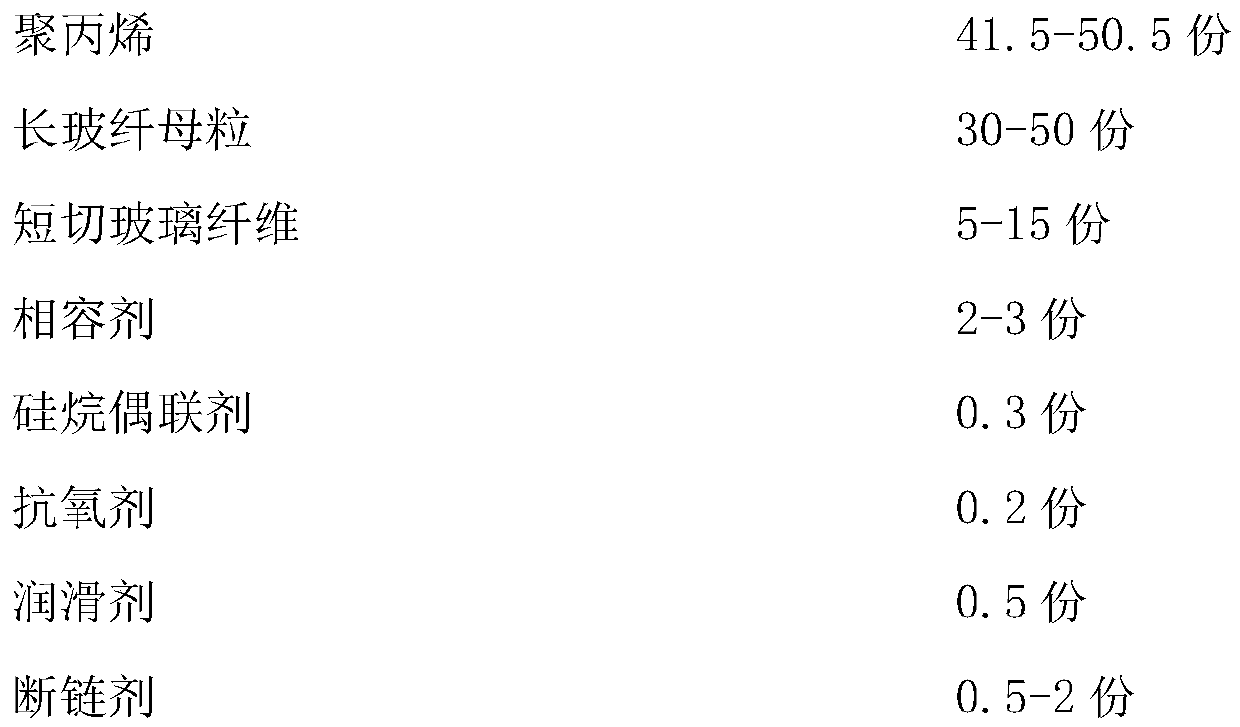

[0044] The reinforced polypropylene specially used for water pumps in this embodiment is composed of the following raw materials in parts by weight:

[0045]

[0046] Concrete preparation method comprises the following steps:

[0047] (1) After the chopped glass fibers are dried, stir and reflux at a low speed for 10 minutes with an ethanol solution of a silane coupling agent with a mass percent concentration of 10%, leave it at room temperature for 12 hours, vacuum filter, and place in an electric heating constant temperature blast drying oven Dry to constant weight at 80°C to obtain chopped glass fibers after surface treatment for subsequent use;

[0048](2) Add polypropylene, compatibilizer, antioxidant, chain breaking agent and lubricant together in a mixer with nitrogen protection and mix at high speed for 2-10 minutes;

[0049] (3) Under the protection of nitrogen, put the mixture of (2) into the parallel twin-screw extruder to melt, then add the chopped glass fiber ...

