Desulfurization and denitrification afterheat power generation systematization device of glass melter flue gas

A glass melting furnace, desulfurization and denitrification technology, applied in the field of environmental protection, can solve the problems of reducing the cost of pollutants, and achieve the effects of saving electrode costs, long service life, and avoiding poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following combines the attachment and the specific embodiments to further explain the present invention.

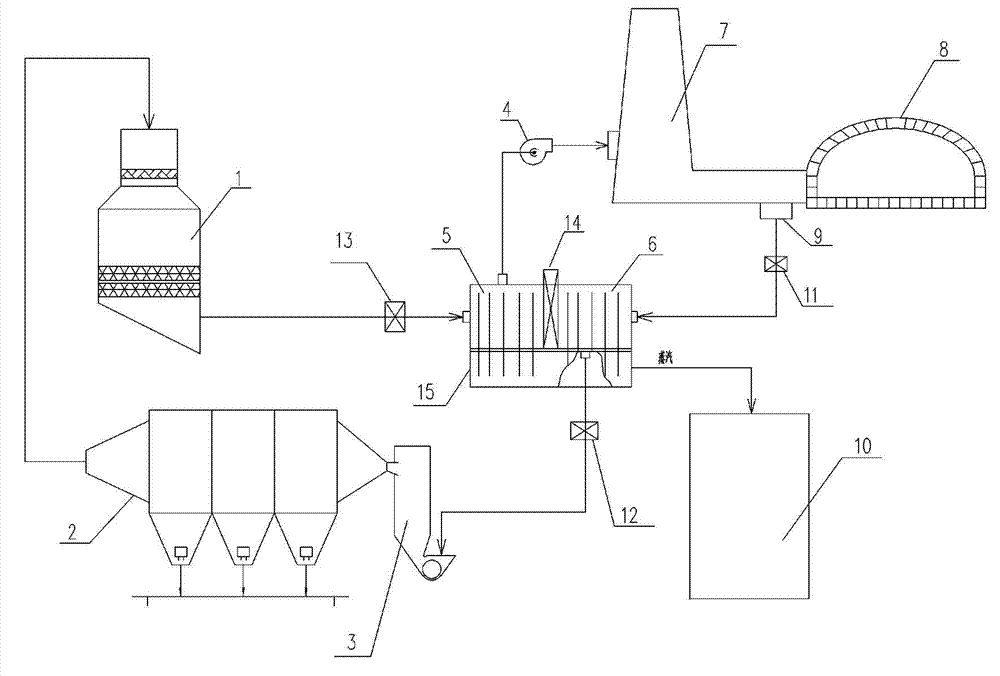

[0032] like figure 1 It shows that a systematic device for desulfurization and denitrification of flue gas provided by the present invention, including the following five parts: the following five parts:

[0033] A. The remaining heat boiler 15, the middle part of the heat exchange part is equipped with 14 gate panels, divided the heat exchange part into high temperature segment 6 and low temperature section 5, the barrier 7 of the chimney 7 is connected to the entrance of the high temperature segment 6, and and the high temperature section 6, and the high temperature section 6 is connected to the entrance.There is the first gates 11 in the Writer's House 9, the low -temperature segment 5 exits are connected to the chimney 7, and there is an inferior fan 4 in the smoke exhaust pipe;It

[0034] B. The high temperature segment 6 is connected to the bypass pipeline an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com