30-liter constant-pressure steam boiler

An atmospheric steam and boiler technology, applied in the field of 30-liter atmospheric steam boilers, can solve the problems of reduced hot water and steam volume, environmental pollution, low thermal efficiency, etc., and achieve the increase of hot water and steam volume, rapid Popularization and application, the effect of high utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

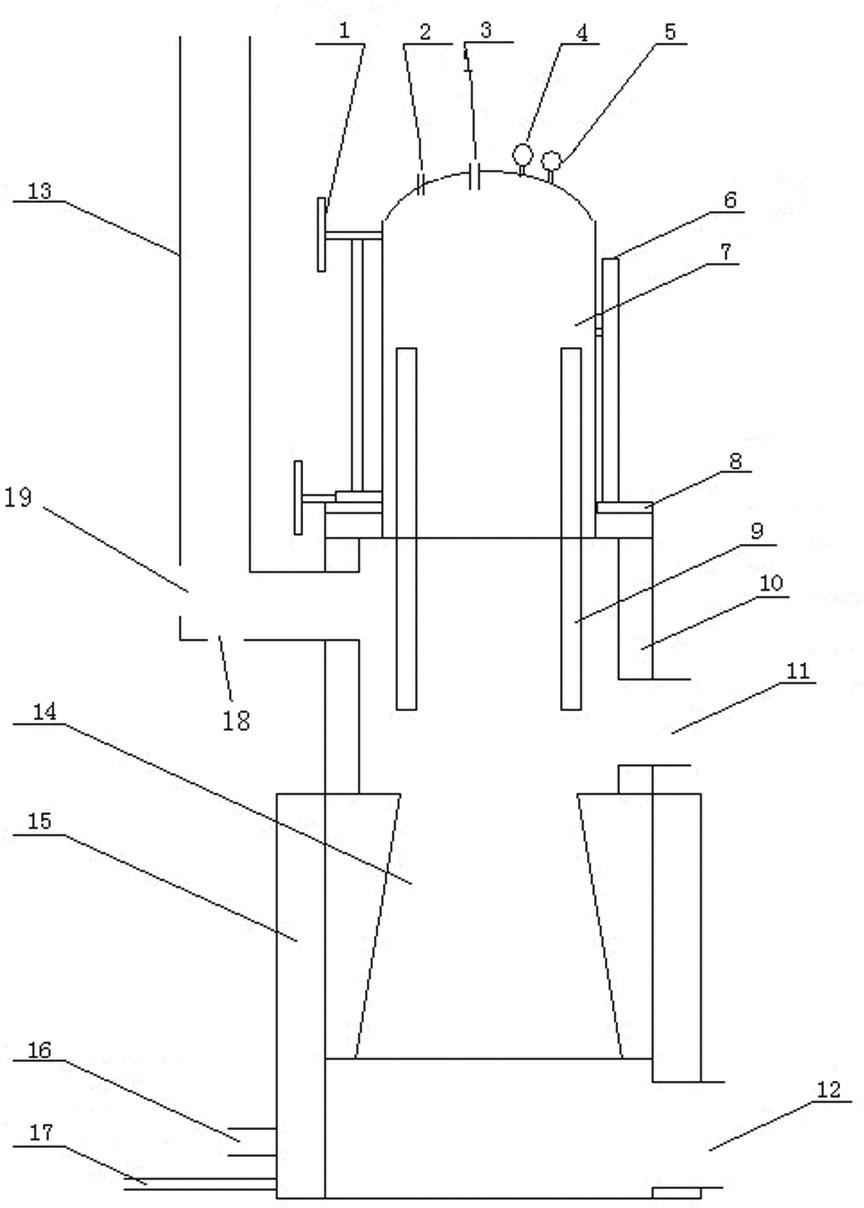

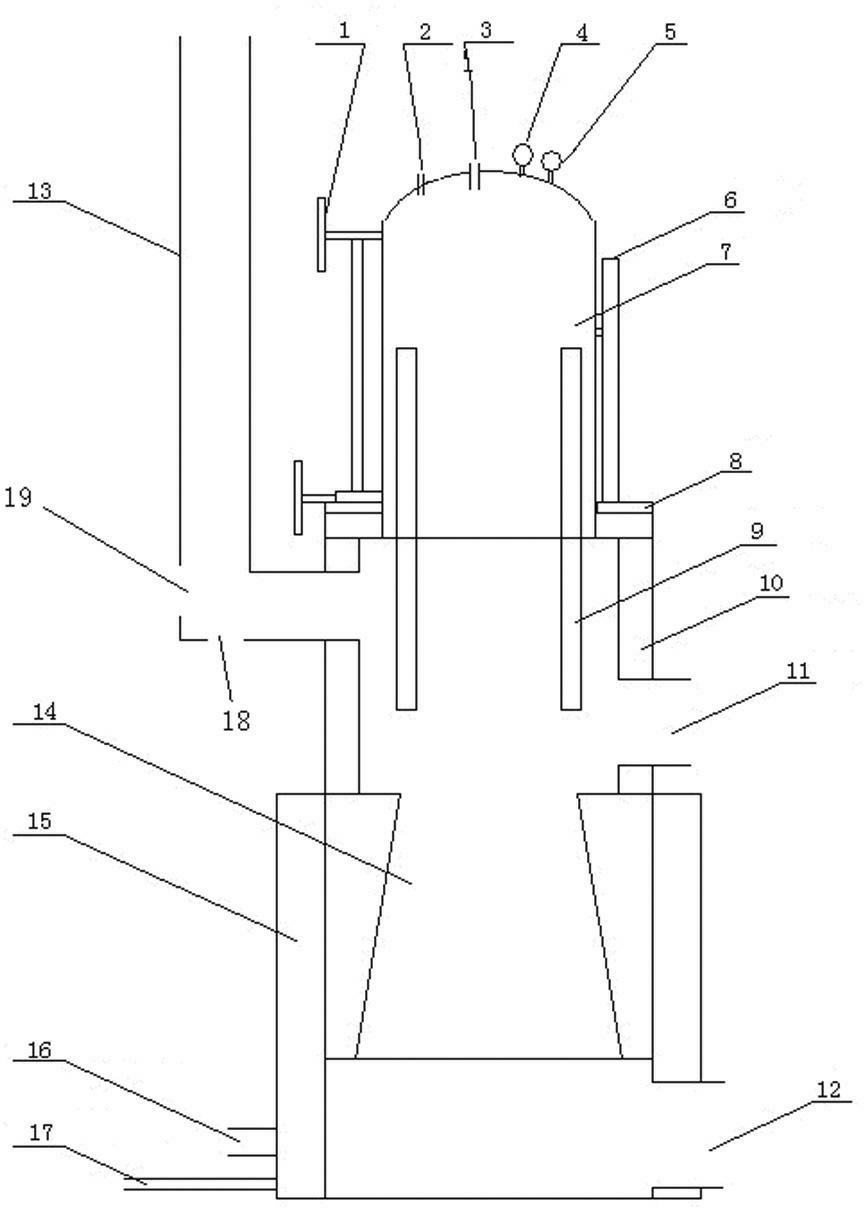

[0014] Embodiment: with reference to accompanying drawing:

[0015] The outer diameter of the furnace seat of the present embodiment is 600mm, the inner diameter is 500mm, and the height is 650mm; cavity. Above the furnace is a furnace chamber 7 with a diameter of 300 mm and a height of 430 mm. Safety valve 2, air outlet 3, pressure gauge 4 and temperature gauge 5 are installed on the furnace chamber 7, and water level gauge 1 and sensor 6 are installed on the periphery; Smoke pipe 13 outlets are opened on the other side above the coal inlet 11 between the furnace and the furnace furnace, and the length of the smoke exhaust pipe is 80 centimeters, and the diameter is 12 centimeters; Its upper end is slightly higher than the top surface of the furnace furnace. A superconducting heat transfer tube 9 is arranged between the furnace and the furnace, the length of the superconducting heat transfer tube is 0.4-1m, and the distance between two adjacent tubes is 5-10cm. The lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com