High-frequency substrate structure and manufacturing method thereof

A substrate and high-frequency technology, applied in the field of high-frequency substrate structure and its manufacturing, can solve the problems of insufficient heat resistance and achieve the effects of good processability, good heat resistance, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

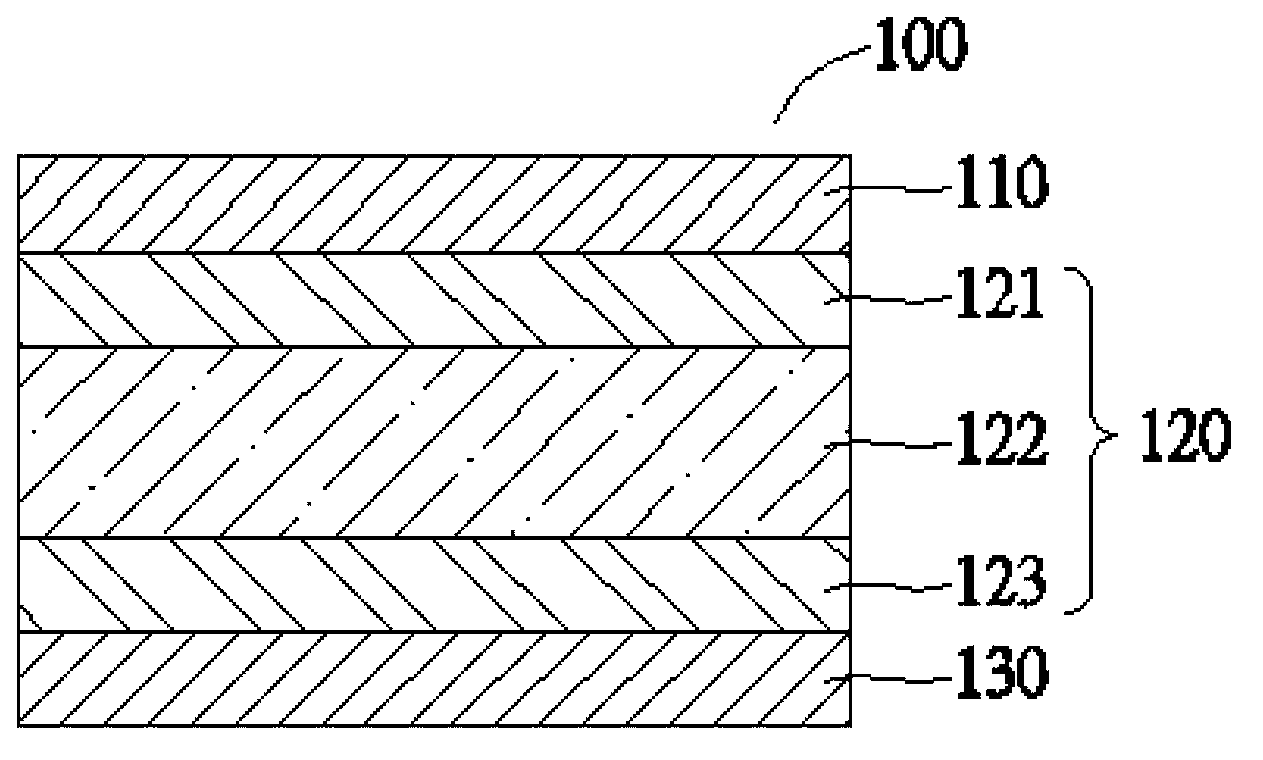

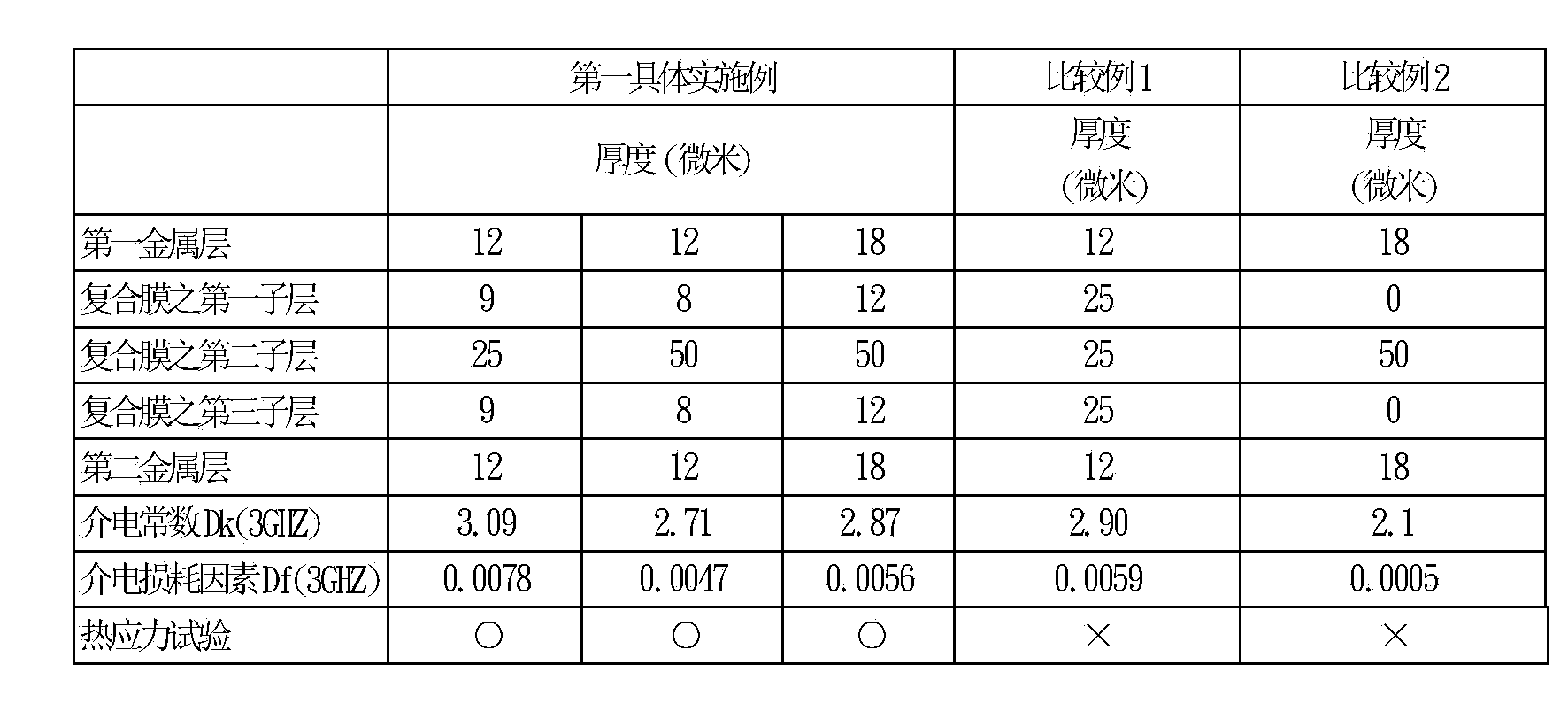

[0021] Example: Please refer to figure 1 , to show the high-frequency substrate structure 100 of the present invention, including: a first metal layer 110; a composite film 120, the composite film has a first sub-layer 121, a second sub-layer 122 and a third sub-layer 123; the second metal layer 130; the first metal layer 110 is formed on the first sub-layer 121 of the composite film 120, so that the first sub-layer 121 is sandwiched between the second sub-layer 122 and the first metal layer 110; the second The metal layer 130 is formed on the third sub-layer 123 such that the third sub-layer 123 is interposed between the second sub-layer 122 and the second metal layer 130 .

[0022] The second sub-layer 122 of the high-frequency substrate structure 100 of the present invention uses a fluorine-based polymer layer with a low dielectric constant material, examples of which include but are not limited to: polytetrafluoroethylene polyhexafluoropropylene copolymer, tetrafluoroethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com