Embodiment 2

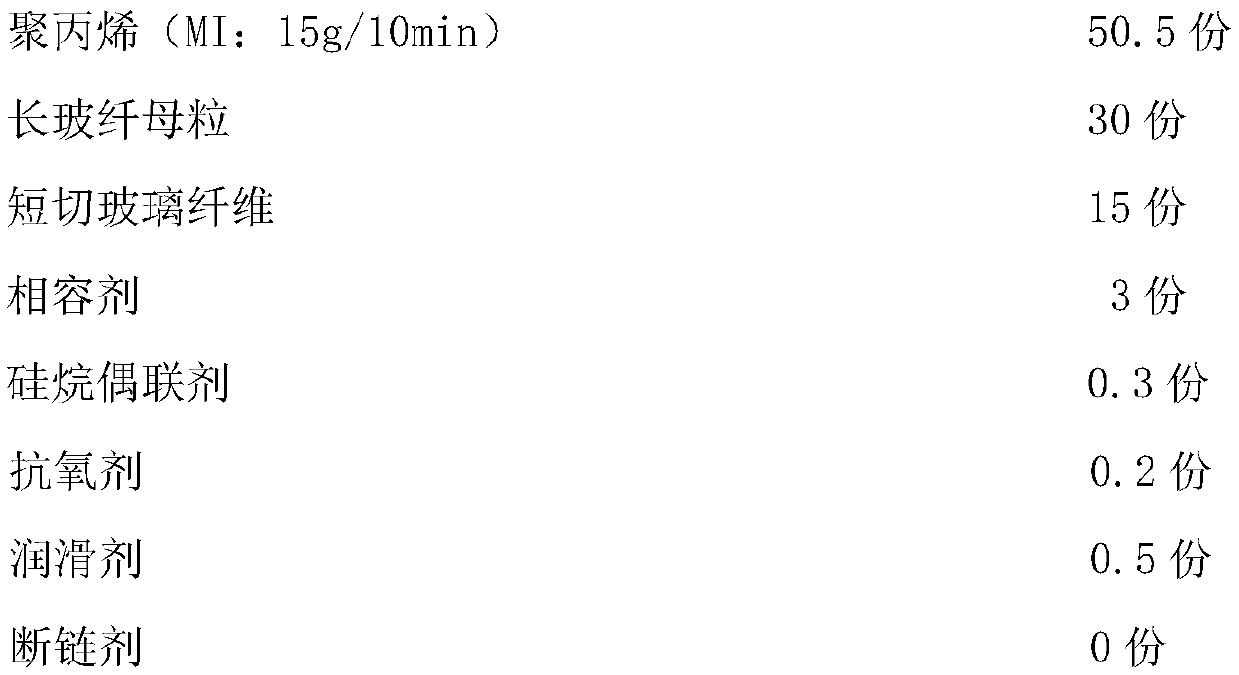

[0066] The reinforced polypropylene specially used for water pumps in this embodiment is composed of the following raw materials in parts by weight:

[0067]

[0068]

[0069] Concrete preparation method comprises the following steps:

[0070] (1) After the chopped glass fibers are dried, stir and reflux at a low speed for 10 minutes with an ethanol solution of a silane coupling agent with a mass percent concentration of 10%, leave it at room temperature for 12 hours, vacuum filter, and place in an electric heating constant temperature blast drying oven Dry to constant weight at 80°C to obtain chopped glass fibers after surface treatment for subsequent use;

[0071] (2) Add polypropylene, compatibilizer, antioxidant, chain breaking agent and lubricant together in a mixer with nitrogen protection and mix at high speed for 2-10 minutes;

[0072] (3) Under the protection of nitrogen, put the mixture of (2) into the parallel twin-screw extruder to melt, then add the chopped...

Embodiment 3

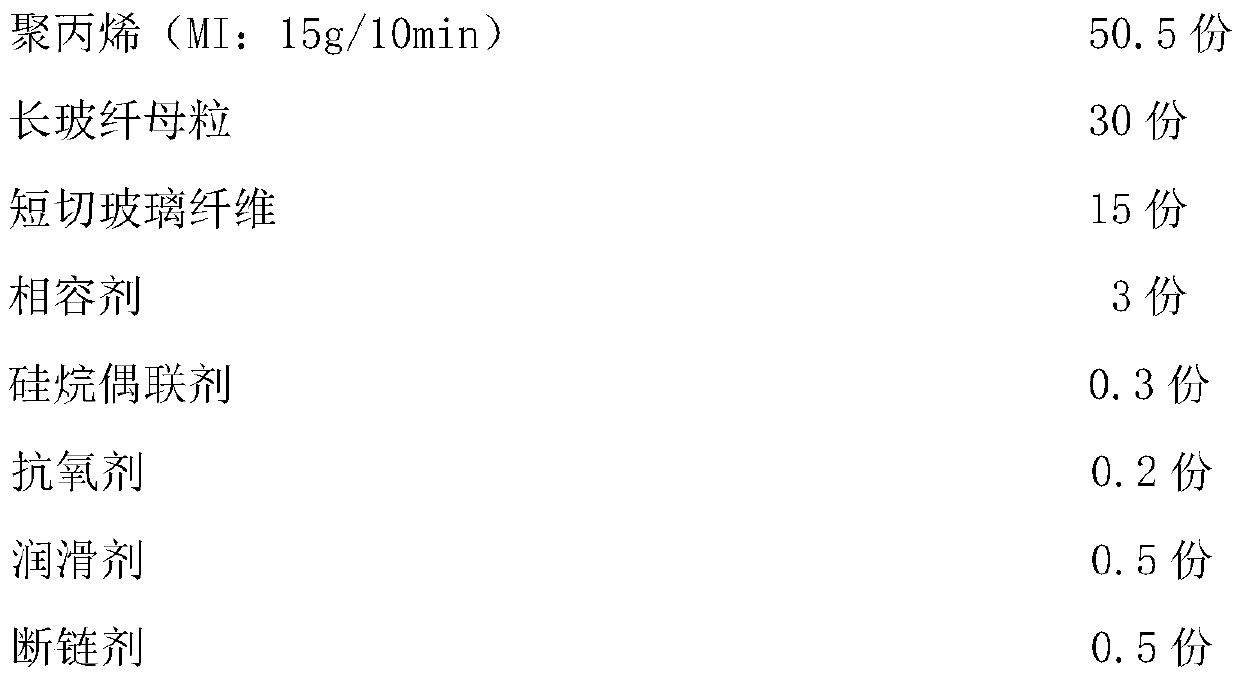

[0075] The reinforced polypropylene specially used for water pumps in this embodiment is composed of the following raw materials in parts by weight:

[0076]

[0077] Concrete preparation method comprises the following steps:

[0078] (1) After the chopped glass fibers are dried, stir and reflux at a low speed for 10 minutes with an ethanol solution of a silane coupling agent with a mass percent concentration of 10%, leave it at room temperature for 12 hours, vacuum filter, and place in an electric heating constant temperature blast drying oven Dry to constant weight at 80°C to obtain chopped glass fibers after surface treatment for subsequent use;

[0079] (2) Add polypropylene, compatibilizer, antioxidant, chain breaking agent and lubricant together in a mixer with nitrogen protection and mix at high speed for 2-10 minutes;

[0080] (3) Under the protection of nitrogen, put the mixture of (2) into the parallel twin-screw extruder to melt, then add the chopped glass fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com