Waste heat recycling power generation equipment taking perfluorohexanone as heat-conducting medium

A technology of perfluorohexanone and heat-conducting medium, which is applied in the field of waste heat recovery and utilization power generation equipment, can solve the problems of no environmental protection treatment equipment, easy leakage of pipelines, energy consumption, and low heat exchange efficiency, so as to increase the amount of high-quality saturated steam, Prevent leakage and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

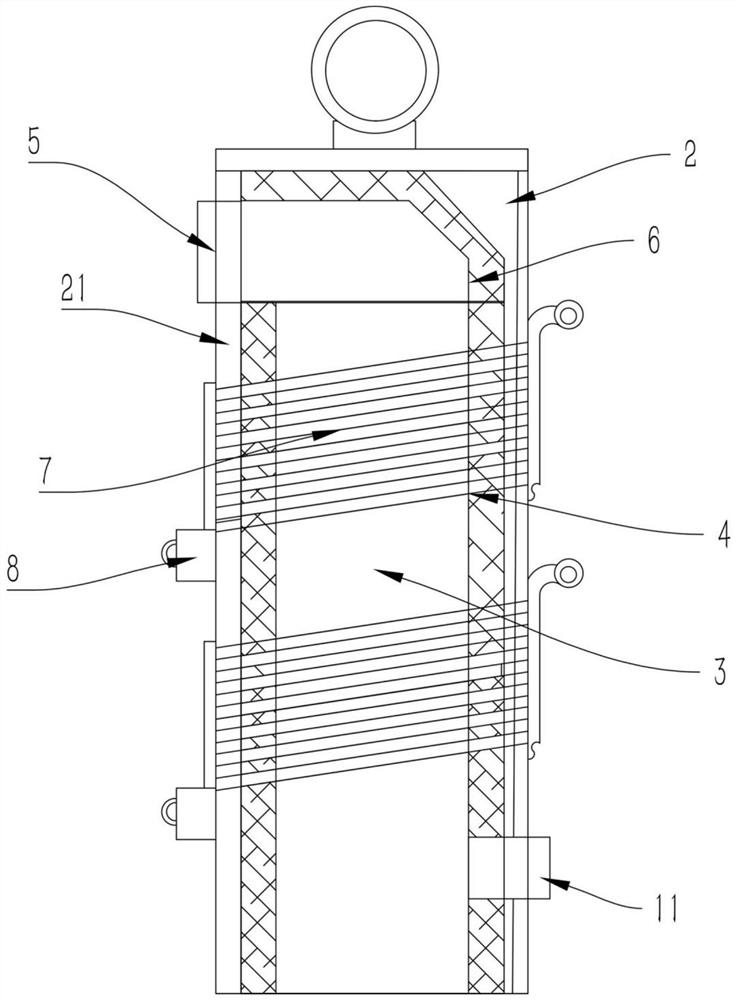

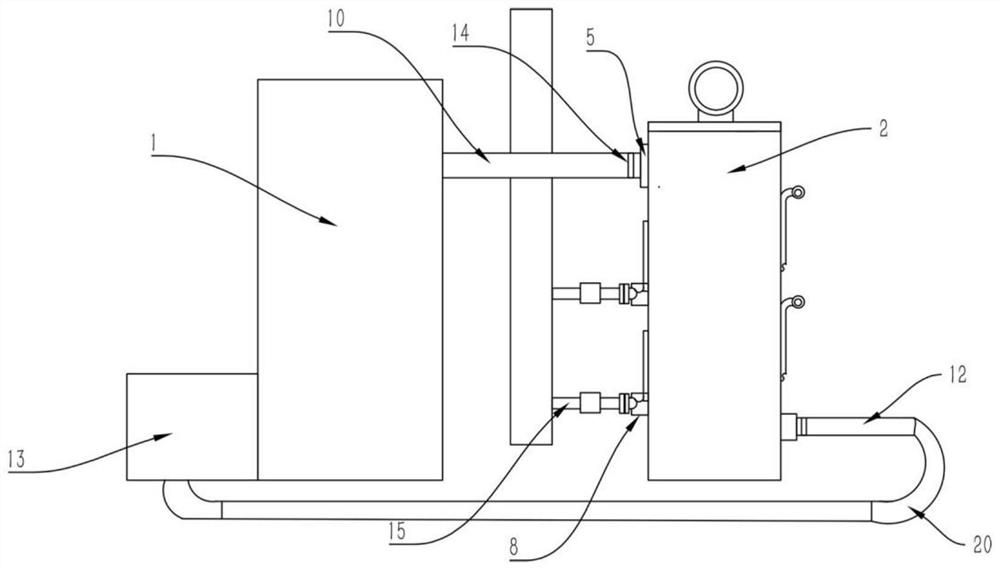

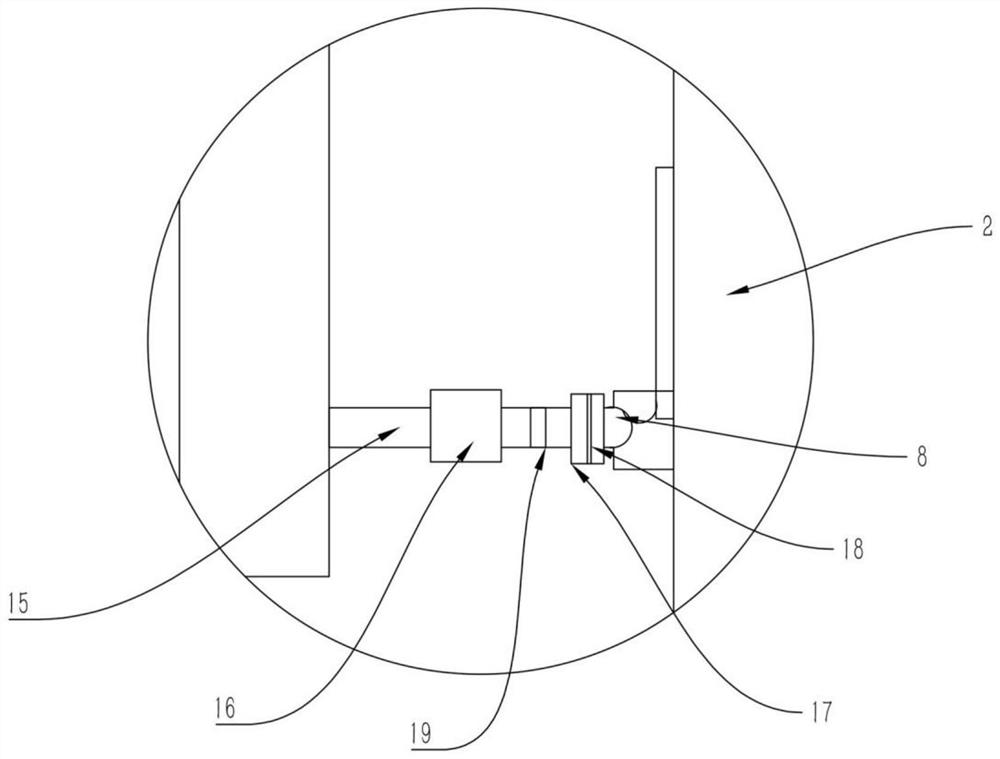

[0025] like Figure 1 to Figure 3 As shown, a waste heat recovery and utilization power generation equipment using perfluorohexanone as a heat transfer medium includes a waste heat boiler 2, a steam turbine generator set and an electric control device. The interior of the waste heat boiler 2 is provided with a vertically extending drum 3 and two There are two evaporators 4 stacked in the vertical direction, the drum 3 is communicated with the roaster 1 located on the side of the waste heat boiler 2 through the boiler smoke inlet 5 arranged on the side wall of the waste heat boiler 2, and the evaporator 4 is provided with a winding The flow evaporation heating surface 6 of the drum 3, the waste heat boiler 2 is respectively provided with a descending pipe 7 wound on the corresponding steamer middle flow evaporation heating surface 6, the bottom of the descending pipe 7 is provided with a main steam pipe seat 8, through the main steam pipe The seat 8 is communicated with the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com