Anti-scratching polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of anti-scratch polypropylene composite materials and its preparation, can solve the problems of large surface curvature, poor compatibility, small crystal grains, etc., and achieve simple operation and guaranteed scratch resistance performance , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific examples, but not limited to these examples.

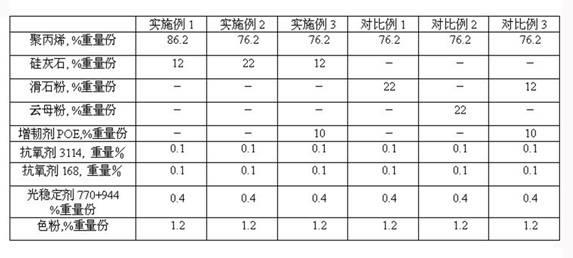

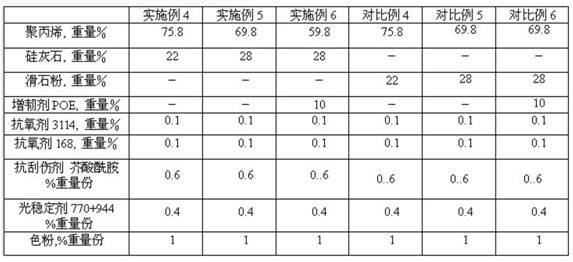

[0031] The formula of each embodiment and comparative example is listed in table 1 and table 3;

[0032] Table 2 and Table 4 compare the comprehensive properties of the various examples and comparative examples of polypropylene composite materials.

[0033]In the formulations of each example and comparative example, polypropylene is selected from high crystalline homopolypropylene or block copolymerized polypropylene with different melt fluidity; the inorganic filler is selected from talcum powder or mica with a particle size ranging from 1 to 10 microns powder; the toughening agent is selected from the POE toughening agent produced by DuPont, which is a linear ethylene-octene copolymer; the selected wollastonite is a natural white non-woven fabric with an aspect ratio ranging from 20:1 to 3:1. Metal-containing acicular or acicular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com