Oxygen-enriched combustion radiant tube heaters

A radiant tube heater and oxygen-enriched combustion technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of poor flue gas waste heat recovery and thermal efficiency problems, and improve stability and reliability. , Improve the heat utilization rate and improve the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

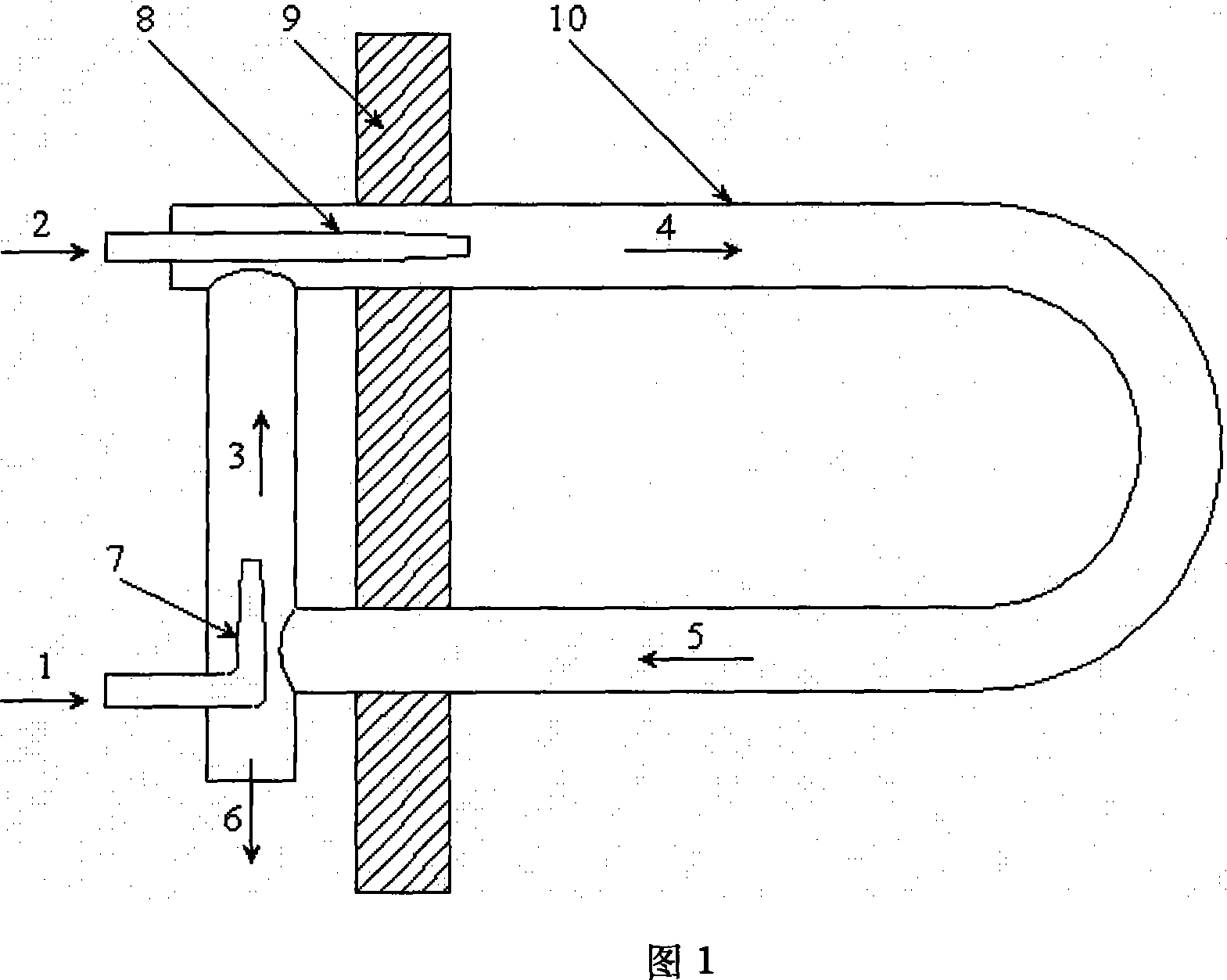

[0013] 1. The ejector is located in the outer radiant tube system structure of the furnace wall. It consists of oxygen or oxygen-enriched air 1, fuel 2, a mixture of oxygen or oxygen-enriched air and combustion flue gas 3, combustion gas 4, flue gas in the radiant tube 5, The flue gas 6 discharged from the radiant tube, the flue gas ejector 7, the burner 8, the furnace wall 9, and the radiant tube 10 are composed. The ejector is located on the outside of the furnace wall. Although it is easy to install, it has certain radiation and convective heat transfer to the environment, which is not good for the environment outside the furnace.

