Patents

Literature

61results about How to "Improve emissivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

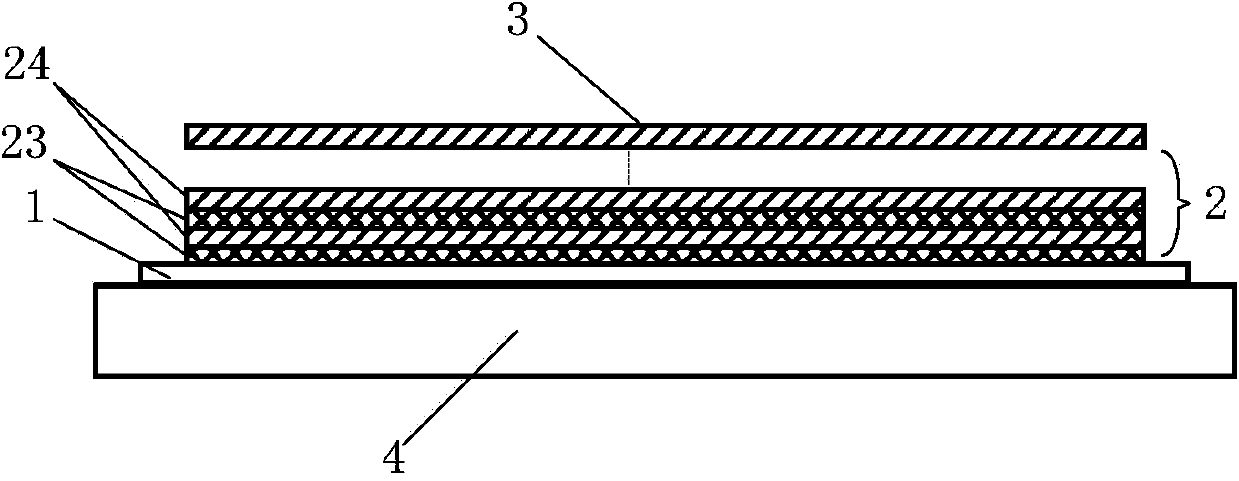

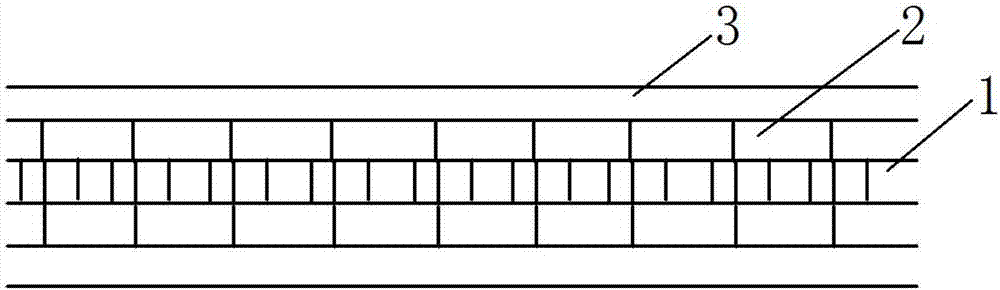

PTC graphene heating printing ink, preparation method thereof and heating film prepared from PTC graphene heating printing ink

InactiveCN107446408AImprove securityAchieving self-limiting temperature characteristicsInksHeating element materialsSilver pasteAdhesive

The invention discloses PTC graphene heating printing ink and a preparation method thereof. The PTC graphene heating printing ink is prepared from the following components in percentages by mass: 50% to 70% of a binder, 9% to 21% of a solvent, 1% to 3% of an additive, 10% to 20% of a conductive filler and 5% to 20% of a PTC functional material. The preparation method comprises the following steps: (1) firstly stirring and dispersing the binder, the solvent and the additive for 20 to 30 min, then adding the PTC functional material into stirring equipment for stirring for 8 to 12 min, and finally adding the conductive filler for uniform stirring to obtain a coarse paste; and (2) carrying out four to six times of three-roller grinding on the coarse paste so as to obtain the PTC graphene heating printing ink. The invention also discloses a heating film. The heating film comprises an organic polymer base material film, the PTC graphene heating printing ink, a conductive silver paste, conductive copper foil and an organic polymer adhesive film. The PTC function of the graphene heating film is increased, the potential safety hazard problem of an existing graphene heating film is eliminated, and the practicability is improved.

