Non-cured rubber asphalt waterproof coating and preparation method thereof

A kind of asphalt waterproof coating and non-curing rubber technology, which is applied in the direction of asphalt coating, fireproof coating, chloroprene homopolymer coating, etc., can solve environmental pollution and other problems, achieve safety fire risk, save gas energy, and enhance adhesion Effects on sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: a kind of non-cured rubber asphalt waterproof coating, each component and its corresponding parts by weight are shown in Table 1, and are prepared by the following steps:

[0077] Step 1: Add the asphalt into the emulsification equipment to melt, keep the temperature at 130-150℃, slowly add anionic emulsifier (half dose), octadecyl fatty alcohol under stirring state, and then slowly add light stabilizer and toughening agent , kept at 120°C to obtain the first mixture;

[0078] Step 2, add water to another emulsification device, heat up to 60°C, add anionic emulsifier (the other half dose) and sodium lauryl sulfate under uniform stirring to make it dissolve evenly, then add it under high-speed stirring. Bentonite, stir evenly to obtain the second mixture;

[0079] Step 3, under high-speed stirring, slowly add the first mixture into the second mixture, stir evenly, and cool to 50°C to form the third mixture;

[0080] Step 4: Slowly add the neoprene latex a...

Embodiment 2-10

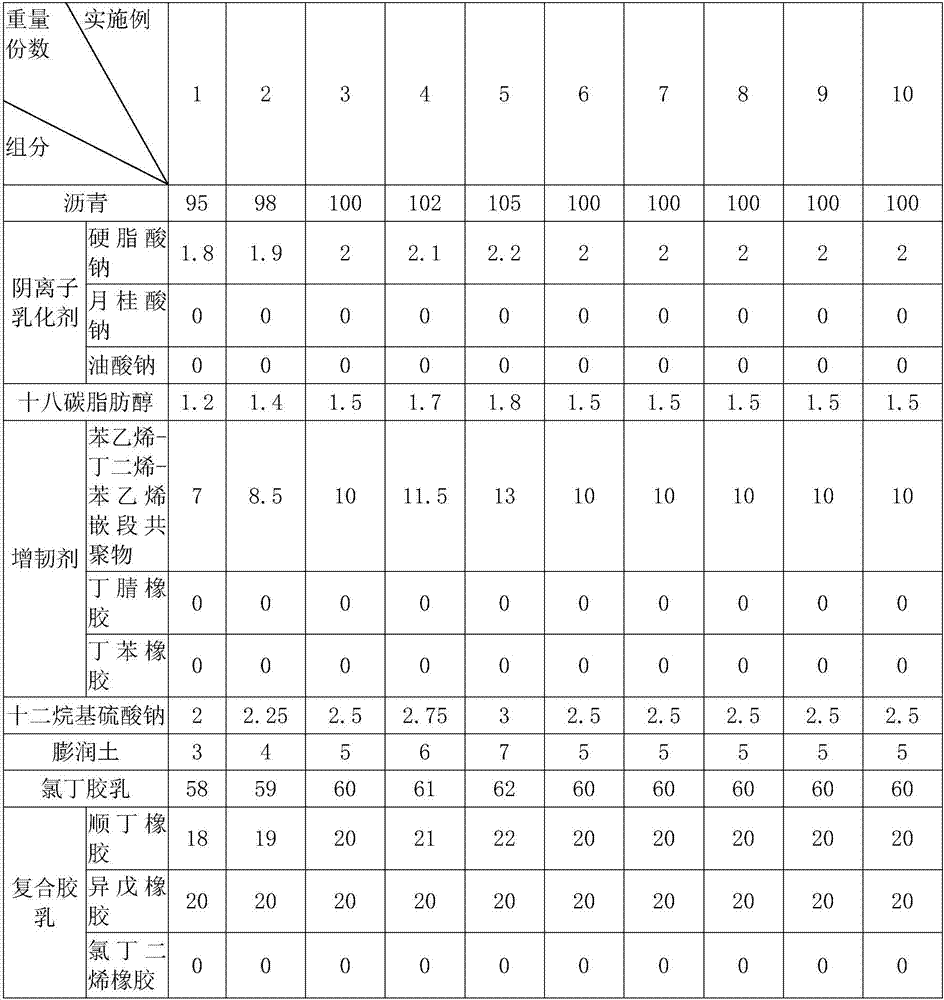

[0083] Example 2-10: a non-cured rubber asphalt waterproof coating, which is different from Example 1 in that each component and its corresponding parts by weight are shown in Table 1.

