Ultraviolet resistant cold-feeling finishing fabric and processing method, and application of silica coated dodecanol microcapsule to fabric

A technology of silica and processing methods, which is applied in fiber treatment, textiles and papermaking, plant fibers, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

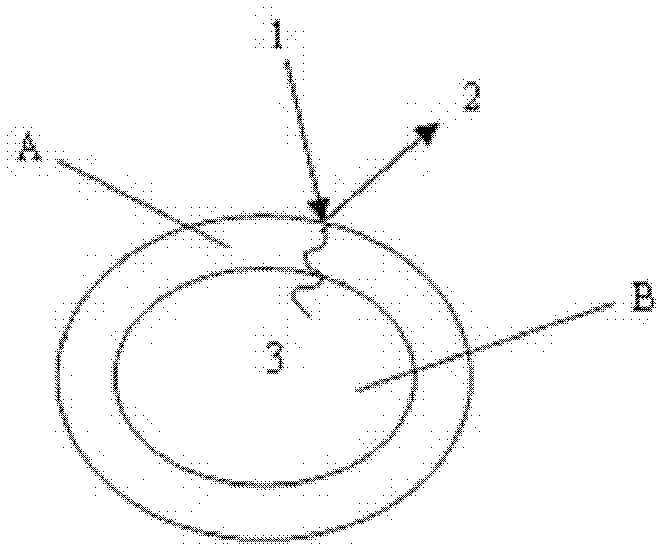

Image

Examples

Embodiment 1

[0029] 1. Fabric: 32s T / C 65 / 35 plain weave

[0030] 2. Fabric padding microcapsule process:

[0031] Microcapsules 40g / L

[0032] Polyurethane (adhesive) 50g / L (produced by Shanghai Linping Chemical Co., Ltd.)

[0033] Drying conditions: temperature: 80°C; time: 3min.

[0034] Baking conditions: temperature: 160°C; time: 1min.

[0035] 1 dipping 1 rolling (rolling rate 80%)→full drying→baking→test indicators

[0036] 3. Anti-ultraviolet cooling performance test:

[0037] Anti-ultraviolet performance is expressed by ultraviolet protection factor (UPF) and ultraviolet transmittance (T(UV-A)AV, T(UV-B)AV); (tested according to AATCC 183 test standard method)

[0038] UPF range Protection classification UV transmittance (%) UPF logo 15-24 better protection 6.7-4.2 15,20 25-39 very good protection 4.1-2.6 25,30,35 40-50,50+ very good protection ≤2.5 40,45,50,50+

[0039] The cooling performance is expressed by the te...

Embodiment 2

[0042] 1. Fabric: 32s T / C 65 / 35 plain weave

[0043] 2. Fabric padding microcapsule process:

[0044] Microcapsules 60g / L

[0045] Polyurethane (adhesive) 50g / L (produced by Shanghai Linping Chemical Co., Ltd.)

[0046] Drying conditions: temperature: 90°C; time: 4min.

[0047] Baking conditions: temperature: 140°C; time: 2min.

[0048] 1 dipping 1 rolling (rolling rate 90%)→full drying→baking→test indicators

[0049] 3. Anti-ultraviolet cooling performance test:

[0050] The test methods of anti-ultraviolet performance and cooling performance are the same as in Example 1.

[0051] The UPF value of the anti-ultraviolet cool fabric produced by this example is 50, and the ultraviolet transmittance (T(UV-A)AV, T(UV-B)AV) is 2.5%; ΔT 40 13°C, ΔT 50 = 15°C.

Embodiment 3

[0053] 1. Fabric: 100D / 144F DTY double-sided small mesh

[0054] 2. Fabric padding microcapsule process:

[0055] Microcapsules 50g / L

[0056] Polyurethane (adhesive) 50g / L (produced by Shanghai Linping Chemical Co., Ltd.)

[0057] Drying conditions: temperature: 80°C; time: 5min.

[0058] Baking conditions: temperature: 150°C; time: 2min.

[0059] 1 dipping 1 rolling (rolling rate 85%)→full drying→baking→test indicators

[0060] 3. Anti-ultraviolet cooling performance test:

[0061] The test methods of anti-ultraviolet performance and cooling performance are the same as in Example 1.

[0062] The UPF value of the anti-ultraviolet cold feeling fabric produced by this example is 50, and the ultraviolet transmittance (T(UV-A)AV, T(UV-B)AV) is 2.9%; ΔT 40 12°C, ΔT 50 = 14°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com