Owner:DEYANG CARBONENE TECH

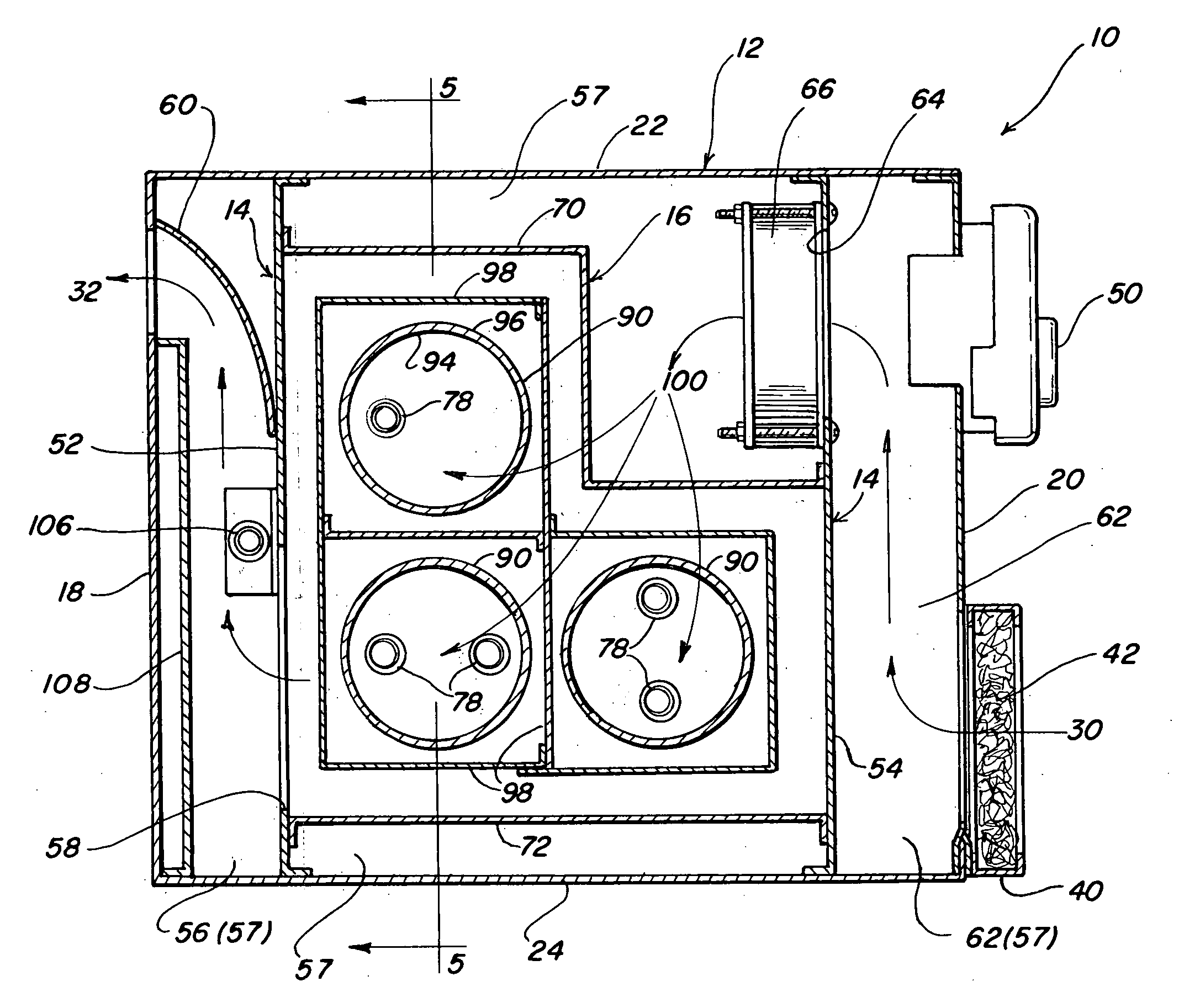

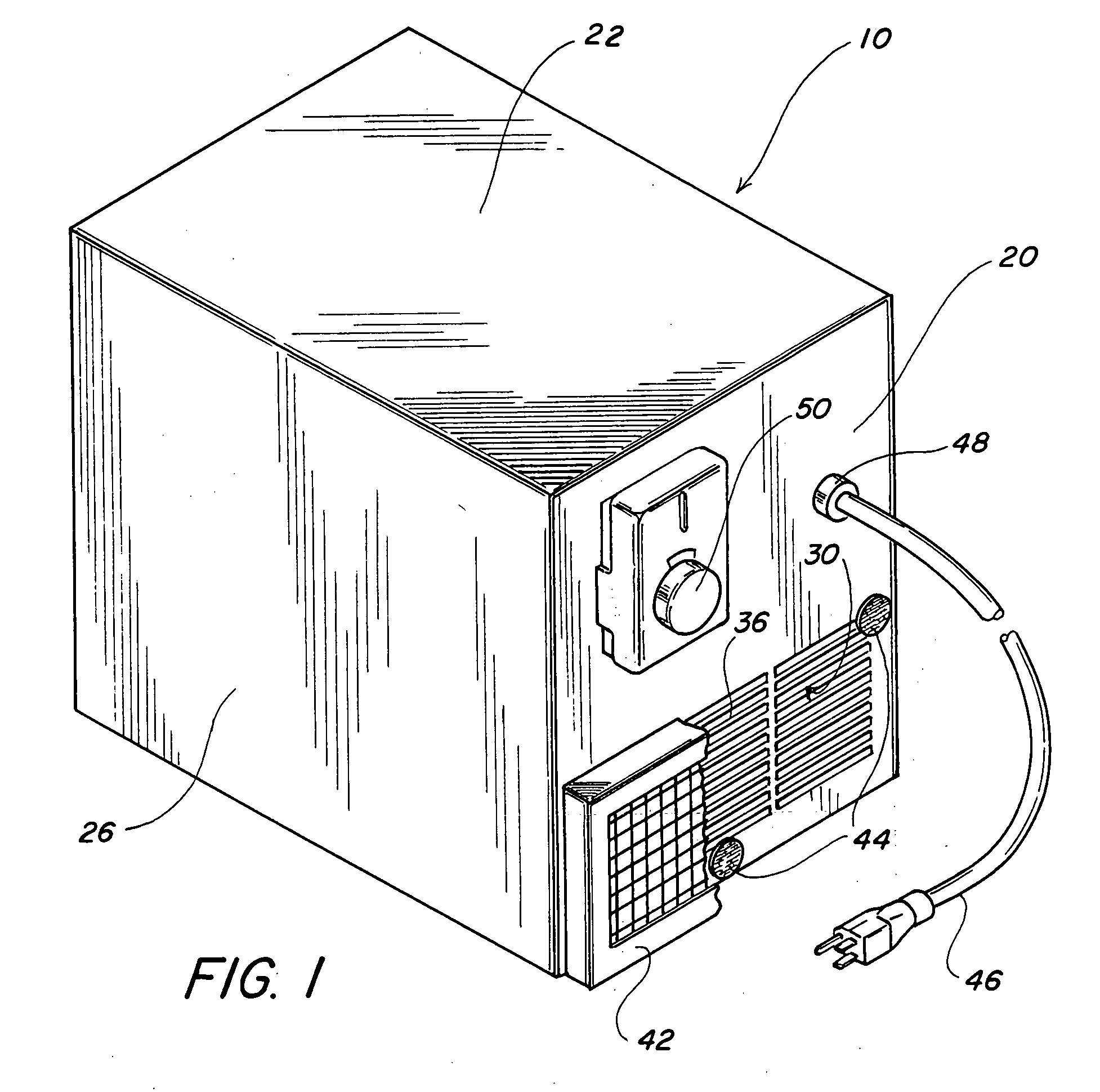

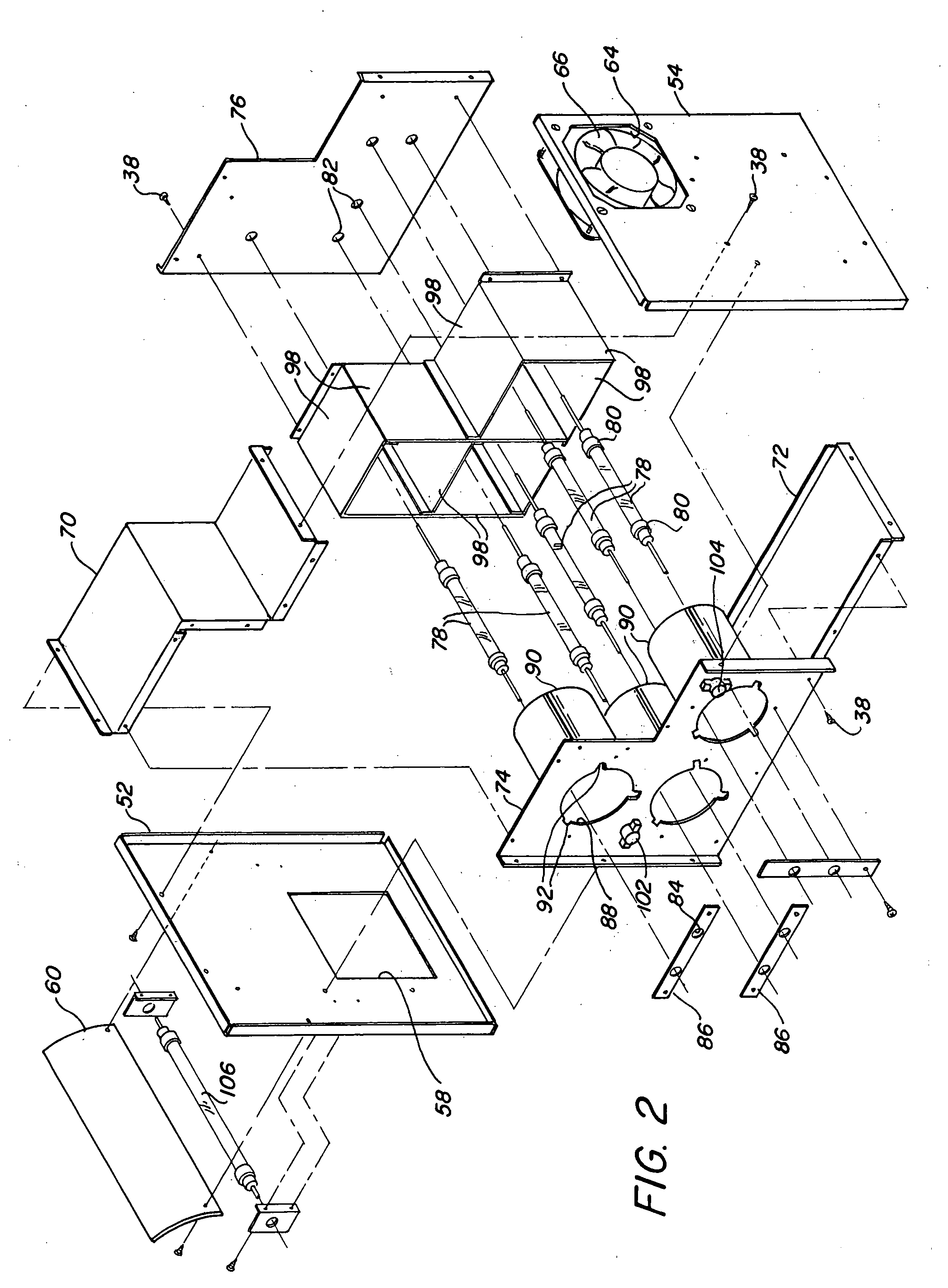

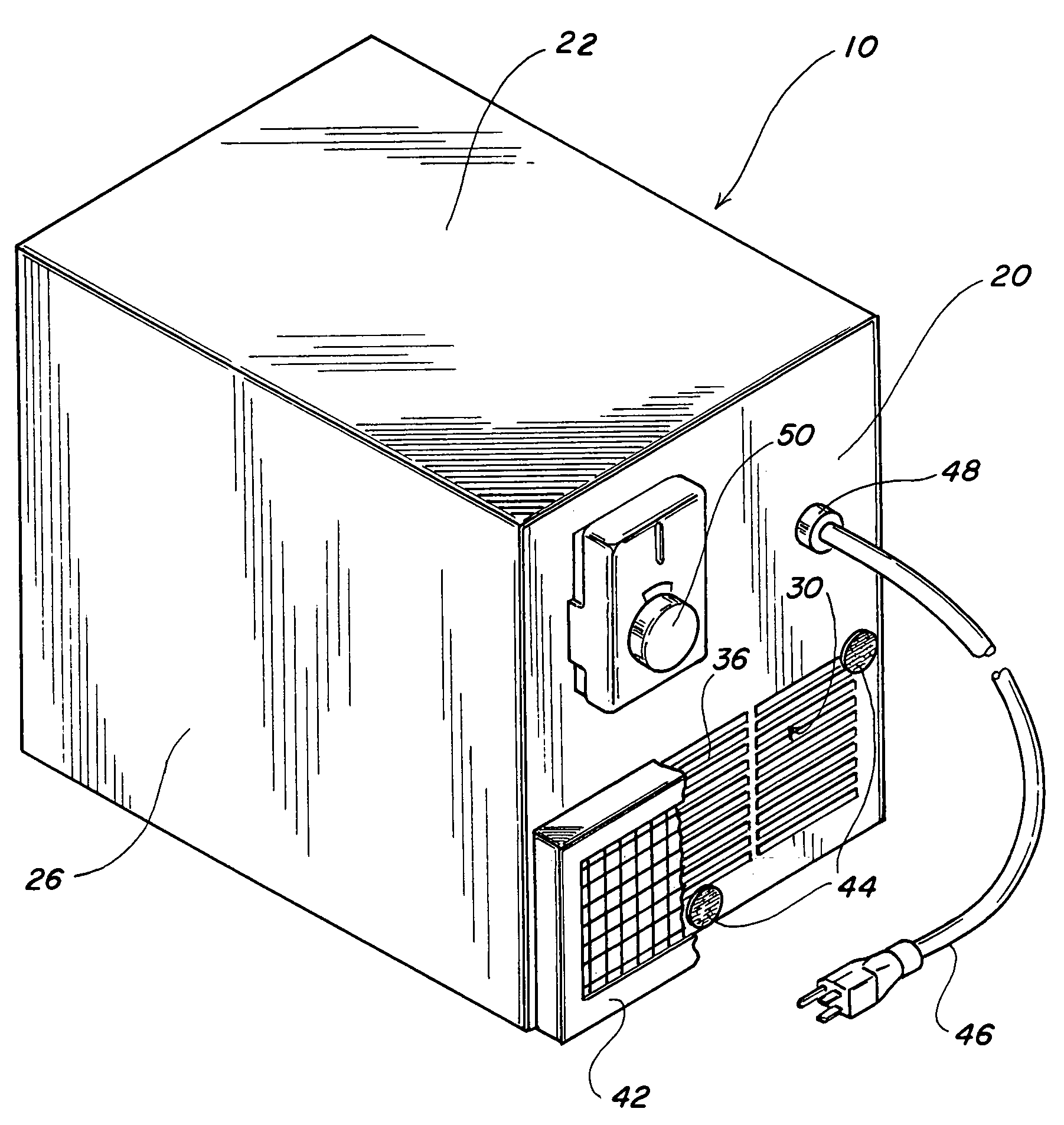

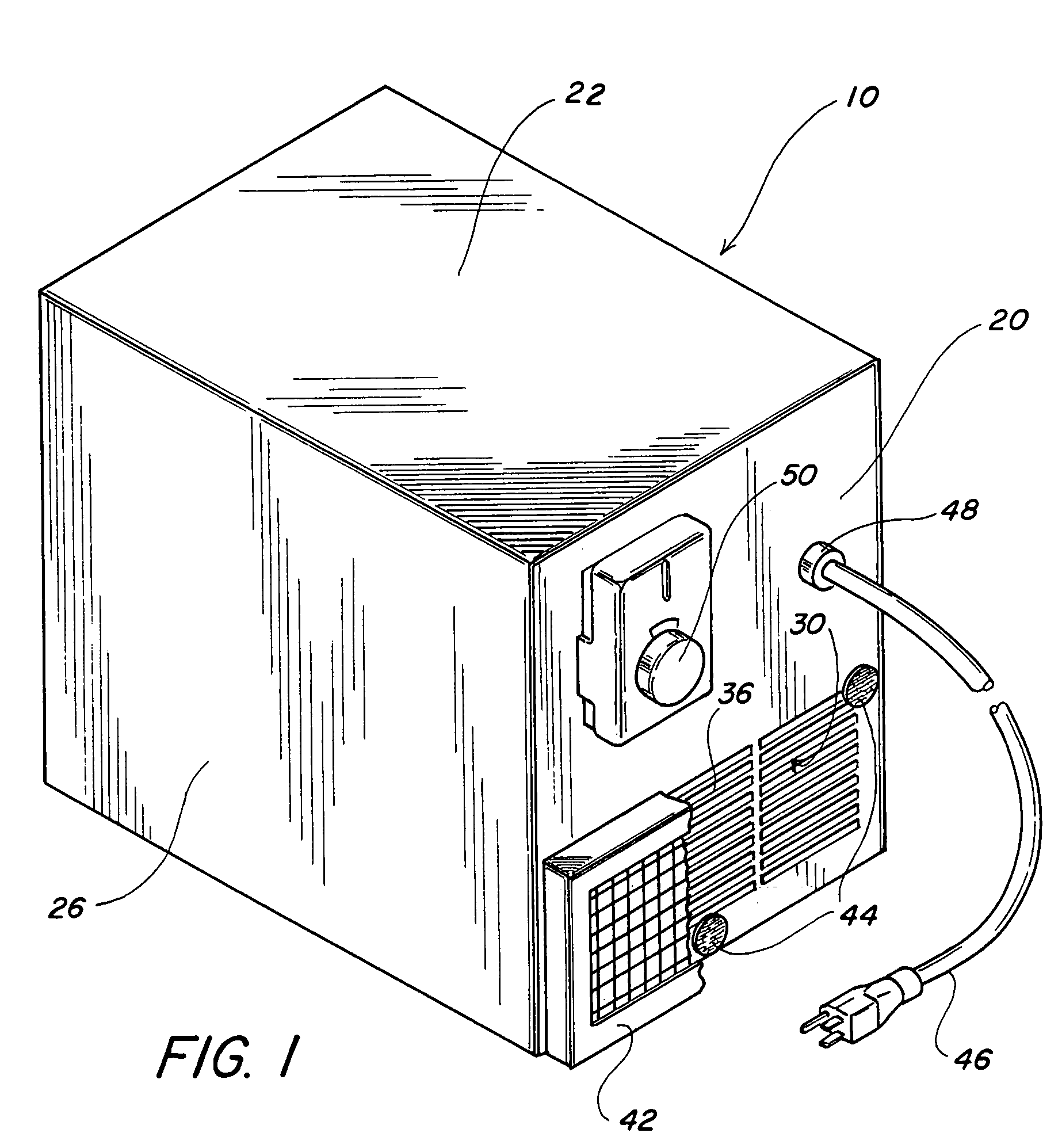

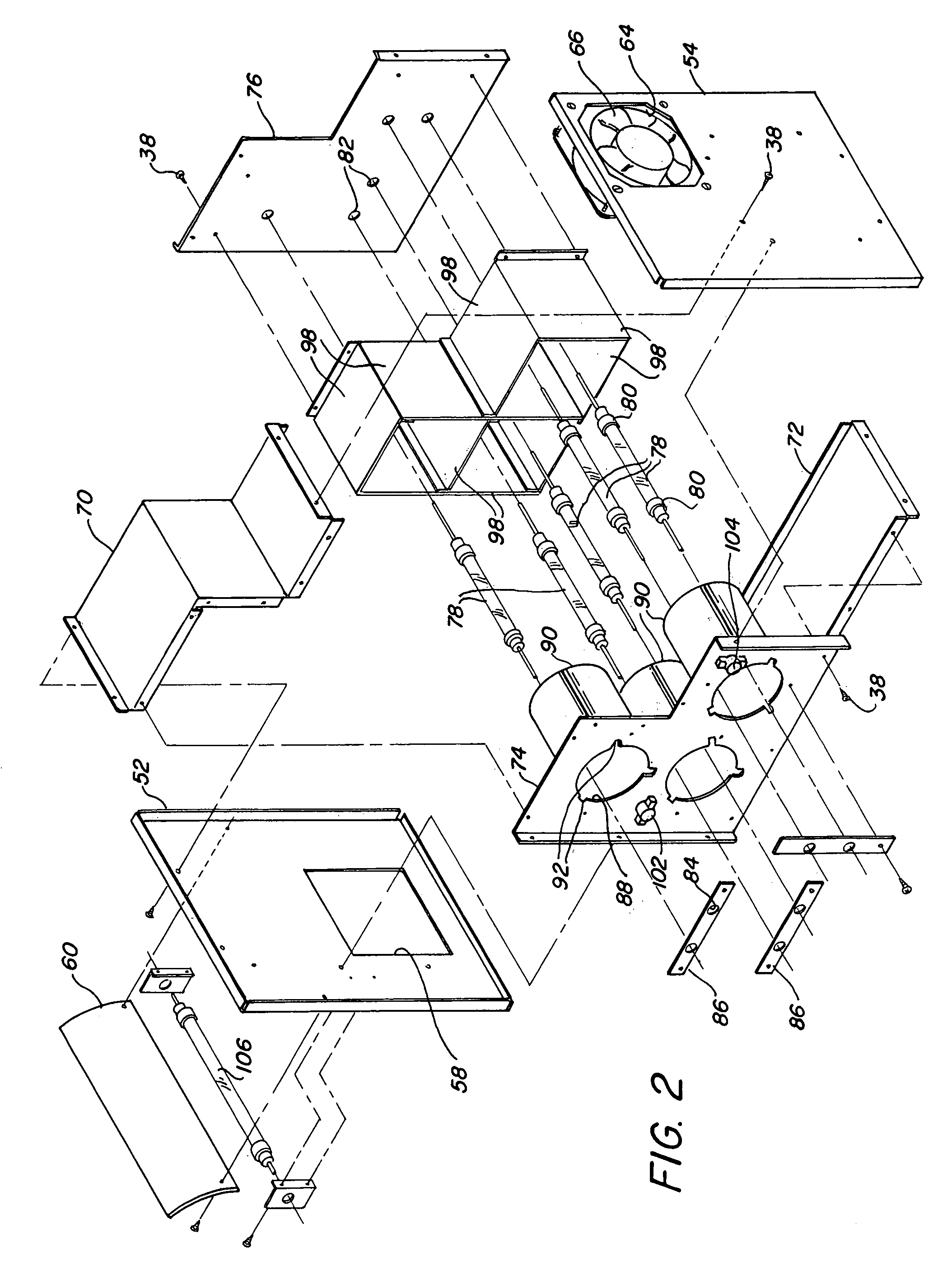

Space heater with pretreated heat exchanger

InactiveUS20060110141A1Improve thermal efficiencySoften copperDomestic stoves or rangesAir heatersElectrolysisEngineering

A space heater with a linear source of infrared radiant energy in heat exchange relationship with a heat exchanger formed of copper or aluminum material. The copper is pretreated to soften the copper and partially blacken the surface thereof. The aluminum is anodized and electrolytically colored dark. The space heater is thermally more efficient than a comparable space heater wherein the copper or aluminum has not been pretreated. The linear source of infrared radiant energy and heat exchanger are mounted in a heater core that is thermally insulated by an air jacket from an exterior case.

