Novel comprehensive energy conservation, emission reduction, production increase and efficiency enhancement type local oxygenation combustion supporting system for fuel furnace kiln

A combustion-supporting system, energy-saving and emission-reduction technology, applied in indirect carbon dioxide emission reduction, non-flammable liquid/gas transportation, furnace and other directions, can solve the problems of lack of alarm control, lack of automation, and lack of oxygen-enriched flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

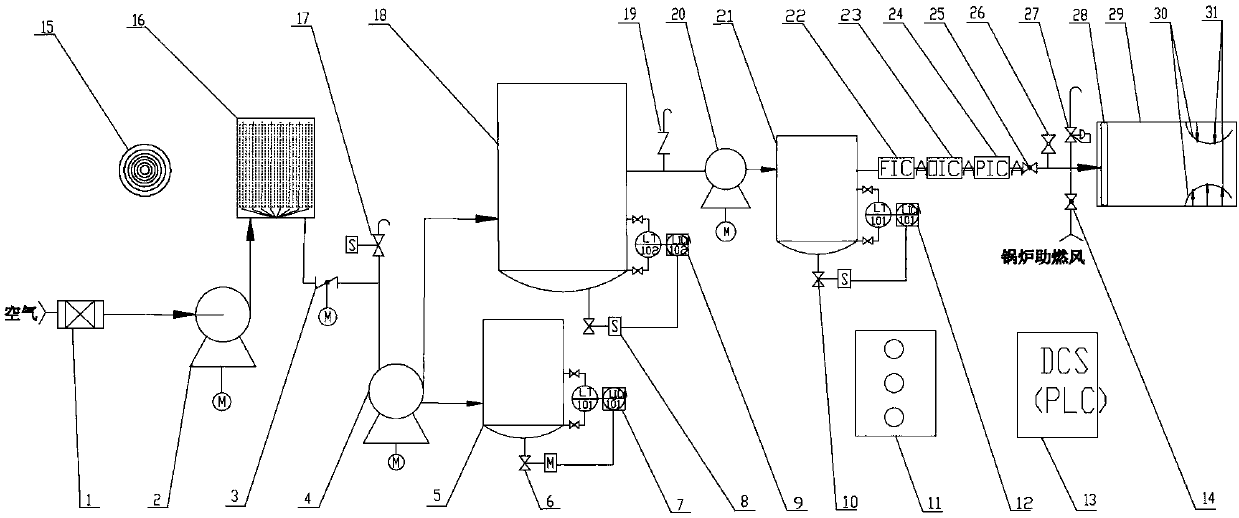

[0043] Example 1 A "α-S type combined combustion" membrane method oxygen-enriched local oxygen-increasing combustion-supporting device for industrial chain heating boilers

[0044] For its procedure, see the attached figure 1 . The local oxygen-increasing combustion-supporting device consists of an oxygen source, a pressurization system, an oxygen-enriched high-efficiency preheater 28, a special oxygen-enriched nozzle 31, an alarm device 15, an oxygen-enriched flow transmitter 22, a micro-pressure transmitter 24, an emergency stop Device 11 and electric control system 13; wherein, by high-efficiency air filter 1, ventilator 2, membrane oxygen enrichment generator 16, electric switch valve 3, membrane oxygen enrichment protection valve 17, water ring vacuum pump 4, circulating water tank 5 It communicates with the oxygen-enriched surge tank 18 in sequence to jointly form the oxygen source of the device;

[0045] The process flow of the oxygen source is as follows: the air pa...

