Method and device for testing rock drillability of deep well drilling and extra-deep well drilling

A testing device and ultra-deep well technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve problems such as poor drillability, high temperature, affecting rock drillability and drilling speed of drilling machinery, etc., to save experimental costs , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

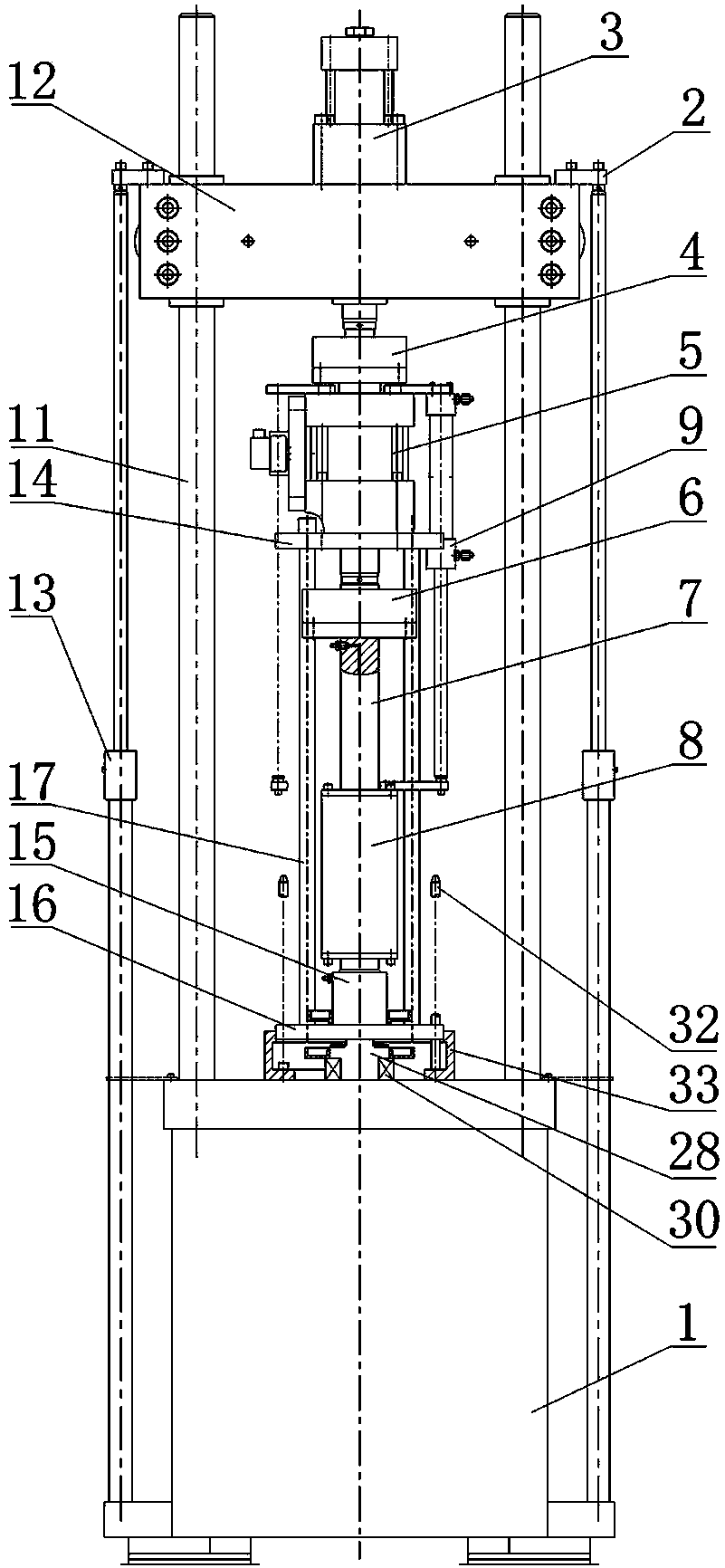

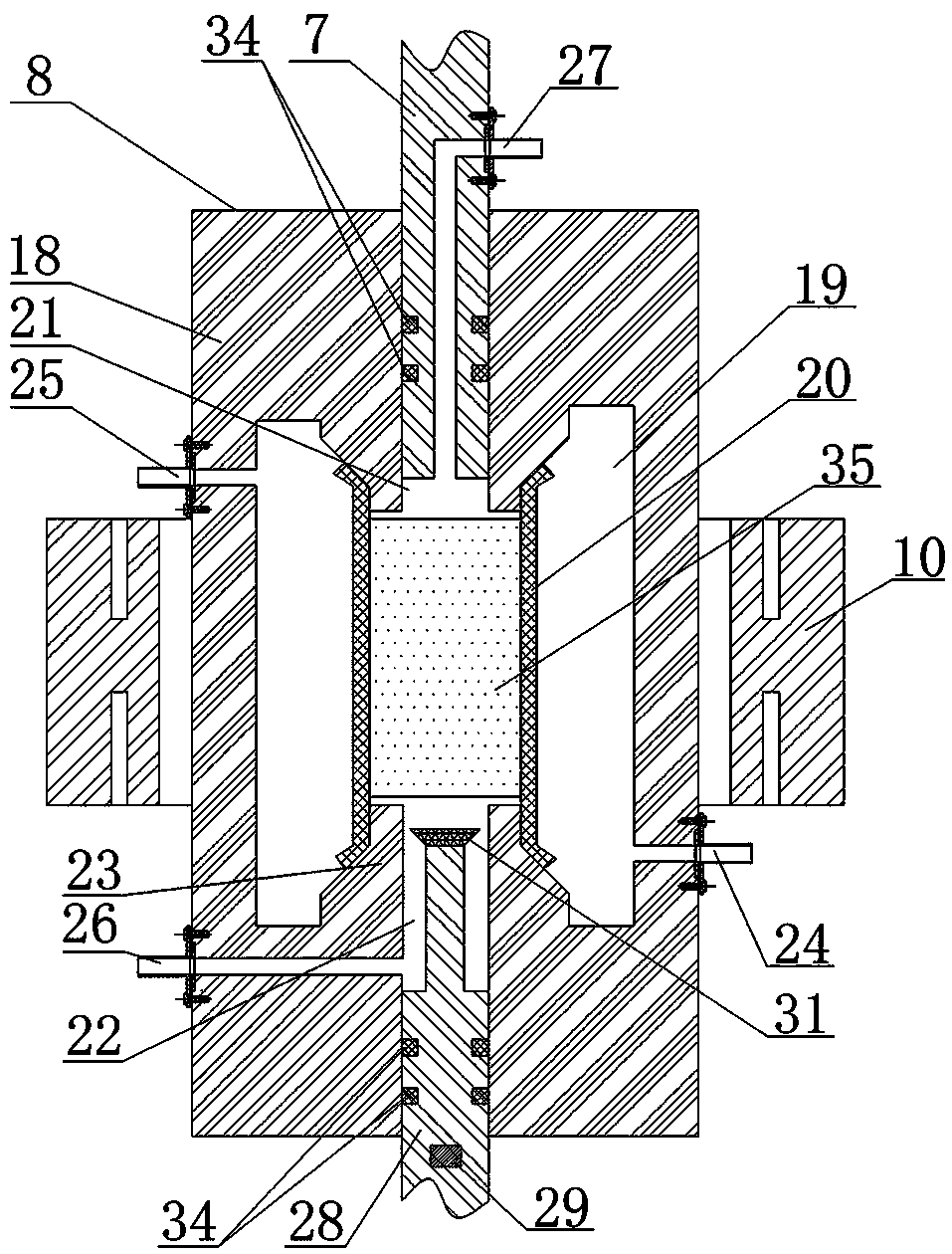

[0027] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0028]The inventor found in the process of scientific research that the existing device for testing rock drillability no longer meets the technical requirements for drilling deep and ultra-deep wells in the field of oil and gas exploration and development, especially cannot effectively reveal the actual drilling process of deep wells and ultra-deep wells under the formation conditions. The reasons for the rock drillability characteristics mainly include the following aspects:

[0029] The first is that the overlying strata pressure is not loaded. During the drilling of deep and ultra-deep wells, the rock at the bottom of the well is subjected to the gravity of the formation rock and pore fluid covering the upper part of the rock. The pressure on the chip failure surface has a significant impact on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com