Owner:MHE

Space heater with pretreated heat exchanger

InactiveUS7046918B1Improve thermal efficiencySoften copperDomestic stoves or rangesAir heatersElectrolysisEngineering

A space heater with a linear source of infrared radiant energy in heat exchange relationship with a heat exchanger formed of copper or aluminum material. The copper is pretreated to soften the copper and partially blacken the surface thereof. The aluminum is anodized and electrolytically colored dark. The space heater is thermally more efficient than a comparable space heater wherein the copper or aluminum has not been pretreated. The linear source of infrared radiant energy and heat exchanger are mounted in a heater core that is thermally insulated by an air jacket from an exterior case.

Owner:MHE

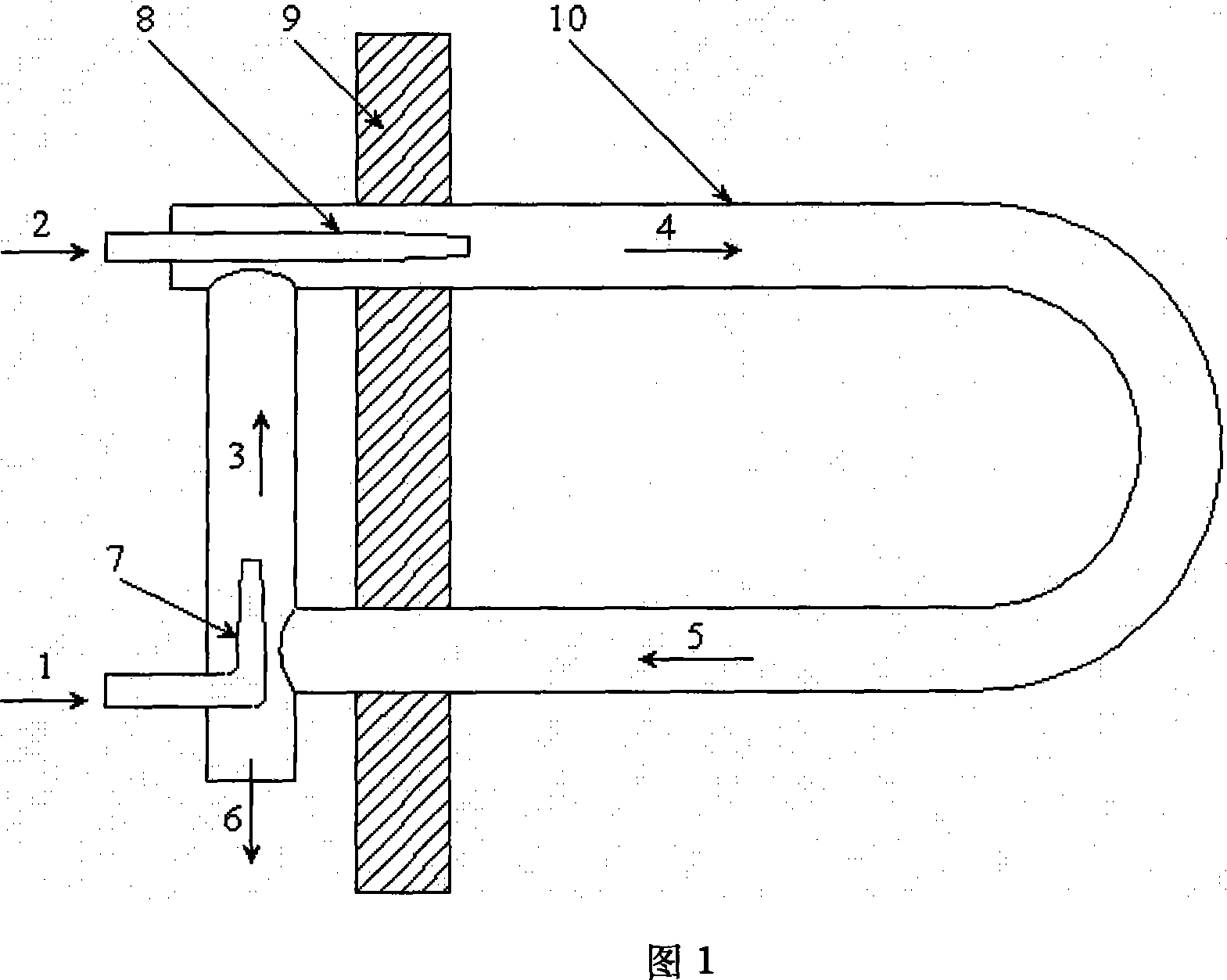

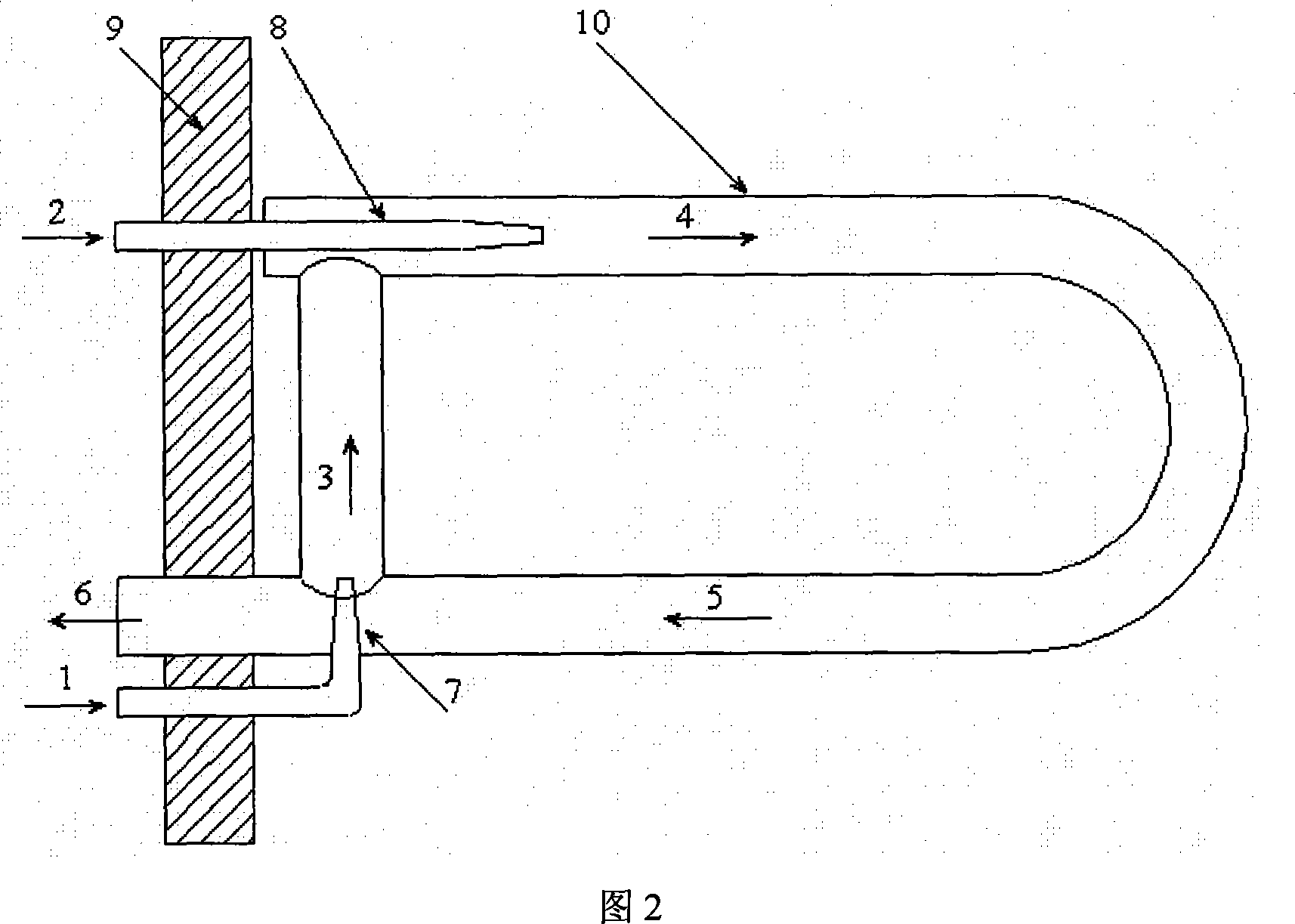

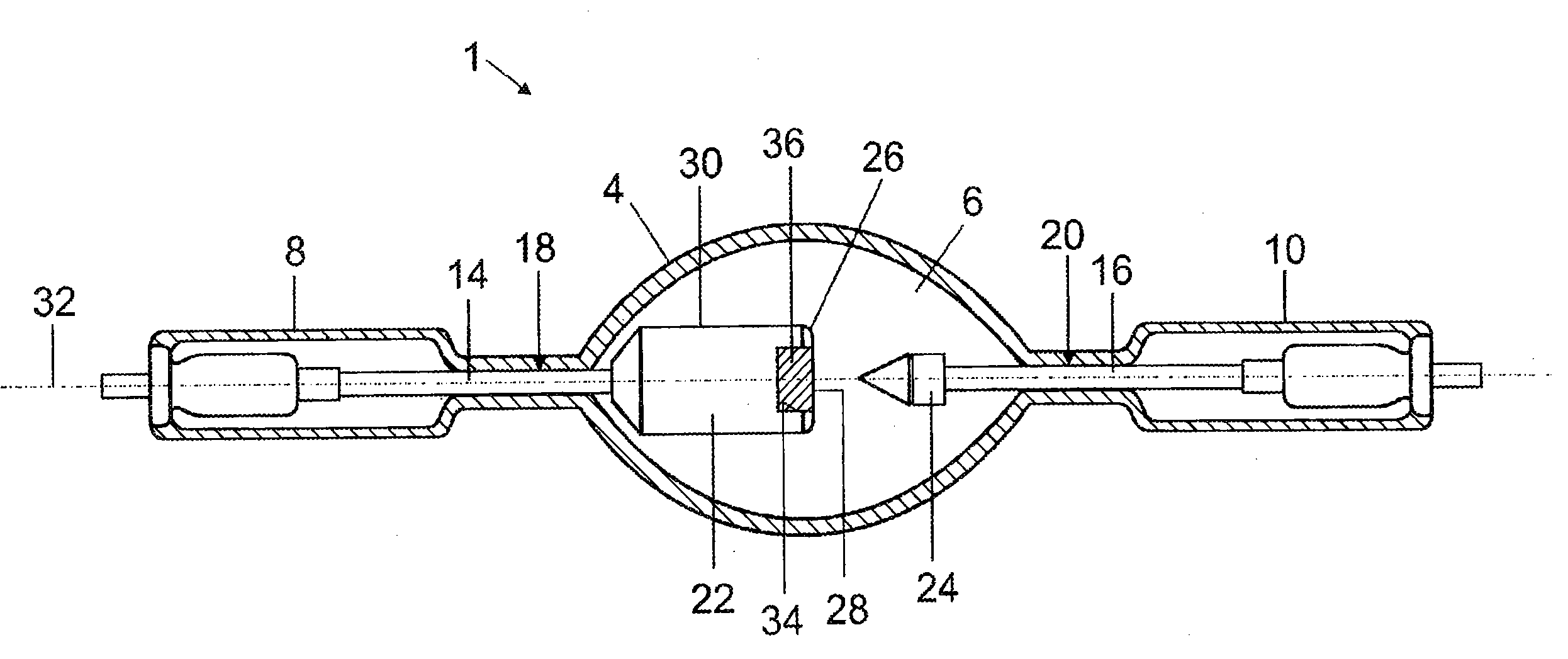

Oxygen-enriched combustion radiant tube heaters

InactiveCN101063525ALower combustion temperatureEnhanced heat transferFurnace typesIndirect carbon-dioxide mitigationInjectorProcess engineering

A radiant-tube heater of oxygen-enriched combustion belonging to the field of environmental protection relates to a new method of oxygen-enriched combustion technology applicable to radiant-tube heater, to develop a combustion system of novel industrial radiant tube that combusts the low-calorific value gas (or other fuel gas) to increase the heat utilization, which is characterized in that the heater comprises oxygen or oxygen-enriched air (1), fuel (2), mixed gas (3) of oxygen or oxygen-enriched air and smoke gas, fuel gas (4), smoke gas (5) in the radiant tube, smoke gas (6) discharged from the radiant tube, a smoke gas injector (7), a combustor (8), a boiler wall (9) and a radiant tube (10). The heater has low combusting temperature, low content of harmful gas like NOx in the smoke gas and high heat efficiency, and is good for collecting the smoke, in particular to CO2 and increases the stability and reliability of the system.

