Evaporation crucible

A crucible and evaporation technology, used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of fluctuation of nozzle jet rate, affecting the stability of evaporation process, and reducing gas pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

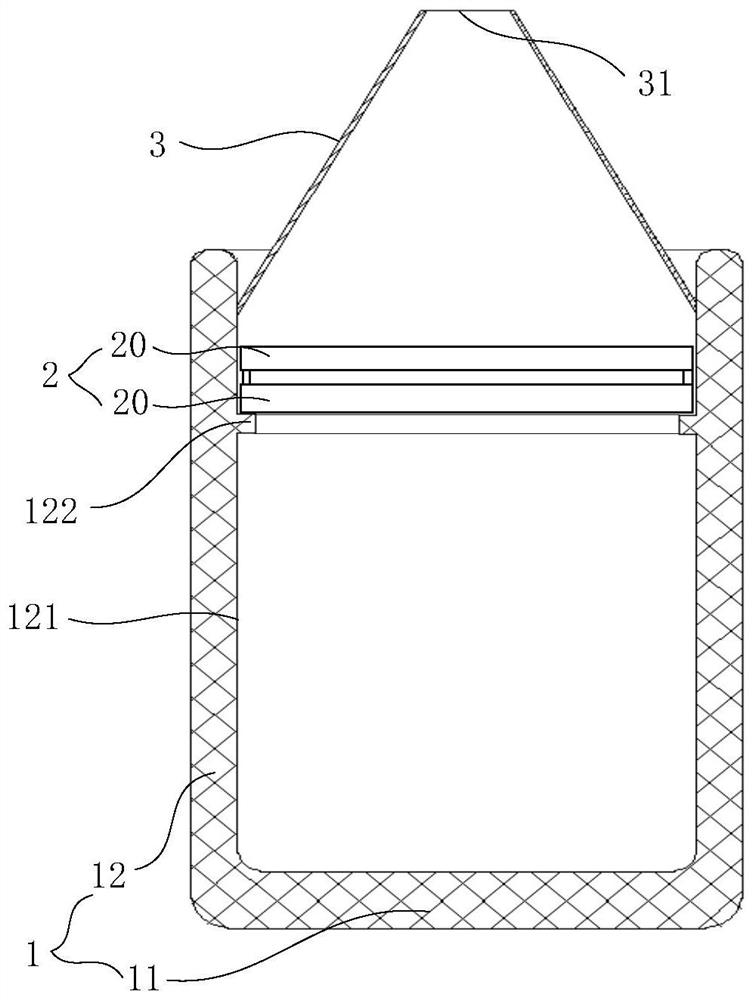

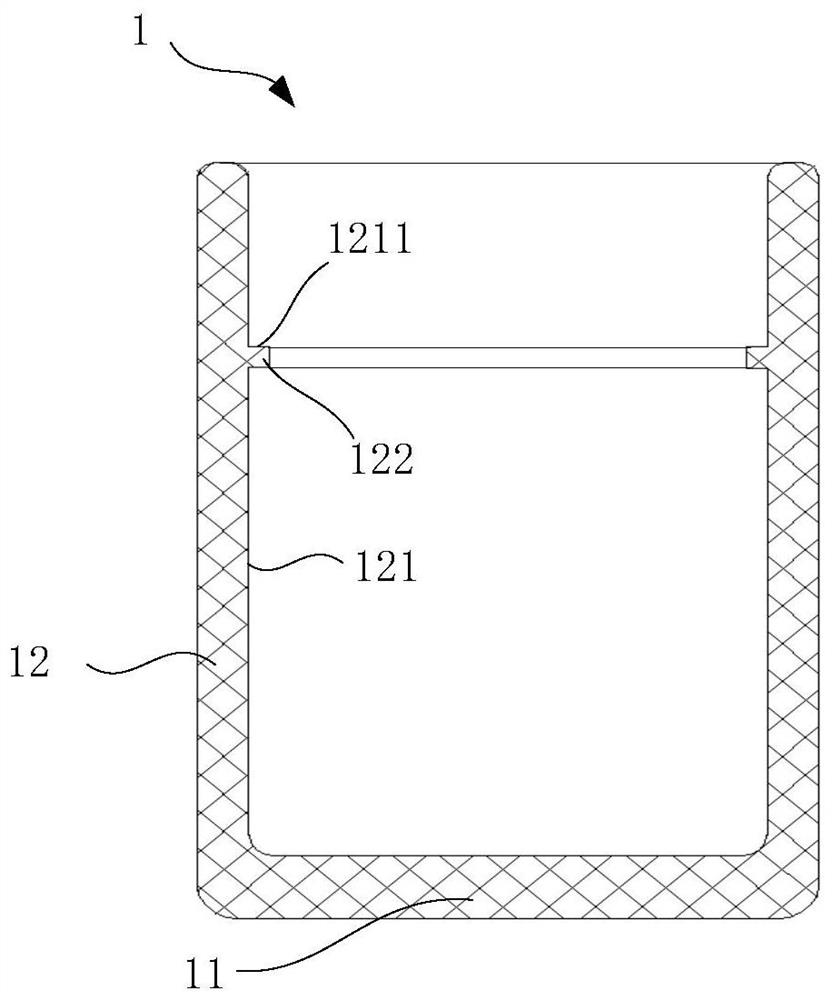

[0039] In some embodiments, referring to figure 2 , the side wall 12 includes a flange 122 extending toward the inside of the accommodating cavity, the flange 122 is located between the bottom wall 11 and the opening of the accommodating cavity, and the flange 122 is annular along the circumferential direction of the accommodating cavity; the supporting surface 1211 is the flange 122 away from the surface of the bottom wall 11. Exemplarily, there can be no less than five millimeters of space between the screen assembly 2 and the coating material, so that the vapor can gather a certain amount in the lower side of the chamber; when the coating material is placed, the height of the coating material is lower than The annular flange 122 prevents the coating material from directly contacting the screen assembly 2 . During the evaporation process, depending on the evaporation material, the temperature in the chamber may reach 800°C or even 1000°C. agents, etc.) are less reliable, ...

