Patents

Literature

33results about How to "Increase the amount of steam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for preparing sulfuric acid from SO2 by non-equilibrium state high-concentration twice conversion

ActiveCN103011092AConducive to expansion and transformationReduce the amount of smokeSulfur compoundsEnergy inputPtru catalystFlue gas

Owner:CHINA NERIN ENG +1

Coal gasification method

InactiveCN102373089ALow investment costLow running costGranular/pulverulent flues gasificationFluidized bedOxygen

The invention provides a fluidized bed-entrained flow bed gas gasification method. The method comprises the following steps: 1) carrying out reaction on raw material coal and a mixture of air and steam or a mixture of oxygen and steam to obtain gas containing incompletely reacted coal and ash; 2) separating the gas obtained from the step 1) to obtain condensed fine coal air-flow and light fine coal air-flow, and carrying out reaction on the condensed fine coal air-flow with air or oxygen to obtain gas containing coal and ash; 3) carrying out reaction on the gas obtained from the step 2) and steam to obtain gas containing coal and ash; 4) carrying out reaction on the gas obtained from the step 3), the light fine coal air-flow separated from the step 2) and a mixture of steam and carbon dioxide to obtain final gas containing coal and ash. The method lowers investment and operating cost of a traditional pulverizing system by an entrained flow bed gasification method and has a substantially increased gasification temperature than a traditional fluidized bed gasification method, so as to reduce equipment cost and increase gasification efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

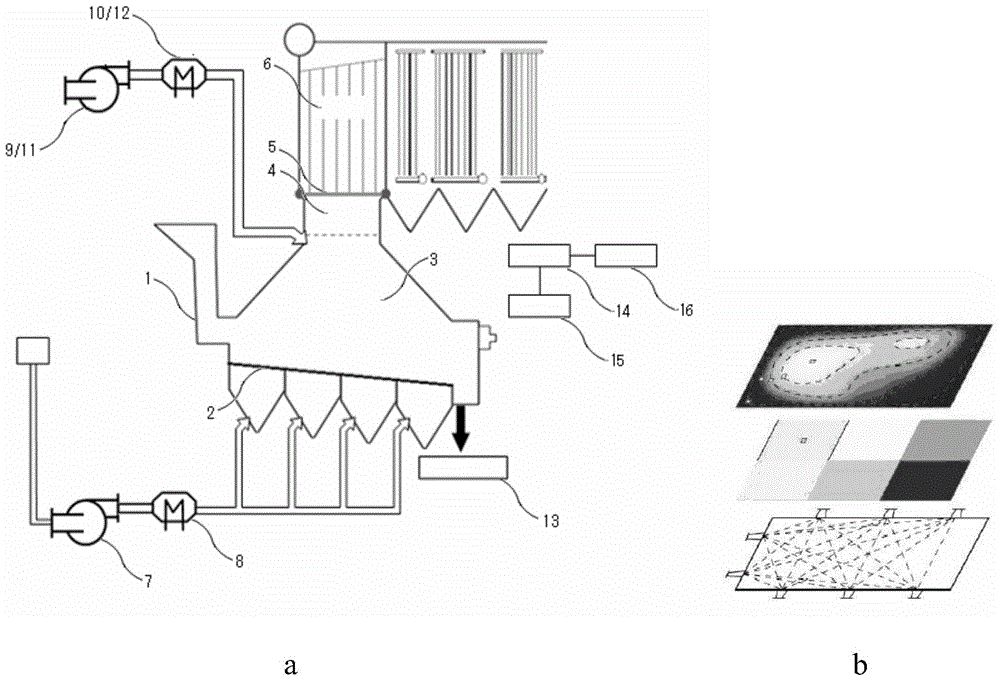

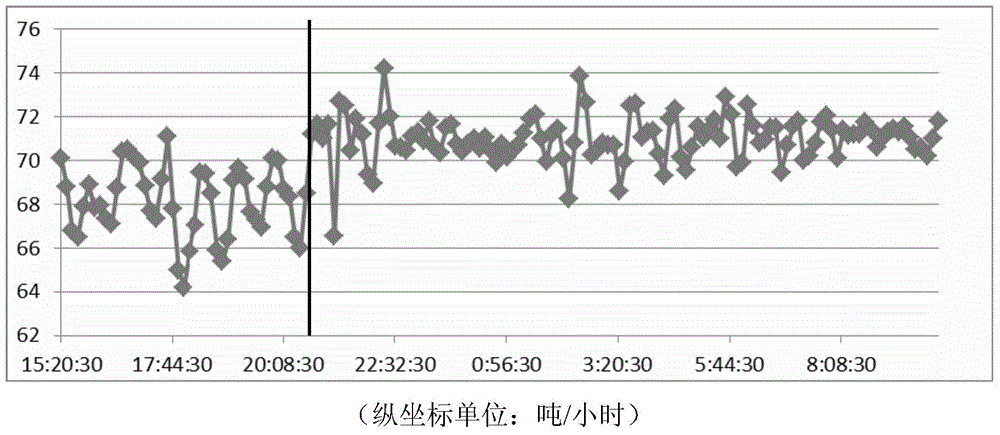

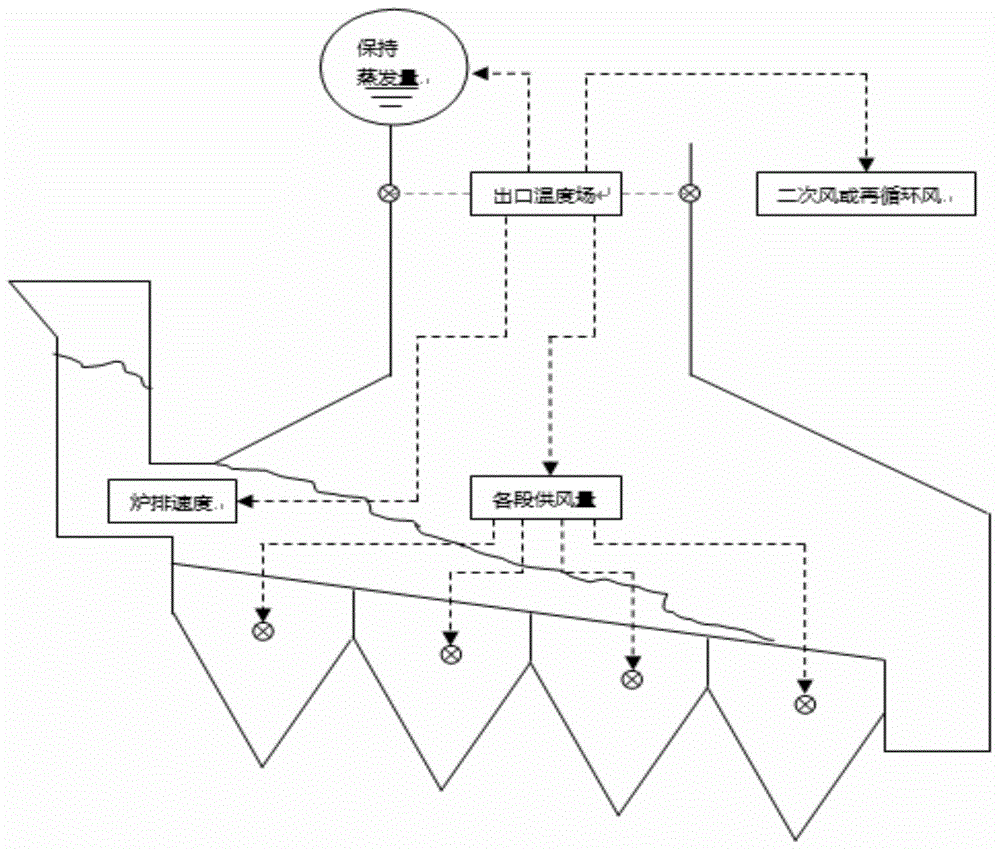

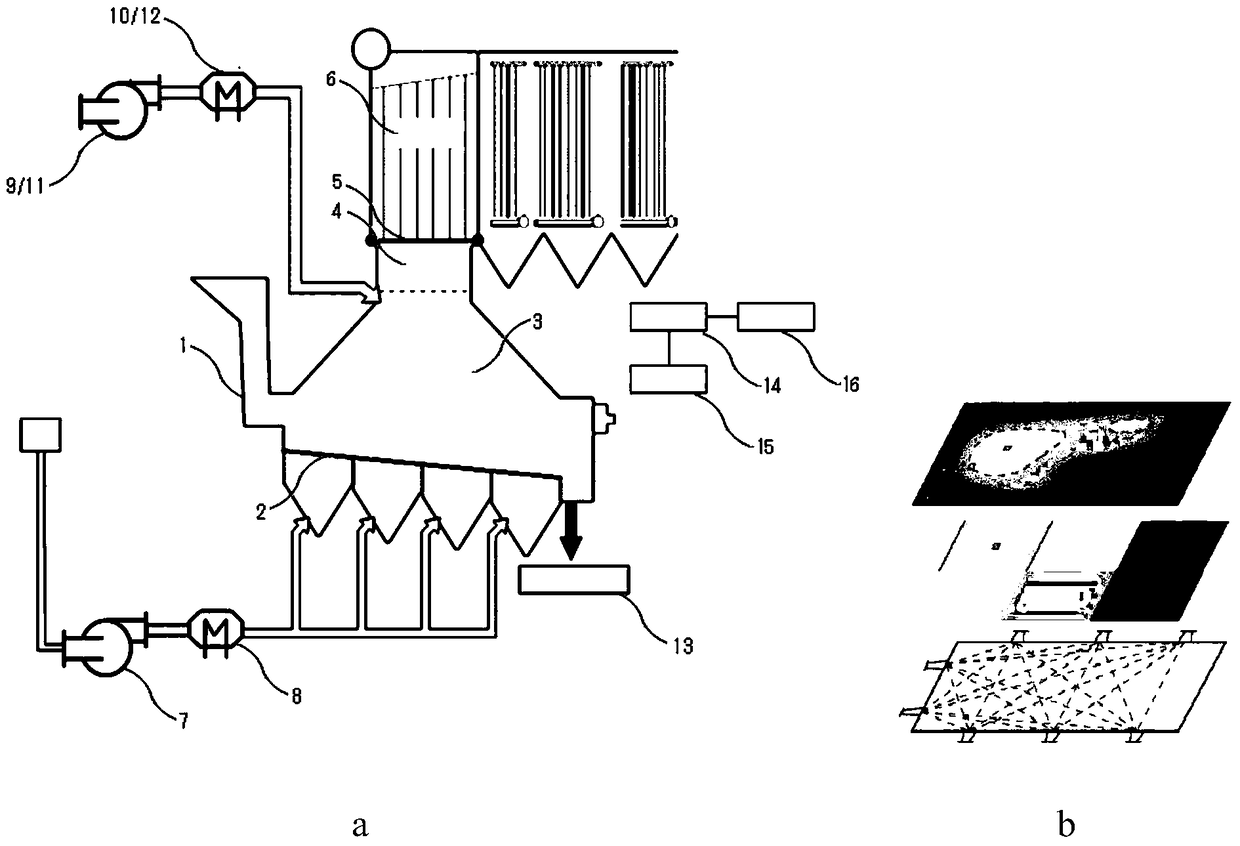

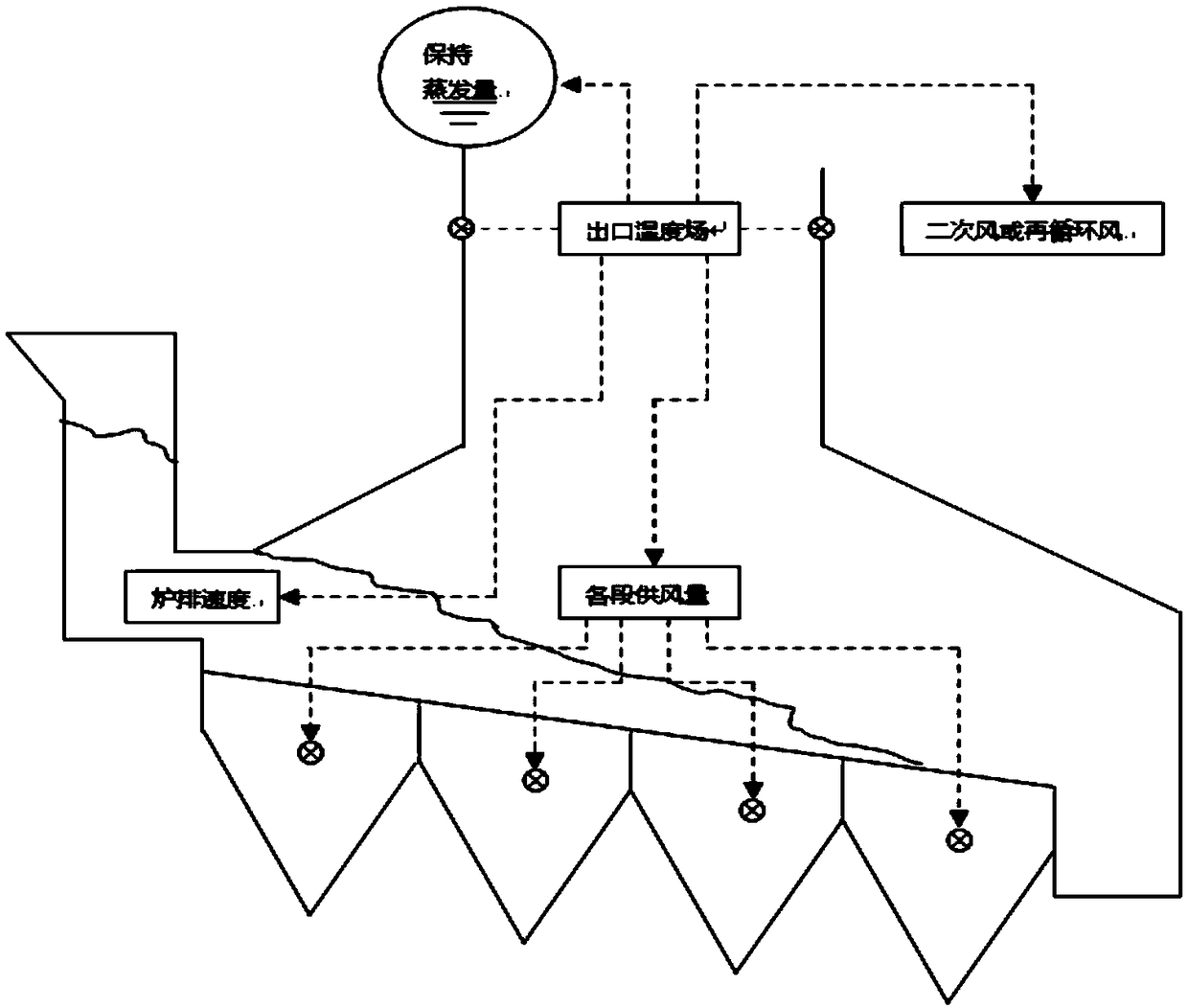

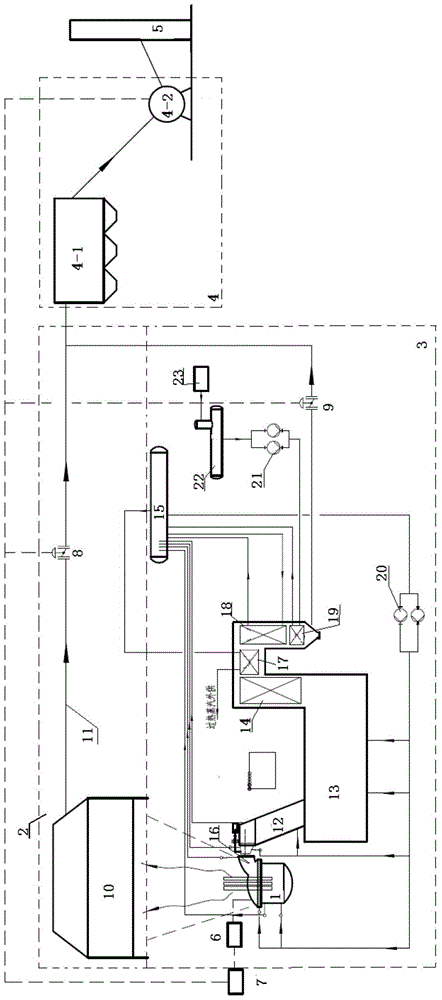

Incineration furnace combustion control method based on temperature field measurement technology

ActiveCN106556014AEmission reductionIncrease the amount of steamIncinerator apparatusCombustionEngineering

The invention relates to the field of design of incineration furnaces, in particular to an incineration furnace combustion control method. The incineration furnace combustion control method comprises the following steps: incineration furnace outlet temperature distribution conditions are provided; an incineration furnace outlet temperature two-dimensional plane distribution diagram is built according to the incineration furnace outlet temperature distribution conditions; an outlet temperature and the position of a high-temperature area of an incineration furnace are judged according to the incineration furnace outlet temperature two-dimensional plane distribution diagram; combustion working conditions are controlled according to the outlet temperature and the position of the high-temperature area; the outlet temperature of the incineration furnace is adjusted; a flame center in the furnace is positioned in a center area of the incineration furnace; an incineration furnace outlet temperature field is divided into multiple areas according to the incineration furnace outlet temperature two-dimensional plane distribution diagram; and the uniform distribution of the temperature field is controlled through the area division. The control method can guarantee the outlet smoke temperature uniformity of the incineration furnace to reduce original smoke pollutant concentration and to increase the boiler steam quantity, and can be applied to various household garbage incineration furnaces.

