Exhaust pipe and exhaust structure of integrated cooker or electric oven baking oven

An exhaust pipe, electric oven technology, applied in the direction of roaster/barbecue grid, household stove, household stove/stove, etc., can solve the problems of food no longer pure, food pollution, taste deterioration, etc., to improve steaming and roasting Effects of reduced speed, power consumption, and increased steam volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

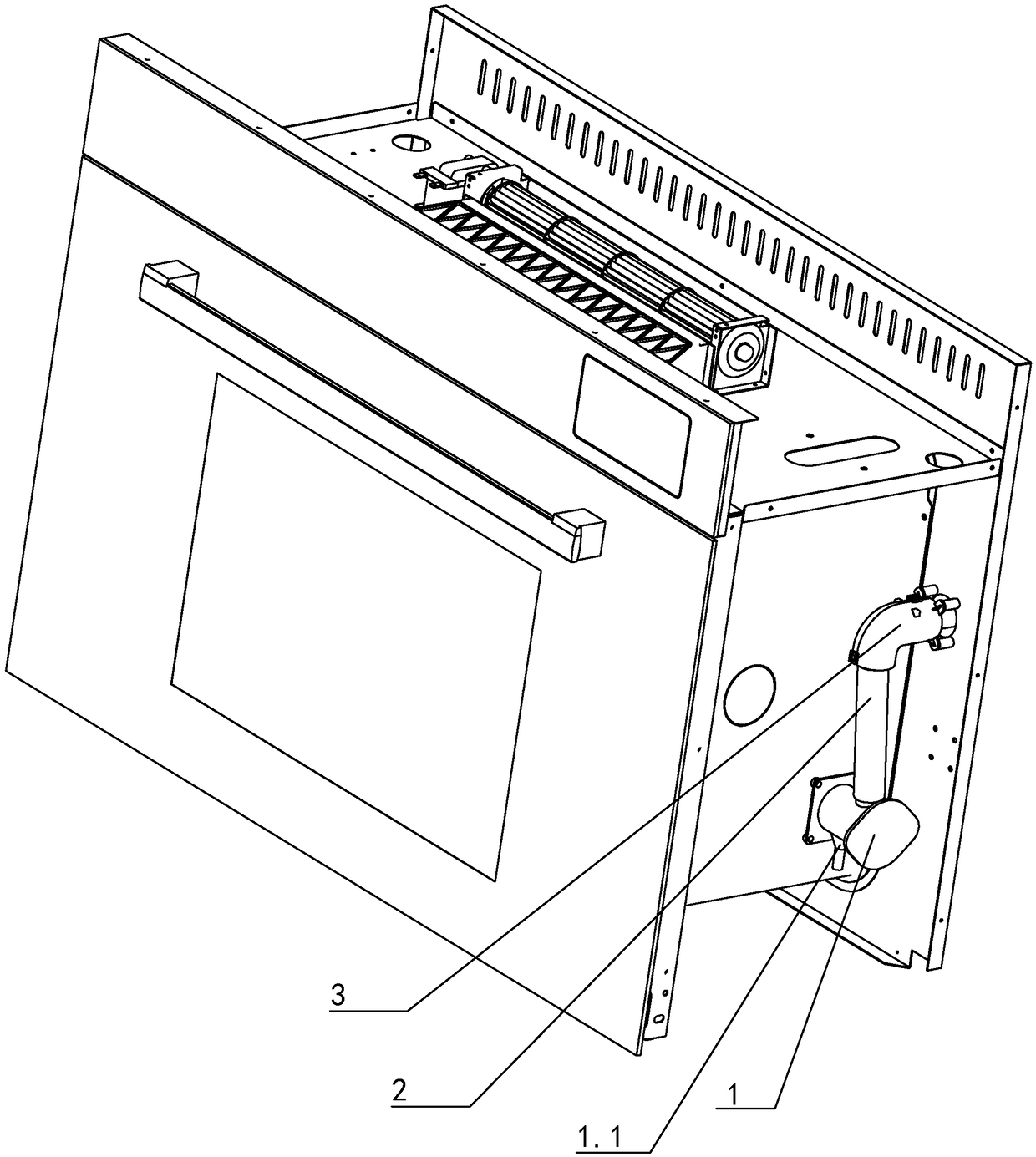

[0017] This example figure 1 Shown is the exhaust structure of an integrated stove or an electric oven, which is composed of a drain joint 1 connected to the oven, a connecting pipe 2 and an exhaust pipe 3 connected in sequence, and the exhaust port of the exhaust pipe 3 passes through the bottom of the box body back panel.