Embodiment 2

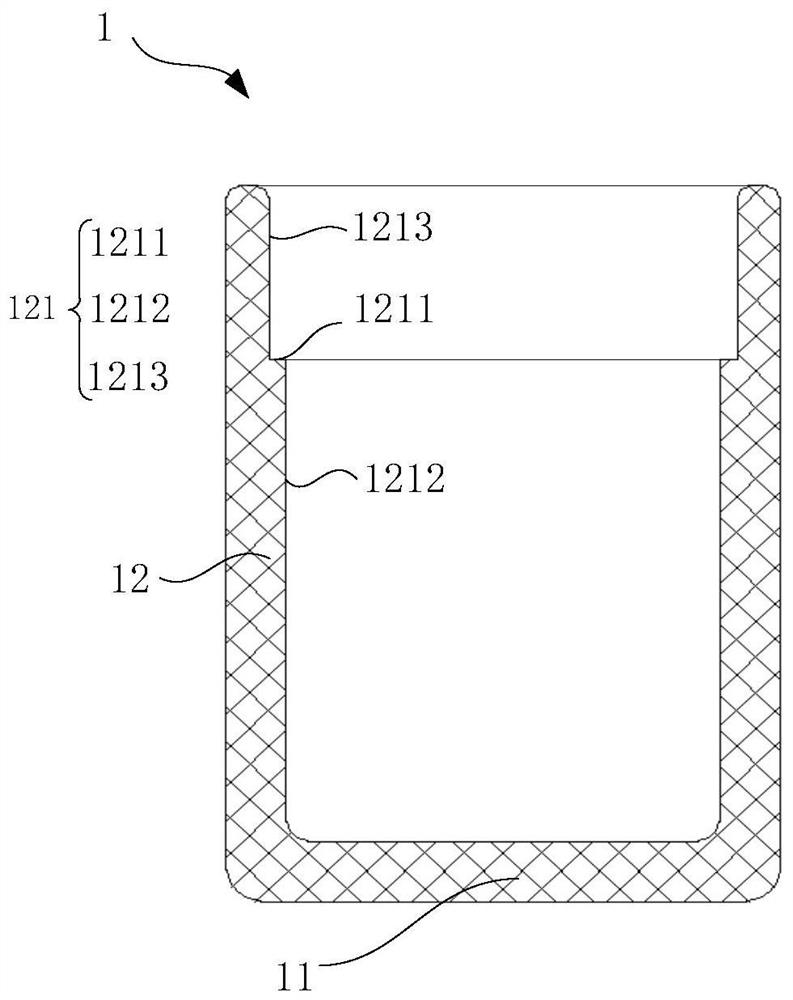

[0042] In some embodiments, referring to image 3 , the first surface 121 further includes a first extension section 1212 and a second extension section 1213 extending in a direction perpendicular to the bottom wall 11, the second extension section 1213 is located on the side of the first extension section 1212 away from the bottom wall 11, and the first The diameter of the extension section 1212 is smaller than the diameter of the second extension section 1213 ; one side of the supporting surface 1211 is connected with the first extension section 1212 , and the other side is connected with the second extension section 1213 . Compared with the method of setting the annular flange 122 on the side wall 12, in this embodiment, the first surface 121 is in a stepped shape, and the side of the side wall 12 away from the bottom wall 11 is in the direction away from the accommodating cavity (toward the outside) Concave, the supporting surface 1211 is a surface parallel to the bottom w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com