Owner:UNIV OF SCI & TECH BEIJING

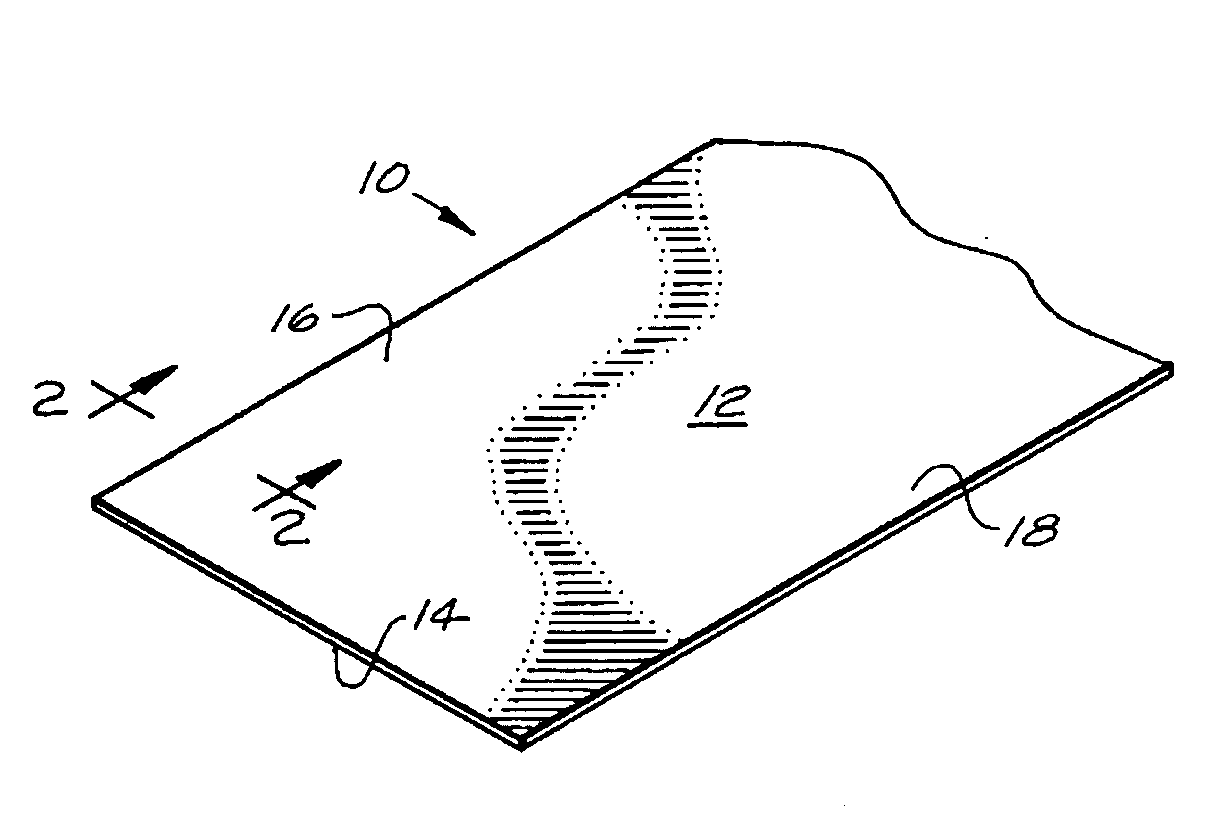

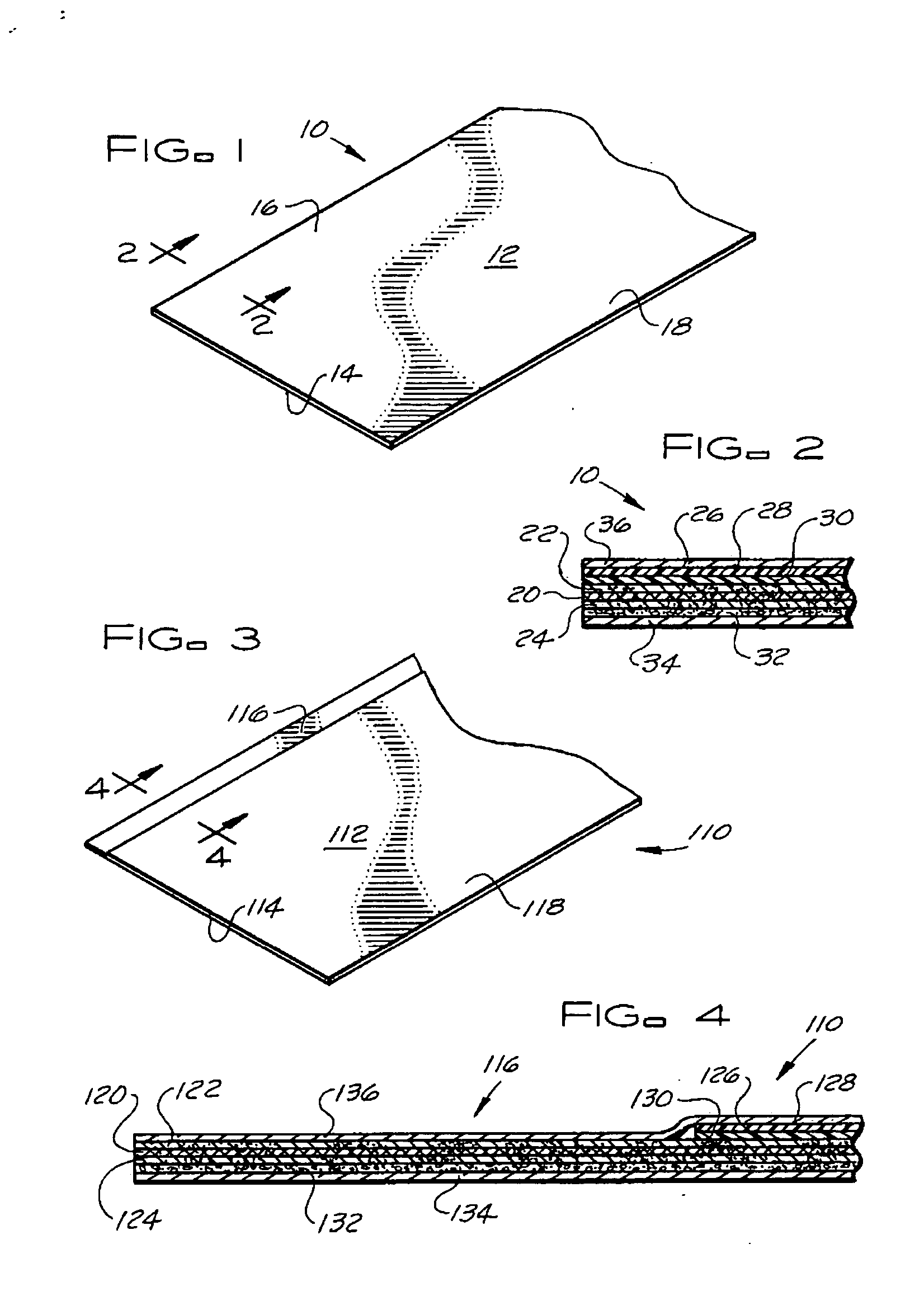

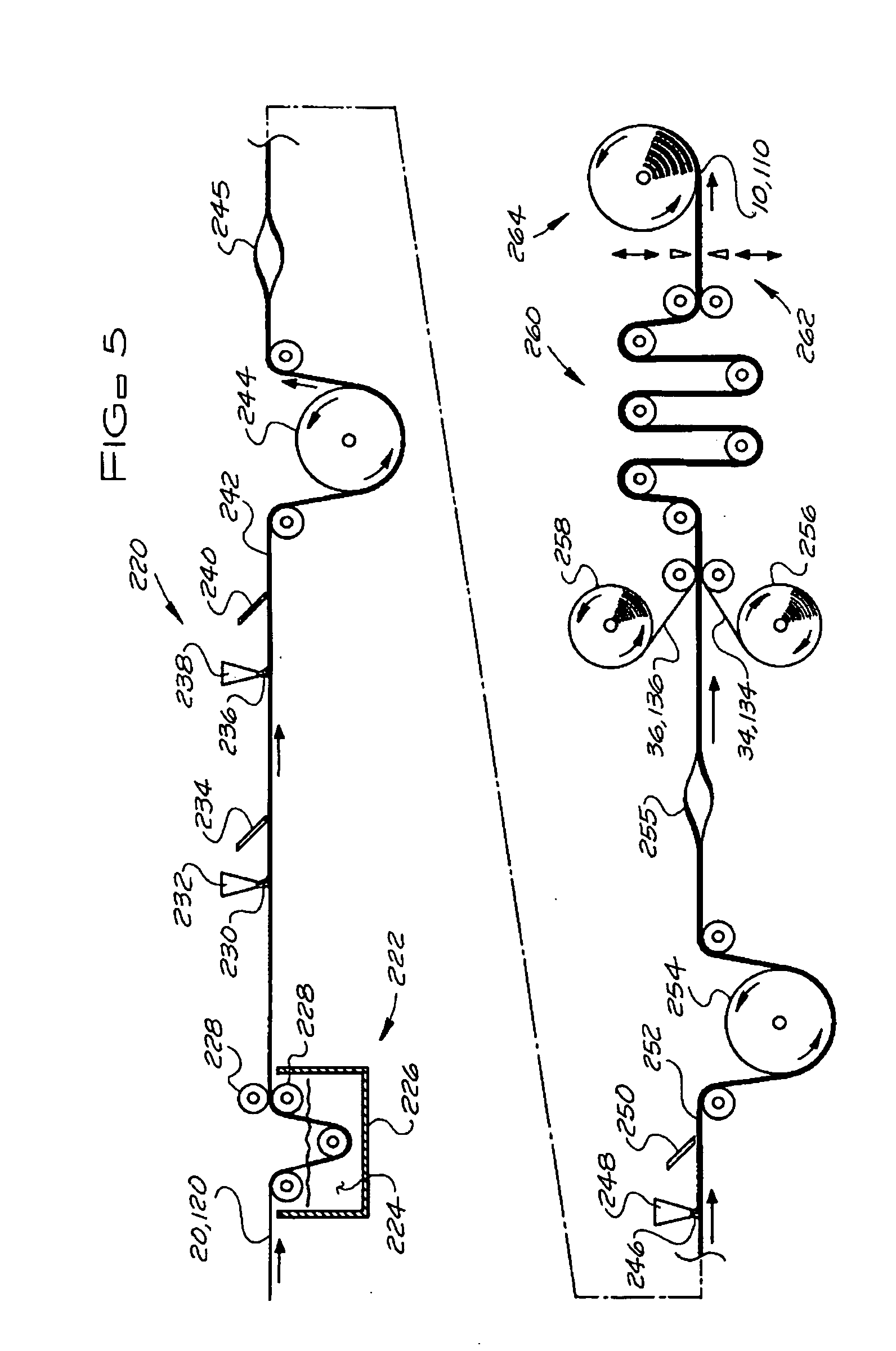

Highly reflective and emissive asphalt-based roofing membrane

InactiveUS20050252137A1Improve reflectivityImprove emissivityRoof covering using tiles/slatesRoof covering using flexible materialsEngineeringAsphalt

A prefabricated asphalt-based waterproof roofing membrane for use in a multi-ply asphalt-based commercial roofing system, e.g. a cap sheet that forms the exposed layer of a multi-ply built-up roofing system, is manufactured at a factory to have a highly reflective and emissive non-asphalt based elastomeric top coating layer. Preferably, a polymer primer layer is interposed between the highly reflective and emissive coating layer and an asphalt saturated and coated reinforcing substrate to keep oils and other colored components in the asphalt from exuding into the highly reflective and emissive coating layer.

