Preparation method of sodium carboxymethylcellulose intercalated modified montmorillonite

A technology of sodium carboxymethyl cellulose and montmorillonite is applied in the directions of fibrous fillers, chemical instruments and methods, inorganic pigment treatment, etc., to achieve the effects of easy availability of raw materials, improved thermal stability and flame retardant performance, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) First prepare a modified montmorillonite, the specific operation steps are as follows:

[0026] Add 10g of montmorillonite powder to 300ml of deionized water, stir well to obtain a uniform dispersion, adjust the pH of the solution to 2.00 with dilute hydrochloric acid, and press MgCl after the temperature reaches 50°C 2 With the ratio of montmorillonite 1.2CEC, add MgCl 2 Inorganic salt, fully reacted and condensed and refluxed for 2 hours to obtain a uniform suspension;

[0027] The solvent in the product obtained above was removed by centrifugation to obtain a precipitate, which was washed several times with deionized water and ethanol. The obtained product is dried, ground and sieved to obtain a primary modified montmorillonite.

[0028] 2) Using primary modified montmorillonite powder as raw material to prepare secondary modified montmorillonite, the specific operation steps are as follows:

[0029] Add 2g of primary modified montmorillonite powder to 150ml of...

Embodiment 2

[0033] Add 15g of montmorillonite powder to 300ml of deionized water, stir well to obtain a uniform dispersion, adjust the pH of the solution to 3.00 with dilute hydrochloric acid, and press ZnCl 2 The ratio with montmorillonite 0.8CEC, adding ZnCl 2Inorganic salt, fully reacted and refluxed for 2h to obtain a uniform suspension. The solvent in the product obtained above was removed by centrifugation to obtain a precipitate, which was washed several times with deionized water and ethanol. The obtained product is dried, ground and sieved to obtain a primary modified montmorillonite;

[0034] Add 3g of primary modified montmorillonite powder to 150ml of deionized water, stir well to obtain a dispersion with uniform concentration, after the temperature reaches 80°C, add Sodium carboxymethyl cellulose, fully reacted and refluxed for 2 hours to obtain a uniform suspension. The solvent in the product obtained above was removed by centrifugation to obtain a precipitate, which was ...

Embodiment 3

[0036] Add 10g of montmorillonite powder to 300ml of deionized water, stir well to obtain a uniform dispersion, adjust the pH of the solution to 2.00 with dilute hydrochloric acid, and press CaCl after the temperature reaches 60°C 2 With the ratio of montmorillonite 1.5CEC, add CaCl 2 Inorganic salts, fully reacted and refluxed for 35 minutes to obtain a uniform suspension. The solvent in the product obtained above was removed by suction filtration to obtain a precipitate, which was washed with deionized water and ethanol several times. The obtained product is dried, ground and sieved to obtain a primary modified montmorillonite;

[0037] Add 4g of primary modified montmorillonite powder to 250ml of deionized water, stir well to obtain a dispersion with uniform concentration, after the temperature reaches 60°C, add Sodium carboxymethyl cellulose, fully reacted and refluxed for 3 hours to obtain a uniform suspension. The solvent in the product obtained above was removed by s...

PUM

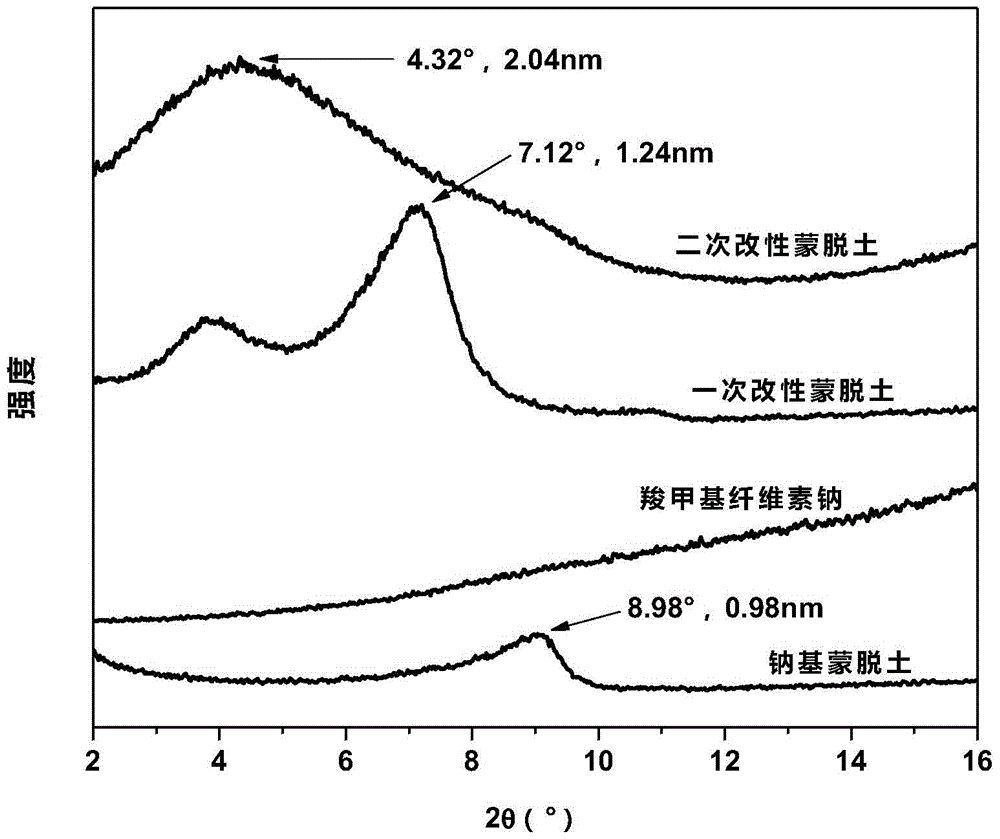

| Property | Measurement | Unit |

|---|---|---|

| 2theta | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com