Double-component fluorine-containing hydrophobic coating as well as preparation and using method thereof

A technology of hydrophobic coatings and superhydrophobic coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficulty in maintaining superhydrophobicity, complicated preparation process, and easy damage to the surface microstructure of materials, so as to improve hydrophobicity , better toughness and processability, better toughness and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of A component

[0047] (1) Under nitrogen, put about 40g of butyl acetate into a 150ml reaction bottle, raise the temperature to 80°C, and gradually add 7.5g of methyl methacrylate MMA, 8.1g of butyl methacrylate BMA, and 6.9g of methyl The mixture of hydroxyethyl acrylate HEMA, 7.5g of trifluorooctyl methacrylate PFMA monomer, 0.66g of azobisisobutyronitrile AIBN initiator and 20g of butyl acetate was dripped for 0.5h, then kept for 2h, supplemented 0.066g AIBN, then finish the reaction after 4h.

[0048] (2) Under nitrogen, put about 30 g of butyl acetate and 11 g of nano-PTFE into a 100 ml reaction bottle, and ultrasonically disperse for 20 min at a stirring rate of 1000 rpm.

[0049] (3) Under the condition of a stirring rate of 700rpm, gradually add the treated nano-PTFE suspension in (2) to (1), then add 0.31g of perfluorohexyl ethyl alcohol, and treat it at 80°C for 1h, Obtain the A component.

[0050] Preparation of component B: 10 g of hexamethy...

Embodiment 2

[0054] Preparation of A component

[0055] (1) Under nitrogen, put about 40g of butyl acetate into a 150ml reaction bottle, raise the temperature to 80°C, and gradually add 7.5g of methyl methacrylate MMA, 6.9g of hydroxyethyl methacrylate HEMA, and 15.6g of formazan Tridefluorooctyl acrylate PFMA monomer, 0.58g azobisisobutyronitrile AIBN initiator and 20g butyl acetate mixture, dripped in 0.5h, then kept warm for 2h, supplemented with 0.03g AIBN, and then ended the reaction after 4h .

[0056] (2) Under nitrogen, put about 25 g of butyl acetate and 7 g of cross-linked polystyrene (PS) nanoparticles into a 100 ml reaction bottle, and ultrasonically disperse for 15 min at a stirring rate of 800 rpm.

[0057] (3) Under the condition of a stirring rate of 700rpm, gradually add (2) the cross-linked PS nanoparticle suspension into (1), and at the same time add 0.23g of hexafluoroisopropanol, and treat at 80°C for 40min to obtain component A .

[0058] Preparation of component B...

PUM

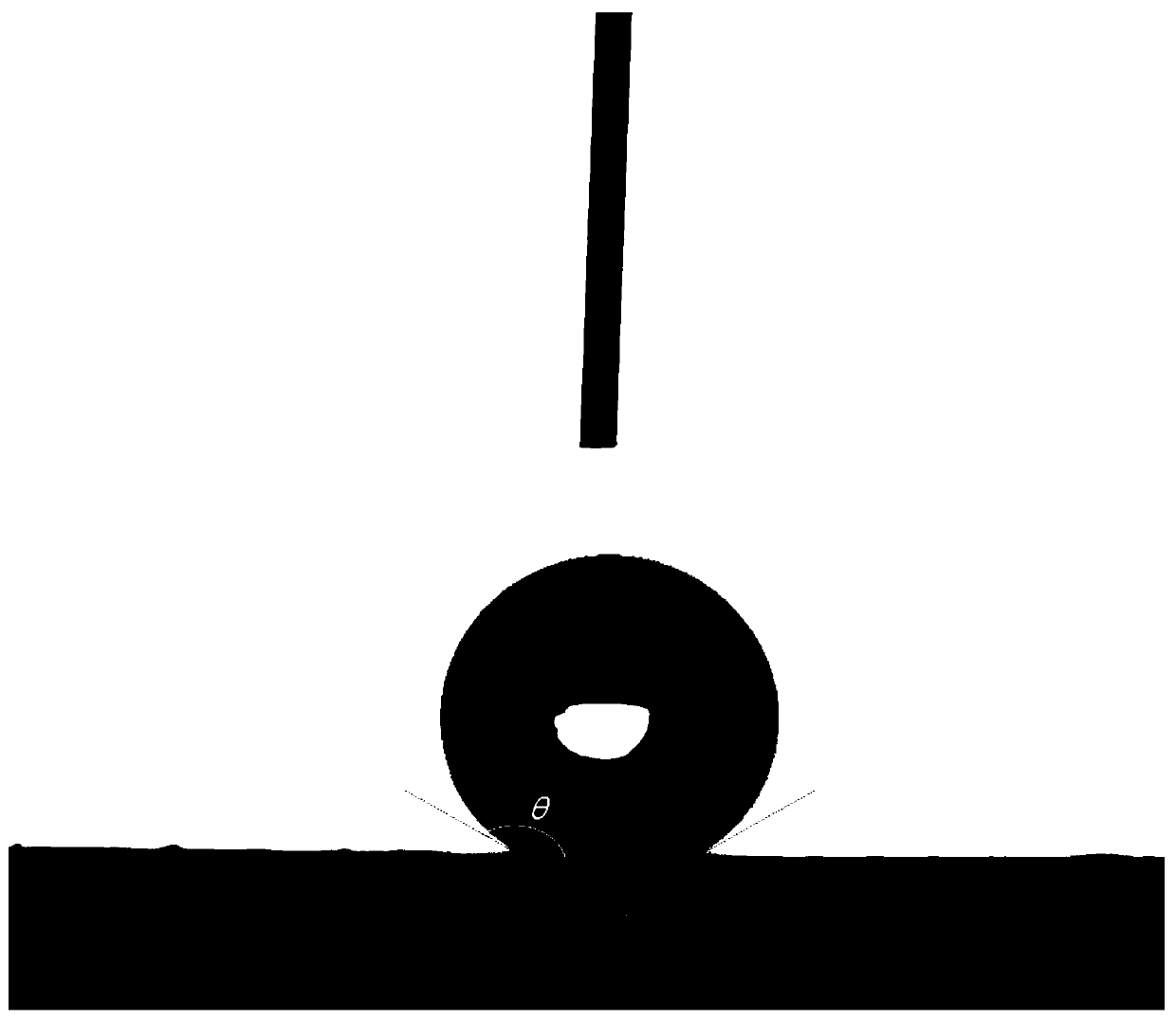

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com