Owner:JOHNS MANVILLE CORP

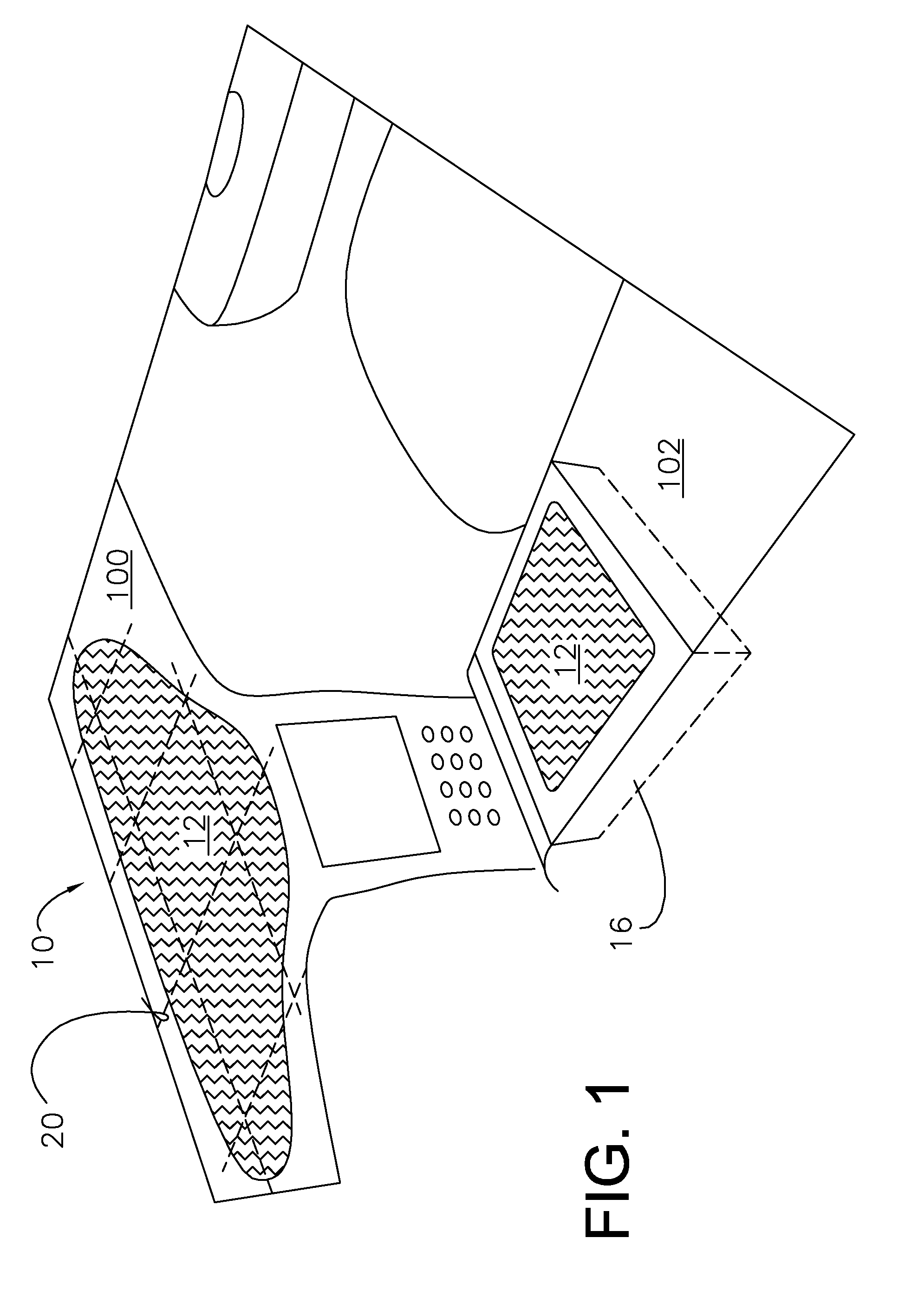

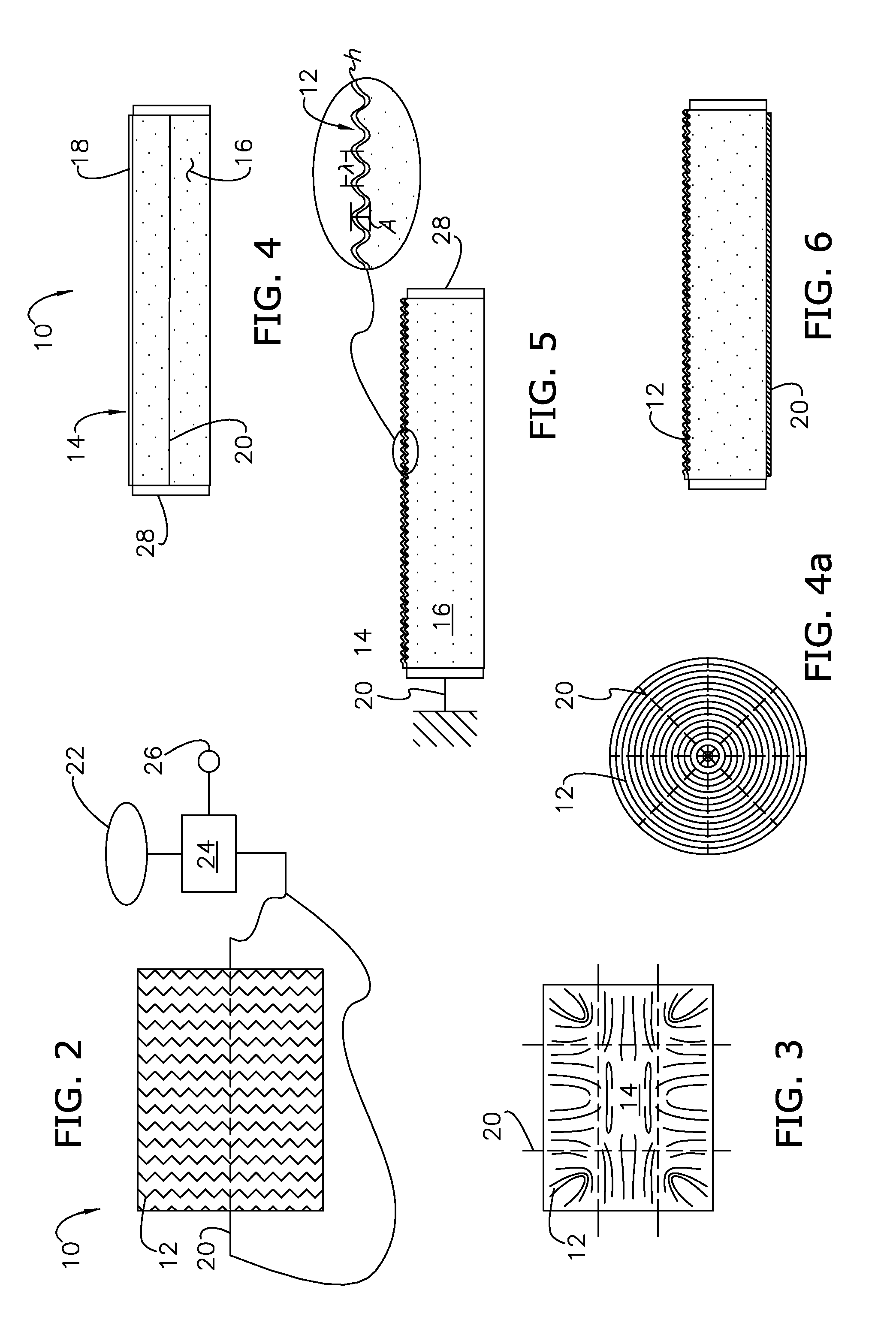

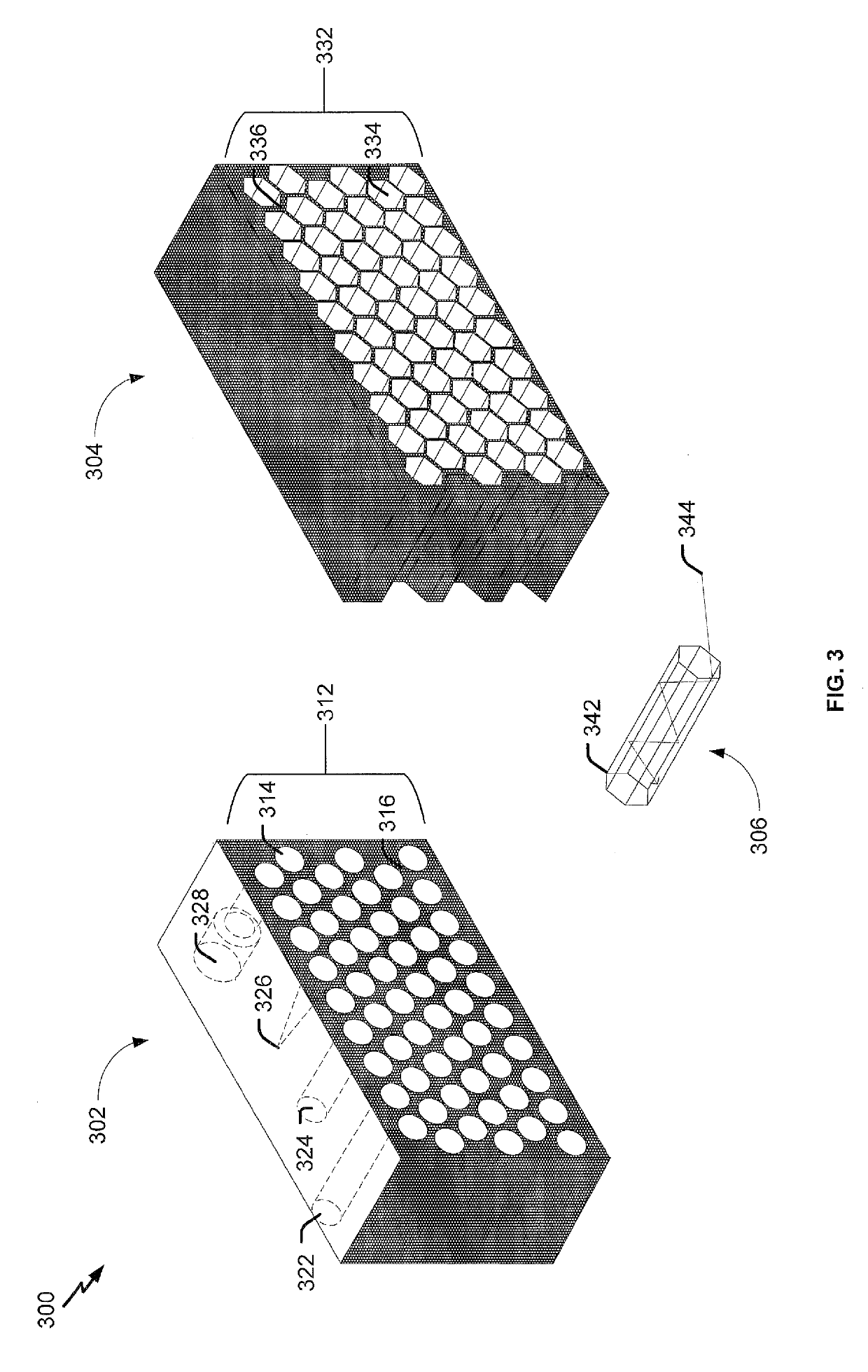

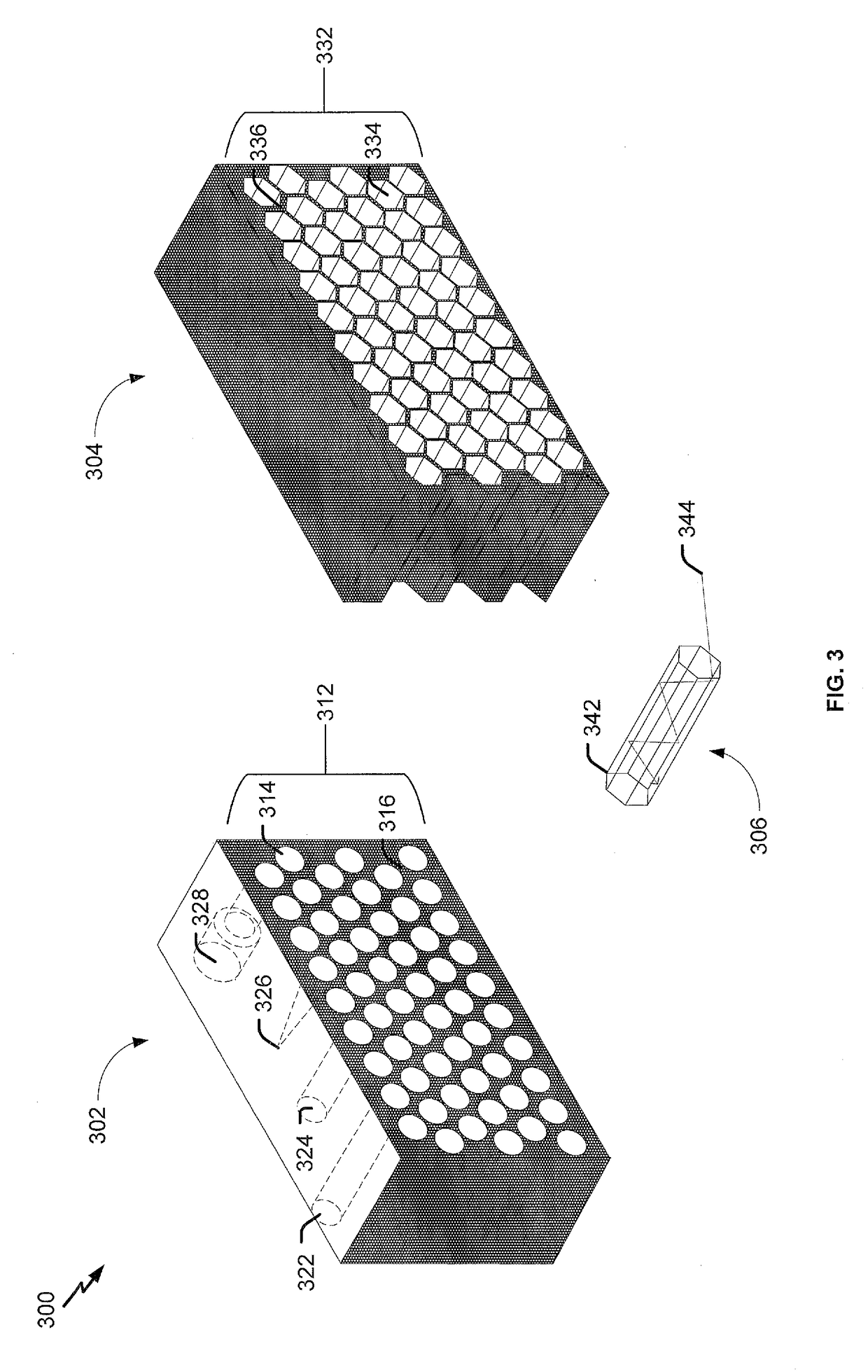

Actively controlled texturing systems

InactiveUS20120015149A1Reducing (or increasing) RADAR scatterDiffuse veiling glareDecorative surface effectsLayered productsWrinkle skinLength wave

Actively controlled texturing systems for and methods of selectively and reversibly forming wrinkles, or modifying the amplitude, wavelength, or pattern of existing wrinkles upon a surface using active material actuation.

Owner:GM GLOBAL TECH OPERATIONS LLC

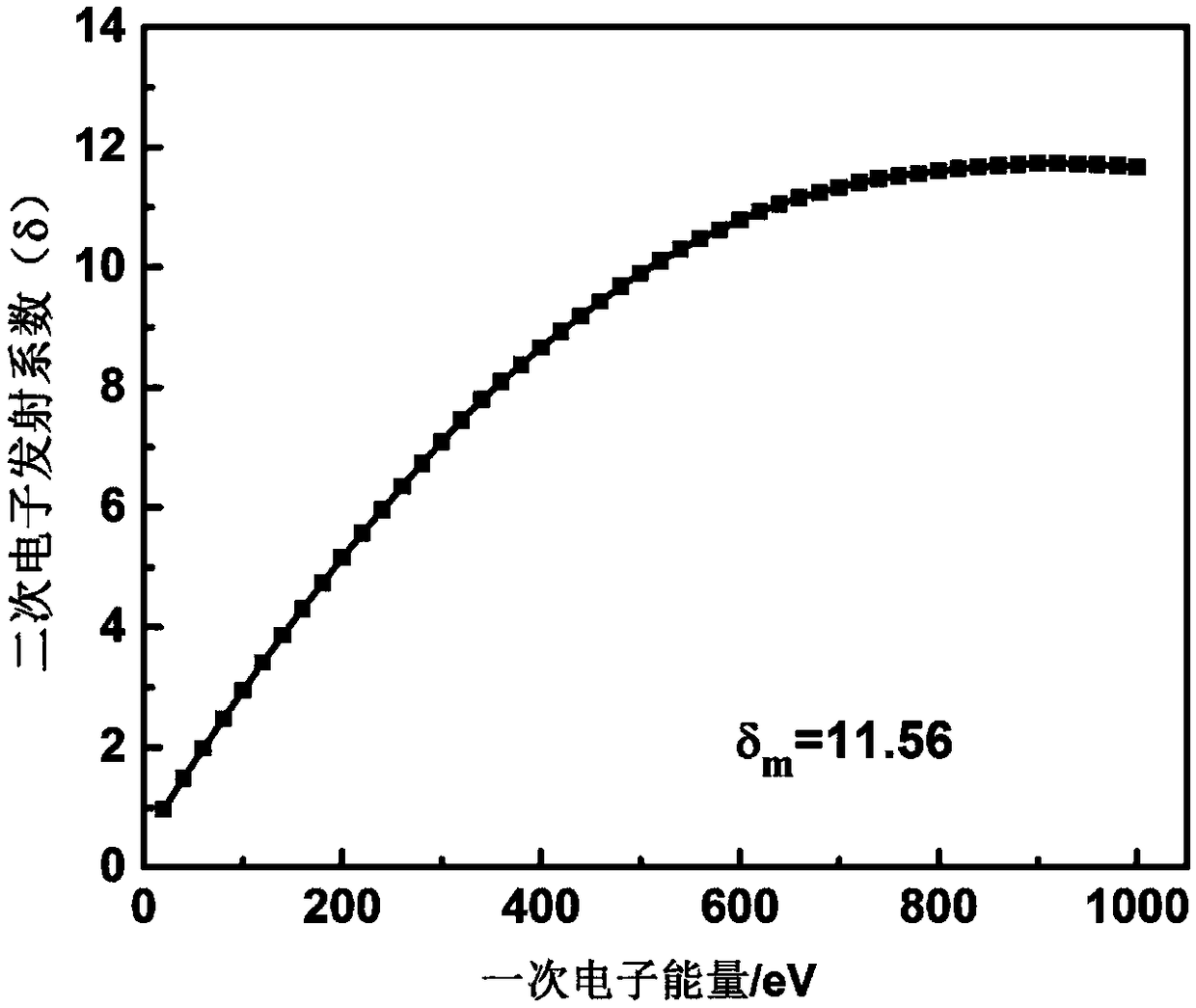

Preparation method of secondary-electron emission thin film

InactiveCN103789730AAdvantages of preparation methodFilm forming process is flexibleVacuum evaporation coatingSputtering coatingSputteringSecondary electrons

The invention discloses a preparation method of a secondary-electron emission thin film. The preparation method comprises the following steps: (1) depositing a buffer layer on a metal substrate; (2) depositing a magnesium oxide and metal mixed layer on the buffer layer by sputtering a magnesium target / magnesium oxide target and sputtering other metal targets; (3) depositing a surface on the magnesium oxide and metal mixed layer. In the step (2), the two targets are used for respectively depositing magnesium oxide and other metals, the sputtering power, the sputtering time, the flow rates of working gas and reactant gas and the temperature of the substrate are individually controlled so as to prepare the magnesium oxide and metal mixed layer with proper magnesium oxide and metal grain size, magnesium oxide crystallization orientation, metal content and distribution of metal grains in a membrane layer and thickness of the membrane layer. The secondary-electron emission thin film prepared by the method has high secondary electron emission yield and good electrical conductivity, and therefore, the secondary-electron emission thin film has high secondary-electron emission stability.

Owner:XI AN JIAOTONG UNIV

Device and method for inhibition of charge injection under transient electric field

InactiveCN107578861AImprove electron work functionIncreased operating lifeWindings insulation materialWindings insulation shape/form/constructionOvervoltageEngineering