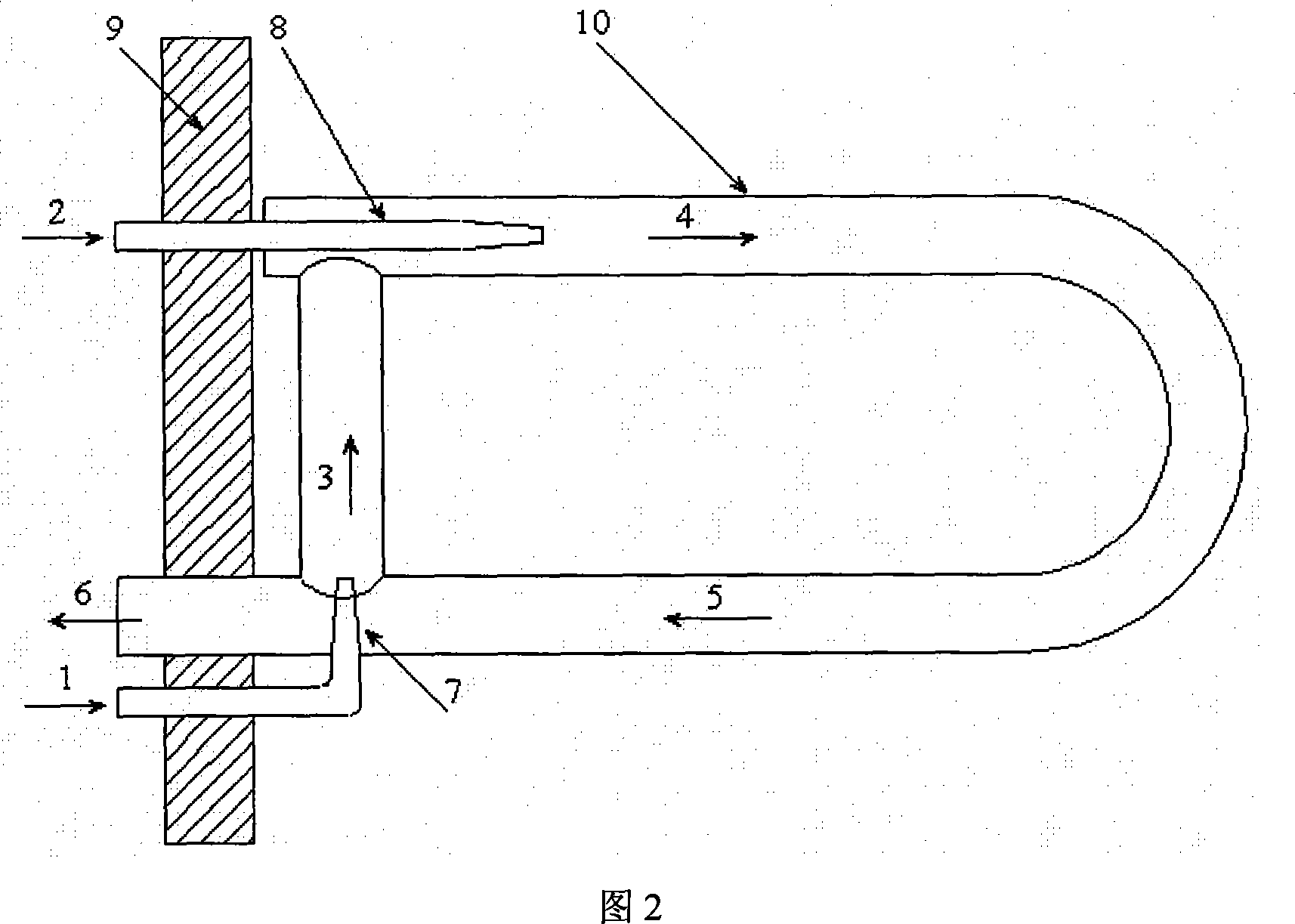

[0014] 2. The ejector is located in the inner radiant tube system structure of the furnace wall, which consists of oxygen or oxygen-enriched air 1, fuel 2, mixed gas 3 of oxygen or oxygen-enriched air and combustion flue gas, combustion gas 4, flue gas in the radiant tube 5, The flue gas 6 discharged from the radiant tube, the flue gas ejector 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com