Direct dry cooling system of natural draft cooling tower

A natural ventilation and dry cooling technology, applied in the engineering field, can solve problems such as increased exhaust pressure drop, long steam distribution pipe, increased turbine back pressure, etc., to achieve exhaust pressure drop control, scientific layout, and improved power generation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

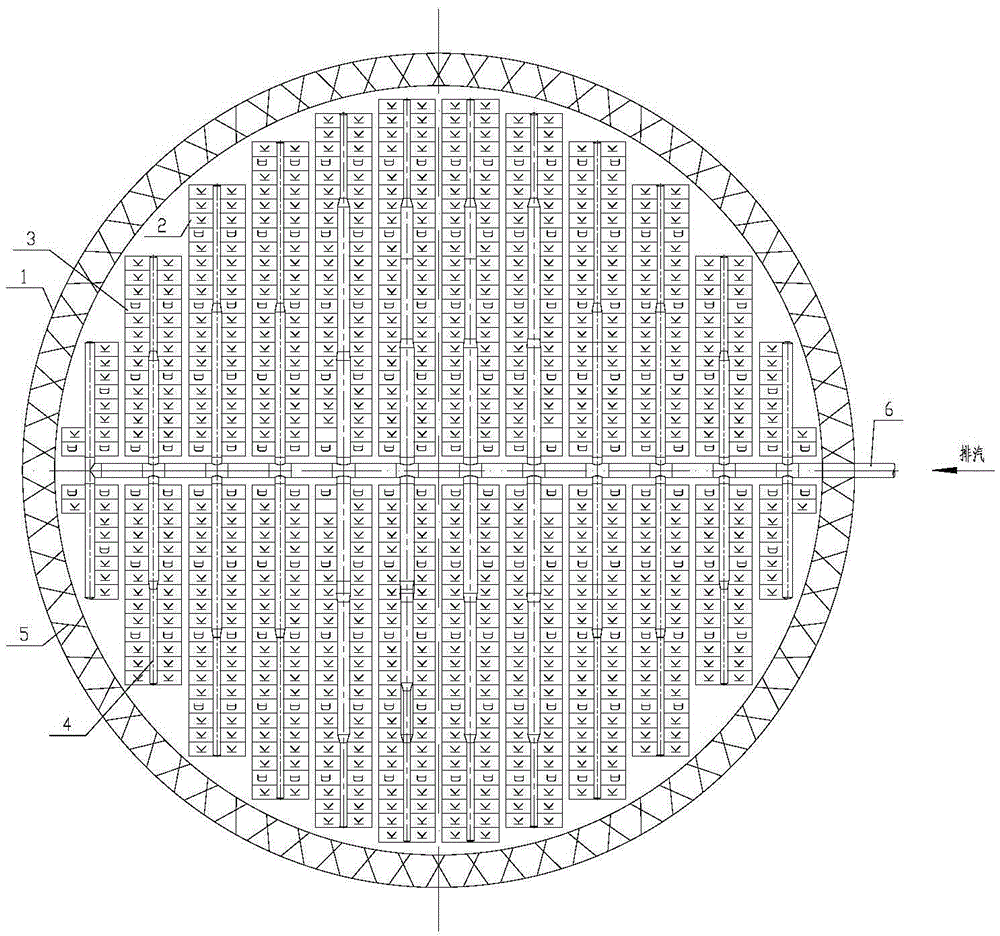

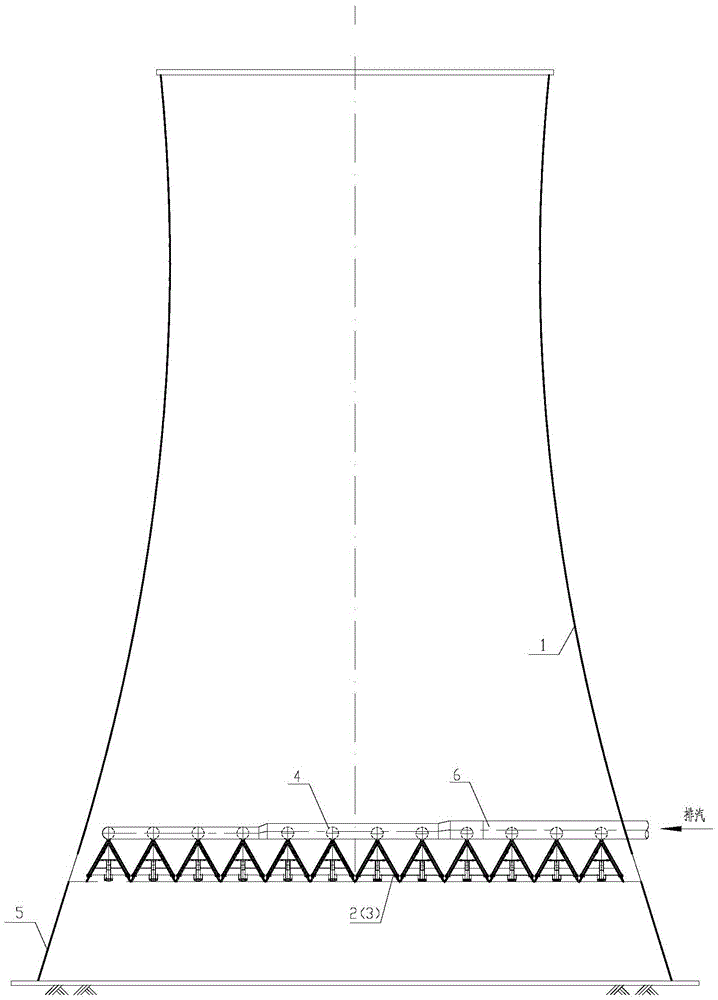

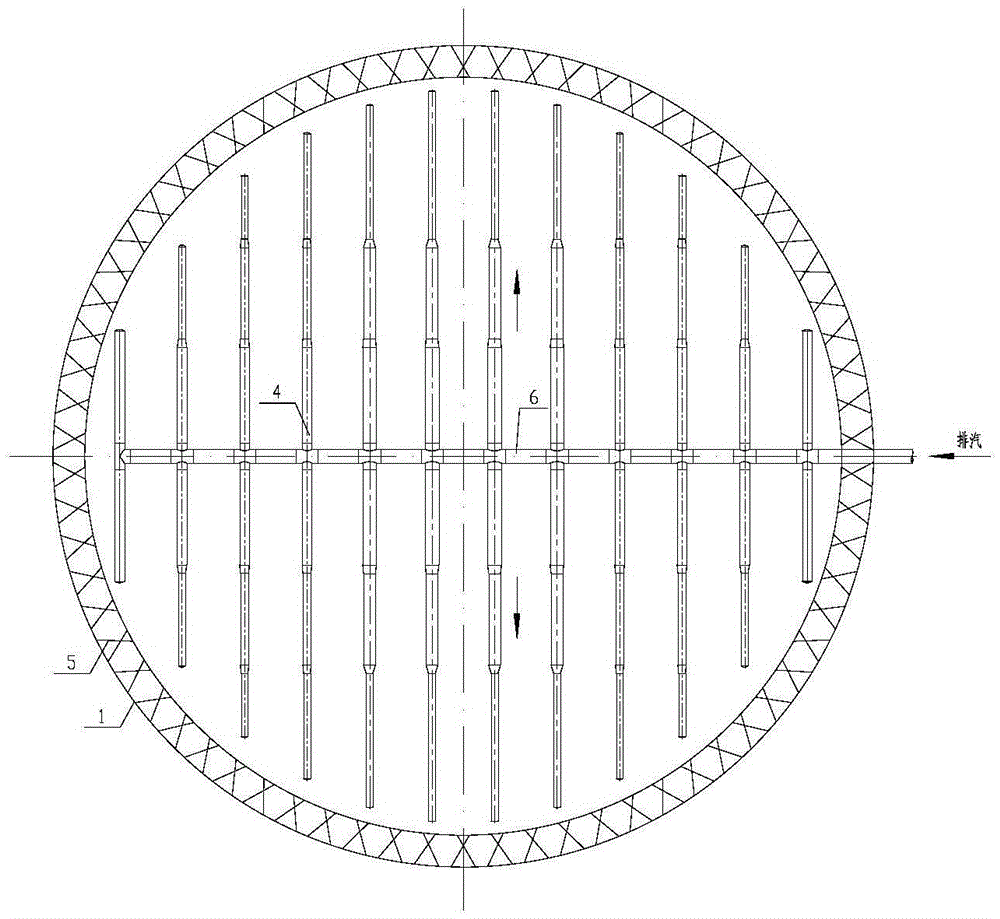

[0024] see Figure 1-3 As shown, the core of the present invention is the arrangement form of the air-cooled radiator in the tower. The direct dry cooling system of the natural draft cooling tower includes the radiator, the steam main pipe 6 and the steam distribution pipe 4. The cross-section of the radiator at a certain height in the tower Above, it is arranged in rows along the diameter direction of the section, and each row of radiators shares a steam distribution pipe. The steam main pipe 6 is arranged in the tower along the diameter of the cross section of the natural ventilation cooling tower 1 at a certain height, and each steam distribution pipe 4 is connected with The steam main pipe 6 is connected, and the length of each steam distribution pipe 4 gradually decreases from the center of the natural ventilation cooling tower to the tower circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com