[0018] Preferably, the bottom of the drain joint 1 is a funnel-shaped condensed water outlet 1.1, which is used to facilitate the collection of condensed water and prevent the condensed water from flowing back into the oven.

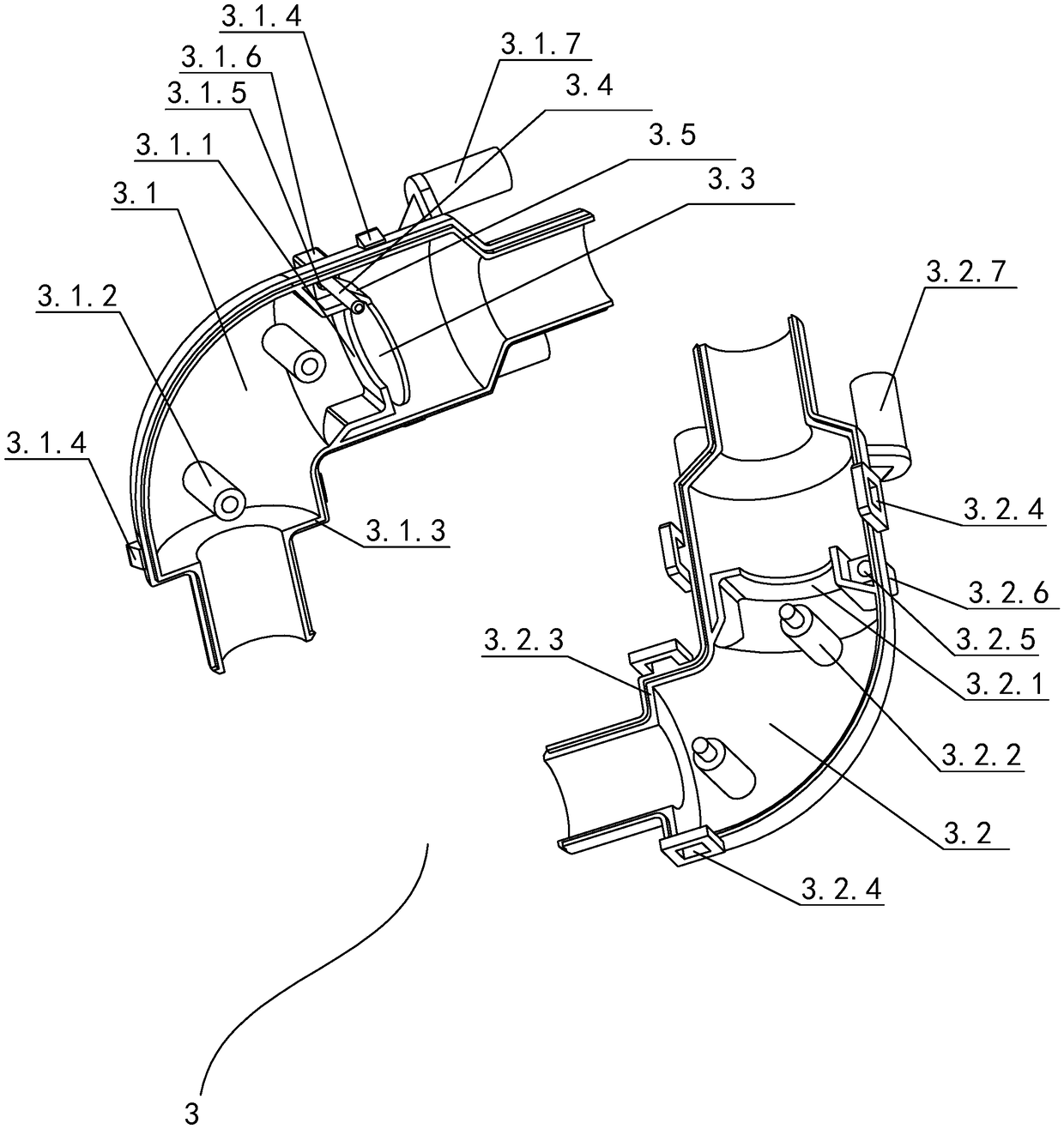

[0019] In this embodiment, the exhaust pipe such as figure 2 As shown, the exhaust pipe body 3 is provided with an anti-backflow structure. Among them, the exhaust pipe body 3 is formed by the airtight buckling of the left pipe tile 3.1 and the right pipe tile 3.2, and a semicircular inner ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com