Owner:SHANGHAI ENVIRONMENTAL ENG DESIGN & RES INST CO LTD +1

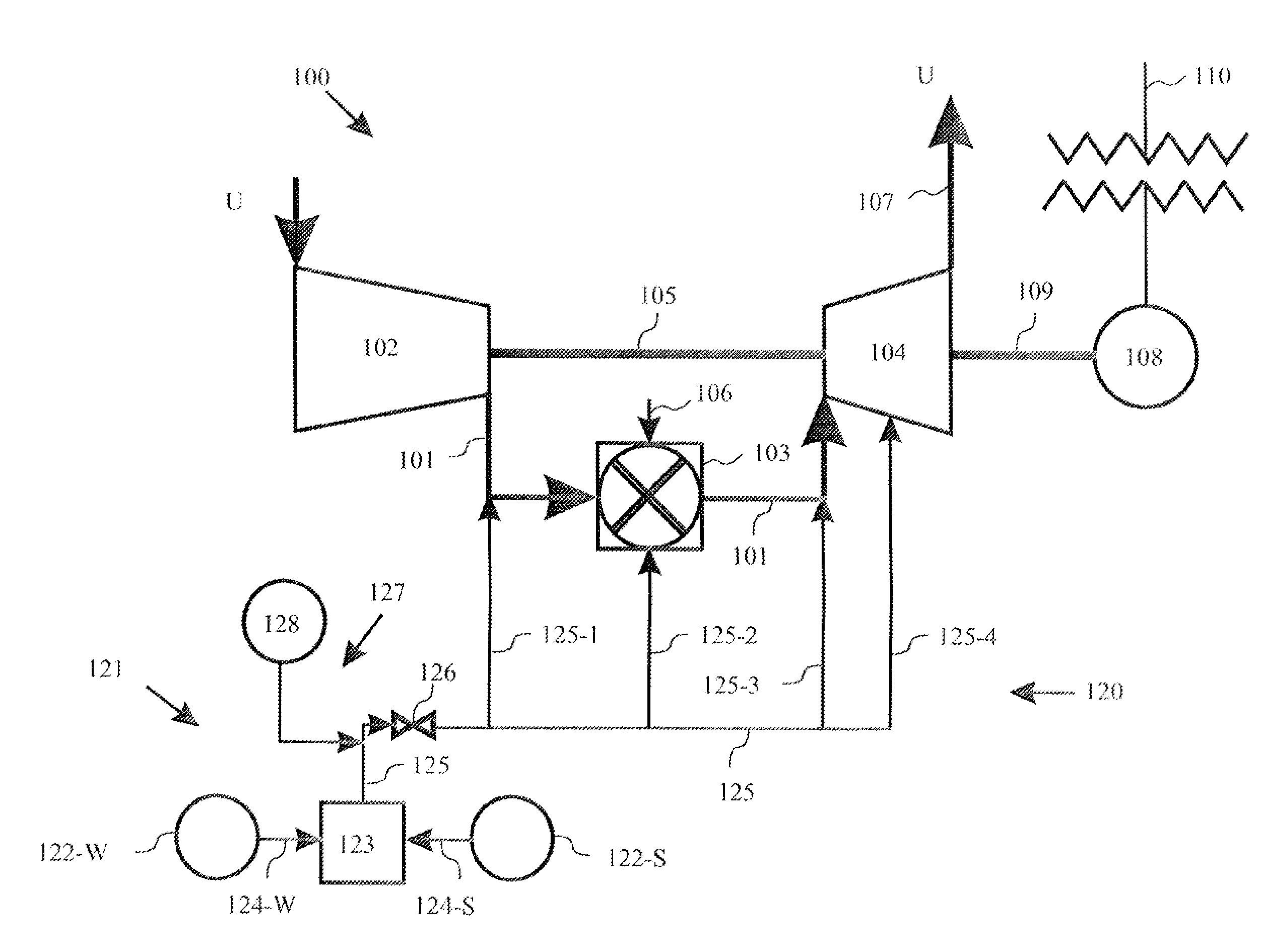

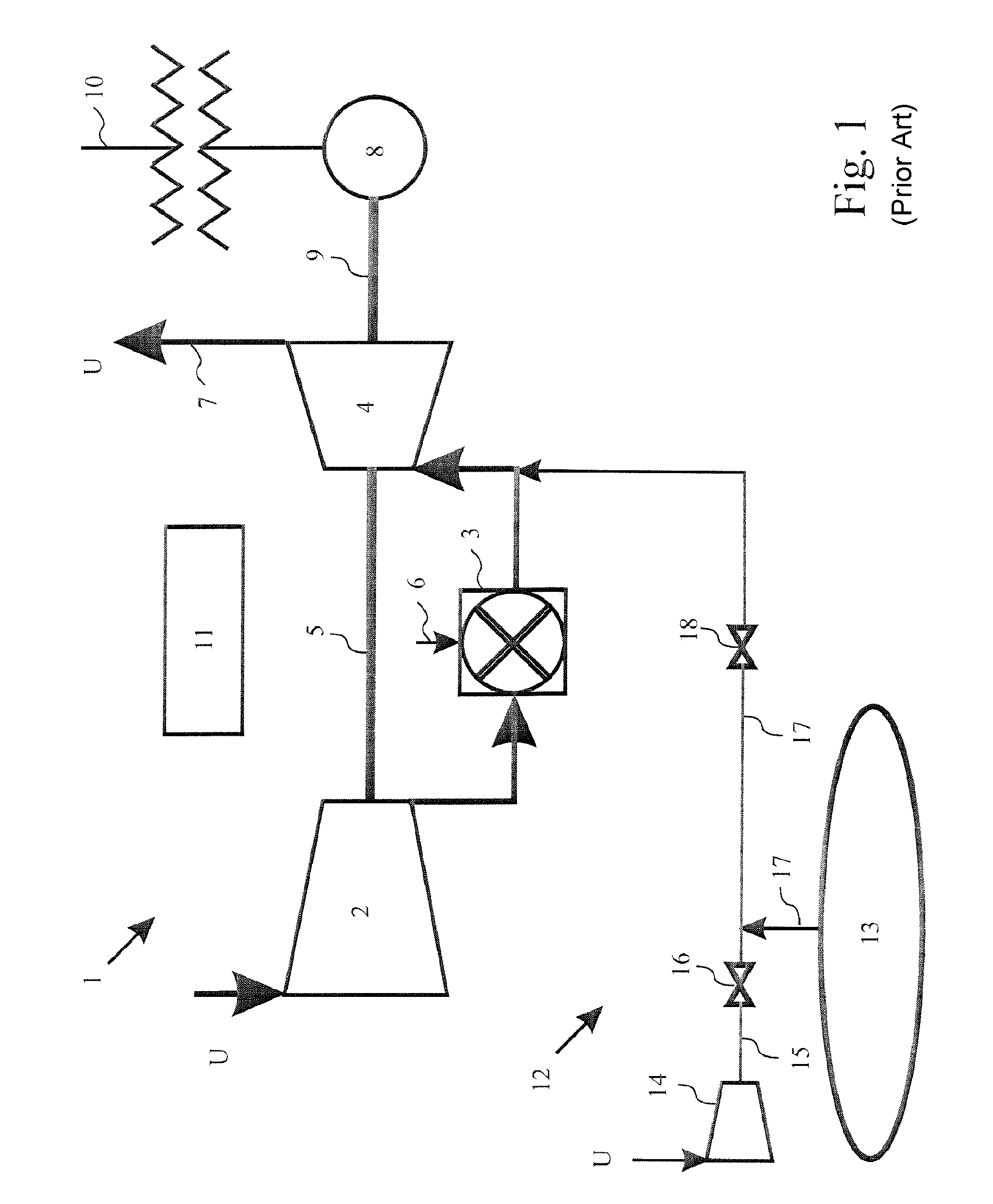

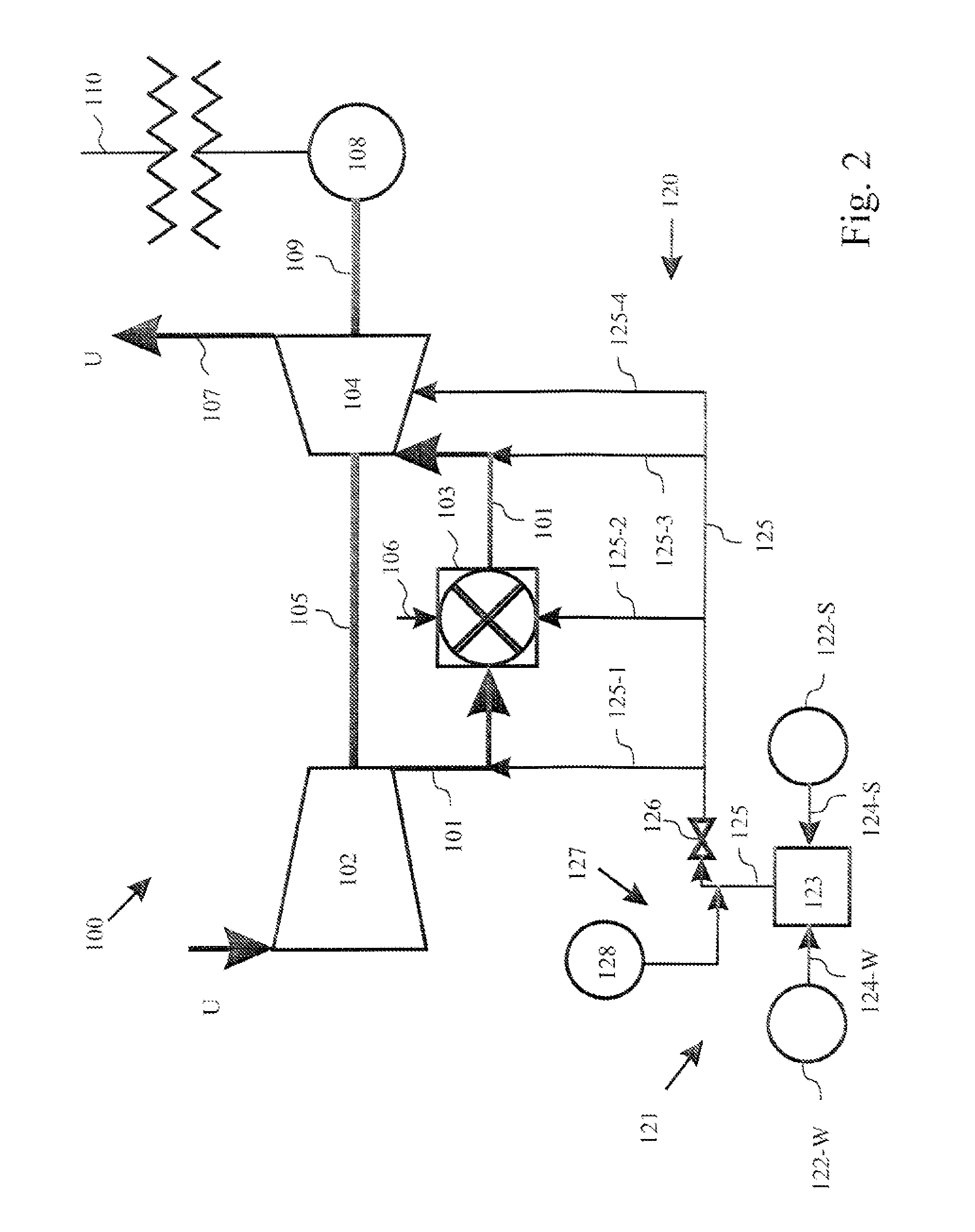

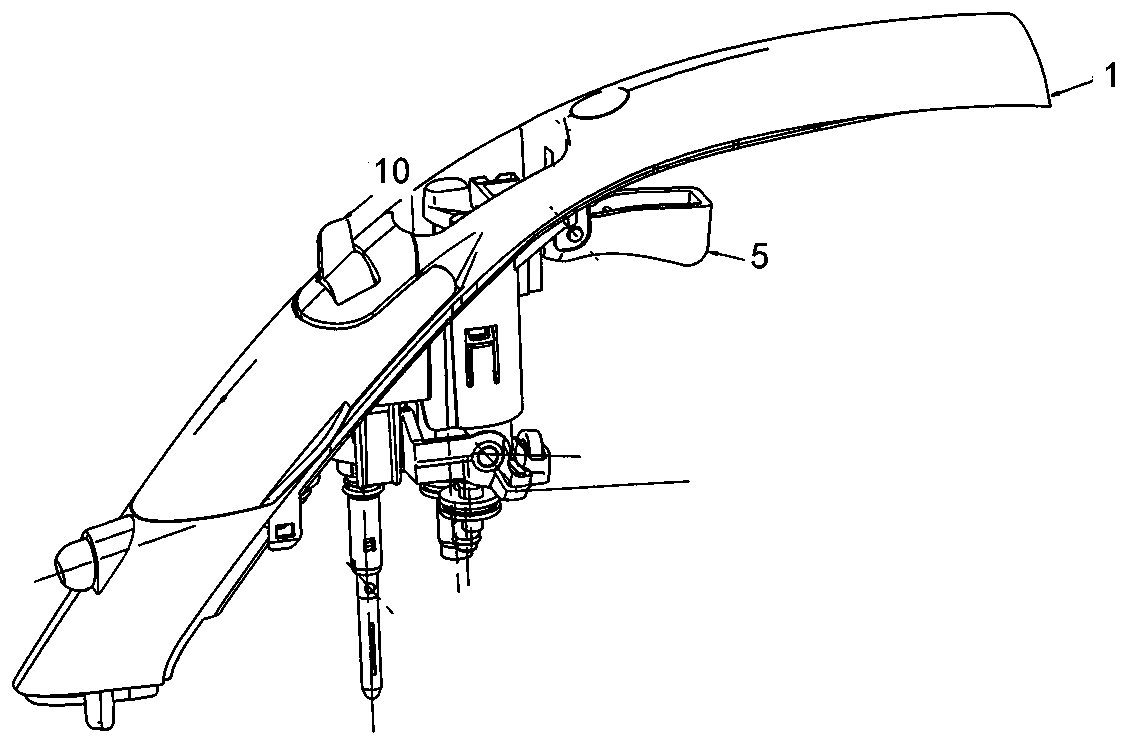

Turbo set with starting device

InactiveUS20070051112A1Easy to superviseSufficient pressure dropEngine fuctionsTurbine/propulsion engine ignitionCombustion chamberTurbocharger

In a turbo set (100) with a starting device (120), the turbo set includes a compressor (102), a combustion chamber (103), and a turbine (104) which are arranged along a flow path of the turbo set. The starting device (120) serves for starting the turbo set and includes a steam generator (121) for the generation of steam which is under overpressure and a supply line (125) for supplying the steam into the flow path (101) of the turbo set (100). In a method for starting the turbo set, the method includes generating steam which is under overpressure and supplying the steam into the flow path of the turbo set.

Owner:ALSTOM TECH LTD

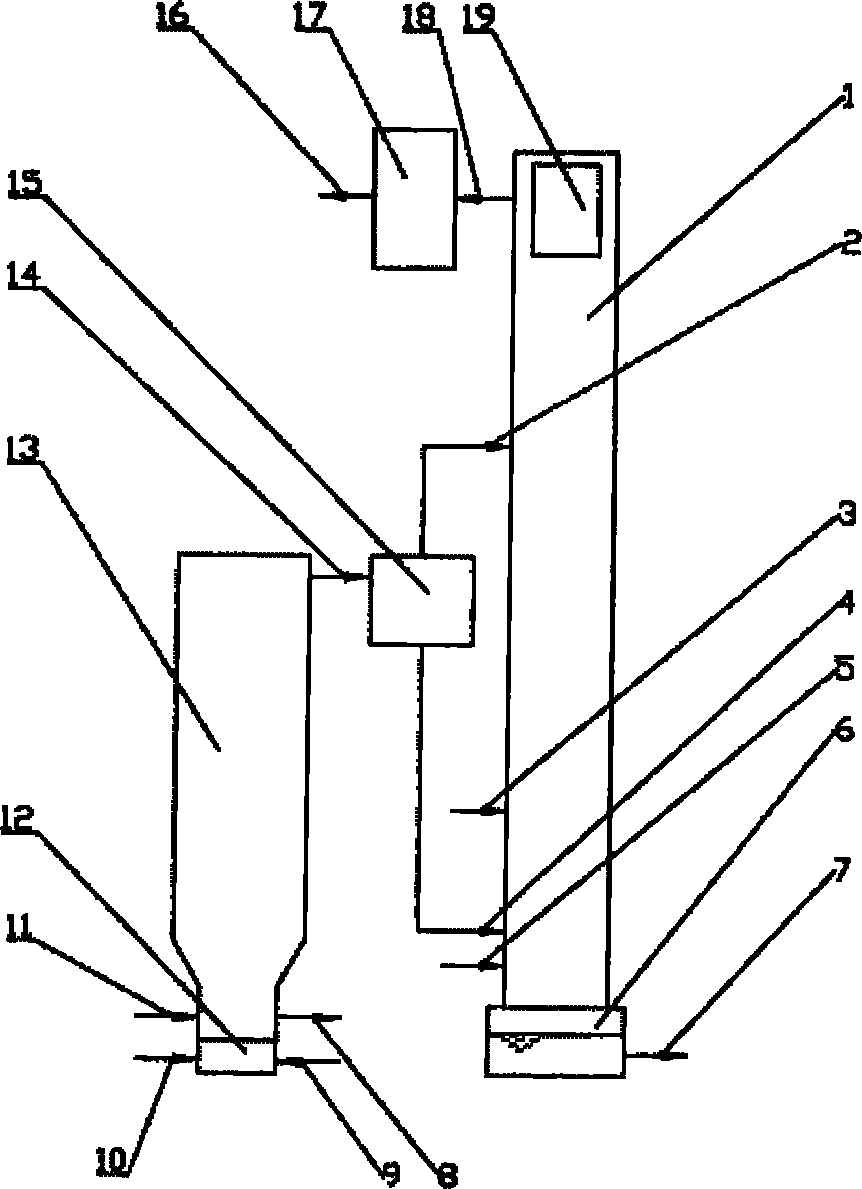

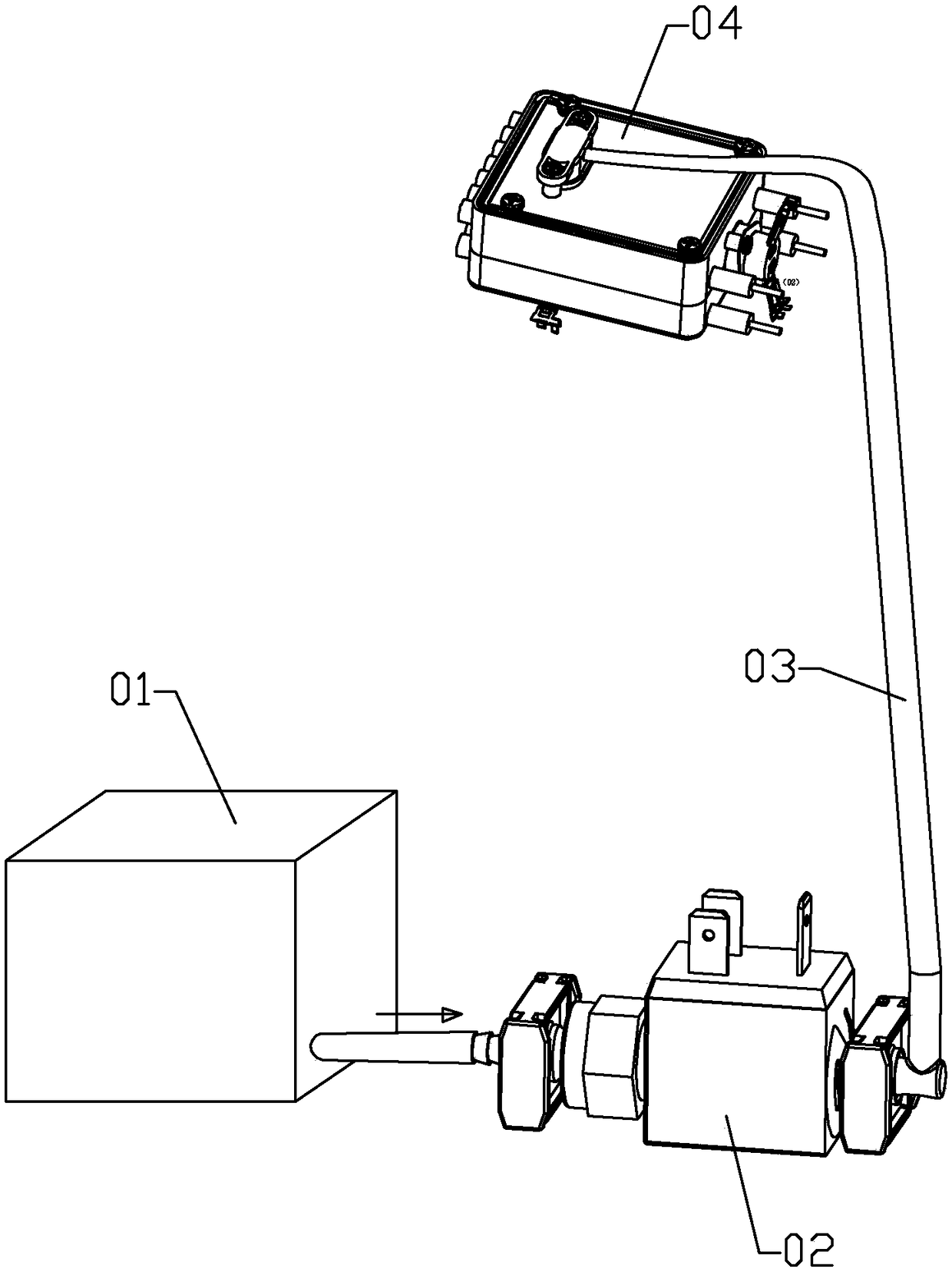

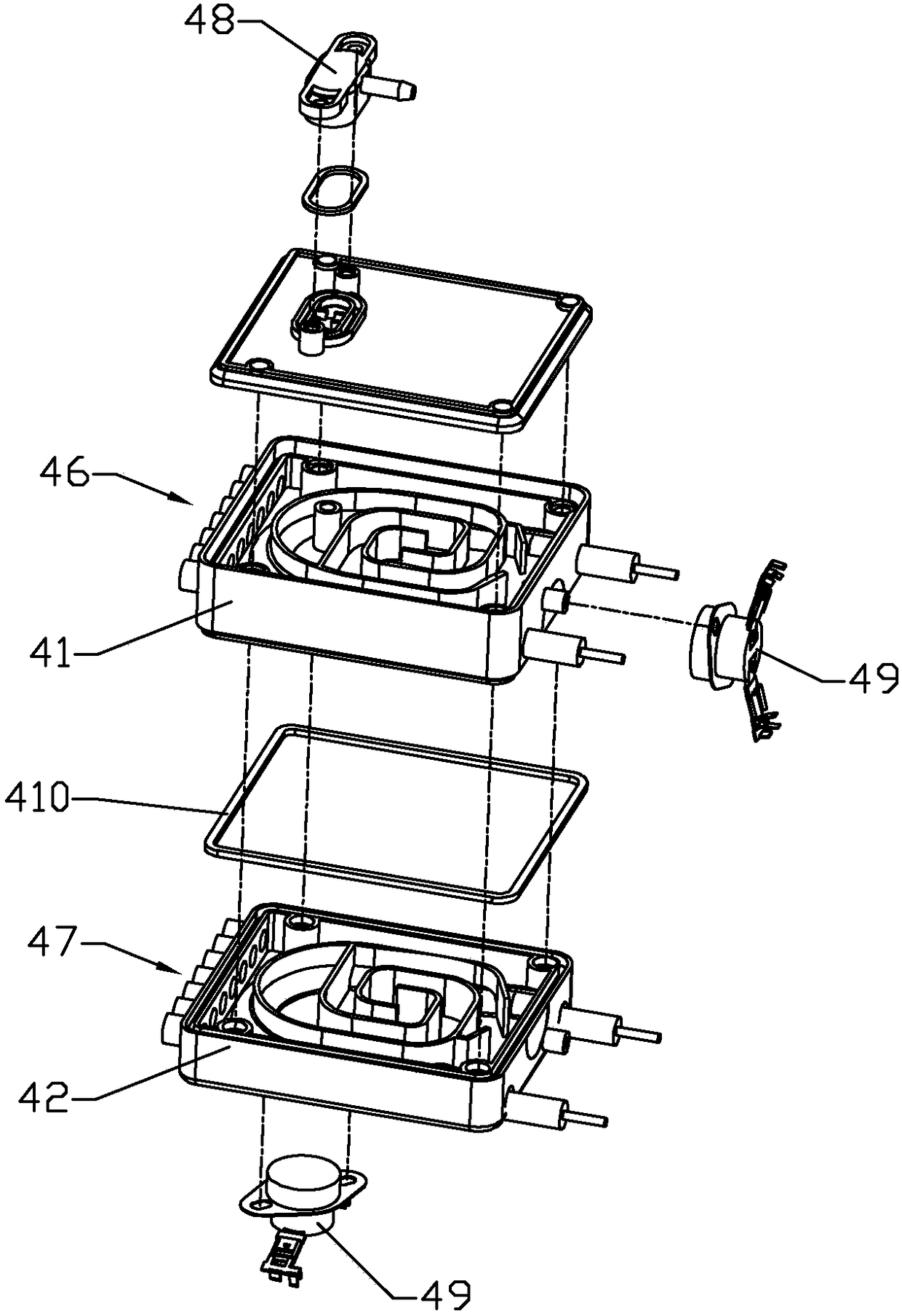

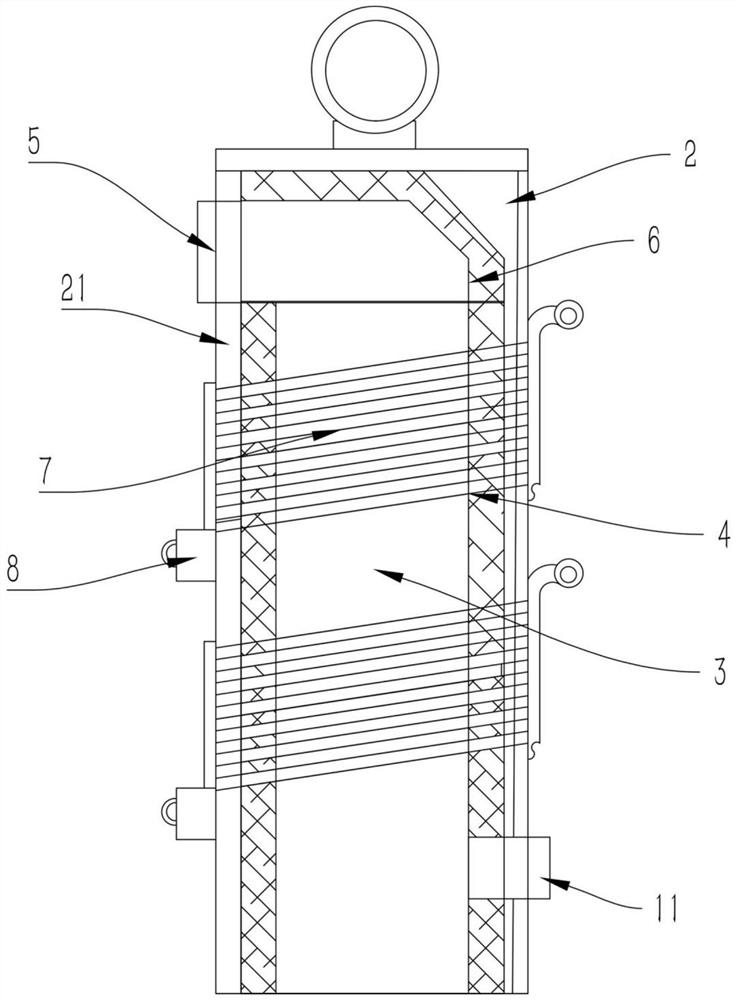

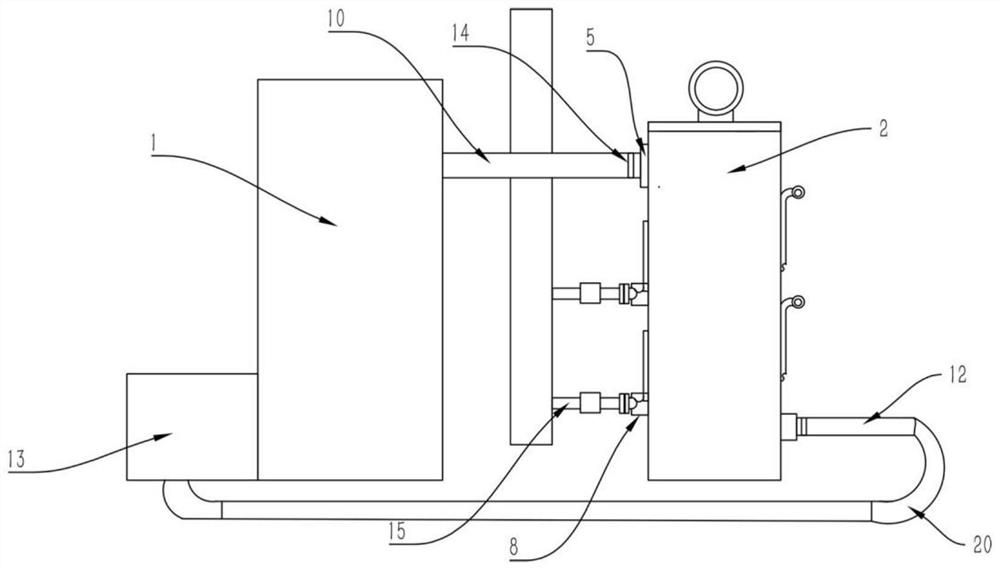

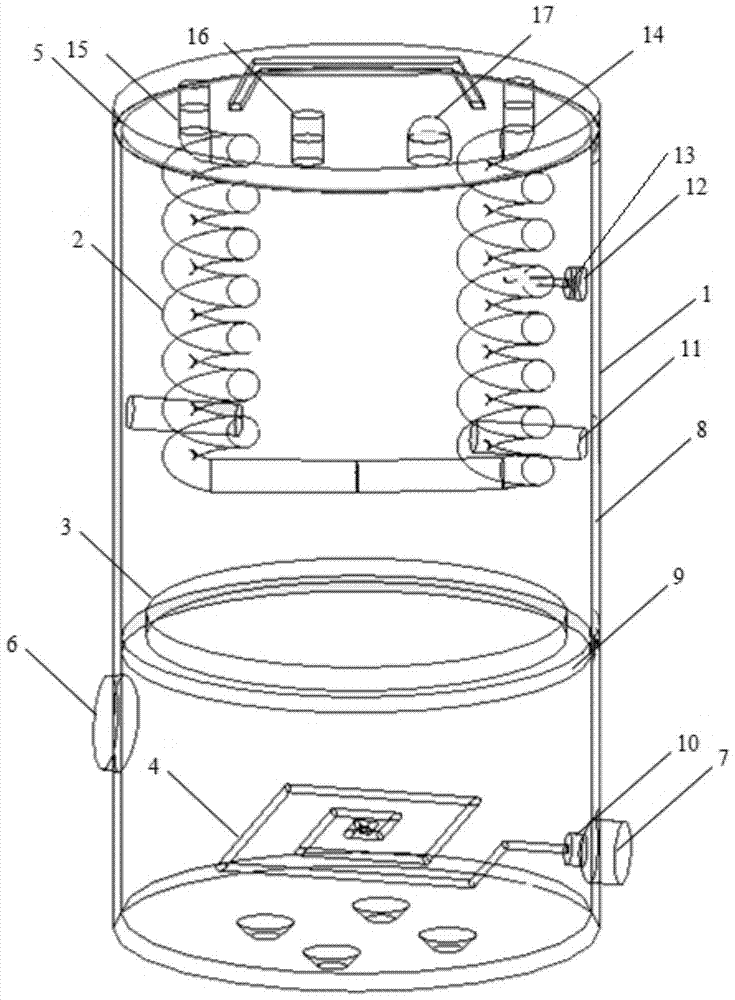

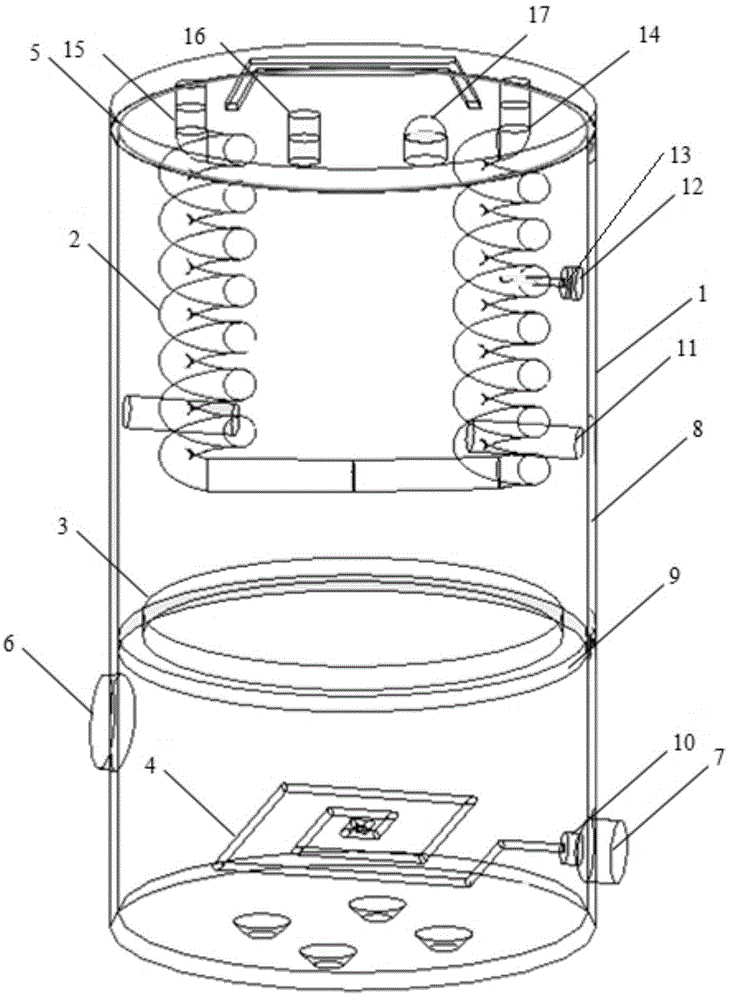

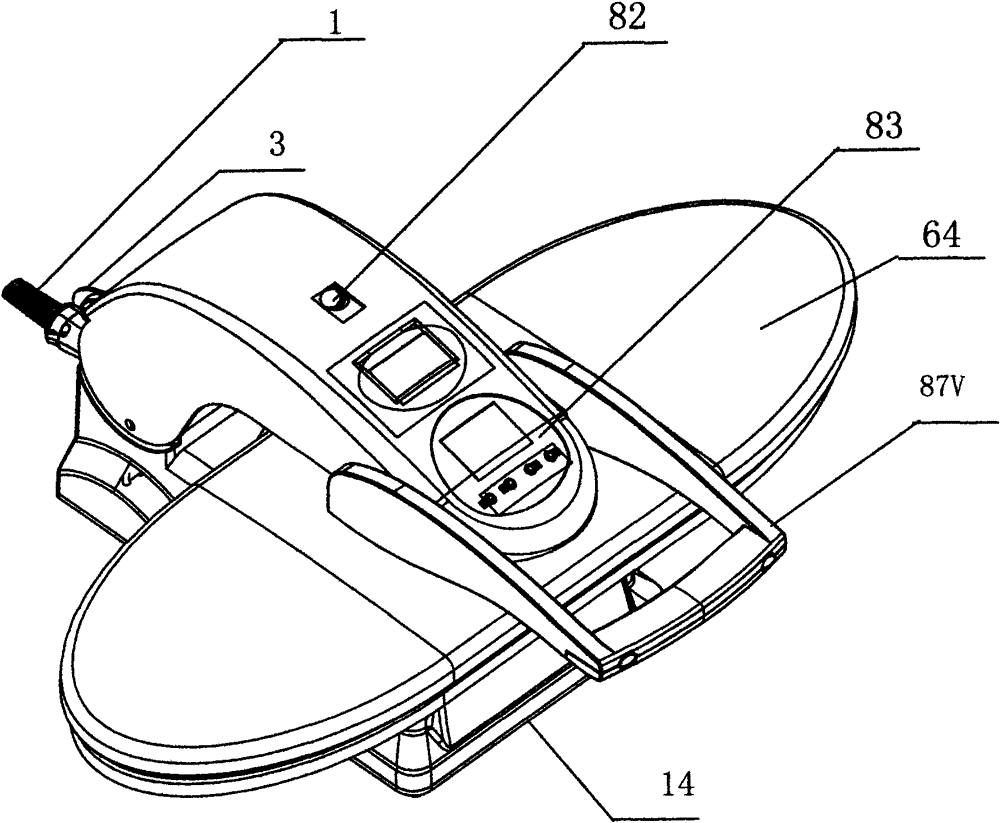

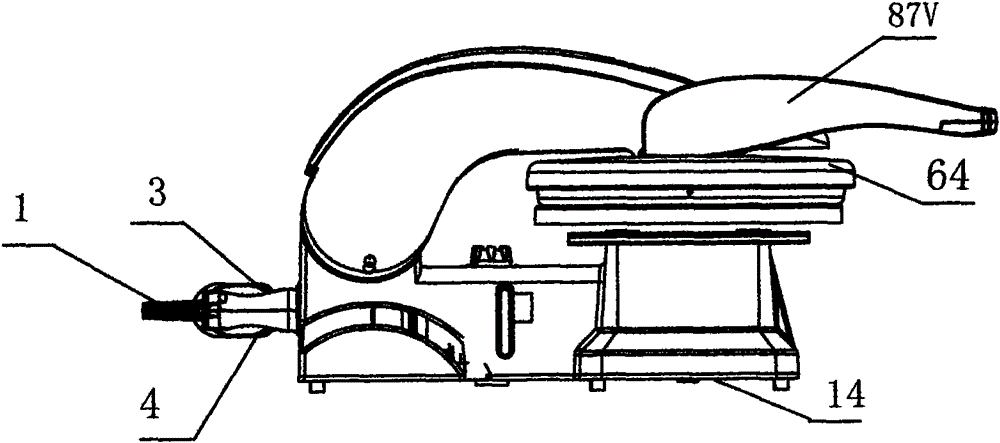

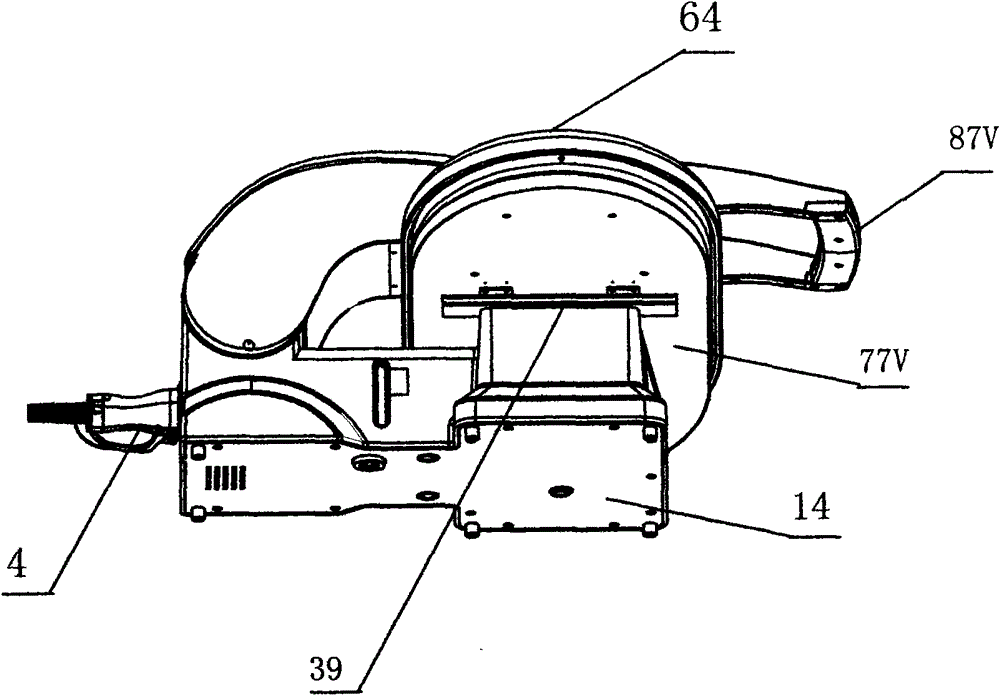

A steam generator with a super large steam volume and a multifunctional steam brush