[0084] Each component and its parts by weight in the embodiment 1-10 of table 1

[0085]

[0086]

Embodiment 11-20

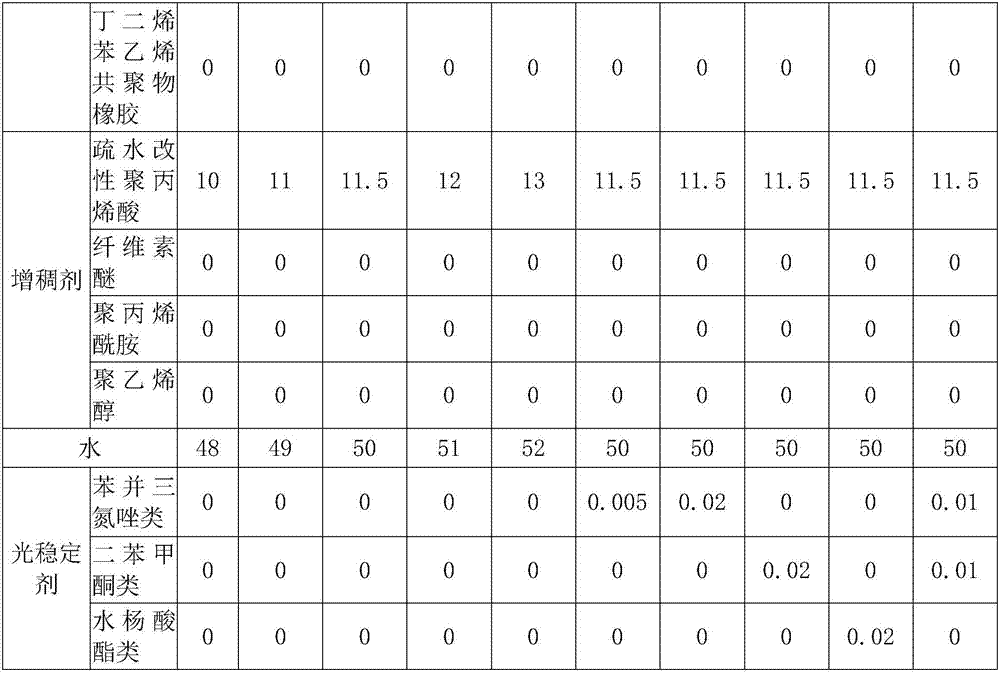

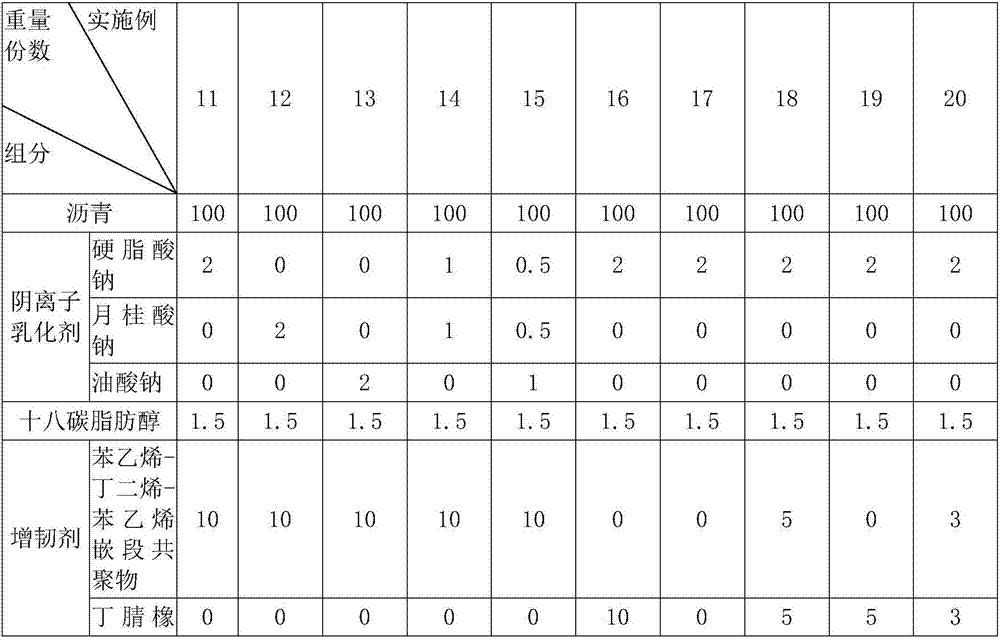

[0087] Examples 11-20: a non-cured rubber asphalt waterproof coating, which is different from Example 3 in that the components and their corresponding parts by weight are shown in Table 2.

[0088] Each component and its parts by weight in the embodiment 11-20 of table 2

[0089]

[0090]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com