Calotropis gigantean fiber composite fiber fabric and manufacturing method thereof

A technology of horn gourd fiber and composite fiber, which is applied in textiles, papermaking, weft knitting, yarn, etc. It can solve the problems of not being suitable for the skin, non-woven fabrics without stretchability, etc., and achieve lightness in wearing, fiber textile processing and Good wearing performance and the effect of saving textile costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

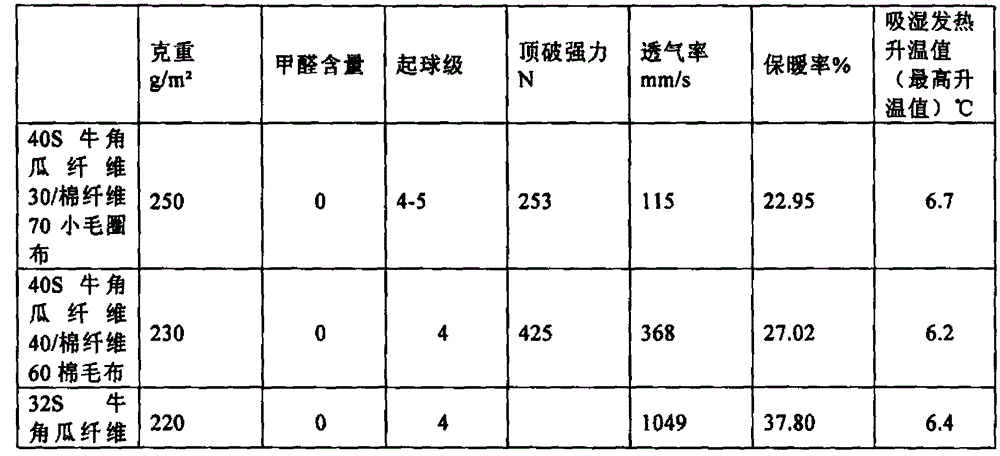

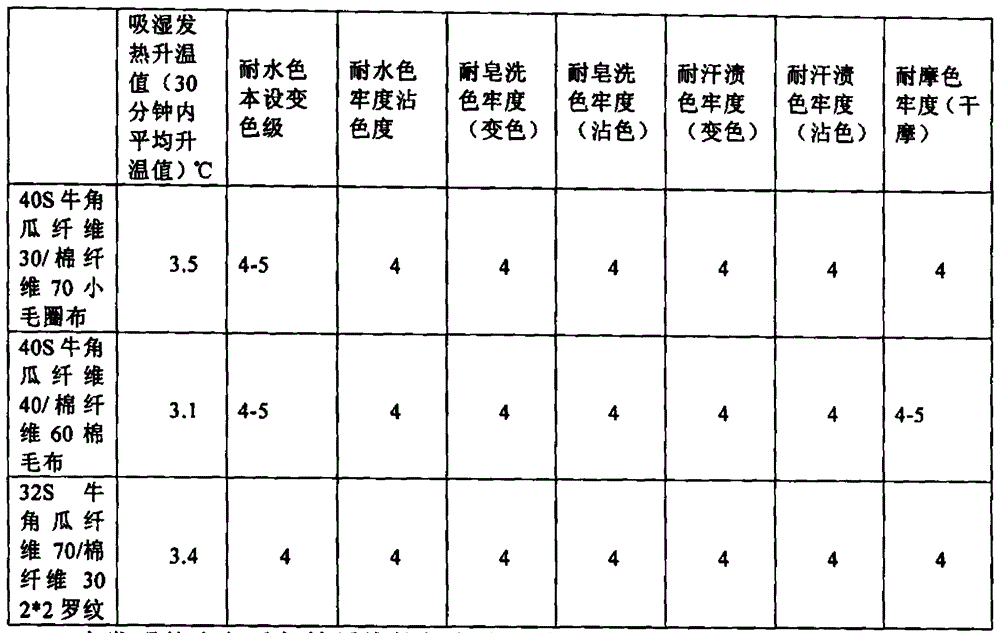

Embodiment 1

[0026] Raw material part:

[0027] A. Proportion of blended yarn: 30% of horn melon fiber / 70% of cotton, the yarn count of spinning ranges from 32S to 40S for trial spinning, and finally 40S is used to make full use of the hygroscopicity, air permeability and heat preservation performance of horn melon fiber , the woven fabric is lighter to wear, the moisture absorption, air permeability and thermal insulation performance are further enhanced, and the fiber textile processing and wearing performance are better.

[0028] B. The spinning method adopts Siro compact spinning: use this method to adjust the yarn to take the most appropriate twist to enhance the strength of the yarn and reduce the hairiness of the yarn, so that the yarn is uniform and the breaking strength is weakened and smoother.

[0029] C. Yarn twist coefficient: choose an appropriate twist coefficient, if the yarn is too tight, there will be no suppleness, and if it is too loose, it will lose strength. Use an ap...

Embodiment 2

[0059] A natural plant horn gourd fiber composite fiber knitted fabric, the knitted fabric is made of 40wt% animal protein fiber and 60wt% cotton fiber evenly fed and spun. The fiber length of croissant melon is equivalent to or even exceeds that of fine velvet. In this level of high-quality fiber, it is necessary to choose the most comfortable double-sided fabric (elastic cotton wool tissue) as one of the choices for developing varieties:

[0060] The manufacturing method of animal protein composite fiber knitted fabric comprises the following steps:

[0061] (1) 40wt% horn gourd fiber and 60wt% cotton fiber are uniformly fed to obtain blended yarn;

[0062] (2) Using the spinning method of Siro compact spinning, the blended yarn is made into the first finished product of knitted fabric through double-sided machine spinning, the twist of the blended yarn is controlled at 920, the twist coefficient is 350, the yarn count of the blended yarn is 40S, Spun and woven into a doubl...

Embodiment 3

[0065] The invention discloses a knitted fabric of natural plant croissant melon fiber composite fiber. The knitted fabric is spun from 70wt% crocodile gourd fiber and 30wt% cotton fiber by uniform yarn feeding. The horned melon can be as high as 3 meters, with single branches growing in clusters, 2-6 meters thick, thick white roots, thick stems, and thick corky. It grows rapidly and the plant can produce environmentally friendly croissant melon fiber instead of cotton fiber for textile production, and the final data of the woven fabric can be measured and the finished product that has been tested and approved. Adoption of another breed involves the following steps:

[0066] (1) 70wt% horn gourd fiber and 30wt% cotton fiber are uniformly fed to obtain blended yarn;

[0067] (2) Using the ring-fixed spinning method, the blended yarn is double-sidedly spun on a flat knitting machine to make the first finished product of the knitted fabric. The twist of the blended yarn is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com