The invention discloses a steam generator with ultra-large steam quantity and a multifunctional steam brush, and belongs to clothing ironing equipment. An existing steam boiler is short in steam channel, and therefore, a large quantity of steam cannot be obtained within a short time. The steam generator comprises at least two stacked boilers, wherein each boiler is provided with an independent steam channel and a heating element; the steam channels of the boilers are serially connected together, so that the lengths of the steam channels are more than twice greater than the length of a steam channel of an existing product. Under the condition that power of products is the same, the quantity of the steam can be increased greatly, and can reach 40 grams per minute or above. Because each boiler is provided with an air outlet, multi-layered steam outlets can be formed, and the purpose of spraying steam with various degrees of dryness and various spraying strength in the same time is achieved.

Owner:NINGBO KAIBO GROUP

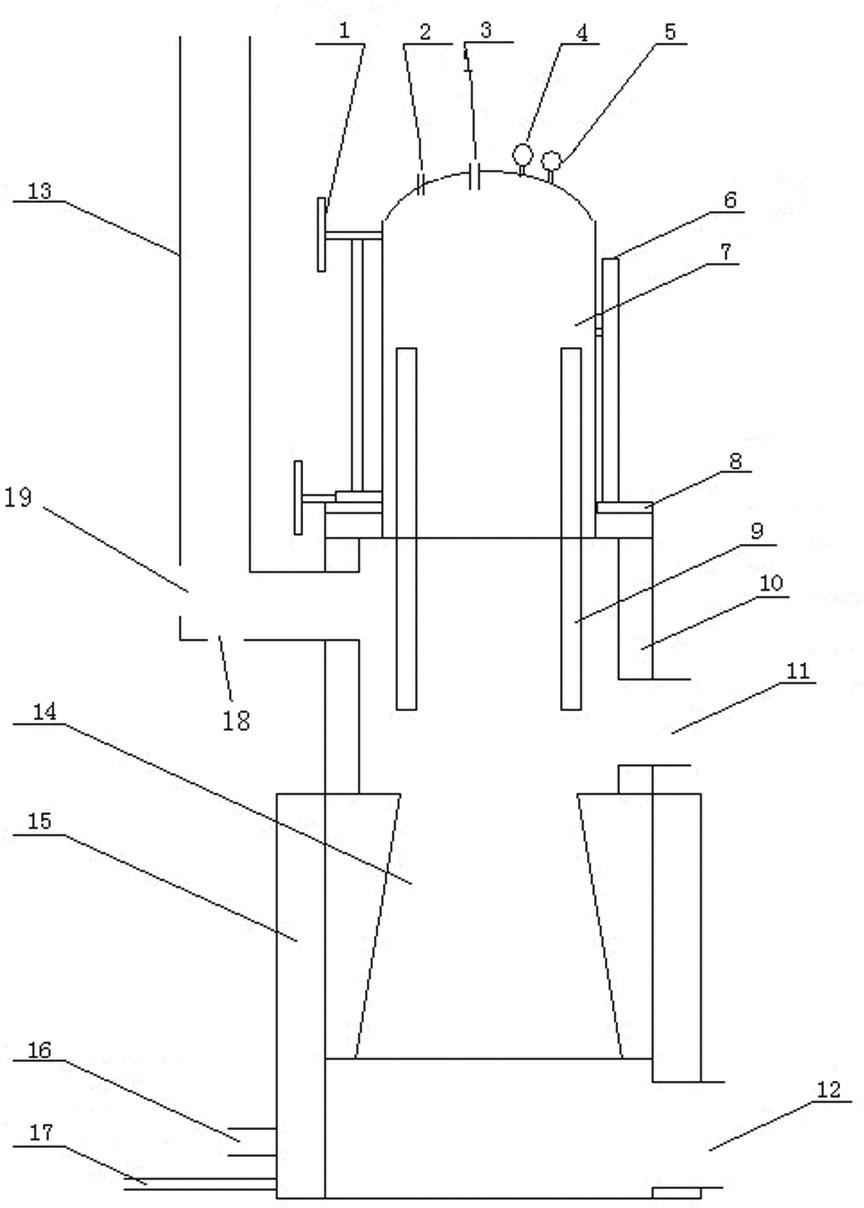

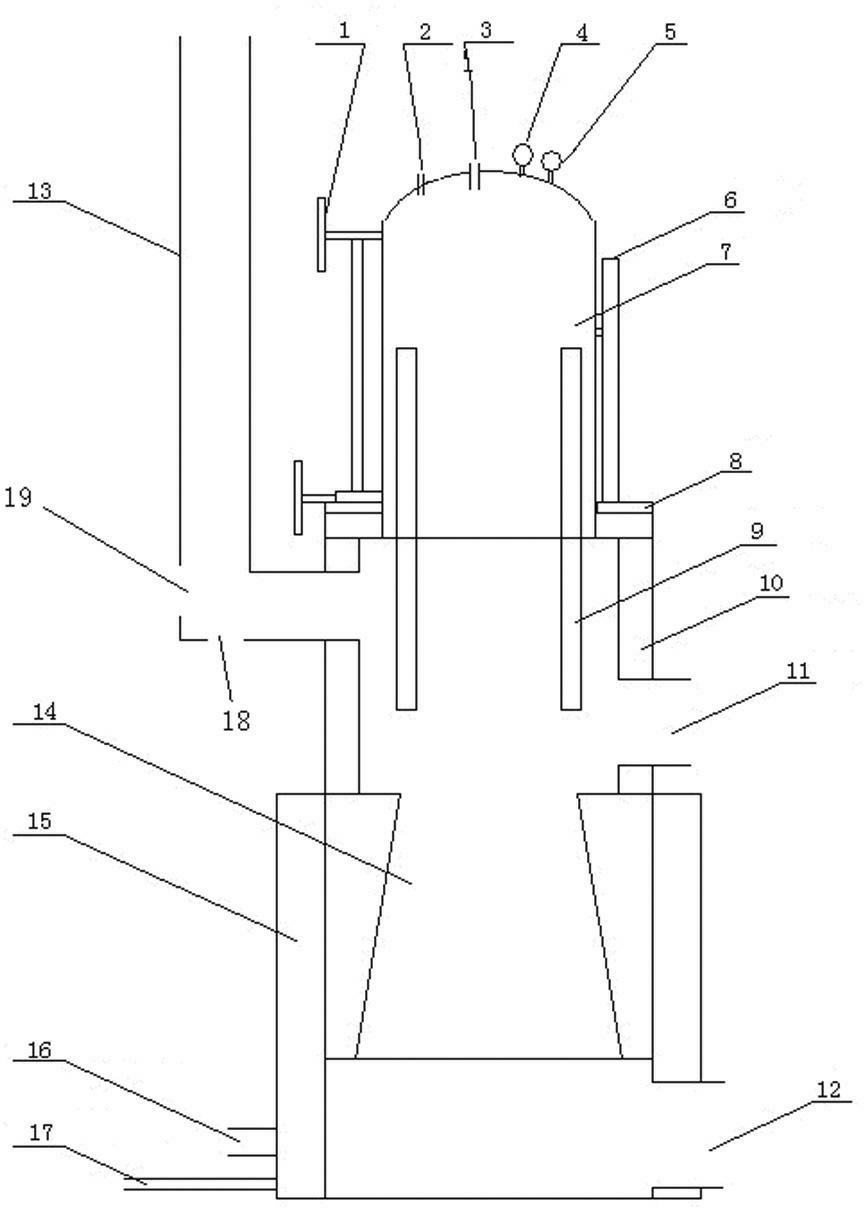

30-liter constant-pressure steam boiler

The invention discloses a 30-liter constant-pressure steam boiler. The smoke discharging tube of the 30-liter constant-pressure steam boiler is arranged on the other side surface above a coaling port between a hearth and a furnace pipe; the length of the smoke discharging tube is 60-100cm, and the upper end of the smoke discharging tube is slightly higher than the top of the furnace pipe; a superconductive heat transfer tube is arranged between the hearth and the furnace pipe; the lower end of the superconductive heat transfer tube is lower than the lowest point of a chimney opening; the hearth is a taper-shaped cavity of which the depth is 40-60cm and the diameter is 30-60cm, the top of the taper-shaped cavity is narrow, and the bottom of the taper-shaped cavity is wide; a furnace holder interlayer water jacket is arranged among a furnace holder, the hearth and a coal ash discharging cavity; a furnace pipe interlayer water jacket communicated with the furnace pipe is arranged between the furnace pipe and a shell; the two interlayer water jackets are mutually communicated; and a water inlet tube is arranged below the interlayer water jacket between the furnace holder and an ash outlet.

Owner:王国祥

High-efficient and low consumptive fire coal additive agent special for boiler

InactiveCN101358154AGood desulfurization effectHigh coal saving rateSolid fuelsChemistryPotassium permanganate

The present invention discloses boiler-dedicated high-efficiency low-consumption coal additive, which contains the ingredients with the following weight portions: 20 to 30 portions of magnesium chloride, 25 to 35 portions of sodium nitrate, 15 portions to 25 portions of potassium nitrate, 5 to 15 portions of sodium chlorate, 5 to 15 portions of potassium chlorate and 1 to 5 portions of potassium permanganate; and the weight portion ratio of the additive and coal is 1 to 3 : 1000. The additive has the following advantages: the burning intensity of coal is enhanced; the temperature of a furnace is increased; the burning area of a furnace chamber is expanded; a layered coal bed becomes expanded and loose; the effects of decoking, ash-cleaning and desulphurizing are good; and the coal-saving rate is increased.

Owner:邹炎龙

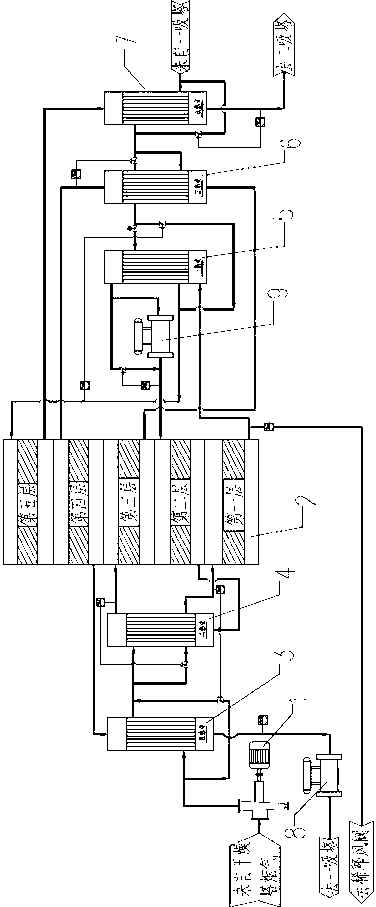

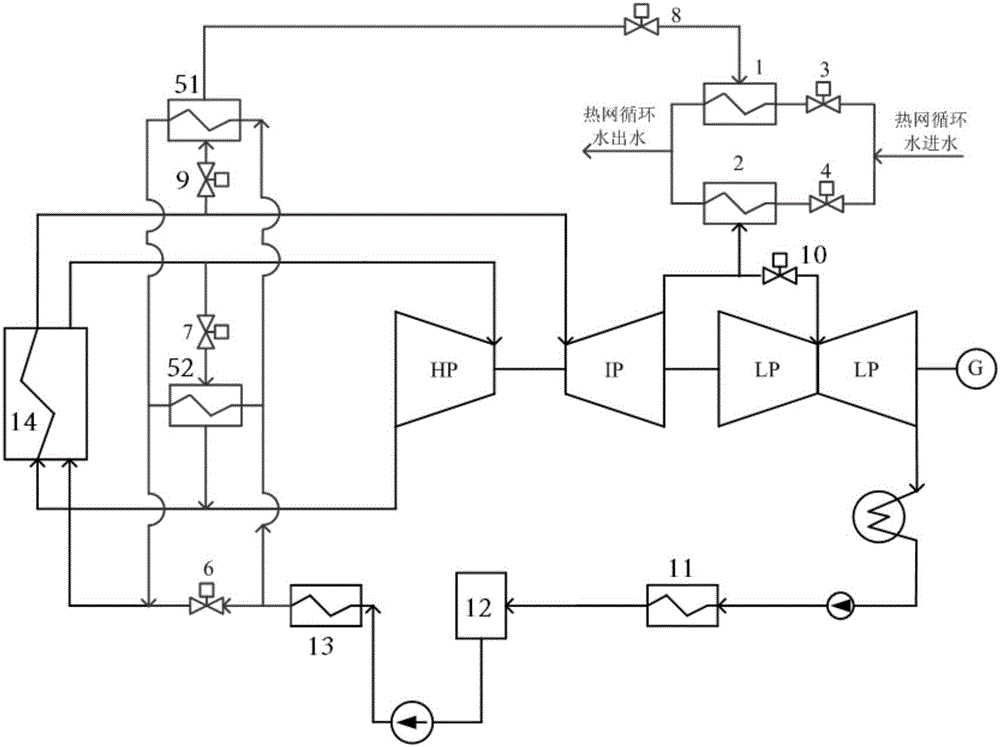

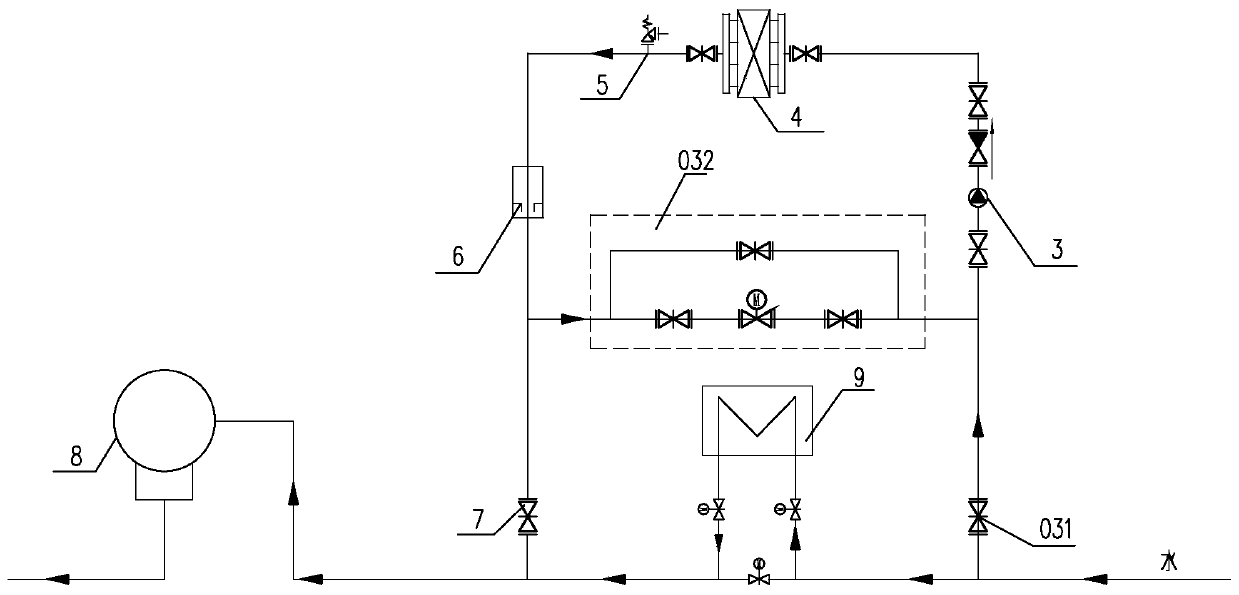

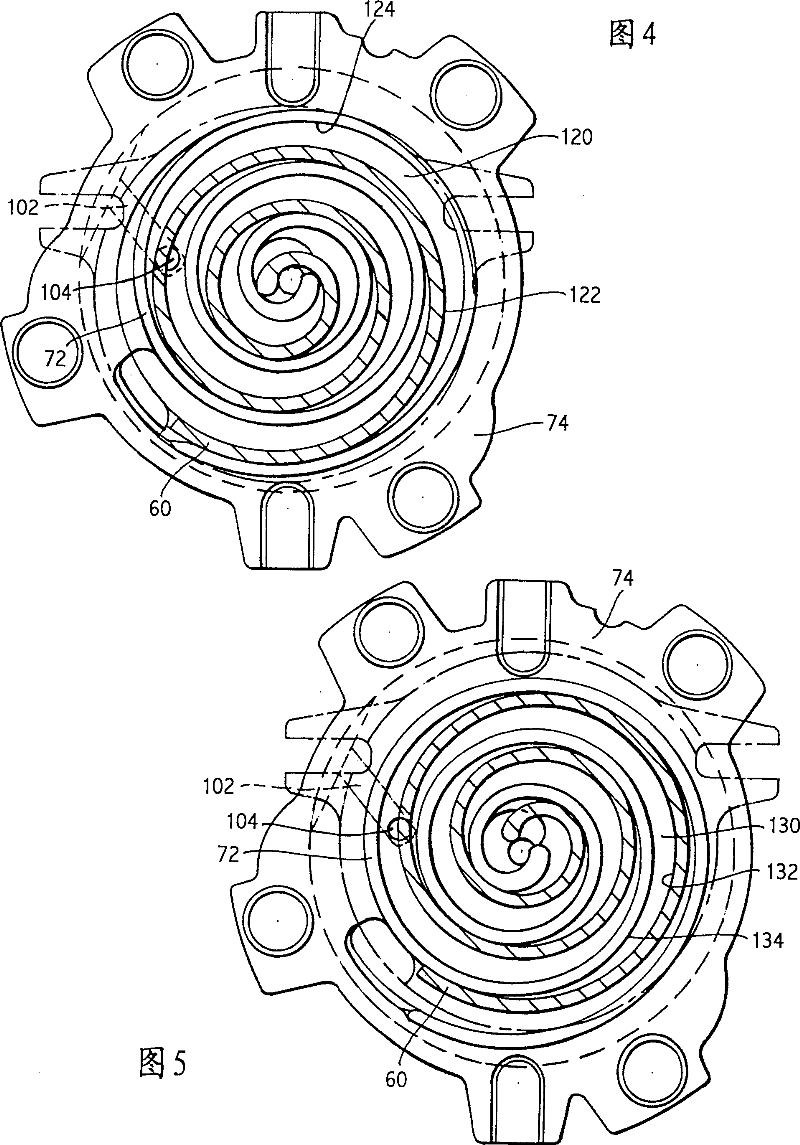

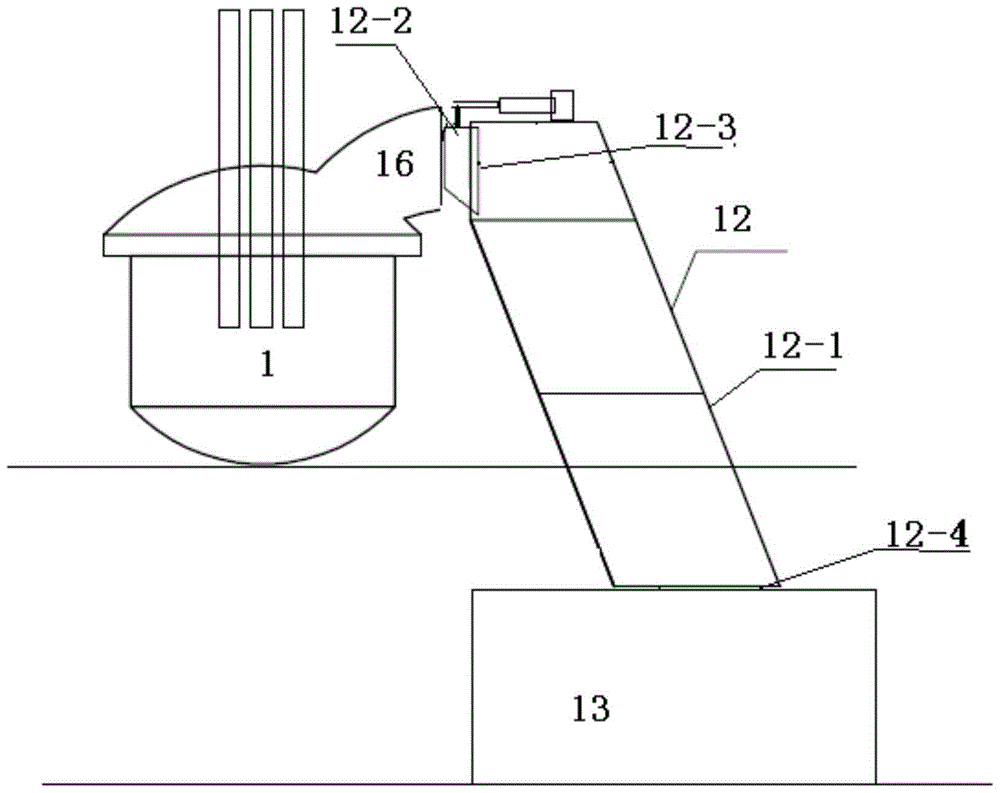

Thermoelectric decoupling system capable of improving energy utilization quality of thermoelectricity plant

ActiveCN107178398ALarge amount of steamIncrease the amount of steamSteam engine plantsThermodynamicsLow voltage

The invention discloses a thermoelectric decoupling system capable of improving energy utilization quality of a thermoelectricity plant. The system comprises a boiler, a high voltage cylinder, a primary bypass adjusting valve, a first additional high voltage heater, a medium voltage cylinder, a second additional high voltage heater, a secondary bypass adjusting valve, a hot net circulating water system, a low voltage cylinder and a water feeding adjusting valve. According to the system disclosed by the invention, decoupling operation of power production and thermal production can be realized, so that heat supply peak shaving ability of a thermoelectric unit can be obviously improved.

