Functional electrolyte for preventing overcharge of lithium battery and production method of functional electrolyte

A production method and electrolyte technology, which are applied in the manufacture of secondary batteries, electrochemical generators, and electrolyte batteries, can solve the problems of battery sequential performance and storage life, low lithium ion conductivity, etc., and achieve increased storage performance, Good cycle performance and the effect of improving high temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

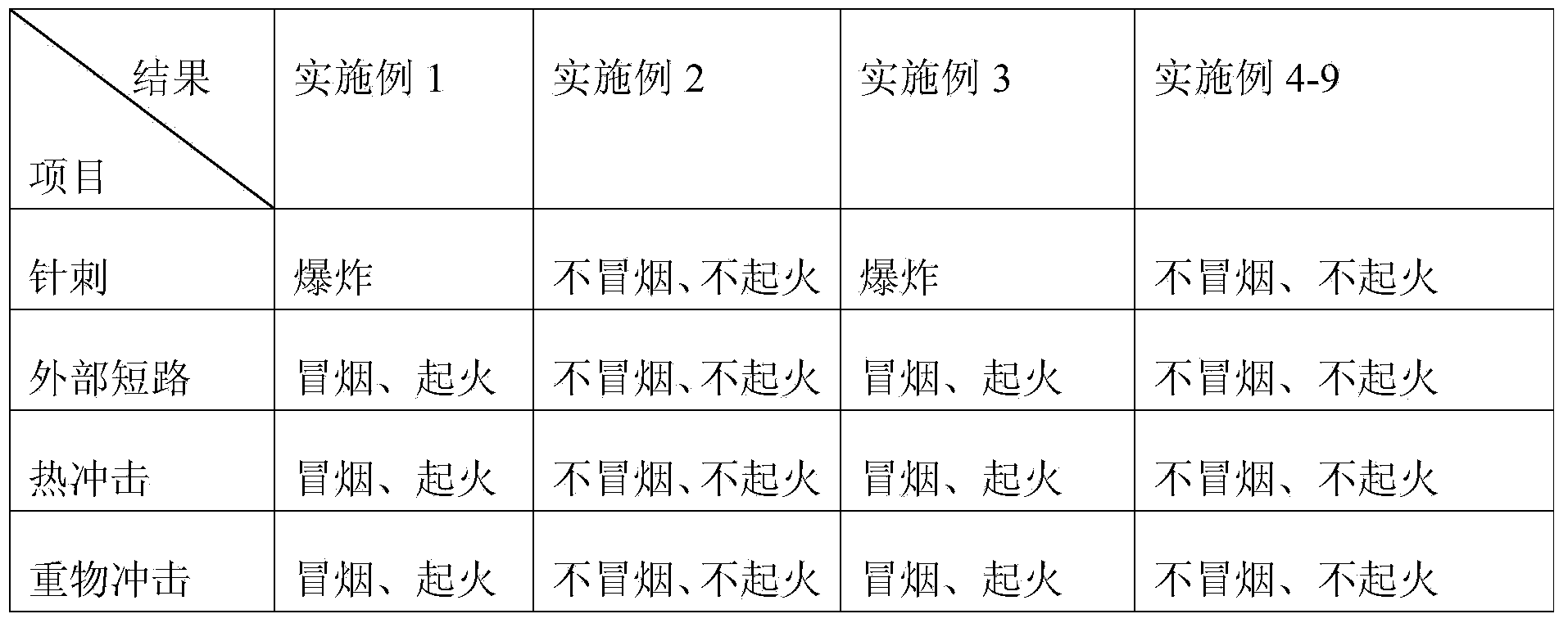

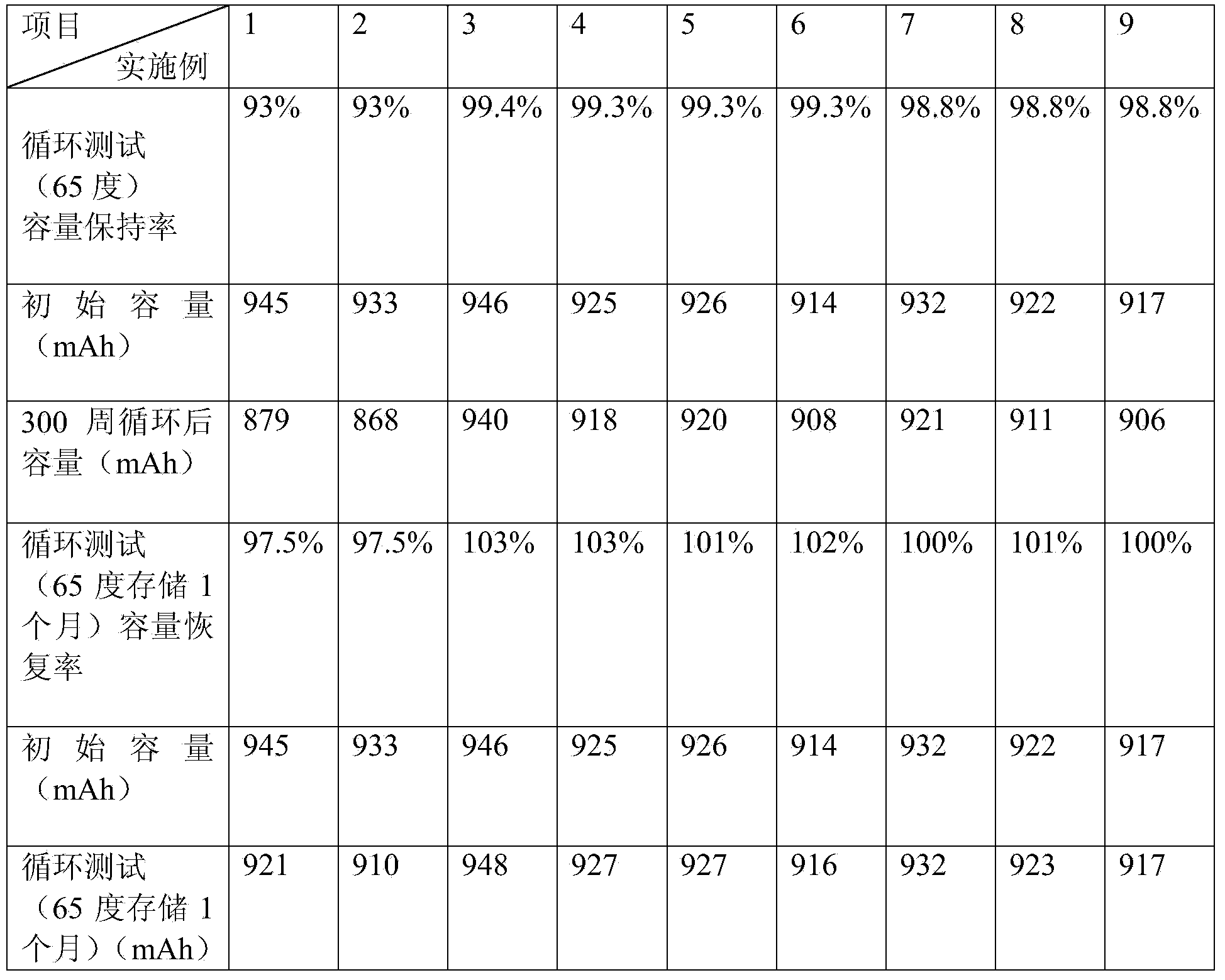

Embodiment 1

[0031] Add 45ml EC, 45ml DME, and 10ml PC to a clean container in turn; after cooling down to room temperature, add 22.79g LiBF to the above mixture 6 The concentration of the substance is 1.5mol / L; after standing clarification, add 13.92g VC (for EC, DME, PC and LiBF) after 3 hours 6 The total weight percentage is 1%); after standing for 6 hours.

Embodiment 2

[0033] After adding 13.92g of VC in Example 1, 7.66g of 2,3,4-trifluorobiphenyl (5% by weight of the base electrolyte) was added, and the rest were the same as in Example 1.

Embodiment 3

[0035] After adding 13.92g VC in embodiment 1, add 7.66g PST (the weight percent with base electrolyte is 5%), and the rest is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com