Embodiment 2

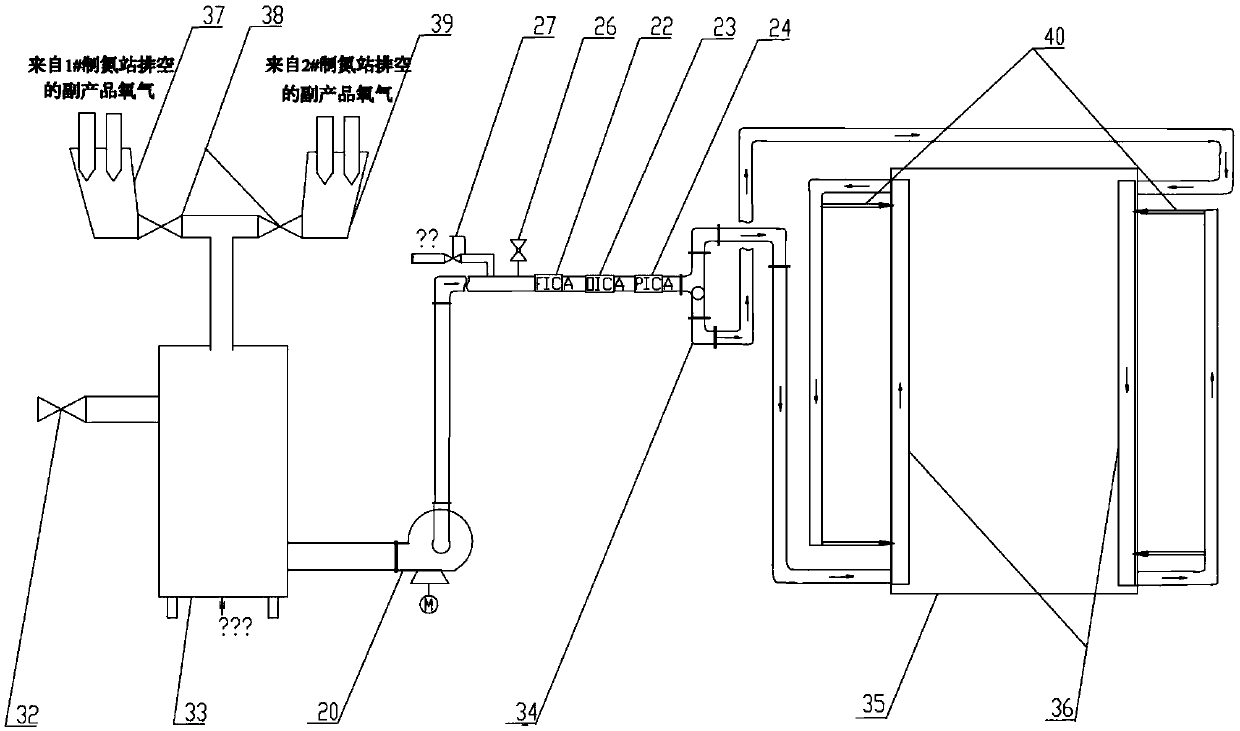

[0055] Example 2 A new type of "gradient combustion" cryogenic oxygen generation and local oxygen-increasing combustion-supporting device for glass melting furnaces

[0056] For its procedure, see the attached figure 2. On the basis of the structure described in Example 1, the new "gradient combustion" cryogenic oxygen generation and local oxygen-increasing combustion-supporting device for glass melting furnaces described in this example is mainly different from Example 1 in that this example The oxygen source used is a by-product of cryogenic nitrogen production. The oxygen concentration of this oxygen source is generally relatively high and not stable. Therefore, an oxygen collection cover (I37 and II39 [spare]), an oxygen collection control valve 38, and an oxygen-enriched Mixing surge tank 33, booster fan 20, oxygen-enriched air intake control valve 32, oxygen-enriched flow transmitter 22, oxygen-enriched concentration transmitter 23, micro-pressure transmitter 24, oxyge...

Embodiment 3

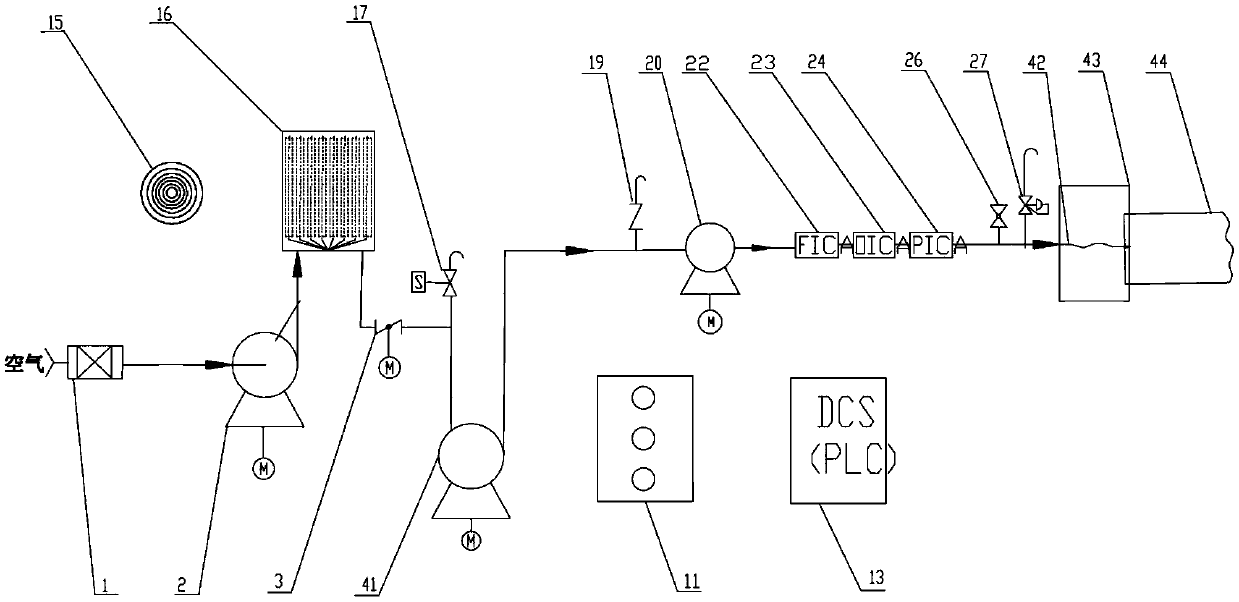

[0058] Example 3 A "arc combustion" membrane oxygen-enriched local oxygen-increasing combustion-supporting device for a rotary kiln

[0059] For its procedure, see the attached image 3 . On the basis of the structure described in Example 1, the main difference between the "arc combustion" film method oxygen-enriched local oxygen-increasing and combustion-supporting device for the rotary kiln described in this example and Example 1 is that the cycle is set by default. Water tank 5, electric control valve 6, magnetic flap liquid level controller Ⅰ7, solenoid valve controller Ⅰ8, magnetic flap liquid level controller Ⅱ9, solenoid valve controller Ⅱ10, magnetic flap liquid level controller Ⅲ12, combustion air Switching valve 14, oxygen-enriched surge tank 18 and high-efficiency demister tank 21; it is the step where the oxygen source is directly processed by the air-cooled reciprocating vacuum pump 41 and then enters the rotary kiln; since the oxygen-enriched amount is relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com