Owner:XIAN XIRE ENERGY SAVING TECH

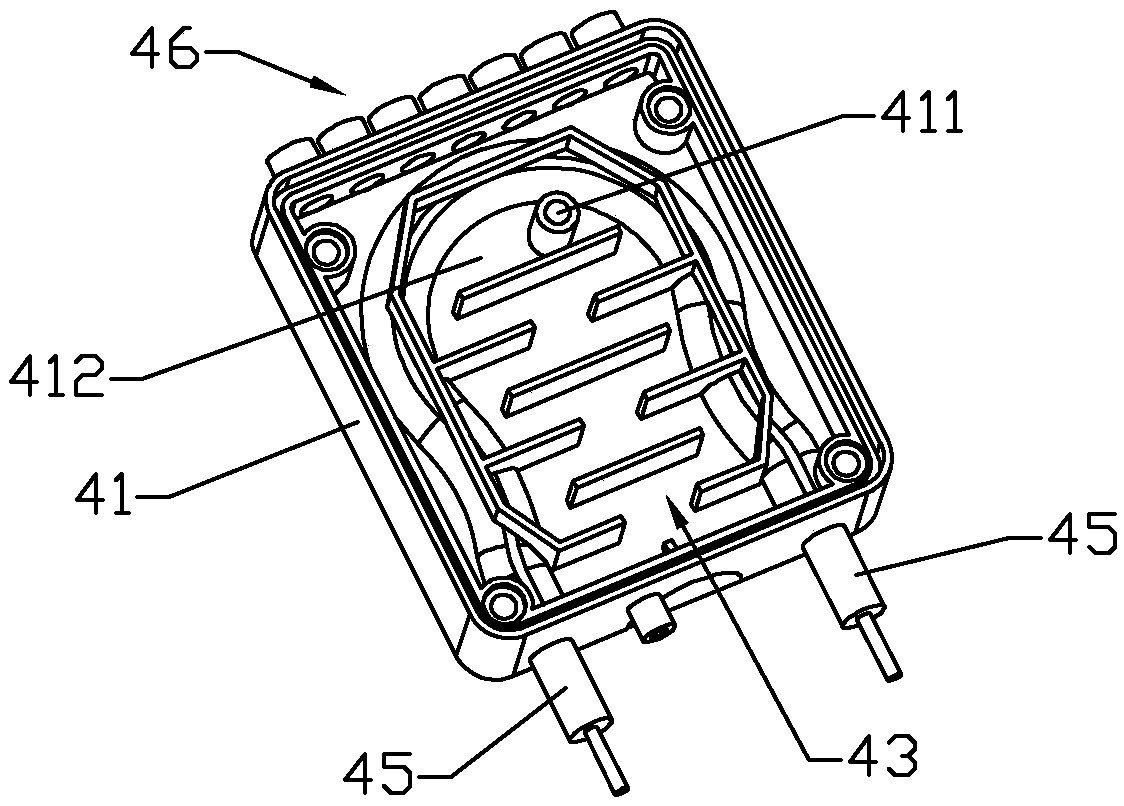

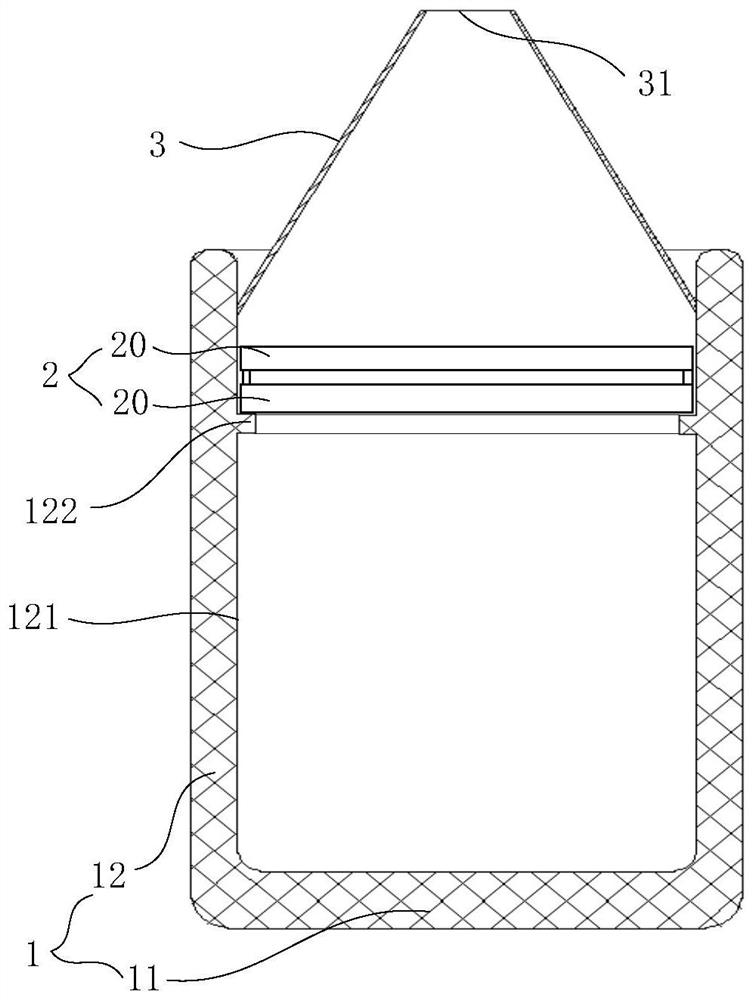

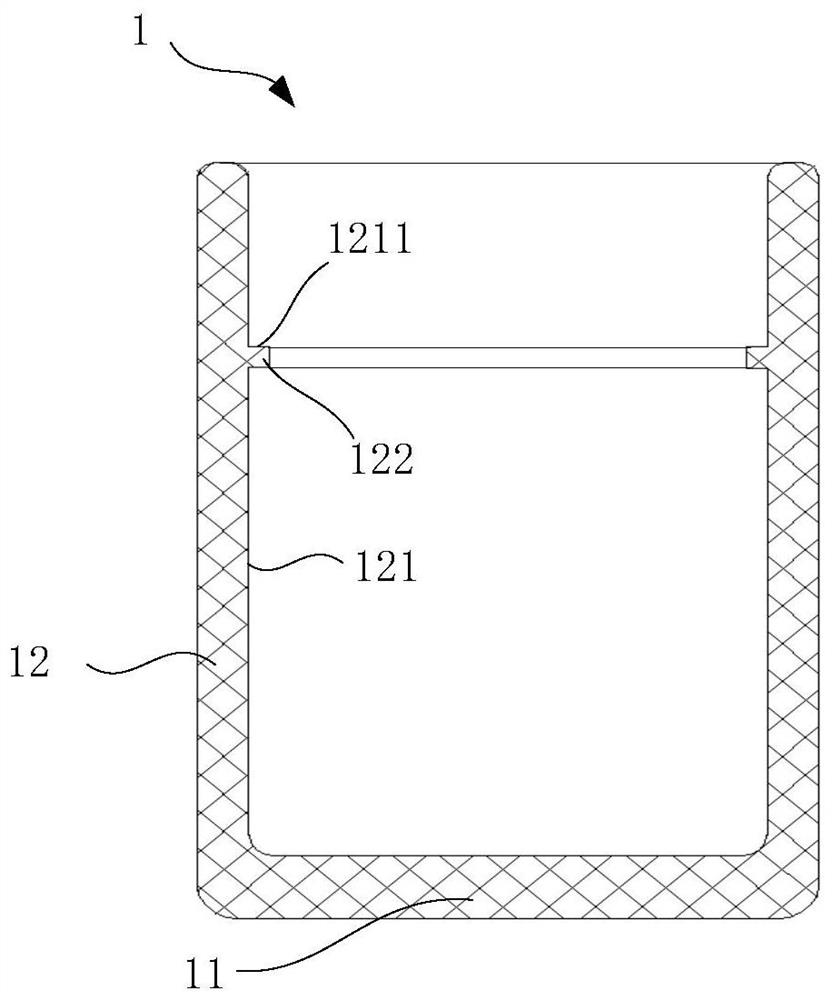

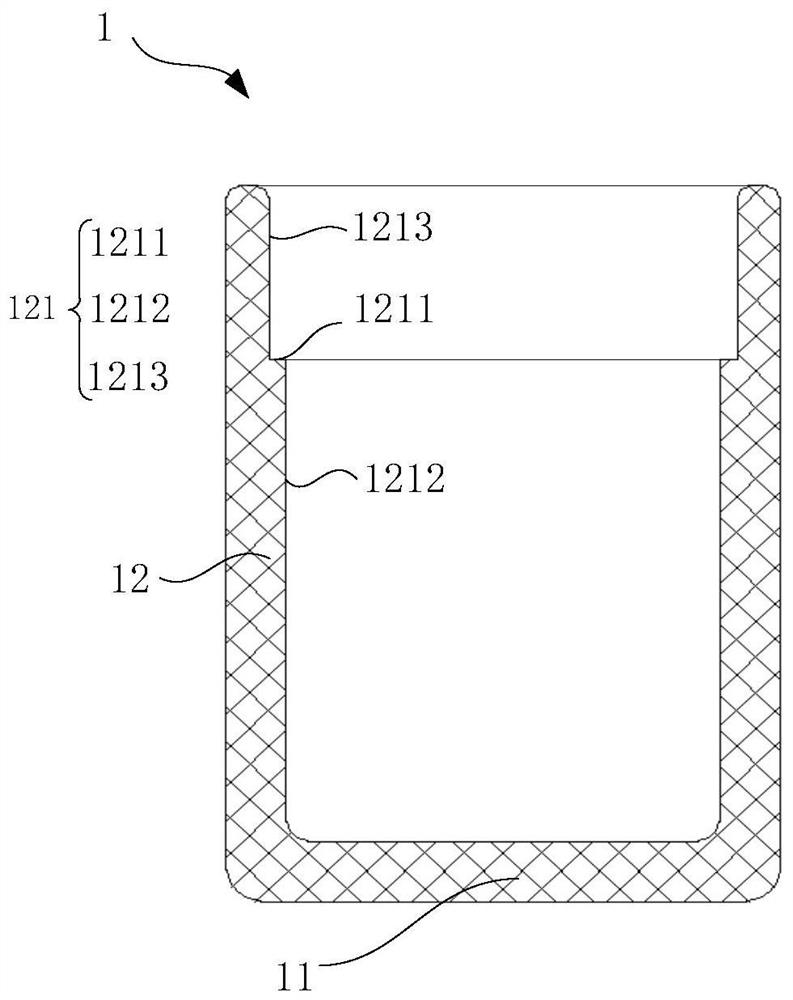

Evaporation crucible

ActiveCN112359324AIncrease the amount of steamImprove stabilityVacuum evaporation coatingSputtering coatingCrucibleIndustrial engineering

The invention discloses an evaporation crucible, relates to the technical field of evaporation equipment, and can reduce the speed fluctuation of steam sprayed by a nozzle and reduce the possibility that a coating material is attached to the inner side of the nozzle and continuously grows. The evaporation crucible comprises a crucible body, a screen plate assembly and the nozzle; the crucible bodycomprises a bottom wall and a side wall which is arranged around the bottom wall, the bottom wall and the side wall define a containing cavity with an opening, the surface, close to the containing cavity, of the side wall is a first surface, the first surface comprises a supporting face parallel to the bottom wall; the screen plate assembly comprises at least one screen plate with meshes, the screen plate assembly is abutted with the supporting surface; and the nozzle is mounted at the opening of the containing cavity and is provided with an air spraying hole. The evaporation crucible disclosed by the invention is used for an evaporation process.

Owner:BOE TECH GRP CO LTD +1

Handheld pressure steam iron

InactiveCN105525500AAvoid damageAvoid contaminationHand ironTextiles and paperElectricityEngineering

A handheld pressure steam iron comprises a casing and a bottom plate, wherein the bottom plate is arranged at the lower end of the casing and provided with at least one steam outlet, a bottom plate electric heating tube and a bottom plate temperature controller are arranged in the bottom plate, the bottom plate electrical heating tube is electrically connected with the bottom plate temperature controller, a boiler is arranged in the casing, a boiler electric heating tube is arranged at the bottom of the boiler, the boiler and the bottom plate adopt split type heating, the bottom plate can realize low-temperature ironing at the temperature of 100-130 DEG C, damage to clothes is avoided, a water inlet is arranged on the boiler, a boiler safety valve is arranged at the water inlet, and a steam tube for conveying steam to the bottom plate is also arranged on the boiler. The inside of the boiler is completely sealed, so that the boiler produces high-pressure steam. The steam amount is greatly increased and is 6 times that of common steam irons, the steam ejection force is greatly increased, continuous high-temperature steam can be produced to realize a steaming function, clothes are prevented from being damaged and stained with droplets, and the iron is simple in structure and convenient to use.

Owner:CUORI ELECTRICAL APPLIANCES GRP

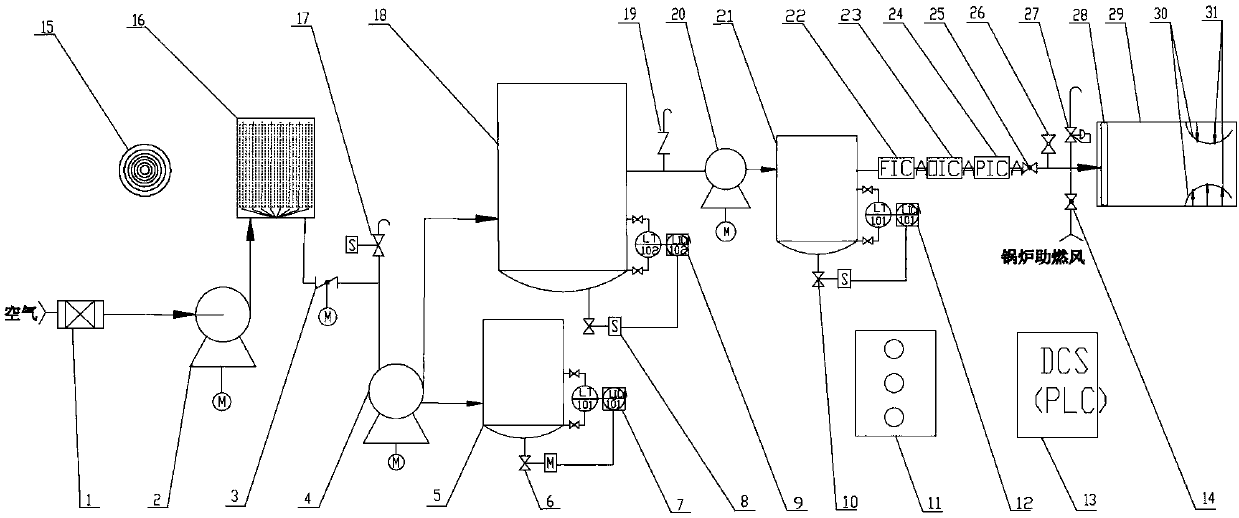

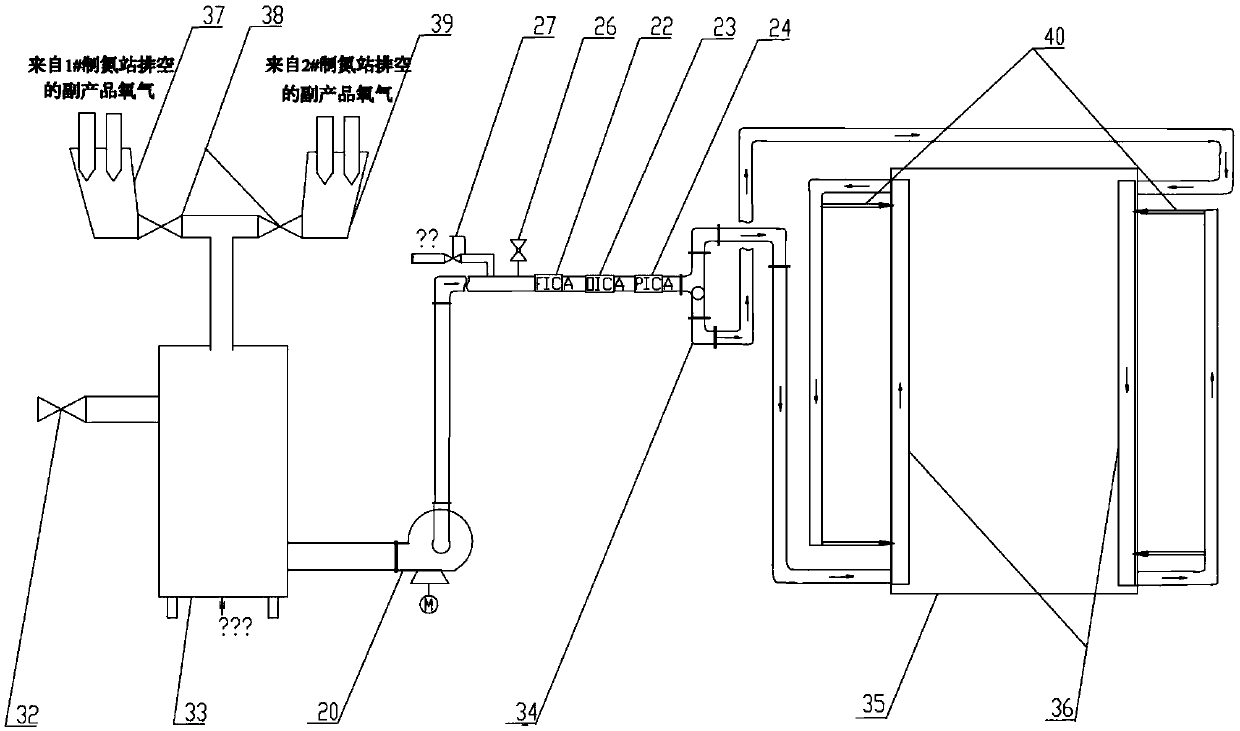

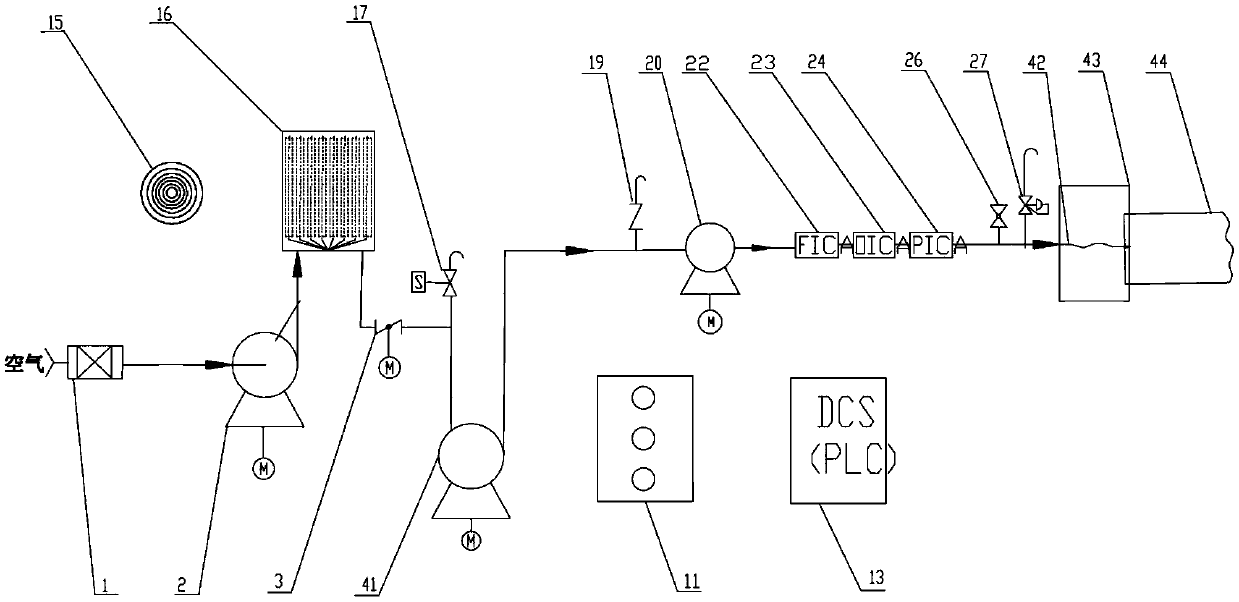

Novel comprehensive energy conservation, emission reduction, production increase and efficiency enhancement type local oxygenation combustion supporting system for fuel furnace kiln

ActiveCN108680041AIncrease the amount of steamThe effects of comprehensive energy saving, emission reduction, production increase and efficiency improvement are obviousIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplySupporting systemElectronic control system

The invention relates to a novel comprehensive energy conservation, emission reduction, production increase and efficiency enhancement type local oxygenation combustion supporting system for a fuel furnace kiln. The system comprises 'arc-shaped combustion', 'alpha-S-shaped combined combustion', 'postponed-S-shaped combined combustion', novel 'gradient combustion' and the like. The local oxygenation combustion supporting system is added beside the fuel furnace kiln. The local oxygenation combustion supporting system comprises seven parts, namely an oxygen source, a pressurization system, an oxygen enrichment efficient preheater and special oxygen enrichment nozzle, an alarm device, an oxygen enrichment flow transmitter and micropressure transmitter, a sudden stop device and an electronic control system. The local oxygenation combustion supporting system is required to be matched with the relevant furnace kiln and is further required to be matched with fuel and the corresponding combustion mode and even performance of relevant products. In addition, compared with traditional local oxygenation combustion supporting technologies, the system is perfected to a greater extent and is moreapplicable.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

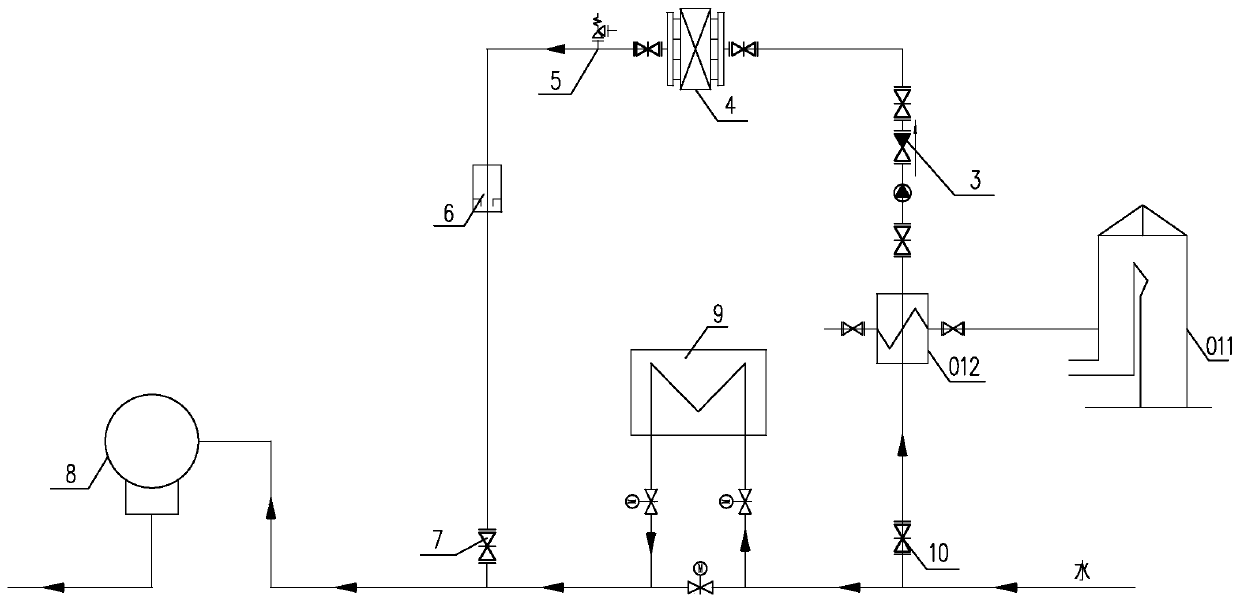

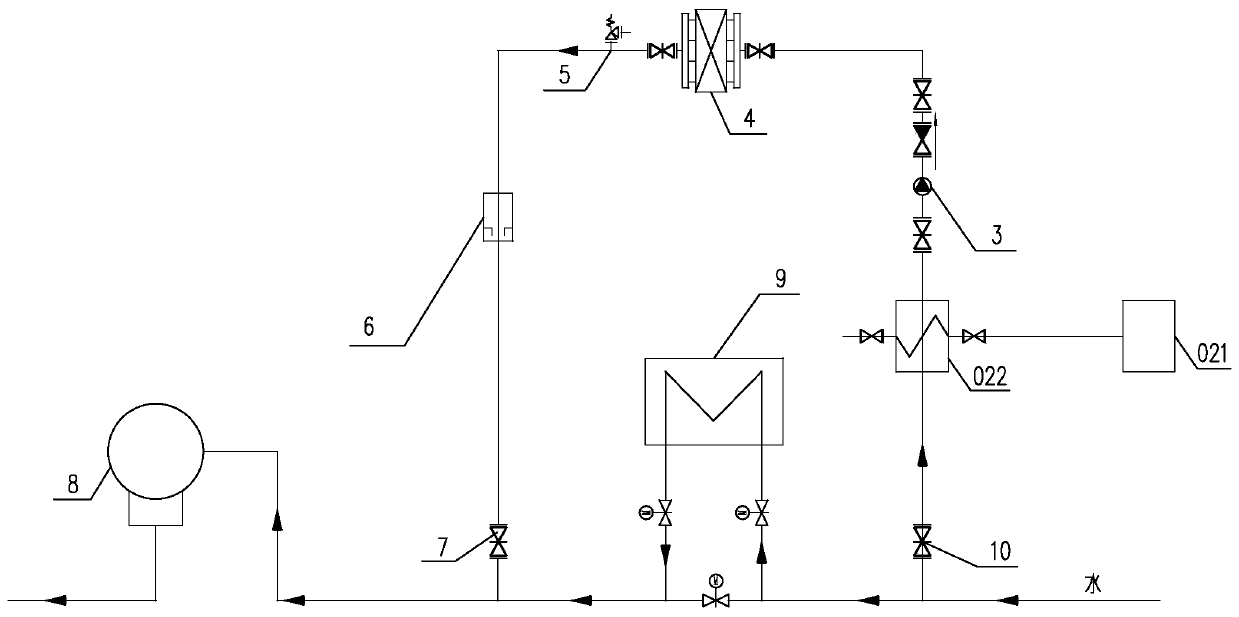

Method for heating inlet water of boiler deaerator

InactiveCN111536501ARaise the water temperatureInlet water temperature guaranteeLiquid degasificationBoiler cleaning apparatusFlue gasWorking pressure

The invention discloses a method for heating inlet water of a boiler deaerator. The method for heating the inlet water of the boiler deaerator comprises the steps of dividing water entering the deaerator into A-path water and B-path water, heating the A-path water by utilizing a regenerative system, heating the B-path water by utilizing waste heat of a boiler, and merging the A-path water heated by the regenerative system with the B-path water heated by the waste heat of the boiler to enter the deaerator. Therefore, the inlet water temperature of the deaerator is improved, and reaches or is close to the saturated temperature under the working pressure of the deaerator, the deaeration effect of the deaerator is improved, the waste heat of flue gas is utilized, the steam extraction quantityof a steam turbine is reduced, the whole plant economy is improved, and the reliability of a boiler flue gas waste heat exchanger can be guaranteed.

