High-strength high-toughness polyvinyl chloride manhole cover and preparation method thereof

A polyvinyl chloride, high-strength and high-toughness technology, applied in the formulation and preparation of high-strength and high-toughness polyvinyl chloride manhole covers, can solve the problems of high cost, poor plasticizing performance, and low strength of aluminum manhole covers, and achieve lubricating effect and Good thermal stability, lower production costs, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

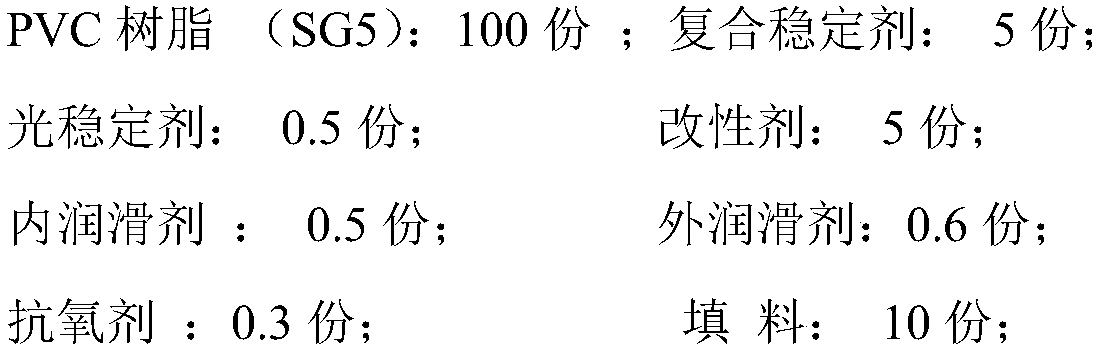

[0054] The high-strength and high-toughness polyvinyl chloride manhole cover formula of the present embodiment, the weight ratio of its various components is as follows:

[0055]

[0056] The PVC resin in this embodiment refers to a PVC resin with a degree of polymerization of 2500, and the addition amount is 10 parts.

[0057] The ACR-g-VC resin in this embodiment refers to a resin formed by polymerizing polyacrylate nanolatex with vinyl chloride monomer, the degree of polymerization is equivalent to that of general PVC resin SG5, and the addition amount is 90 parts.

[0058] The modifying agent of this embodiment is MBS resin, and the addition amount is 5 parts.

[0059] The composite stabilizer of the present embodiment selects calcium-zinc composite stabilizer, and the addition amount is 5 parts.

[0060] The light stabilizer of this embodiment is titanium dioxide, and the addition amount is 0.5 parts.

[0061] The lubricant in this embodiment adopts a mixture of inte...

Embodiment 2

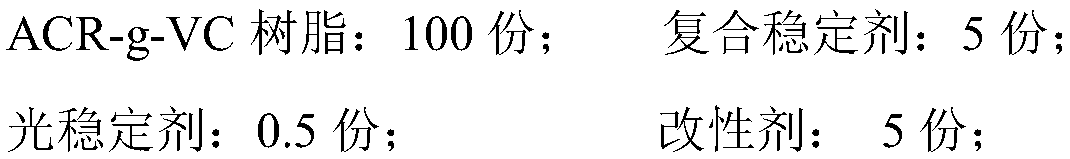

[0067] The high-strength and high-toughness polyvinyl chloride manhole cover formula of the present embodiment, the weight ratio of its various components is as follows:

[0068]

[0069] The PVC resin in this embodiment refers to a PVC resin with a degree of polymerization of 2500, and the addition amount is 20 parts.

[0070] The ACR-g-VC resin in this embodiment refers to a resin formed by polymerizing polyacrylate nanolatex with vinyl chloride monomer. The degree of polymerization is equivalent to that of general-purpose PVC resin SG5, and the addition amount is 80 parts.

[0071] The modifying agent of this embodiment is MBS resin, and the addition amount is 5 parts.

[0072] The composite stabilizer of the present embodiment selects calcium-zinc composite stabilizer, and the addition amount is 5 parts.

[0073] The light stabilizer of this embodiment is titanium dioxide, and the addition amount is 0.5 parts.

[0074] The lubricant in this embodiment is a mixture of ...

Embodiment 3

[0080] The high-strength and high-toughness polyvinyl chloride manhole cover formula of the present embodiment, the weight ratio of its various components is as follows:

[0081]

[0082] The PVC resin in this embodiment refers to a PVC resin with a degree of polymerization of 2500, and the addition amount is 30 parts.

[0083] The ACR-g-VC resin in this embodiment refers to a resin formed by polymerizing polyacrylate nanolatex with vinyl chloride monomer, the degree of polymerization is equivalent to that of general-purpose PVC resin SG5, and the addition amount is 70 parts.

[0084] The modifying agent of this embodiment is MBS resin, and the addition amount is 5 parts.

[0085] The composite stabilizer of the present embodiment selects calcium-zinc composite stabilizer, and the addition amount is 5 parts.

[0086] The light stabilizer in this embodiment is titanium dioxide, and the addition amount is 0.6 parts.

[0087] The lubricant in this embodiment adopts a mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com