Water injection component and ironing device

A technology for ironing devices and components, applied in the field of water injection components and ironing devices, can solve the problems of low steam volume, wet clothes, inconvenience, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the drawings and various embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

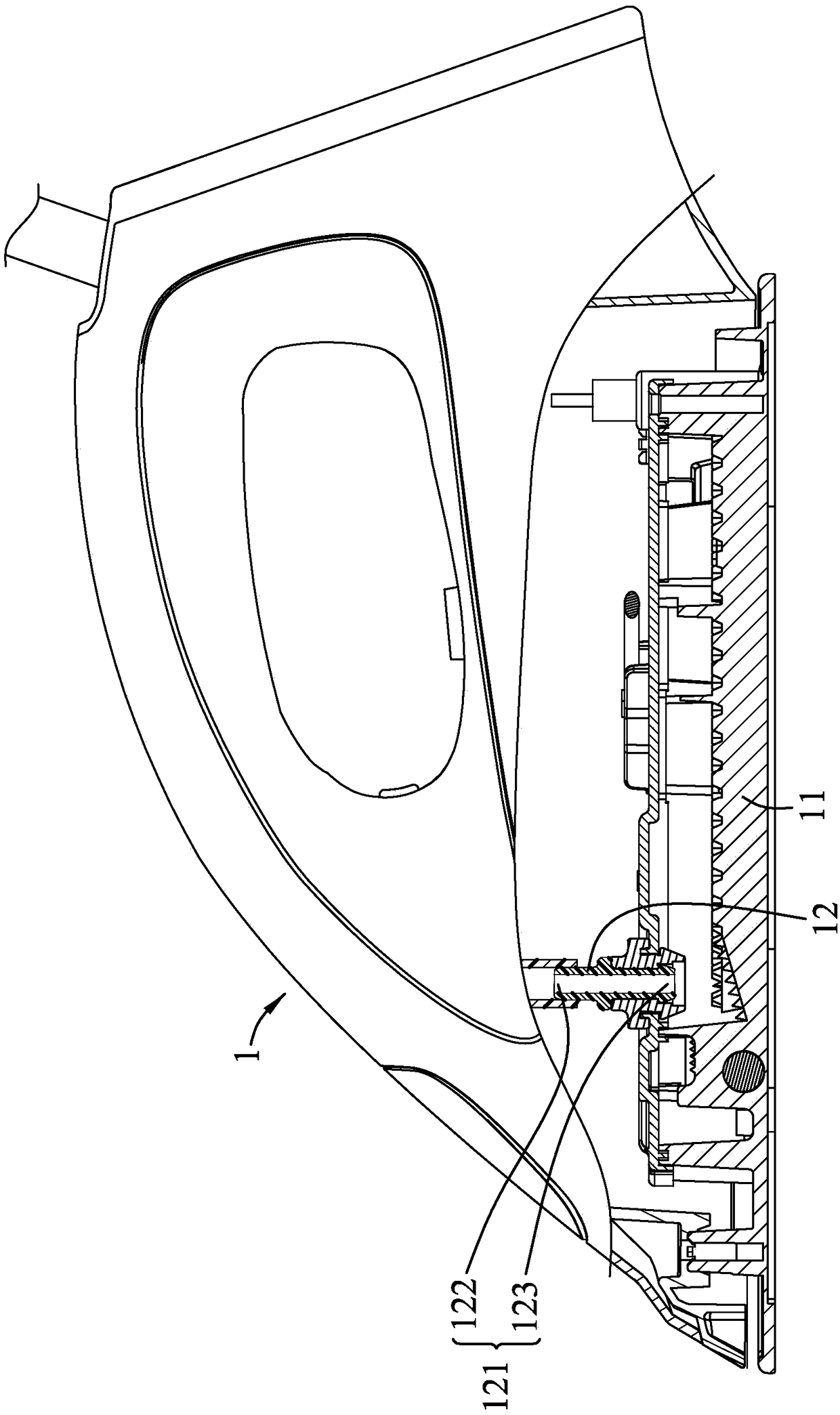