Owner:JINAN DANENG POWER TECH

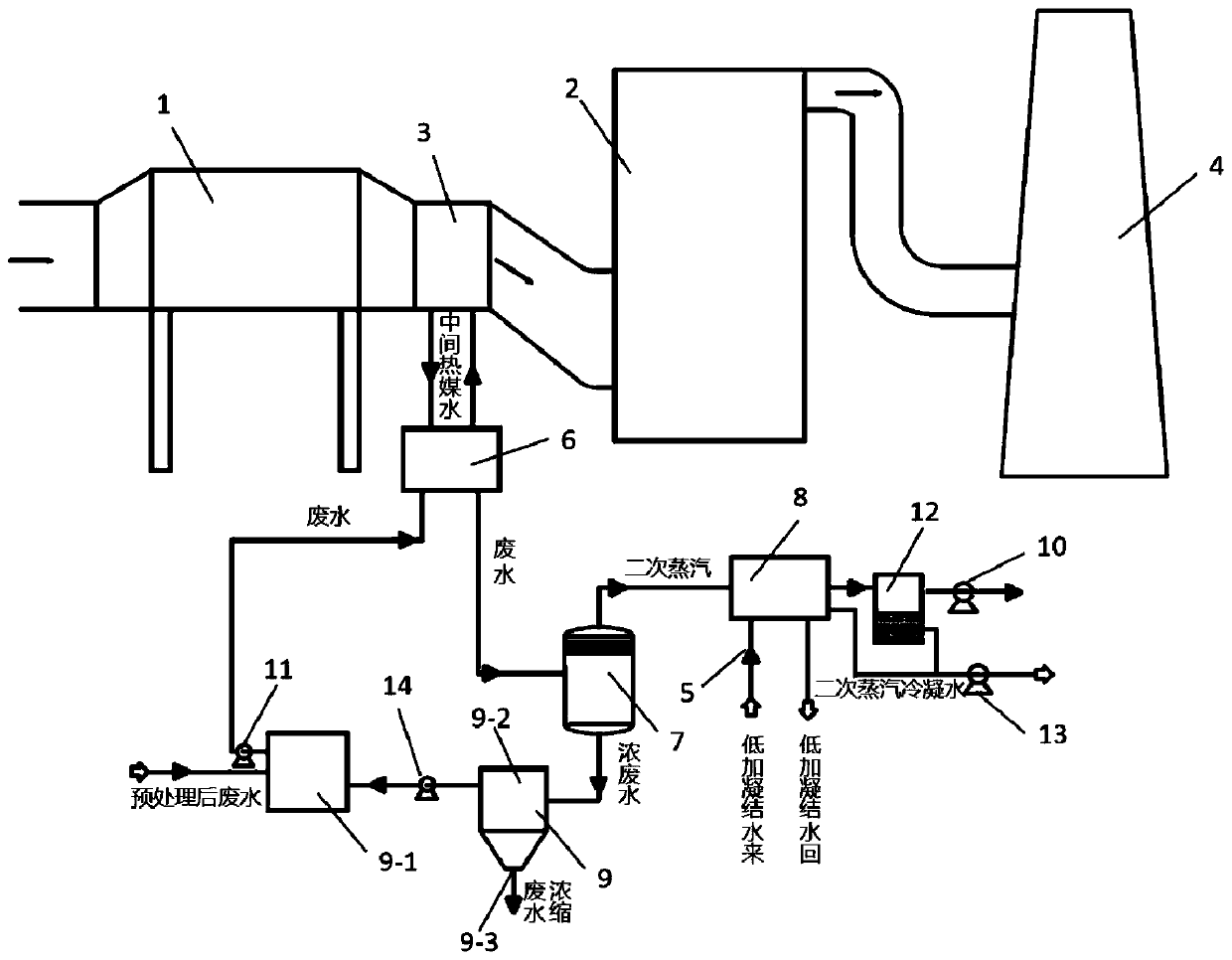

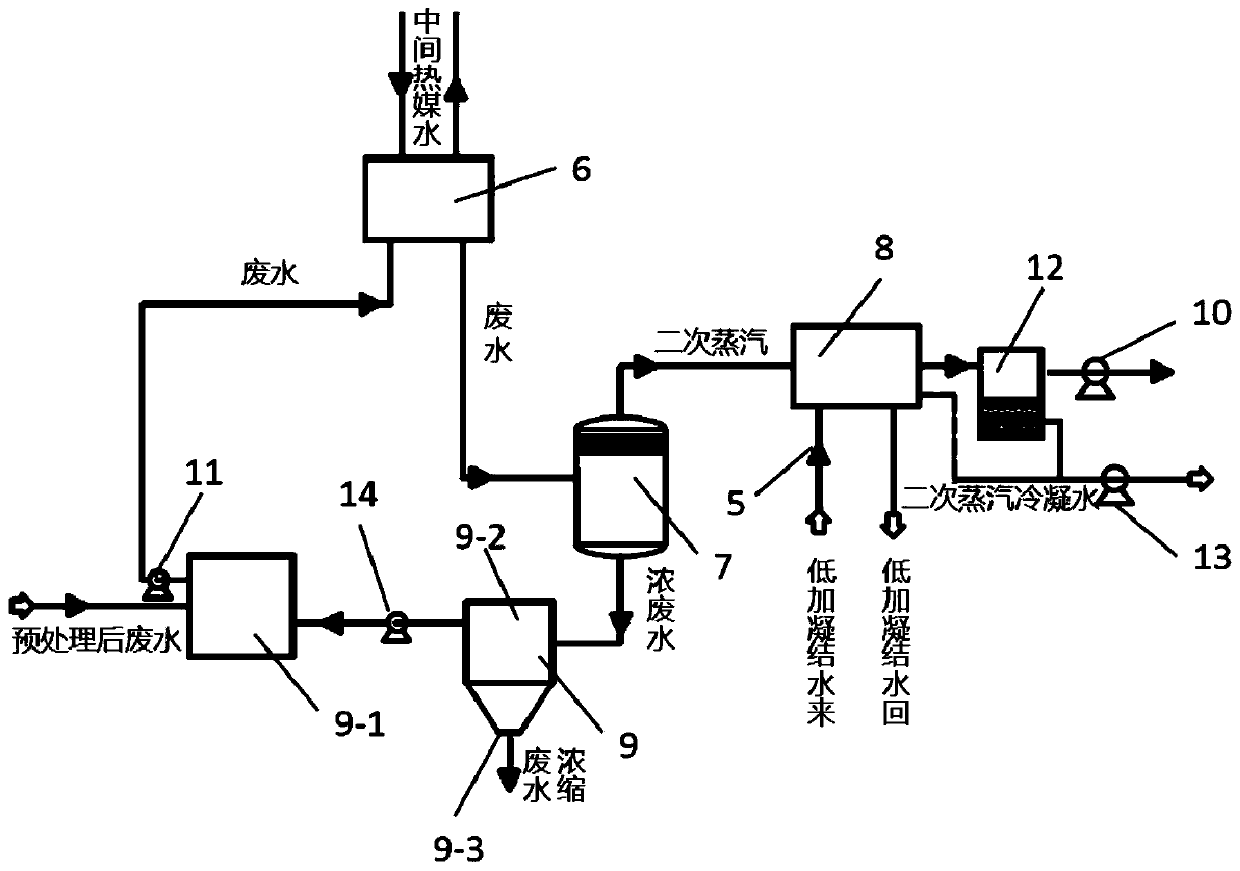

Vacuum phase change wastewater concentration and flue gas waste heat recovery system

PendingCN110642444AImprove concentrationIncrease temperatureRecuperative heat exchangersWaste water treatment from gaseous effluentsEconomizerPhysics

According to a vacuum phase change wastewater concentration and flue gas waste heat recovery system provided by the invention, flue gas exchanges heat with a first heat exchange medium after passing through a coal economizer, and a flash tank realizes multistage flash evaporation by utilizing gradient vacuum, so that the concentration of desulfurization wastewater is facilitated; meanwhile, steamwith different temperatures can be formed through multi-stage flash evaporation, the steam and a second heat exchange medium are subjected to stepped heat exchange after entering the heat exchange assembly, and the heat exchange effect is improved; due to the economizer, the flue gas waste heat is used for increasing the wastewater temperature; after wastewater flash evaporation, recovered flue gas waste heat is brought out along with steam, the second heat exchange medium recovers heat contained in the steam, and finally the heat is returned to a low-pressure heater system, so that gradient utilization of heat energy is realized under the condition that the flue gas waste heat is hardly lost, the defect that high-quality heat energy is consumed by utilizing a conventional route is overcome, and the energy consumption of a unit is reduced. By means of the mode, waste water concentration is achieved, meanwhile, the problem of flue gas waste heat recovery of a coal-fired power plant or other industries is solved, and good social and economic influences are achieved.

Owner:CHINA HUADIAN ENG +1

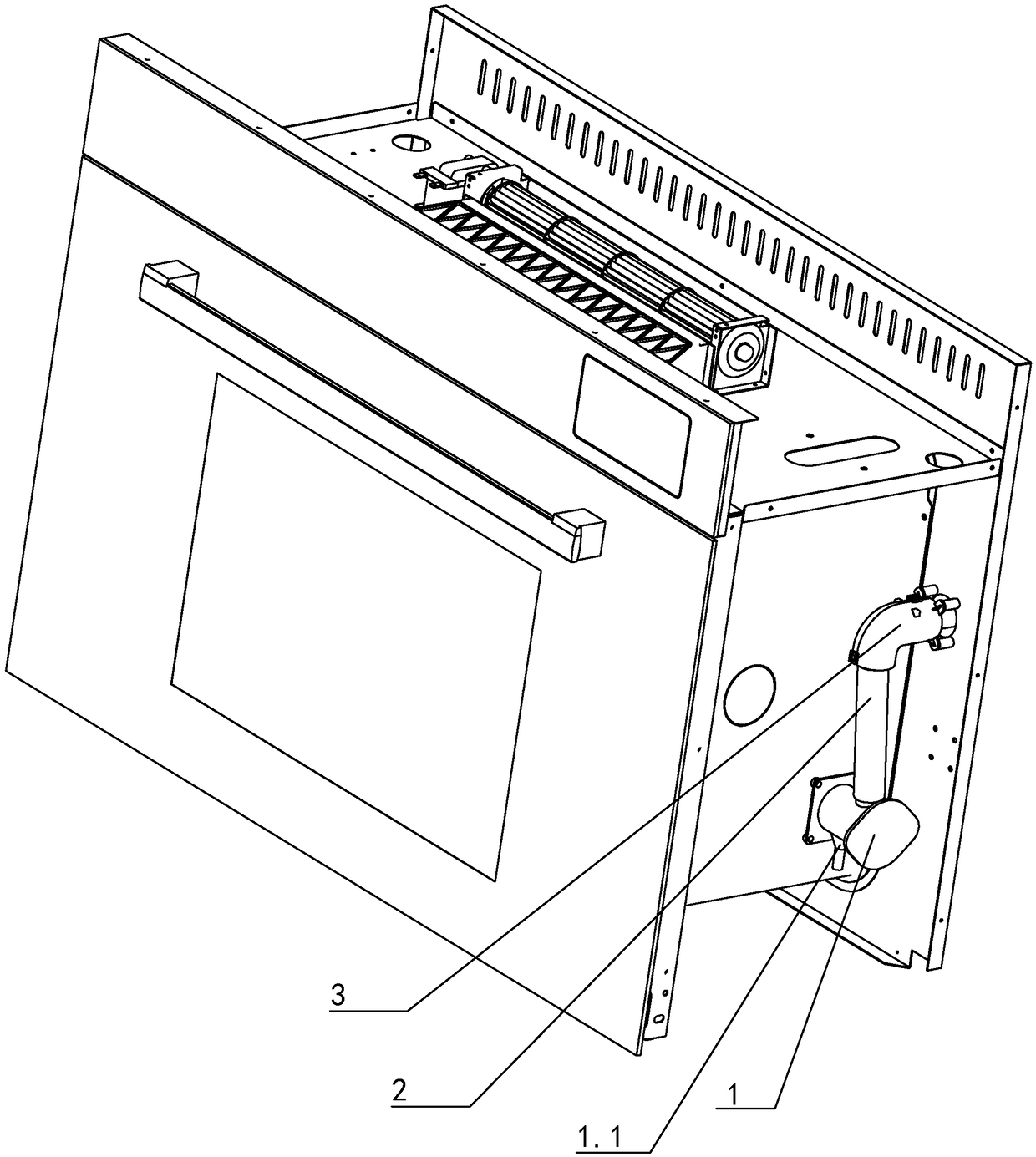

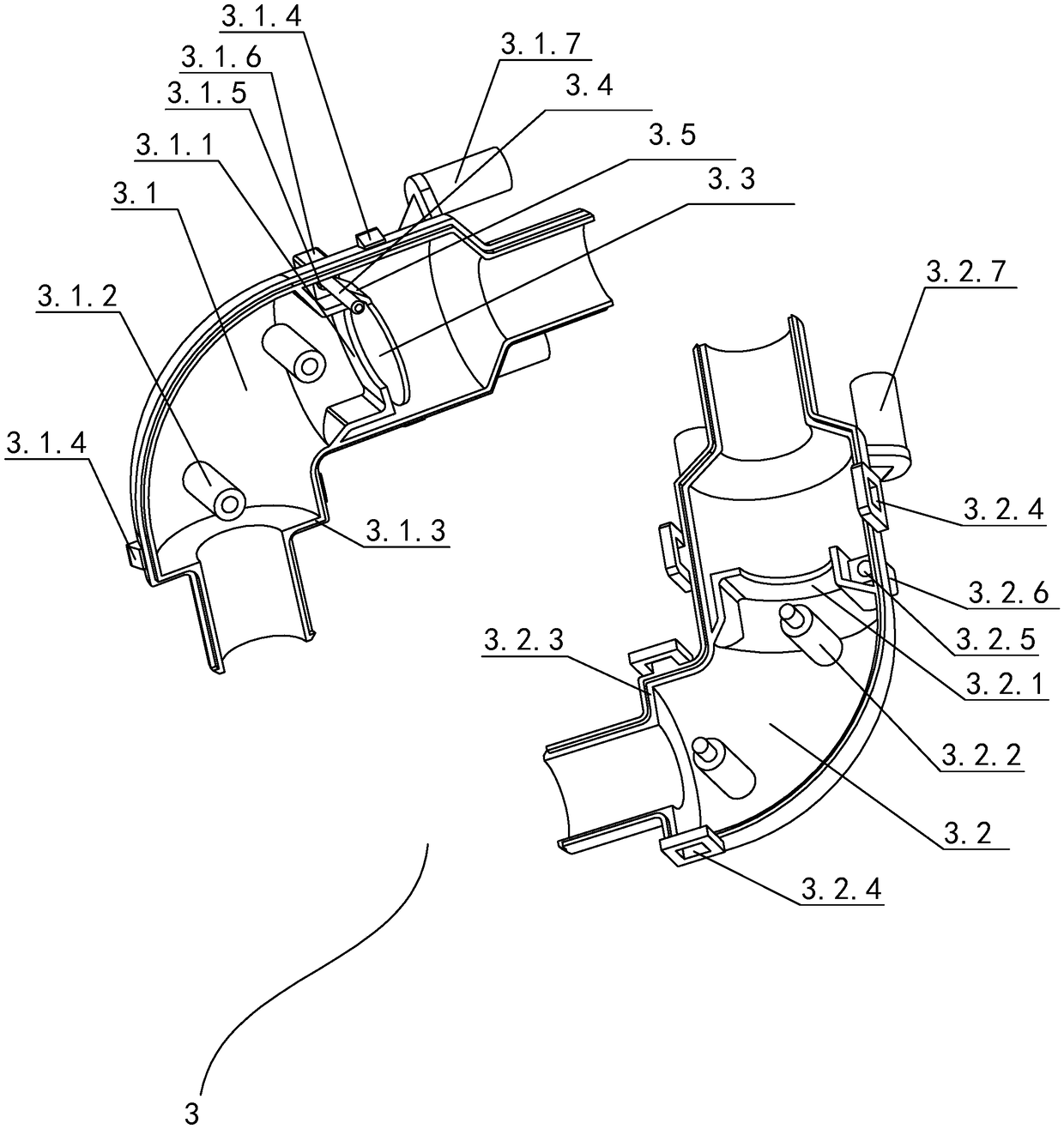

Exhaust pipe and exhaust structure of integrated cooker or electric oven baking oven

InactiveCN108709208AIncrease air pressurePrevent backflowDomestic stoves or rangesLighting and heating apparatusProduct gasEngineering

The invention discloses an exhaust pipe and an exhaust structure of an integrated cooker or an electric oven baking oven. A reverse filling preventing structure is arranged in the pipe body of the exhaust pipe; the exhaust pipe has the advantages that the reverse filling preventing structure is additionally arranged in the pipe body to discharge gas in the baking oven out, prevent mixed gas from filling in the baking oven reversely, and ensure that baked food is pure in taste; the additional arrangement of the reverse filling preventing structure enables the air pressure of the baking oven tobe slightly increased and to be within the safe range, and increases the steam quantity of the baking oven, and increase of the steam quantity increases the food steaming and baking speed, so that thesteaming and baking time is shortened and the power consumption is reduced accordingly, wherein the pipe body of the exhaust pipe is formed through buckling two pipe tiles in an airtight manner; semi-circular inner rings are symmetrically arranged in each of the pipe tiles; and a cover plate is hinged to the interior of the pipe body of the exhaust pipe and covers the rear wall of an inner ring formed by the two semi-circular inner rings to facilitate installation of the cover plate.

Owner:宁波欧燕电器有限公司

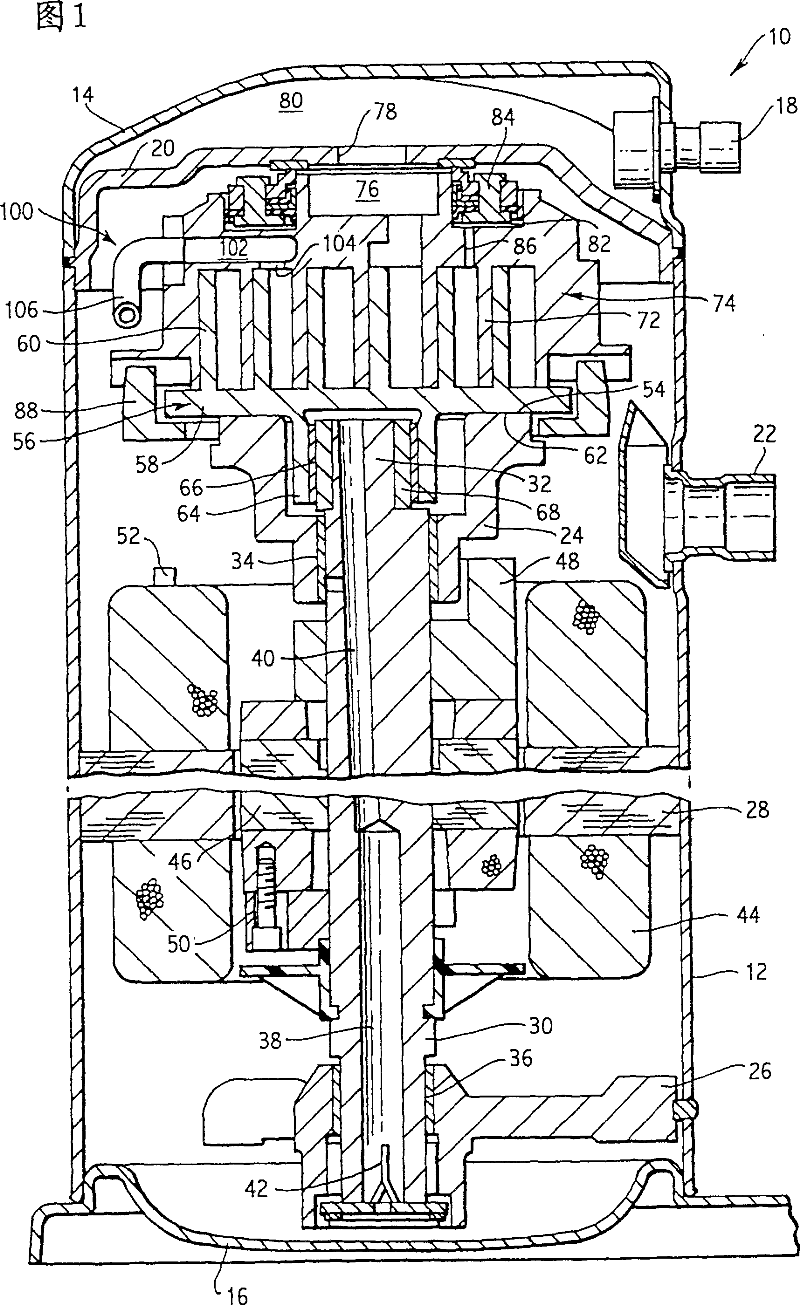

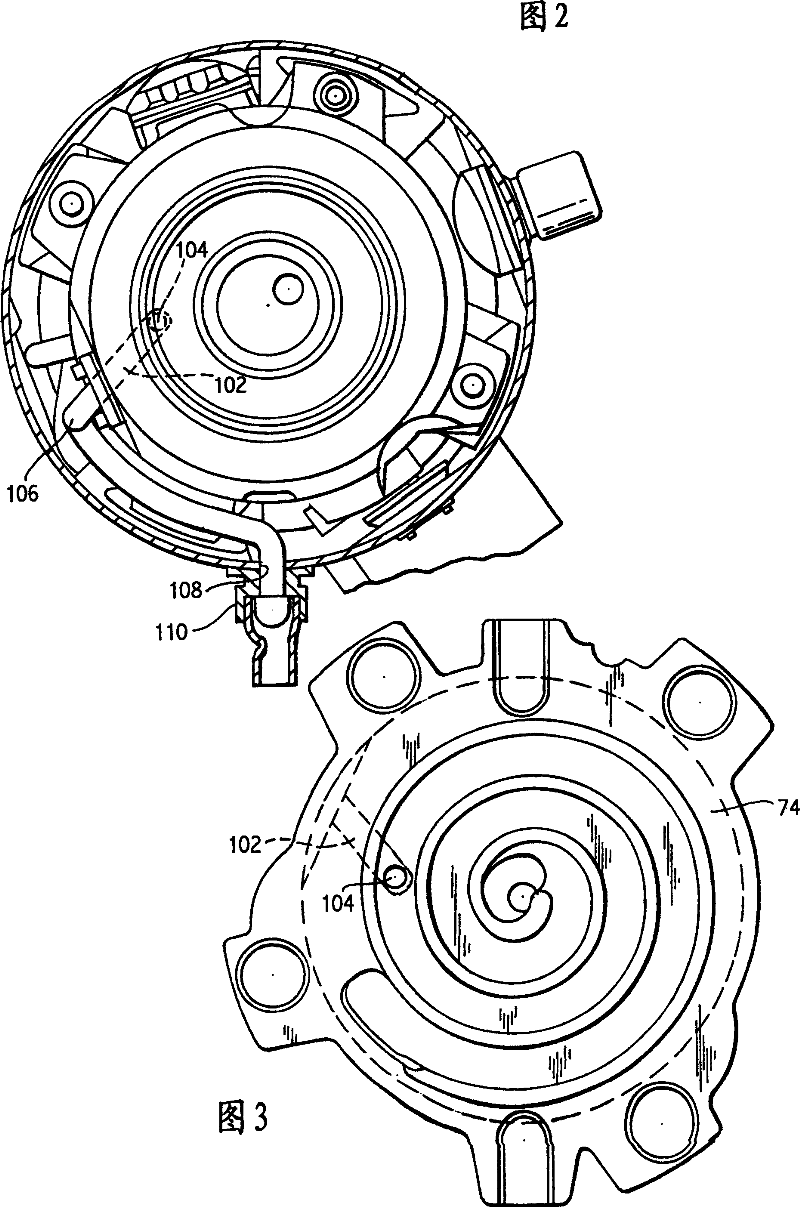

Vortex comprexxor with steam jet

InactiveCN100335789CWill not migrateIncrease the amount of steamRotary piston pumpsRotary piston liquid enginesInjection portEngineering

Owner:EMERSON CLIMATE TECH INC

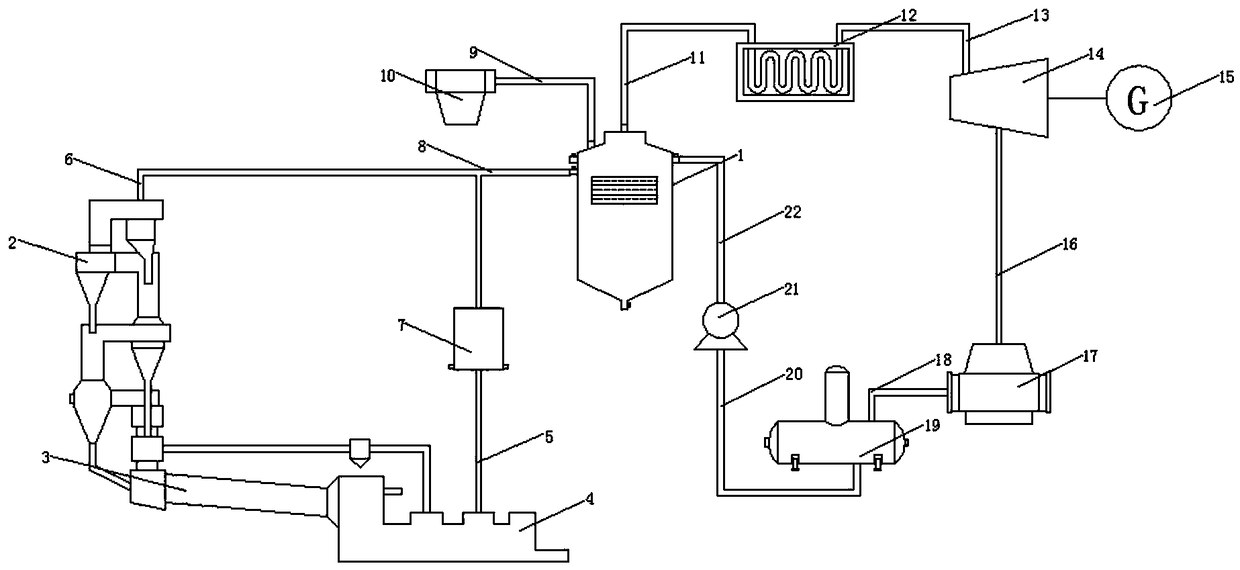

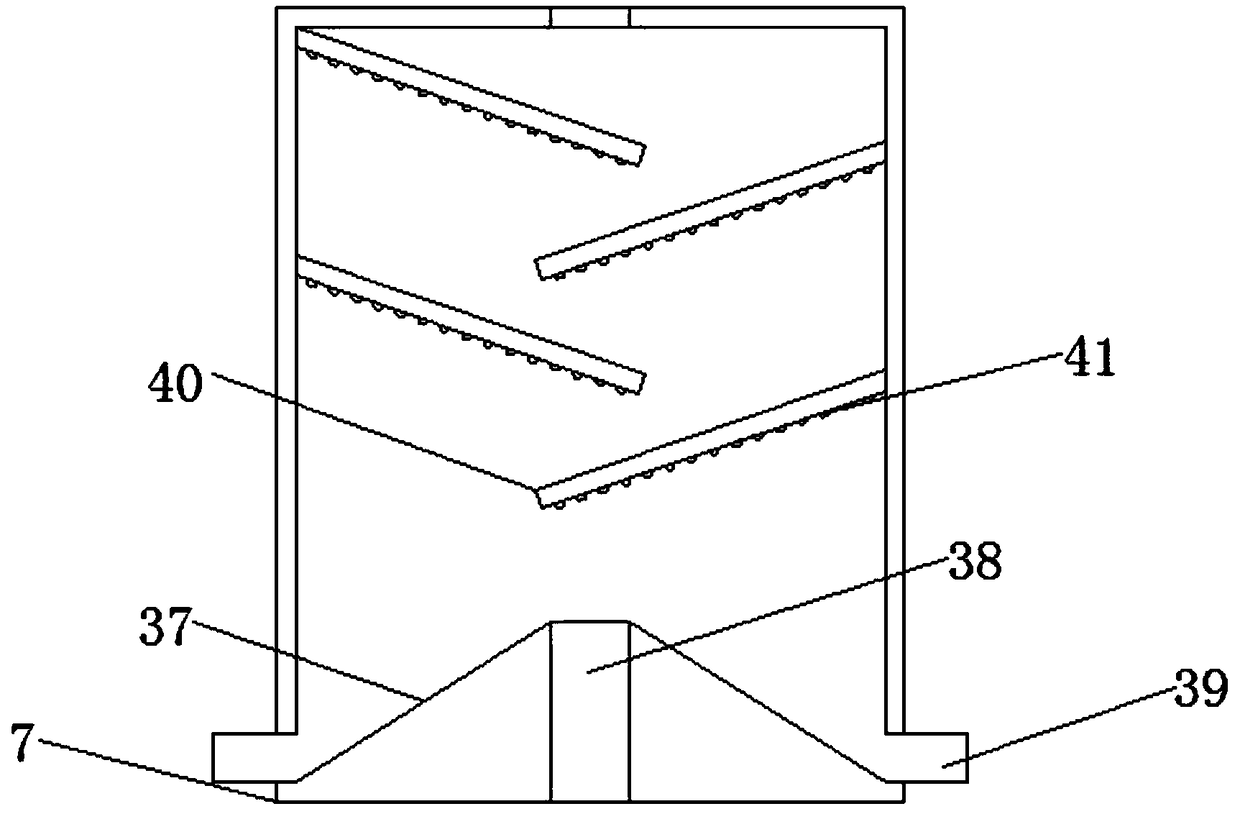

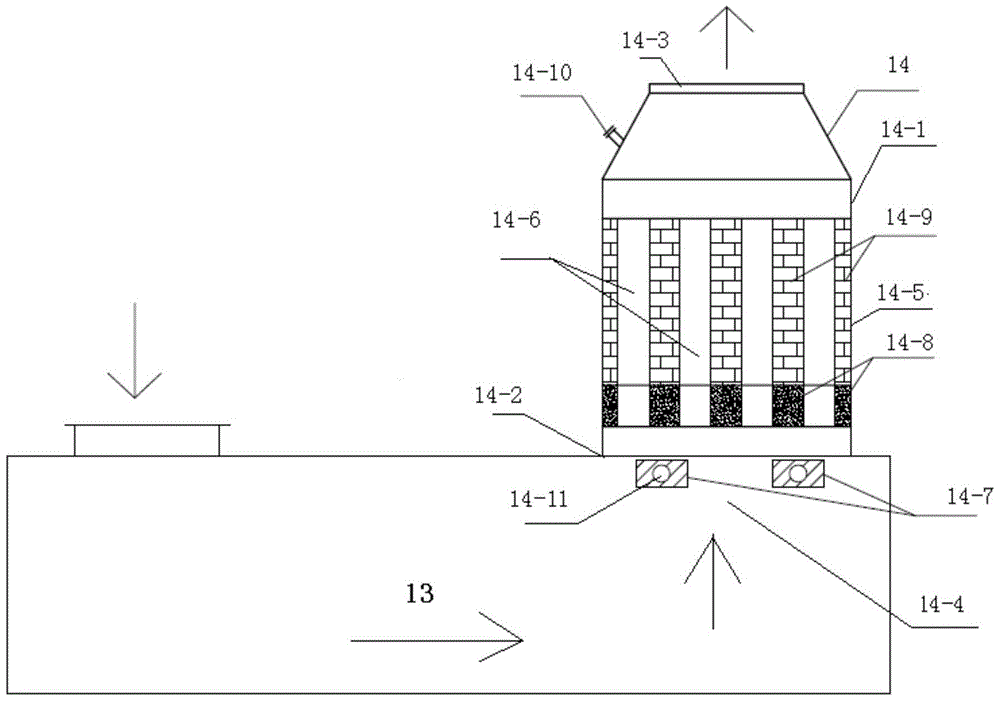

Cement kiln pure low temperature waste heat generator

ActiveCN109028980AGuaranteed to blockWhile blocking, it is also convenient for the rapid fall of clinker particlesIncreasing energy efficiencyClinker productionEngineeringCement kiln

The invention discloses a cement kiln pure lowtemperature waste heat generator.One end of a preheater is provided with a rotary kiln, one end of the rotary kiln is provided with a cooling machine, oneend of the cooling machine is fixedly connected with a waste gas pipe of a pit head, the middle of the waste gas pipe of the pit head is provided with a settling box, and inclined blocks are arrangedon both sides of the bottom end of the settling box. Bafflesare installed on both sides of the top of the inclined block, and a cellar tail exhaust pipe is fixedly connected with one end of a cellarhead exhaust pipe, and a mixed exhaust pipe is fixedly connected with one end of the cellar tail exhaust pipe, and a generator body is installed at one end of the mixed exhaust pipe. The top of the generator body is provided with a tank body, the inside of the tank body is provided with a steam generating chamber, and the bottom of the tank body is equipped with a dust exhausting bucket. Accordingto the a cement kiln pure lowtemperature waste heat generator, the bottom end of the bafflesareprovided with a plurality of elastic bumpswhich play a certain buffering role and can weaken the impactof waste gas from the pit head containing clinker particles on the baffles in the flow process, is simple and practical, service life of the baffles are prolonged, and later maintenance cost is reduced.

