Co-extruded SPC stone-plastic floor

A technology of stone-plastic flooring and stone-plastic, which is applied in the direction of architecture, building structure, floor, etc., to achieve the effect of no thermal expansion and cold contraction deformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

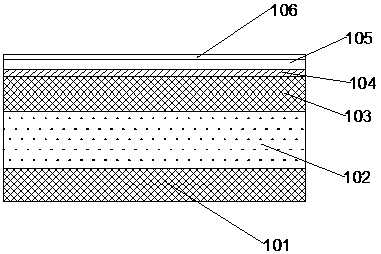

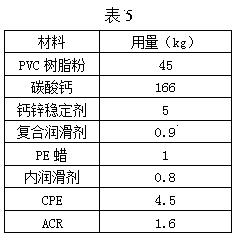

[0044] The stable layer 101, the strength layer 102, and the elastic layer 103 use the components listed in Table 1-3.

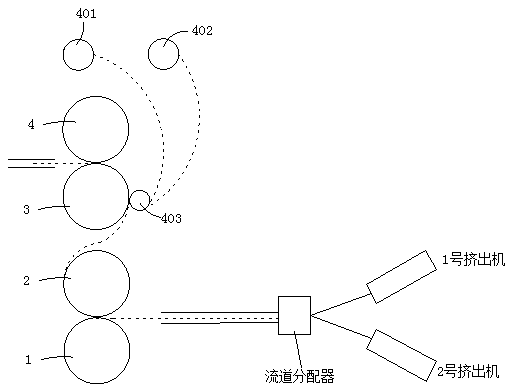

[0045] In this embodiment, as attached figure 2 As shown, the manufacturing method of this floor comprises, at first according to the raw material in table 1, 3 and throwing A material in No. 1 extruder, and wherein the throwing amount of each raw material of A material is the throwing-in of elastic layer and stabilizing layer Half of the total amount; according to Table 2, put material B into the No. 2 extruder, and the amount of each raw material of material B is the amount of strength layer. The No. 1 extruder simultaneously extrudes the elastic layer and the stable layer of equal quality and thickness, and the No. 2 extruder extrudes the strength layer. Then it is extruded into the mold runner distributor, so that the strength layer is located between the elastic layer and the stable layer, and then enters the die for extrusion to form the SPC substrat...

Embodiment 2

[0048] The difference from Example 1 is that the proportions of the stable layer, the strength layer and the elastic layer are different, and the specific proportions are shown in Table 1-3.

Embodiment 3

[0050] The difference from Example 1 is that the proportions of the stable layer, the strength layer and the elastic layer are different, and the specific proportions are shown in Table 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com