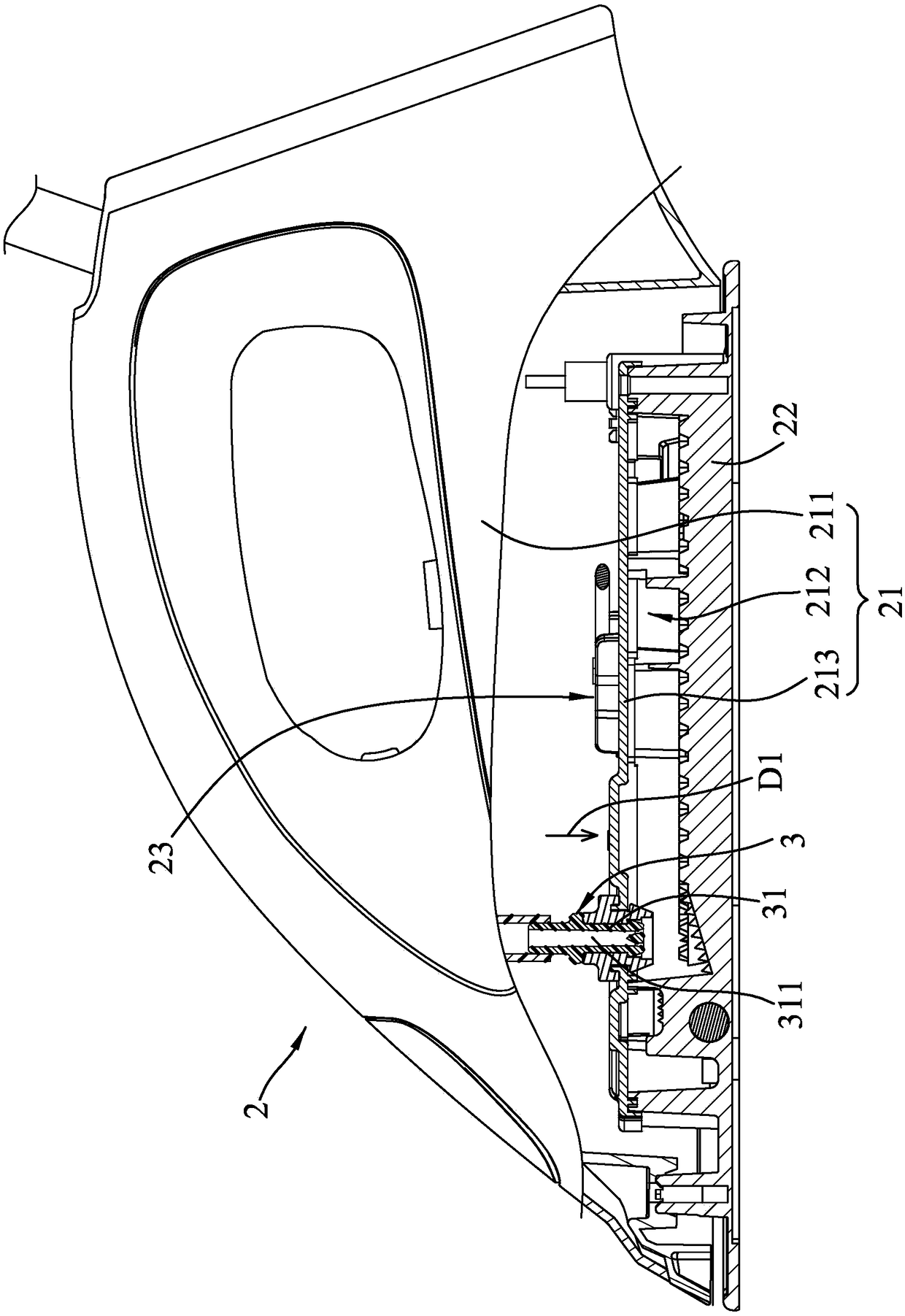

[0033] refer to Figures 3 to 6 , a first embodiment of the water injection component and the ironing device of the present invention is an iron 2, and includes a casing 21, a heating plate 22 arranged at the bottom of the casing 21, a heating plate arranged in the casing 21 A control unit 23, and a water injection part 3 inserted in the casing 21.