Owner:SICHUAN MIANZHU AODONG CEMENT CO LTD

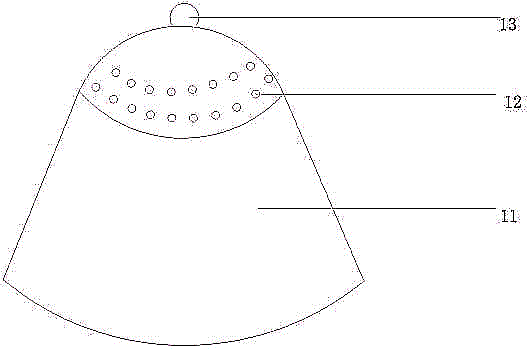

Rice cooking clock used for high-capacity electric cooker

The invention relates to the field of household appliances, in particular to a rice cooking clock used for a high-capacity electric cooker. The rice cooking clock is characterized in that the rice cooking clock is in the shape of a buckled-clock-shaped vessel with the bottom closed or open, a plurality of small holes smaller than rice grains are distributed in the buckled-clock-shaped upper spherical surface, the ratio of the volume of the rick cooking clock to that of the electric cooker is 1:50 to 1:100, and preferentially, the ratio is 1:100. The rice cooking clock is placed in the high-capacity electric cooker, the amount of steam in the electric cooker can be increased, the steam heating time is prolonged, the interior of the cooker is evenly heated, the cooked rice is evenly and thoroughly cooked and tastes good, and the phenomenon that the interior of the rice is burnt and the exterior of the rice is uncooked is avoided.

Owner:吴青平

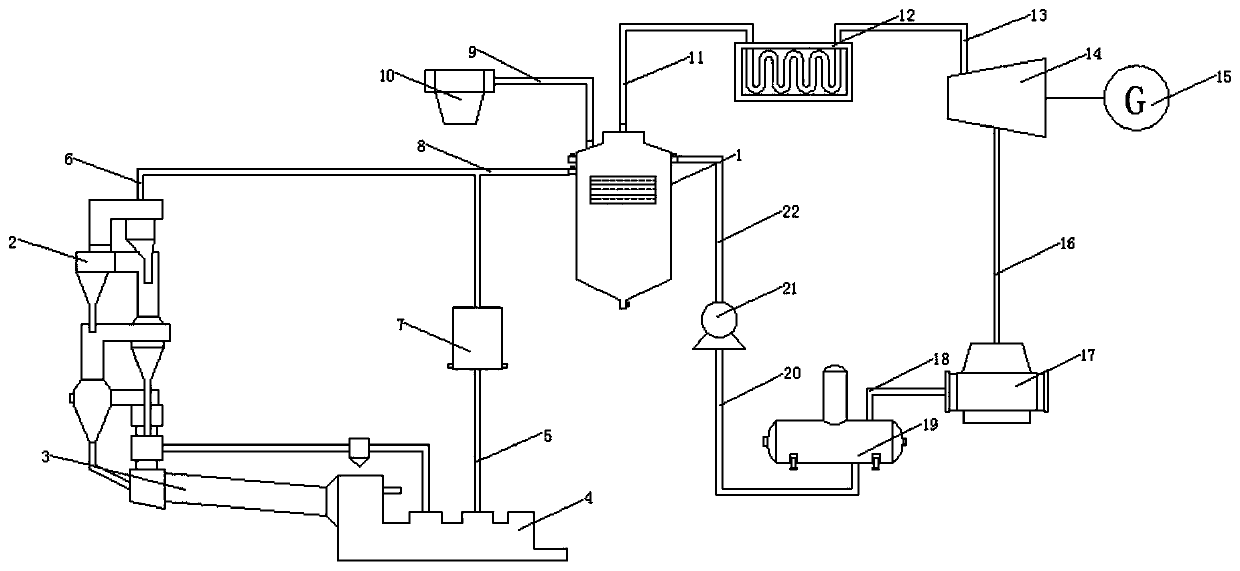

Waste heat recycling power generation equipment taking perfluorohexanone as heat-conducting medium

PendingCN114857560AIncrease profitIncrease power generationBoiler drums/headersEnergy industryProcess engineeringElectric control

Waste heat recycling power generation equipment with perfluorohexanone as a heat-conducting medium comprises a waste heat boiler, a steam turbine generator unit and electric control equipment, a boiler barrel extending in the vertical direction and two evaporators stacked in the vertical direction are arranged in the waste heat boiler, and flow evaporation heating surfaces wound around the boiler barrel are arranged on the evaporators. The waste heat boiler is internally provided with descending pipelines wound on the corresponding steam device midstream evaporation heating surfaces, the bottoms of the descending pipelines are provided with main steam pipe bases, the descending pipelines are communicated with the steam turbine generator unit through the main steam pipe bases, and liquid perfluorohexanone circulates in the descending pipelines and is communicated with the steam turbine generator unit through the main steam pipe bases. In conclusion, the perfluoro-hexanone heat exchange device has the advantages that energy consumption is reduced, the heat exchange efficiency is high, the safety performance is good, the perfluoro-hexanone heat exchange device is environmentally friendly, leakage is not prone to occurring, and use is convenient.

Owner:河南沁迪科技有限公司

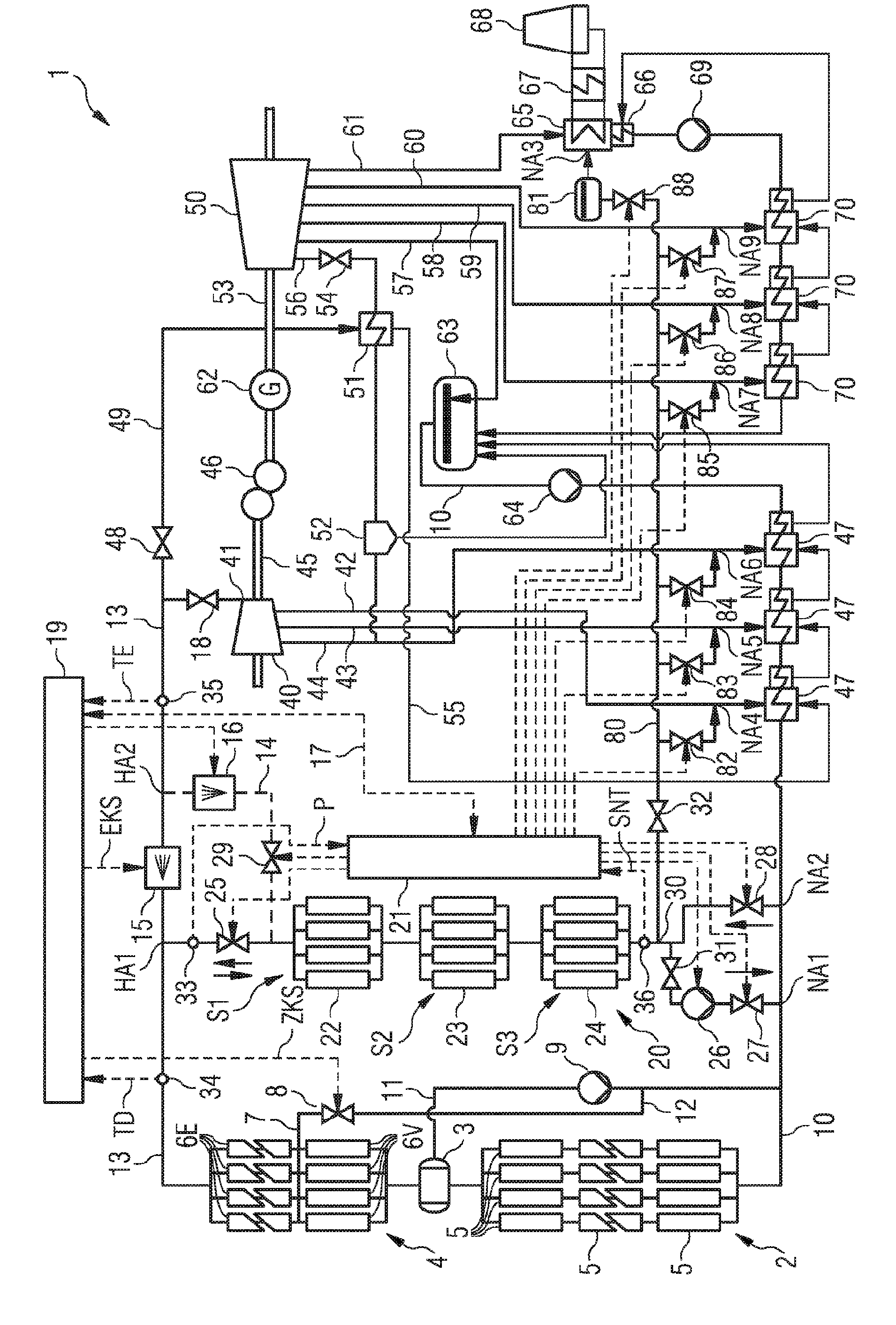

Solar thermal power plant and method for operating a solar thermal power plant

InactiveCN102762858AStable temperatureIncrease powerFrom solar energyMachines/enginesThermal energyHigh temperature storage

The invention relates to a solar thermal power plant (1) comprising a solar collector steam generator unit (2) for generating steam, a solar collector steam superheater unit (4), downstream of the solar collector steam generator unit (2), for superheating the steam, and a steam turbine (40) which is connected to an outlet of the solar collector steam superheater unit (4) via a steam conduit system (13), superheated steam being supplied to the steam turbine when in use.; The solar thermal power plant (1) comprises an intermediate storage (20) which is connected to the steam conduit system (13) at least in a first high-temperature storage connecting point (HA1) interposed between the solar thermal steam superheater unit (4) and the steam turbine (40) to remove steam superheated in a storage mode from the steam conduit system (13) and which comprises a heat reservoir (22, 23, 24) in which thermal energy is drained from the steam fed into during the storage mode and is accumulated and the stored thermal energy is given off to the steam in an extraction mode, said steam being fed to the steam conduit system (13) from the intermediate storage (20). The intermediate storage is connected to a condenser (65) and / or a relaxation device (89) of the solar thermal power plant (1) in a low-temperature storage connecting point (NA3).; The invention also relates to a method for operating said solar thermal power plant (1).

Owner:SIEMENS AG

A pure low temperature waste heat generator for cement cellar

ActiveCN109028980BGuaranteed to blockConvenient whereaboutsIncreasing energy efficiencyClinker productionEngineeringCement kiln

The invention discloses a cement kiln pure lowtemperature waste heat generator.One end of a preheater is provided with a rotary kiln, one end of the rotary kiln is provided with a cooling machine, oneend of the cooling machine is fixedly connected with a waste gas pipe of a pit head, the middle of the waste gas pipe of the pit head is provided with a settling box, and inclined blocks are arrangedon both sides of the bottom end of the settling box. Bafflesare installed on both sides of the top of the inclined block, and a cellar tail exhaust pipe is fixedly connected with one end of a cellarhead exhaust pipe, and a mixed exhaust pipe is fixedly connected with one end of the cellar tail exhaust pipe, and a generator body is installed at one end of the mixed exhaust pipe. The top of the generator body is provided with a tank body, the inside of the tank body is provided with a steam generating chamber, and the bottom of the tank body is equipped with a dust exhausting bucket. Accordingto the a cement kiln pure lowtemperature waste heat generator, the bottom end of the bafflesareprovided with a plurality of elastic bumpswhich play a certain buffering role and can weaken the impactof waste gas from the pit head containing clinker particles on the baffles in the flow process, is simple and practical, service life of the baffles are prolonged, and later maintenance cost is reduced.

Owner:SICHUAN MIANZHU AODONG CEMENT CO LTD

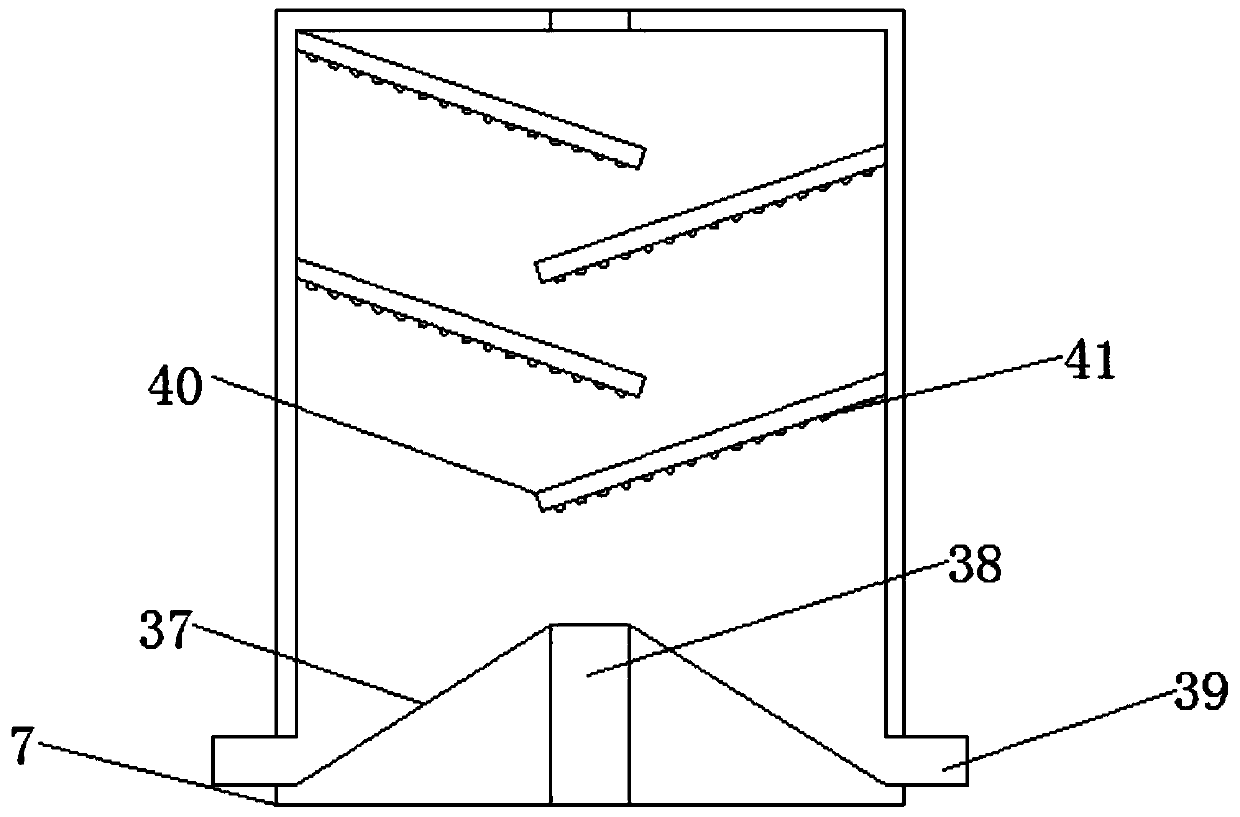

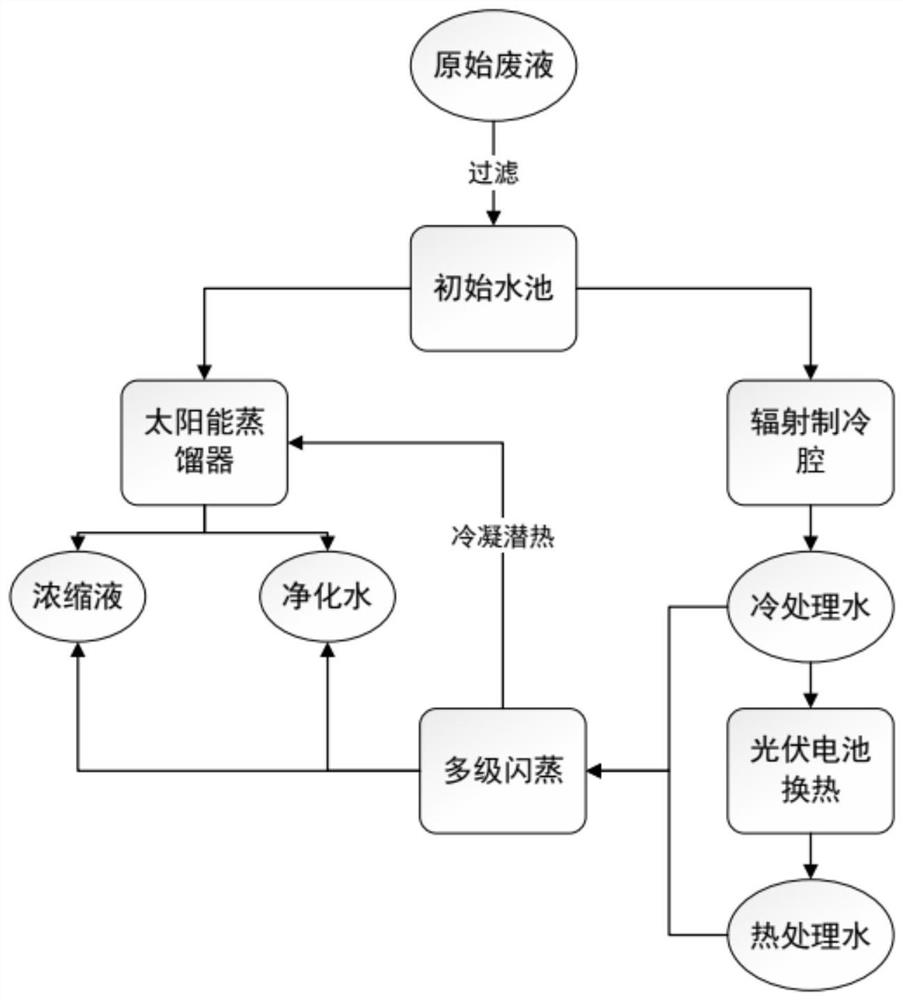

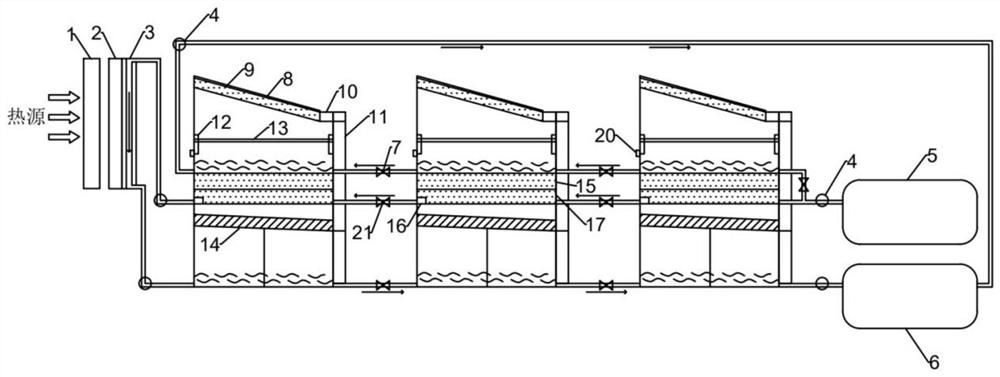

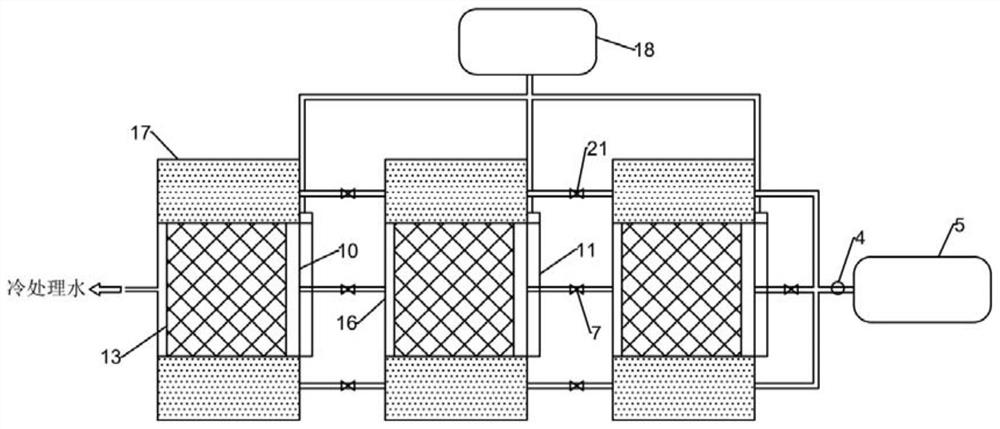

Composite water treatment system based on near-field thermophotovoltaic waste heat utilization

ActiveCN114873678ARealize secondary useSimple flow directionGeneral water supply conservationWater/sewage treatment by heatingWater treatment systemWater resources

The invention relates to a composite water treatment system based on near-field thermophotovoltaic waste heat utilization, and aims to solve the problem of low efficiency of the technology of recovering waste heat for water treatment in the prior art, and the purposes of photovoltaic cell heat dissipation and water resource acquisition are achieved at the same time by combining near-field thermophotovoltaic, radiation refrigeration, solar distillation, multi-stage flash evaporation and other technologies. The water to be treated in the application has dual effects in the circulation process: the photovoltaic cell is cooled, so that the cell can be maintained at a normal working temperature; and waste heat generated by the near-field thermophotovoltaic system is absorbed, purified water is obtained through the flash evaporation device, and secondary utilization of energy is achieved. According to the invention, solar energy is utilized to further improve the yield of purified water; the liquid flowing direction is simple, pipeline arrangement is convenient, actual installation of equipment is facilitated, and efficiency is high.

Owner:HARBIN INST OF TECH

A closed high-efficiency evaporation-condensation instant water heater

Owner:XI AN JIAOTONG UNIV

A Combustion Control Method of Incinerator Based on Temperature Field Measurement Technology

ActiveCN106556014BEmission reductionIncrease the amount of steamIncinerator apparatusCombustionEngineering

The invention relates to the field of design of incineration furnaces, in particular to an incineration furnace combustion control method. The incineration furnace combustion control method comprises the following steps: incineration furnace outlet temperature distribution conditions are provided; an incineration furnace outlet temperature two-dimensional plane distribution diagram is built according to the incineration furnace outlet temperature distribution conditions; an outlet temperature and the position of a high-temperature area of an incineration furnace are judged according to the incineration furnace outlet temperature two-dimensional plane distribution diagram; combustion working conditions are controlled according to the outlet temperature and the position of the high-temperature area; the outlet temperature of the incineration furnace is adjusted; a flame center in the furnace is positioned in a center area of the incineration furnace; an incineration furnace outlet temperature field is divided into multiple areas according to the incineration furnace outlet temperature two-dimensional plane distribution diagram; and the uniform distribution of the temperature field is controlled through the area division. The control method can guarantee the outlet smoke temperature uniformity of the incineration furnace to reduce original smoke pollutant concentration and to increase the boiler steam quantity, and can be applied to various household garbage incineration furnaces.

