High-performance halogen-free flame-retardant PC/ABS alloy material and preparation process thereof

An alloy material and high-performance technology, which is applied in the processing field of halogen-free flame-retardant alloy materials, can solve problems such as the decline in mechanical properties of halogen-free flame-retardant PC/ABS alloys, damage to key components of electrical equipment, and failure to meet production needs. Achieve the effects of unique self-extinguishing property, good flame retardancy, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

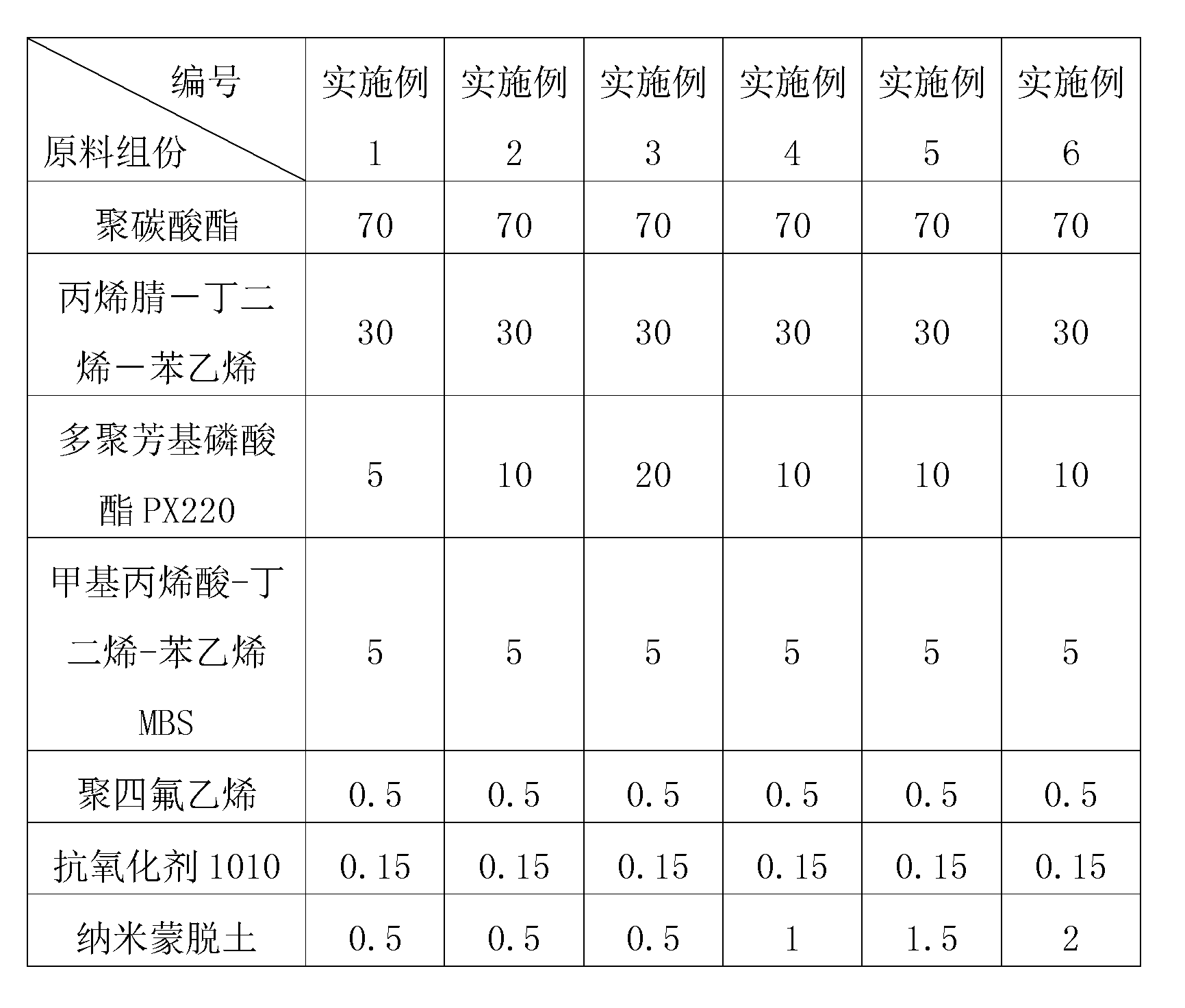

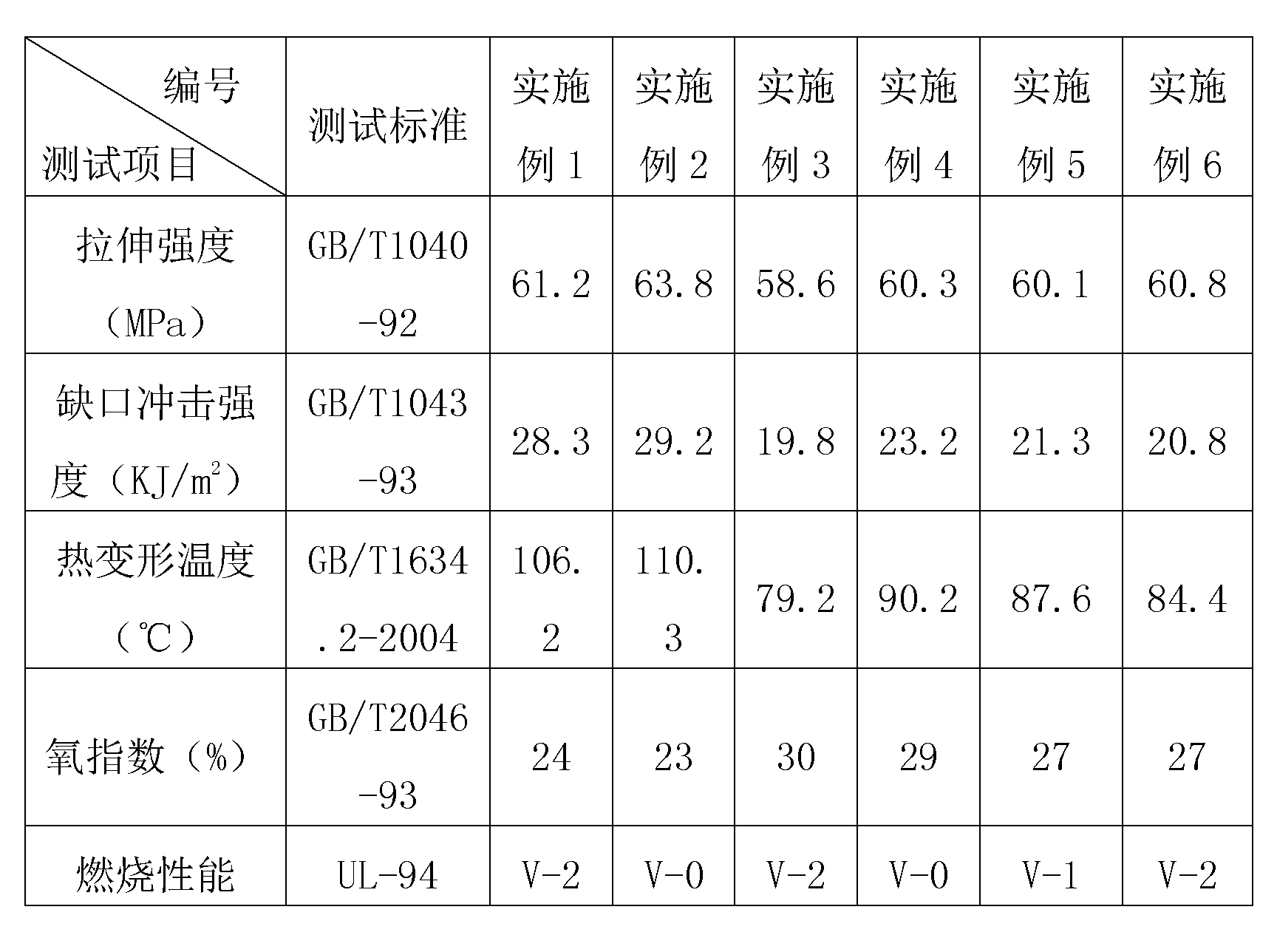

[0016] Embodiments 1 to 6 provide the preparation method of the high-performance halogen-free flame-retardant PC / ABS alloy material of the present invention, wherein the flame retardant is polyaryl phosphate PX220; the compatibilizer is methacrylic acid- Butadiene-styrene MBS.

[0017] Examples 1 to 6 are all based on the weight content of the raw materials described in Table 1 in the halogen-free flame-retardant PC / ABS alloy material, and the halogen-free flame-retardant PC / ABS alloy material is prepared according to the following steps:

[0018] (1) First, polycarbonate, acrylonitrile-butadiene-styrene, polyaryl phosphate PX220, methacrylic acid-butadiene-styrene MBS, polytetrafluoroethylene, antioxidant 1010 and nanometer desoiling for drying;

[0019] (2) Then mix the raw material components according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com