Thermosetting membrane for adhesion of bulletproof fiber and processing method of thermosetting membrane

A bulletproof fiber and thermal curing technology, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of product fiber embrittlement, poor sizing uniformity, and low production efficiency. Achieve good film-forming properties, improve bulletproof ability, excellent adhesion and flexible deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

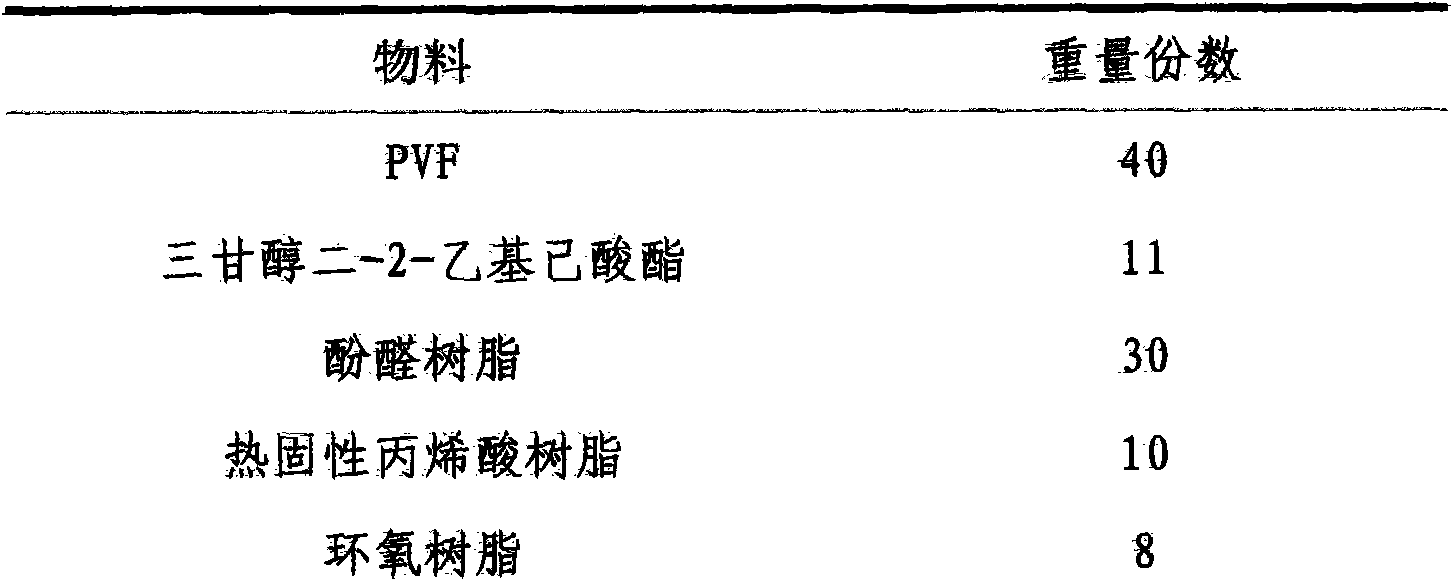

[0024] A kind of thermosetting film of following proportion is prepared:

[0025]

[0026]

[0027] The production process of heat curing film is as follows:

[0028] 40 parts by weight of PVF, 11 parts by weight of triethylene glycol di-2-ethylhexanoate, 30 parts by weight of phenolic resin, 10 parts by weight of thermosetting acrylic resin, 8 parts by weight of epoxy The resin and 1 part by weight of the silane coupling agent are weighed, put into a mixer, stirred evenly, and then extruded to granulate. Next, it is extruded in a 35-type extruder, and the process is as follows: the molding temperature is 120° C., the molding pressure is 3 MPa, and the molding time is 8 minutes.

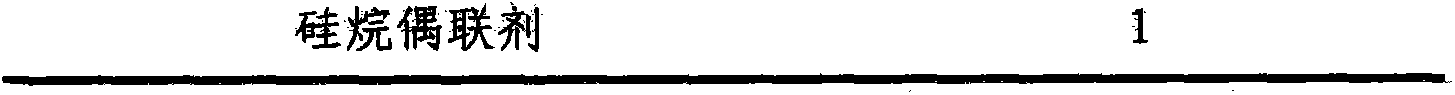

[0029] The process can produce a heat-cured film with good film-forming properties, a uniform precision of plus or minus 0.001mm, a crosslinking degree of less than 5%, and a thickness of 0.05-0.2mm. The properties of the thermally cured film prepared under the conditions of the above resin f...

Embodiment 2

[0033] A kind of thermosetting film of following proportion is prepared:

[0034]

[0035] The production process of heat curing film is as follows:

[0036] The PVB of 50 parts by weight, the dibutyl sebacate of 15 parts by weight, the phenolic resin of 30 parts by weight, the epoxy resin of 4 parts by weight, the silane coupling agent of 1 parts by weight weighed and put into Stir evenly in a mixer, then extrude to granulate. Next, extrude and form in a 35-type extruder, the process is that the forming humidity is 100° C., the forming pressure is 2 MPa, and the forming time is 4 minutes.

[0037] The process can produce a heat-cured film with good film-forming properties, a uniform precision of plus or minus 0.001mm, a crosslinking degree of less than 5%, and a thickness of 0.05-0.2mm. The properties of the thermally cured film prepared under the conditions of the above resin formulation and process parameters are shown in Table 1.

[0038] The technical index of the t...

Embodiment 3

[0041] A kind of thermosetting film of following proportion is prepared:

[0042]

[0043] The production process of heat curing film is as follows:

[0044]The PVFA of 40 parts by weight, the dihexyl adipate of 13 parts by weight, the benzoxazine resin of 25 parts by weight, the silicone resin of 15 parts by weight, the hexamethylenetetramine of 6 parts by weight 1. The silane coupling agent of 1 weight part is weighed and put into a mixer to stir evenly, and then extruded to granulate. Next, extrude and form in a 35-type extruder, the process is that the forming temperature is 130° C., the forming pressure is 4 MPa, and the forming time is 10 minutes.

[0045] The process can produce a heat-cured film with good film-forming properties, a uniform precision of plus or minus 0.001mm, a crosslinking degree of less than 5%, and a thickness of 0.05-0.2mm. The properties of the thermally cured film prepared under the conditions of the above resin formulation and process parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com