Owner:SHANGHAI ENVIRONMENTAL ENG DESIGN & RES INST CO LTD +1

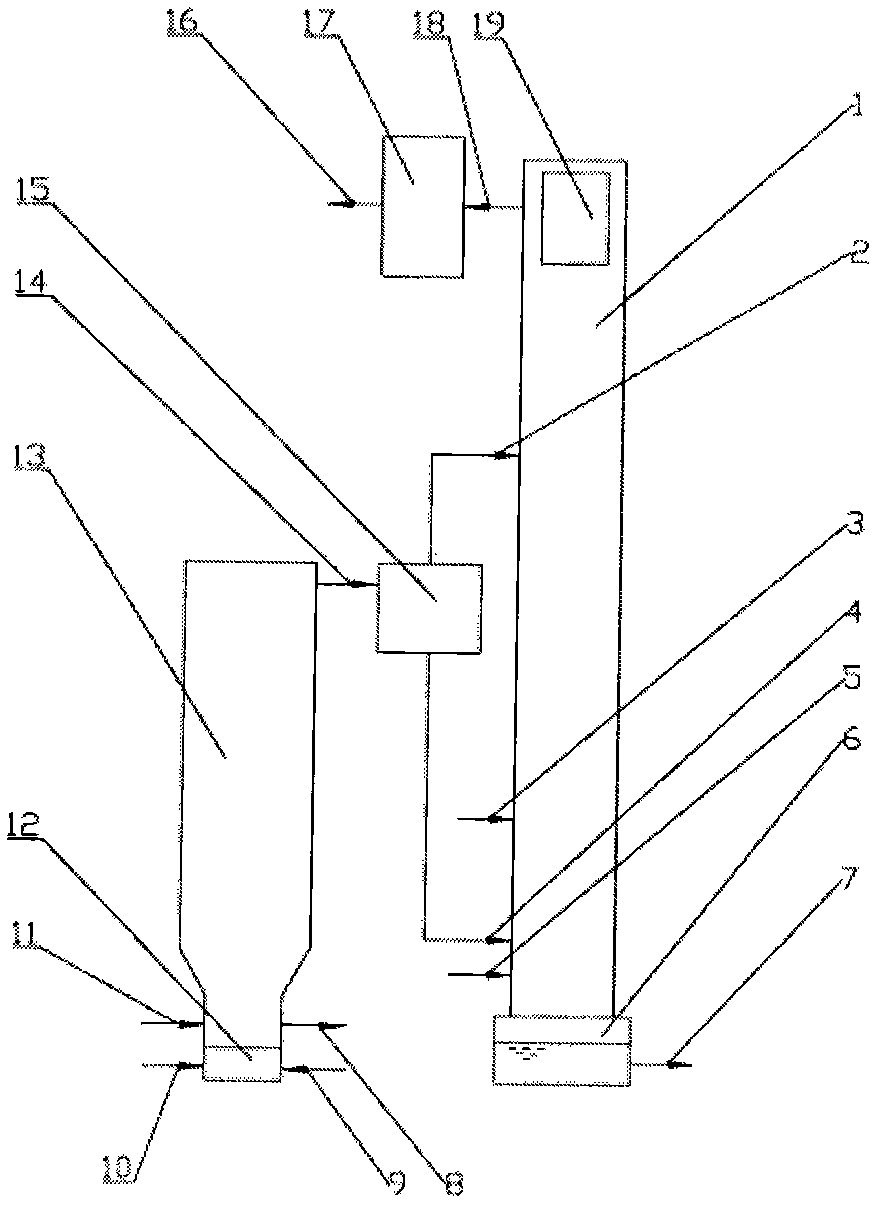

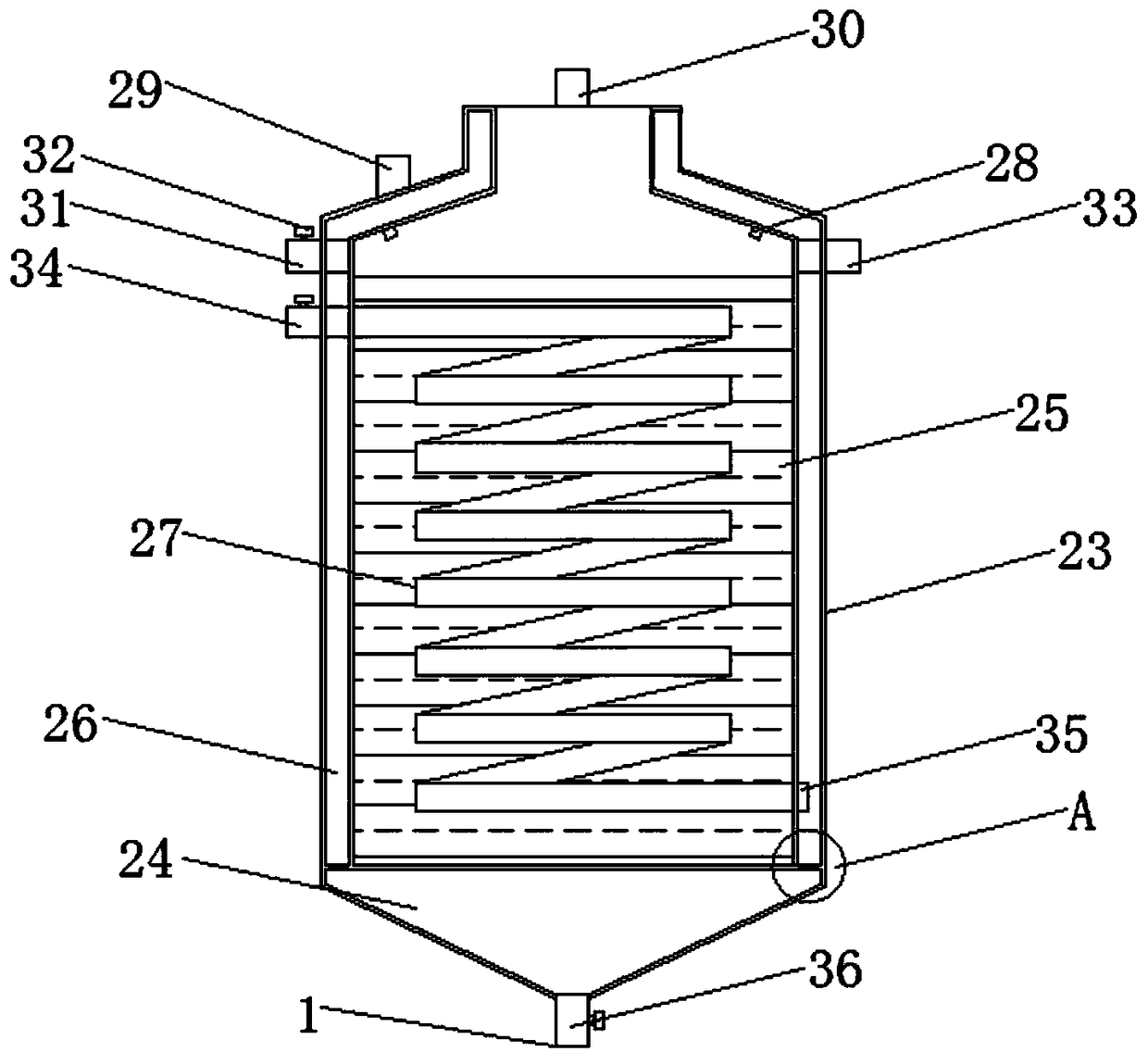

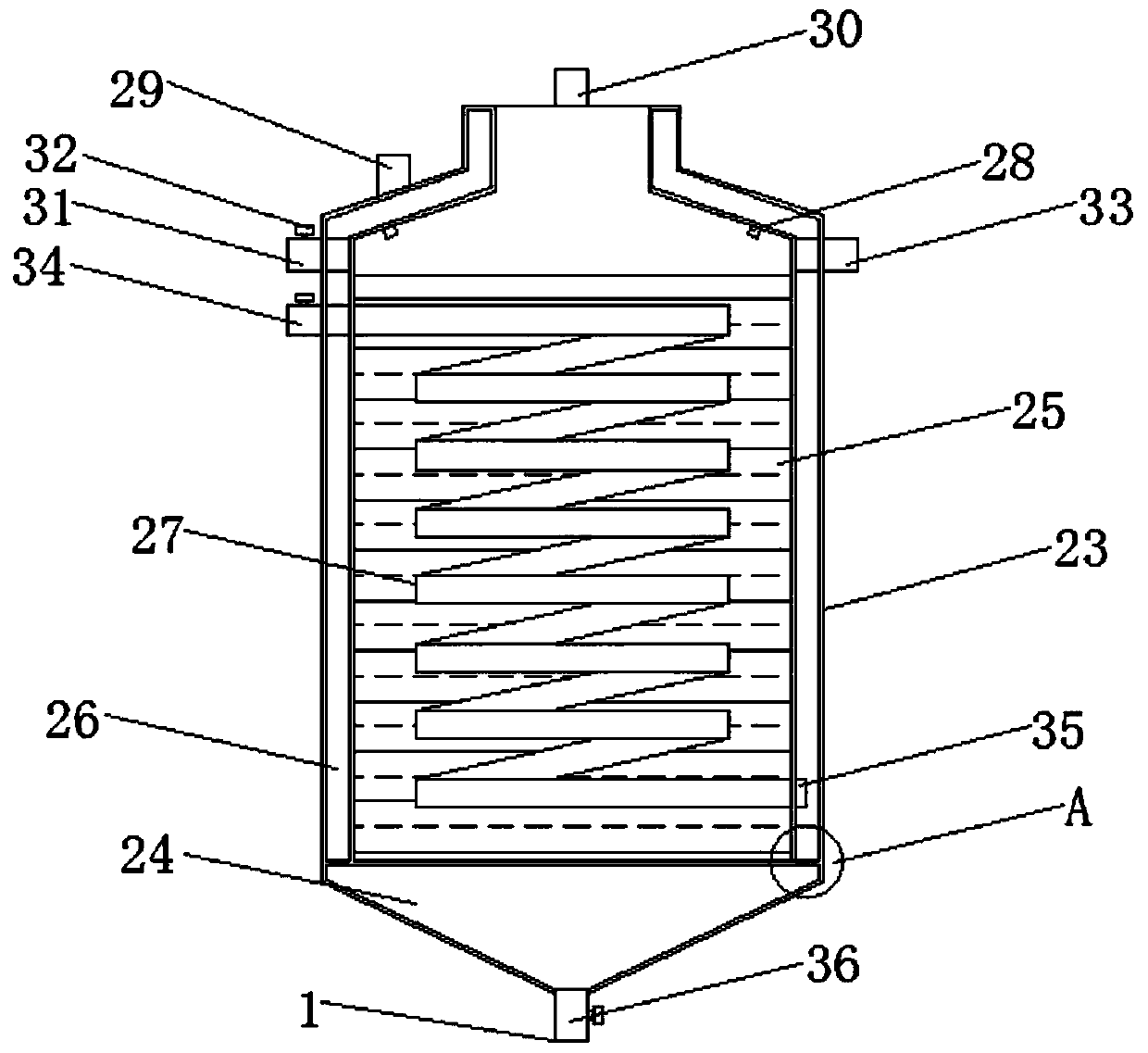

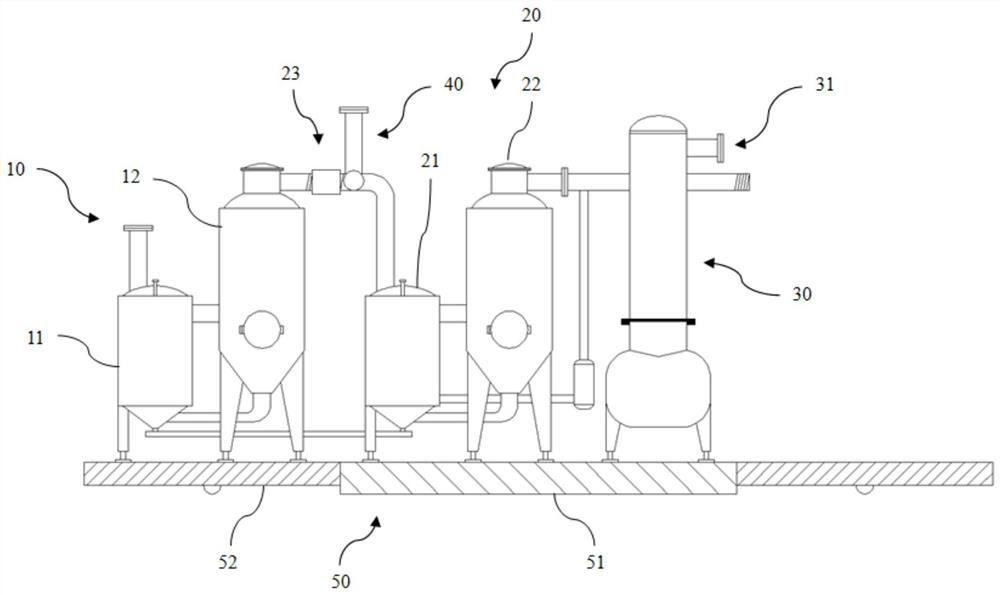

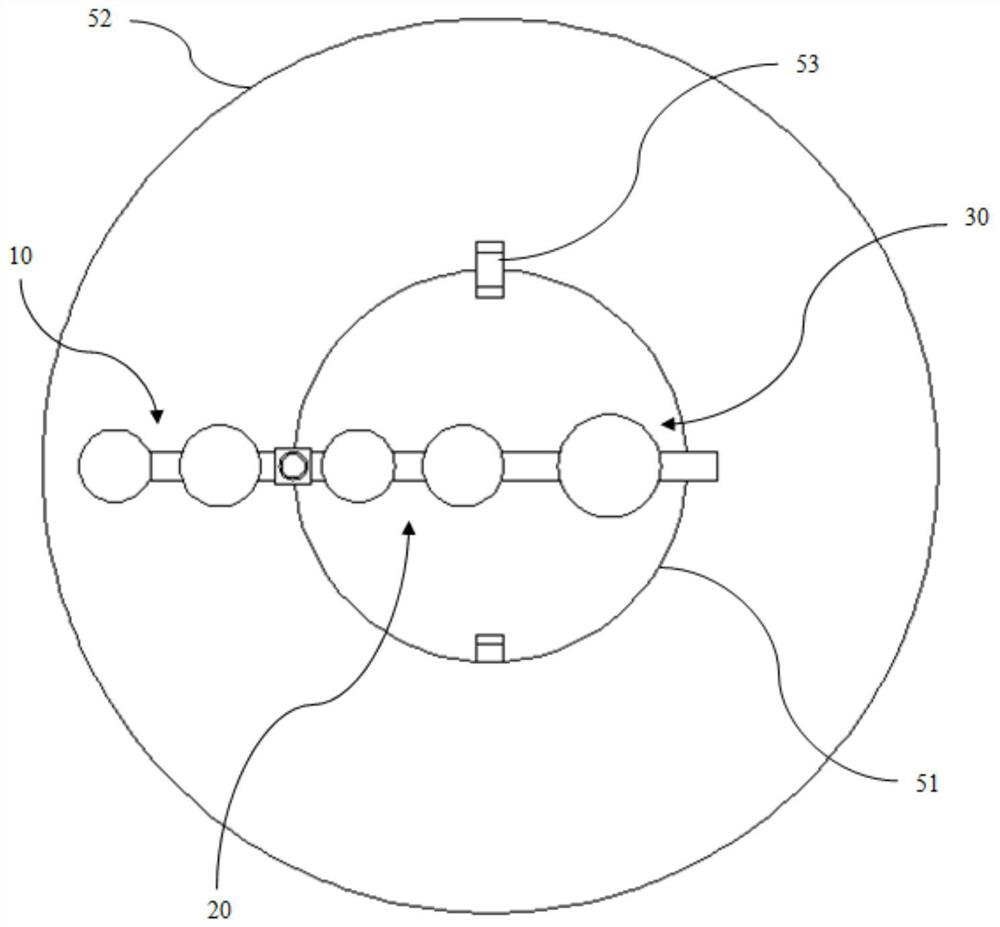

Double-effect energy-saving evaporation and concentration system

ActiveCN113546434AIncrease the amount of steamIncrease temperatureEvaporator accessoriesEvaporator regulation/controlThermodynamicsEngineering

The invention discloses a double-effect energy-saving evaporation and concentration system, which can be used for preparing Geshan food retention removing particles. The system comprises a first-effect heater, a first-effect evaporator, a second-effect heater, a second-effect evaporator, a condenser and a vacuum pump which are connected in sequence, and further comprises a heating enhancing mechanism. The heating enhancing mechanism comprises a steam supplementing pipe, the first-effect evaporator is connected with the second-effect heater through a steam conveying pipe, the steam supplementing pipe communicates with the steam conveying pipe, and a one-way valve is arranged on the steam supplementing pipe. By using the double-effect energy-saving evaporation and concentration system, steam can be supplemented and added into the double-effect heater so as to increase the steam amount and temperature, so that the concentration efficiency of liquid medicine in the double-effect evaporator is accelerated, the steam in the single-effect evaporator is utilized to achieve the energy-saving effect, and the processing efficiency of the double-effect evaporator is improved.

Owner:红云制药(贵州)有限公司

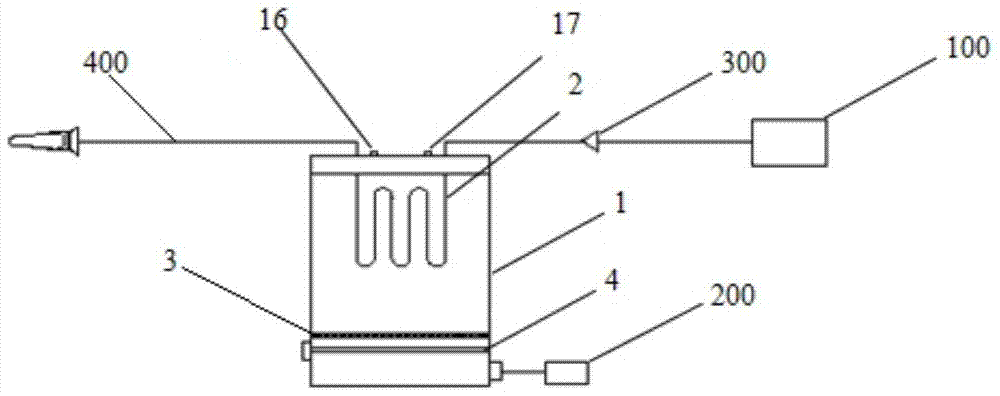

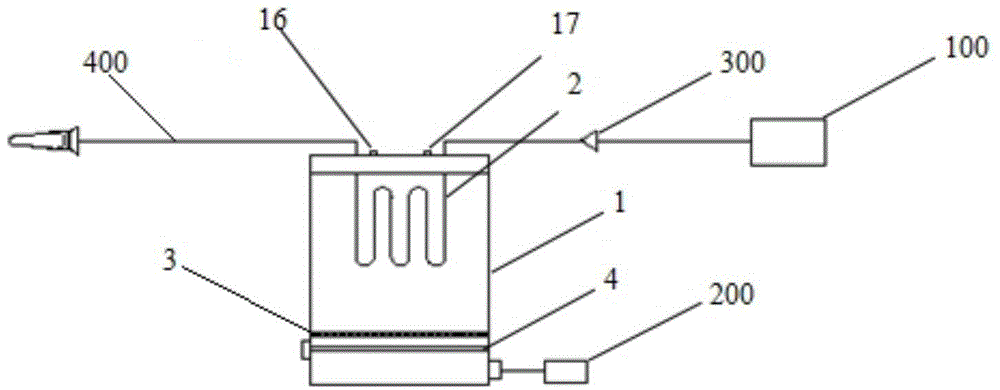

Enclosed and highly-efficient evaporation-condensation instant water heater

The invention discloses an enclosed and highly-efficient evaporation-condensation instant water heater. The enclosed and highly-efficient evaporation-condensation instant water heater comprises a controller, a box body, a buzzer, a water source, a supply device and a water outlet pipeline. Coil pipes, a perforated plate and a support rack used for supporting the perforated plate are arranged in the box body. The inner side surface of the box body is provided with a temperature sensor and a pressure sensor. An output end of the temperature sensor and an output end of the pressure sensor are connected with an input end of the controller. An output end of the controller is connected with a control end of a heater and a control end of the buzzer. The enclosed and highly-efficient evaporation-condensation instant water heater is high in heating speed and the heater is low in power and small in size.

Owner:XI AN JIAOTONG UNIV

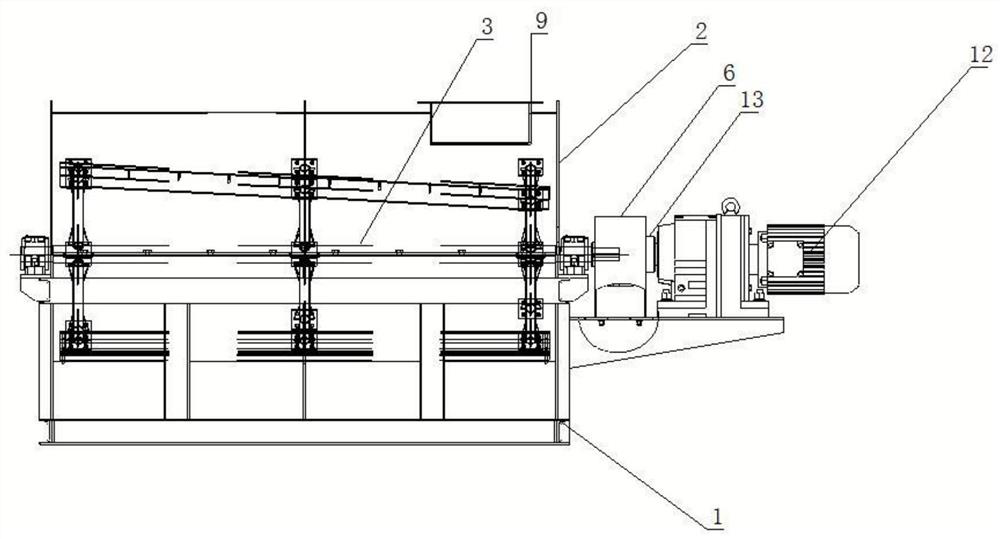

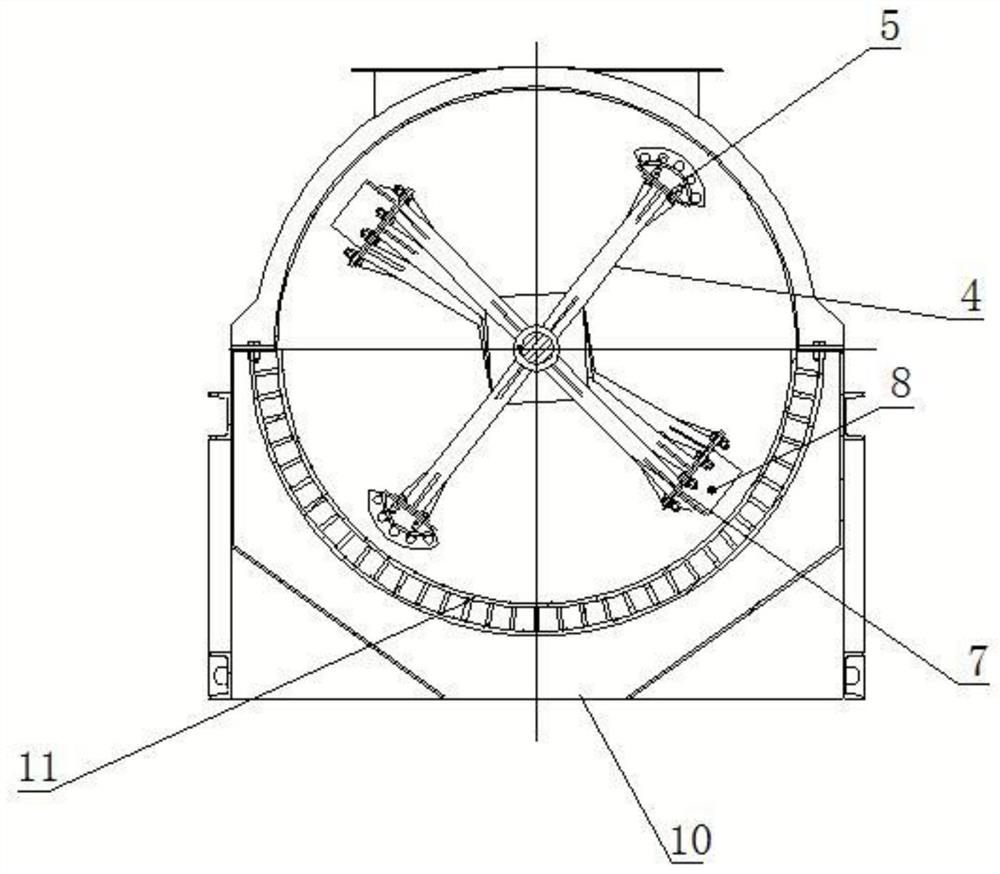

Drum-type fruit removing machine for fresh palm fruit bunches

The invention relates to the technical field of palm squeezing oil-making equipment, and particularly relates to a drum-type fruit removing machine for fresh palm fruit bunches. The machine comprisesa screen drum frame, an upper cover arranged on the screen drum frame, a separating device arranged in the screen drum frame and a driving device for driving the separating device to rotate, wherein the separating device comprises a main shaft, two scrapers and two stirring knives, the two ends of the main shaft are rotatably mounted on the screen drum frame through bearings, the two scrapers aresymmetrically arranged on the two sides of the main shaft through first supporting rods, and the two stirring knives are symmetrically arranged on the two sides of the main shaft through second supporting rods. According to the invention, palm fruit grains are separated from palm fruit bunches, the palm fruit bunches are separated into the palm fruit grains and empty fruit bunches, due to the factthat the size of the palm fruit grains is much smaller than that of the palm fruit bunches, a small conveyor can be selected when the palm fruit grains are conveyed, the equipment cost and the energyconsumption cost are reduced, and due to the fact that only the palm fruit grains can be sterilized during sterilization, and the palm fruit bunch does not need to be wholly sterilized as before, thesize of a sterilization tank is reduced to one half of the size of the previous sterilization tank.