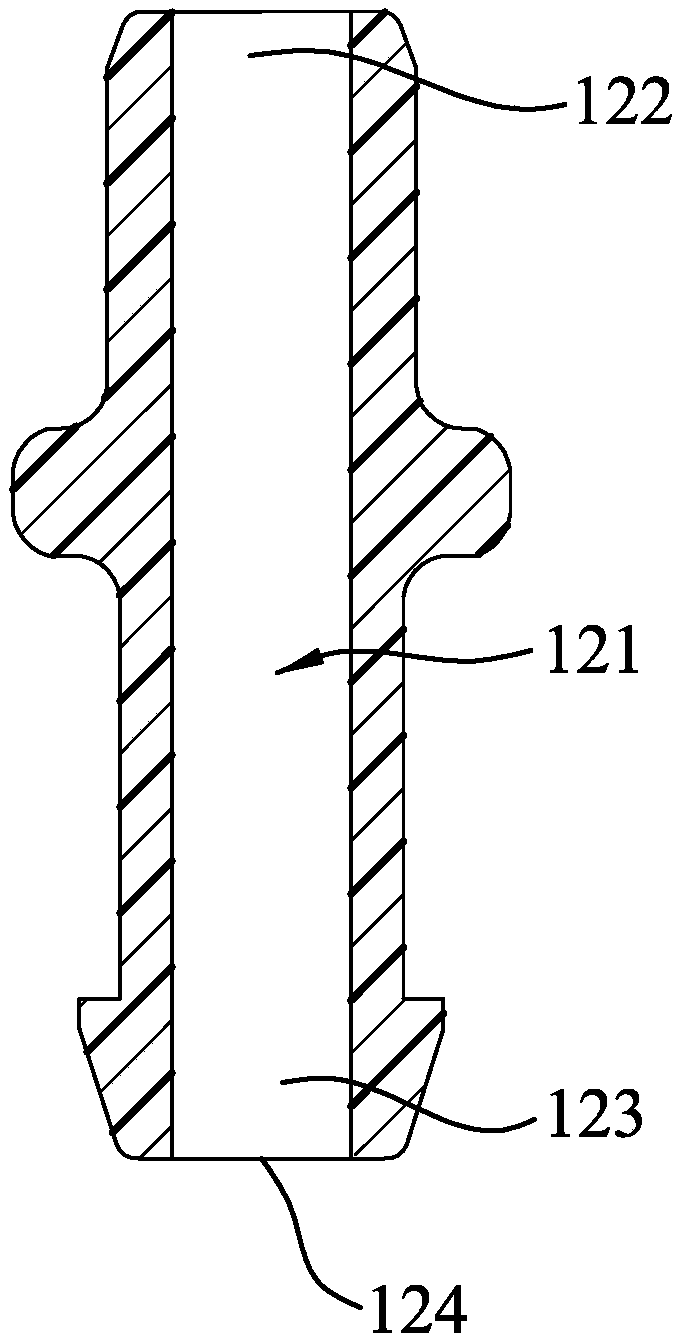

[0034] The casing 21 includes a casing 211 which is arranged outside the heating plate 22 and the water injection part 3 , and a shell plate which is arranged on the heating plate 22 and cooperates with the heating plate 22 to define a steam chamber 212 213. The shell plate 213 is inserted thereon by the water injection component 3 relative to the heating plate 22 at intervals up and down. The heating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com