Owner:焦作亚华机电设备有限公司

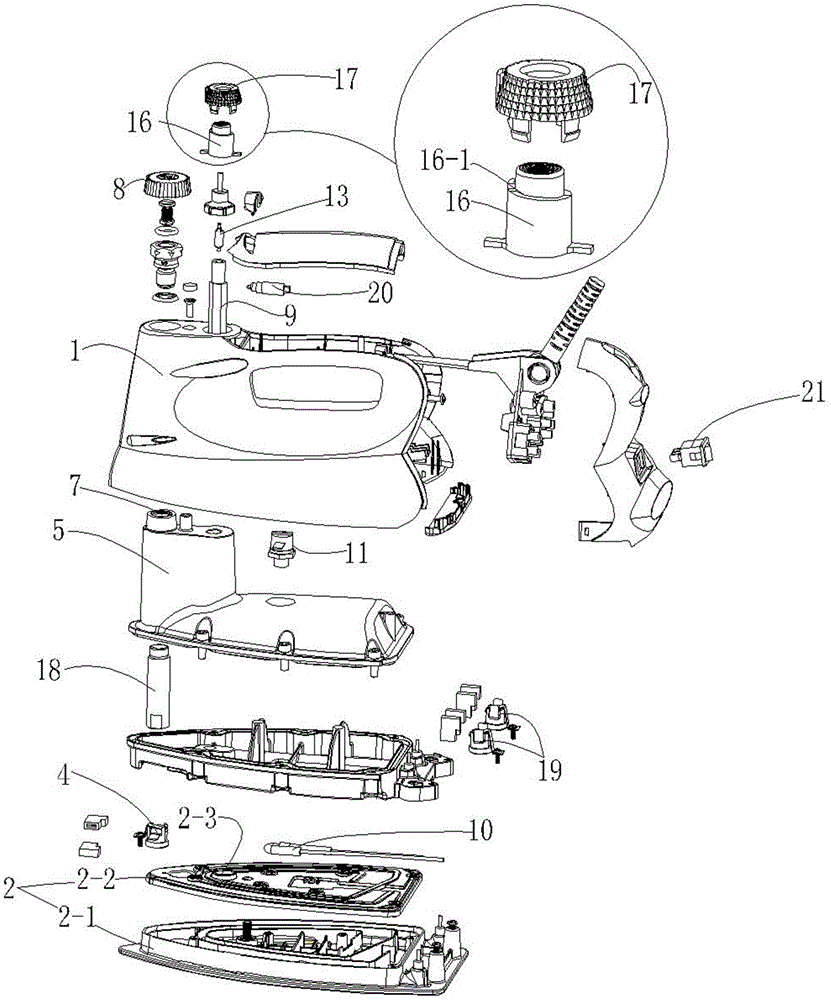

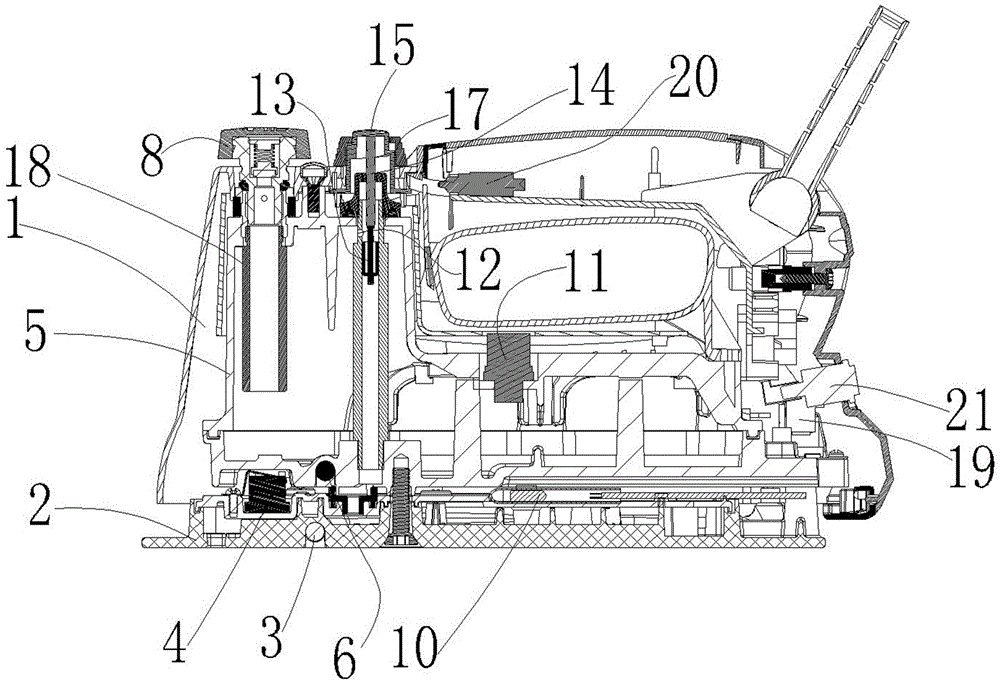

Ironing machine

ActiveCN101792968BSolve technical problems with water leakageUniform outputHand ironIroning apparatusElectricityWater leakage

The invention provides an iron, and relates to an ironing machine for ironing clothes. The ironing machine comprises a lower plate (77V), an adjustable temperature controller and an electrical heating element. Theinvention is characterized in that the ironing machine also comprises a water tank (8) for storing water, a water pump (18) which is communicated with the water tank and is used for pumping water, a steam generator which is communicated with the water pump (18) and is used for gasifying water and a steam pipe which is communicated with the steam generator at one end and is used for transferring the steam generated by the steam generator, a plurality of steam outlets are distributed on a bottom ironing plate as steam vents, and the steam generated by the steam generator is sprayed on the clothes through the outlets on the bottom ironing plate after being heated by the heating element. The technical proposal of the invention has the advantages that the steam production is increased, the technical problem of water leakage caused by insufficient heating of ironing machine in the market can be solved, and the double heating can homogenize the steam output per unit time.

Owner:JINBO CHUBAO ELECTRIC IND ZHONGSHAN CITY

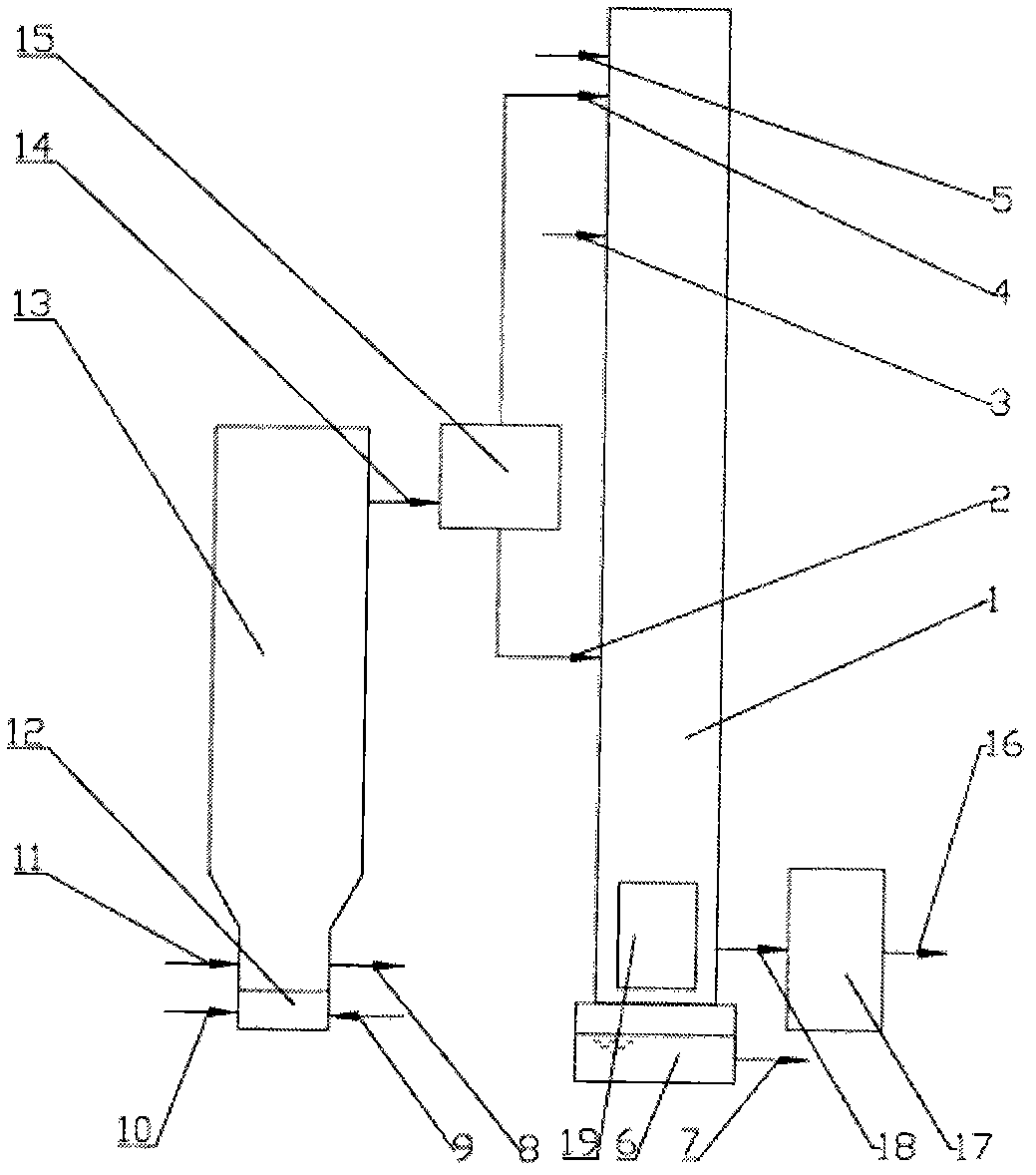

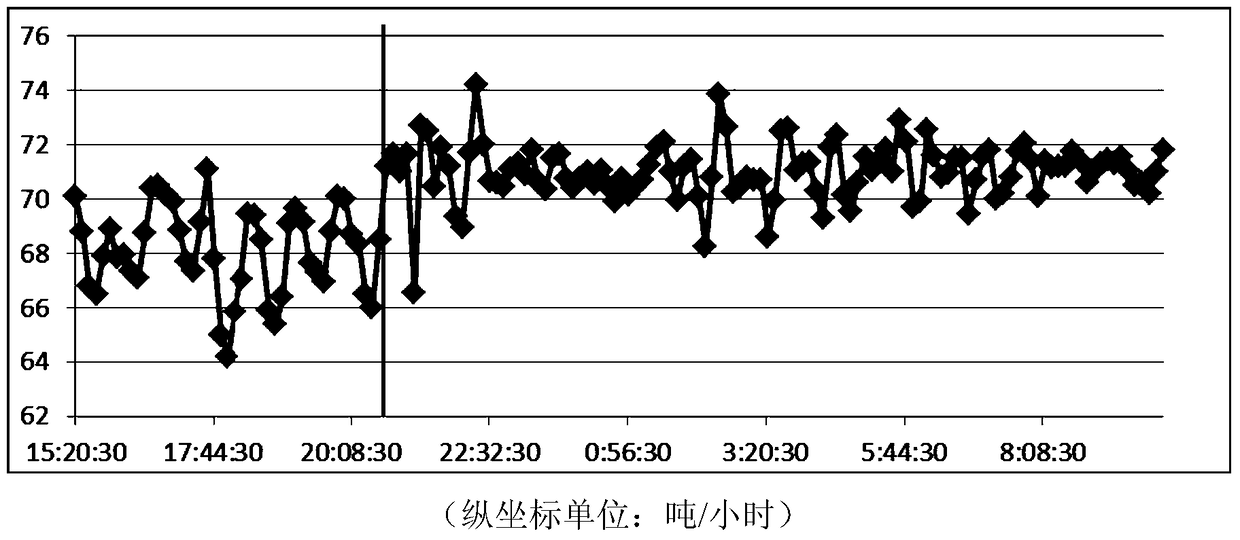

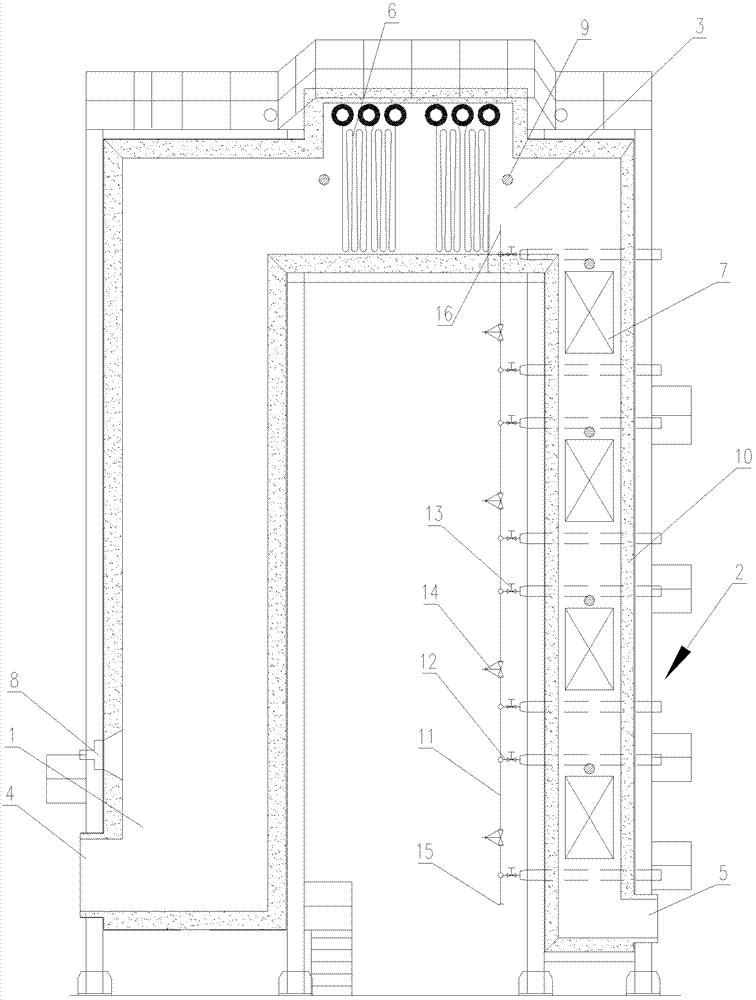

An electric furnace flue gas waste heat full vaporization, regenerative recovery system and its working method

ActiveCN104848704BImprove qualityLittle fluctuationSteam generation using hot heat carriersWaste heat treatmentSuperheaterStreamflow

Disclosed is an electric furnace flue gas waste heat complete vaporization and heat accumulation type recovery system. An intermittent high-temperature flue gas heat accumulation device and a heat convection superheater are connected between a combustion settling chamber and a heat convection evaporator in sequence. The intermittent high-temperature flue gas heat accumulation device and the heat convection superheater are additionally arranged in an existing flue gas waste heat recovery system, wherein the intermittent high-temperature flue gas heat accumulation device is applied to a high-temperature flue gas outlet of the combustion settling chamber. When the flue gas flow and temperature fluctuation of an electric furnace happens due to feeding, stable output of the flue gas temperature is achieved through a heat absorption and release reaction of a heat accumulator. When normal smelting is conducted, the temperature of flue gas generated by the electric furnace is high, and part of heat of the flue gas is absorbed by the heat accumulator after the flue gas passes through the intermittent high-temperature flue gas heat accumulation device. When feeding of the electric furnace is conducted, the temperature of flue gas generated by the electric furnace is low, the low-temperature flue gas absorbs the heat in the heat accumulator again after the flue gas passes through the intermittent high-temperature flue gas heat accumulation device, then a stable heat accumulation function is fulfilled, and the situation that high-quality steam is generated by follow-up heating is guaranteed.

Owner:山东耀华能源投资管理有限公司

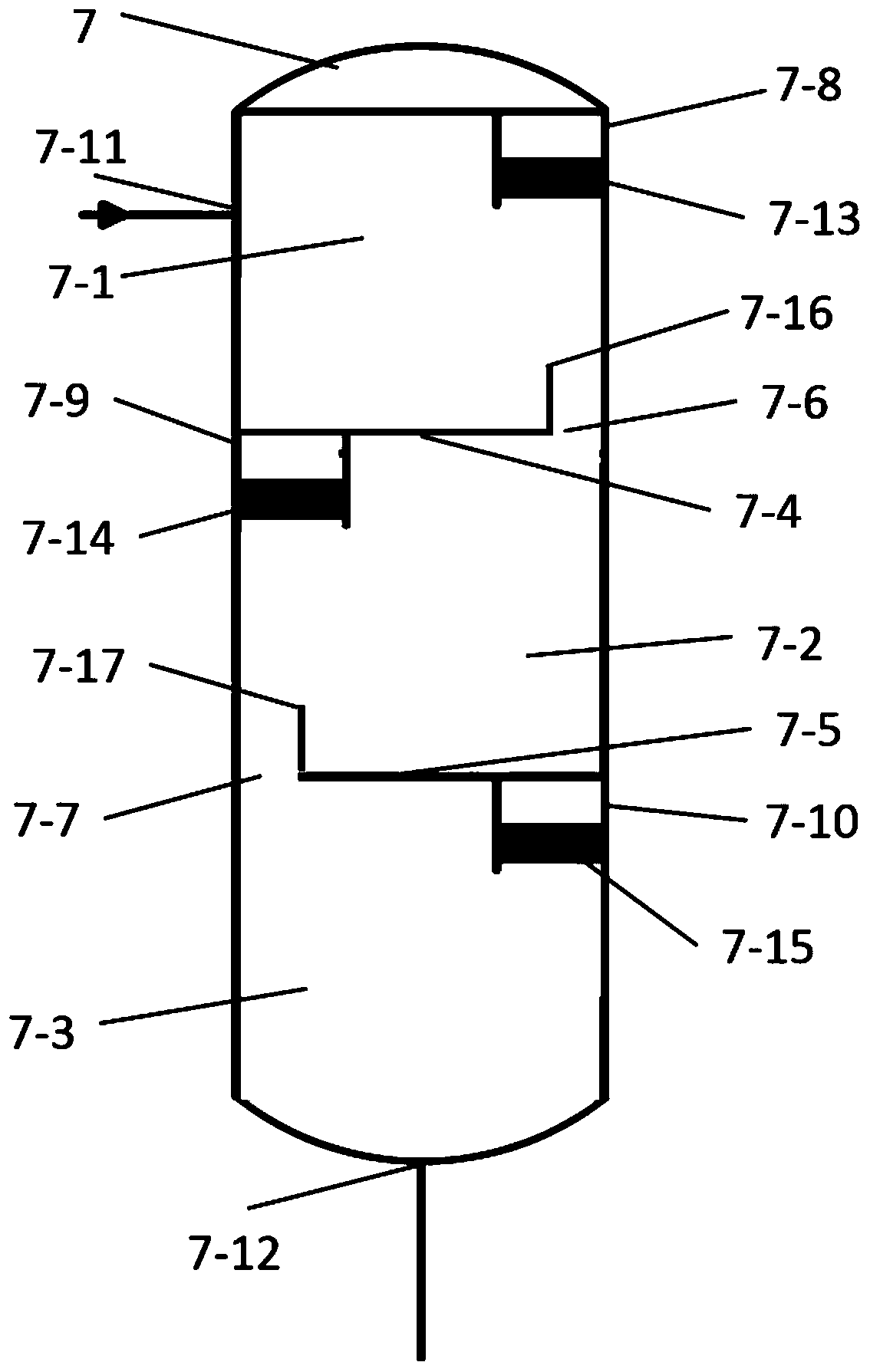

Waste heat boiler for preparing olefins from methanol

ActiveCN102384459BIncrease temperatureIncrease the amount of steamSteam boilersSteam boilers componentsSuperheaterHearth

Owner:SUZHOU HAILU HEAVY IND

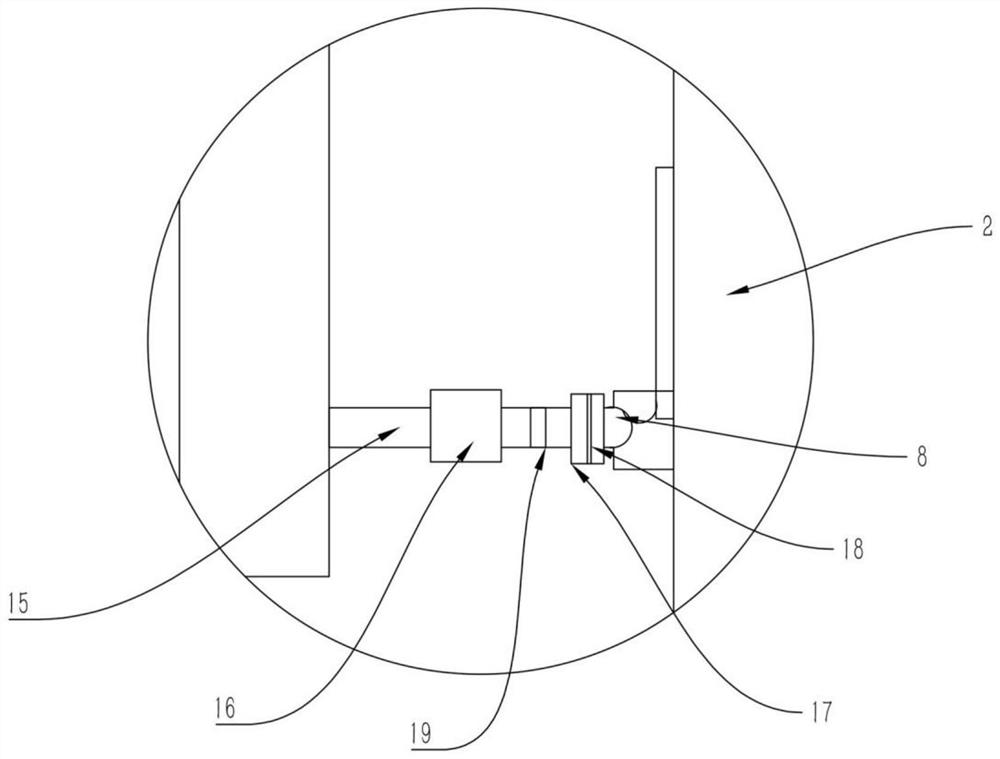

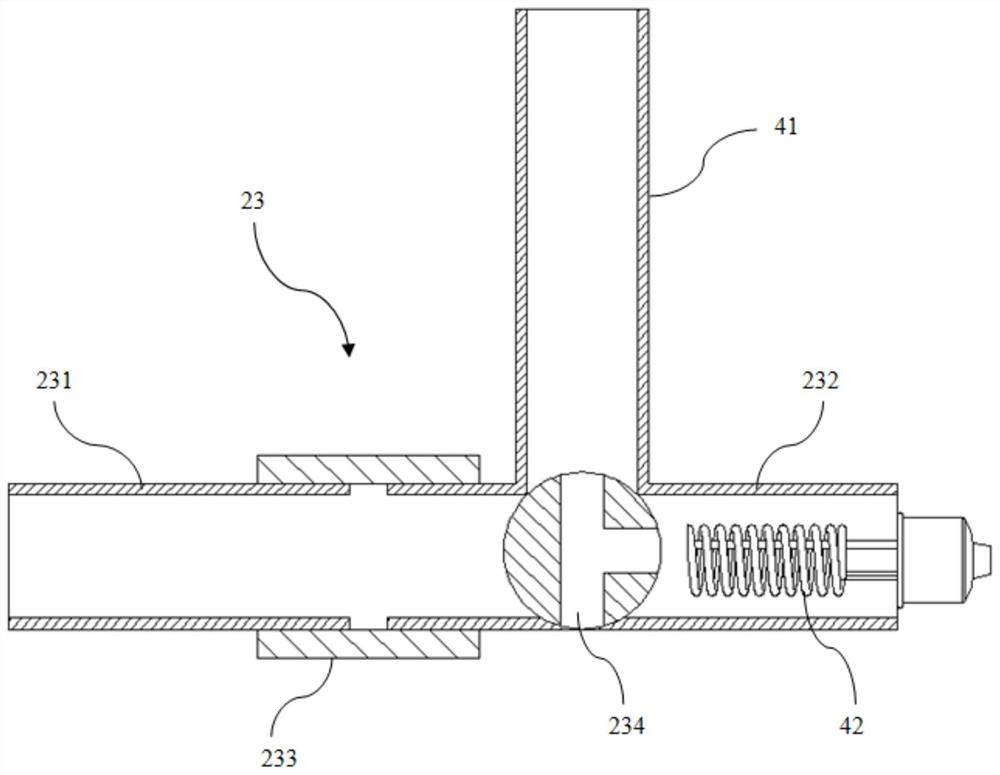

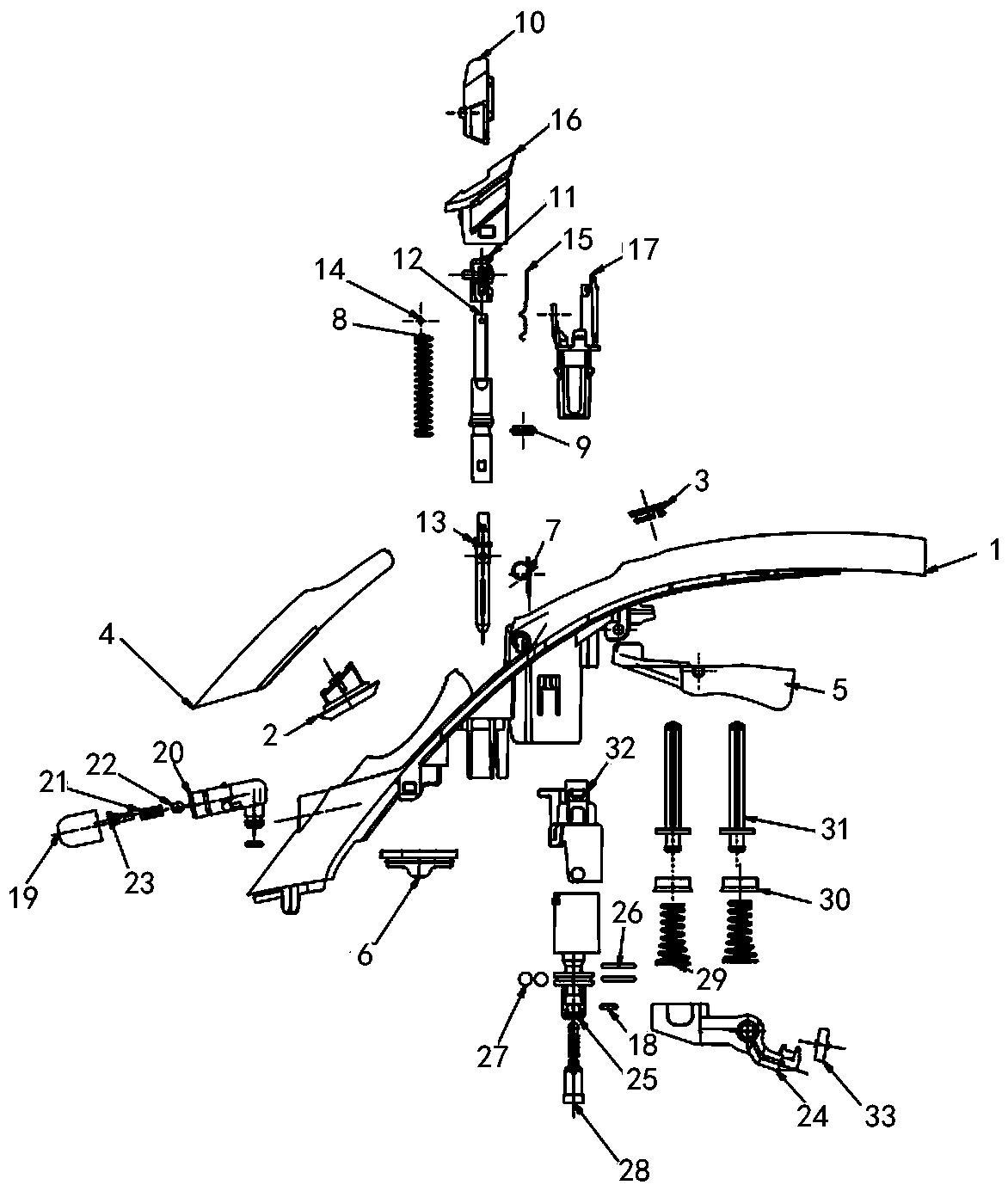

A top handle device for an electric iron

ActiveCN106012467BEffortless adjustmentSimple structureHand ironTextiles and paperEngineeringSteel ball

The invention provides a novel electric iron top handle device. The electric iron top handle device comprises an arc-shaped installation handle, a spray assembly, a movable plate assembly, a steam switch assembly and a control button assembly; the spray assembly comprises a spray body, a spray mushroom ball, a spray spring, a spray insert and a spray cover which are sequentially assembled from right to left; the movable plate assembly comprises a movable plate and a movable plate sealing gasket; the steam switch assembly comprises a shaft pin, a shaft support body, a shaft switch guide part, a shaft switch, a shaft sealing gasket arranged in the middle of the side face of the shaft support body, a shaft spring arranged on the upper portion of the side face of the shaft support body, a metal shaft arranged at the top end of the shaft support body, a shaft lock blade installed on the right side face of the shaft switch guide part and a shaft shell; the control button assembly comprises a pump cover, a pump rod, a pump nut, a pump spring, a steel ball, a pump shell and a pump switch. According to the electric iron top handle device, the steam amount and the water amount of an electric iron are increased, accurate control over the control switch is improved, the processing difficulty is reduced, batch continuous production is achieved, and the material cost and the assembly cost are both reduced.

Owner:SHANGHAI WEIMAO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com