The invention relates to the technical field of power transmission and distribution equipment, in particular to a device and method for inhibition of charge injection under a transient electric field.When a high-voltage electric appliance operates in a transient overvoltage waveform, a local high-voltage electric field enables charge injection into an insulating medium and enables continuous physical processes of charge injection and extraction and the like under the action of external stress, and consequently local electric field distortion is aggravated, and internal breakdown and surface flashover faults can be probably caused. The method for inhibition of charge injection under the transient electric field includes steps: selecting a magnesium oxide target material, and adopting a magnetron sputtering instrument to form a magnesium oxide film on the surface of a substrate; performing insulating coverage on a high-voltage equipment current-carrying module by the aid of the substrate. The electron work function of a metal insulating interface can be increased, the surface secondary electron emission coefficient is increased, and insulating surface flashover starting voltage under a high vacuum condition is raised.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

High-radiation coating applied to outer wall surface of rhenium-iridium engine combustion chamber

The invention relates to a high-radiation coating applied to the outer wall surface of a rhenium-iridium engine combustion chamber. The high-radiation coating is prepared through the steps of preparing mixed powder by taking HfO2 as a main part and Pr6O11 as an additive part through a roasting process; and after ball milling and sieving the mixed powder, preparing the coating on the surface of the combustion chamber with a rhenium-based iridium coating by taking powder with the particle size of 40-80mu m as a plasma spraying raw material through a plasma spraying technology, wherein the key process parameters are as follows: the voltage is 50-70V, the current is 650-750A, the argon flow is 80-100L / min, the hydrogen flow is 10-12L / min, the supply air rate is 30-50g / min, the service life of the prepared coating can be kept for 8 hours at the temperature of 2000 DEG C, and the radiation coefficient is not lower than 0.85. The high-radiation coating is applied to the outer surface of the rhenium-iridium engine combustion chamber, can be used for effectively reducing radiant heat loss and reducing the wall surface temperature of the combustion chamber and is significant in improving the working reliability of an engine.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

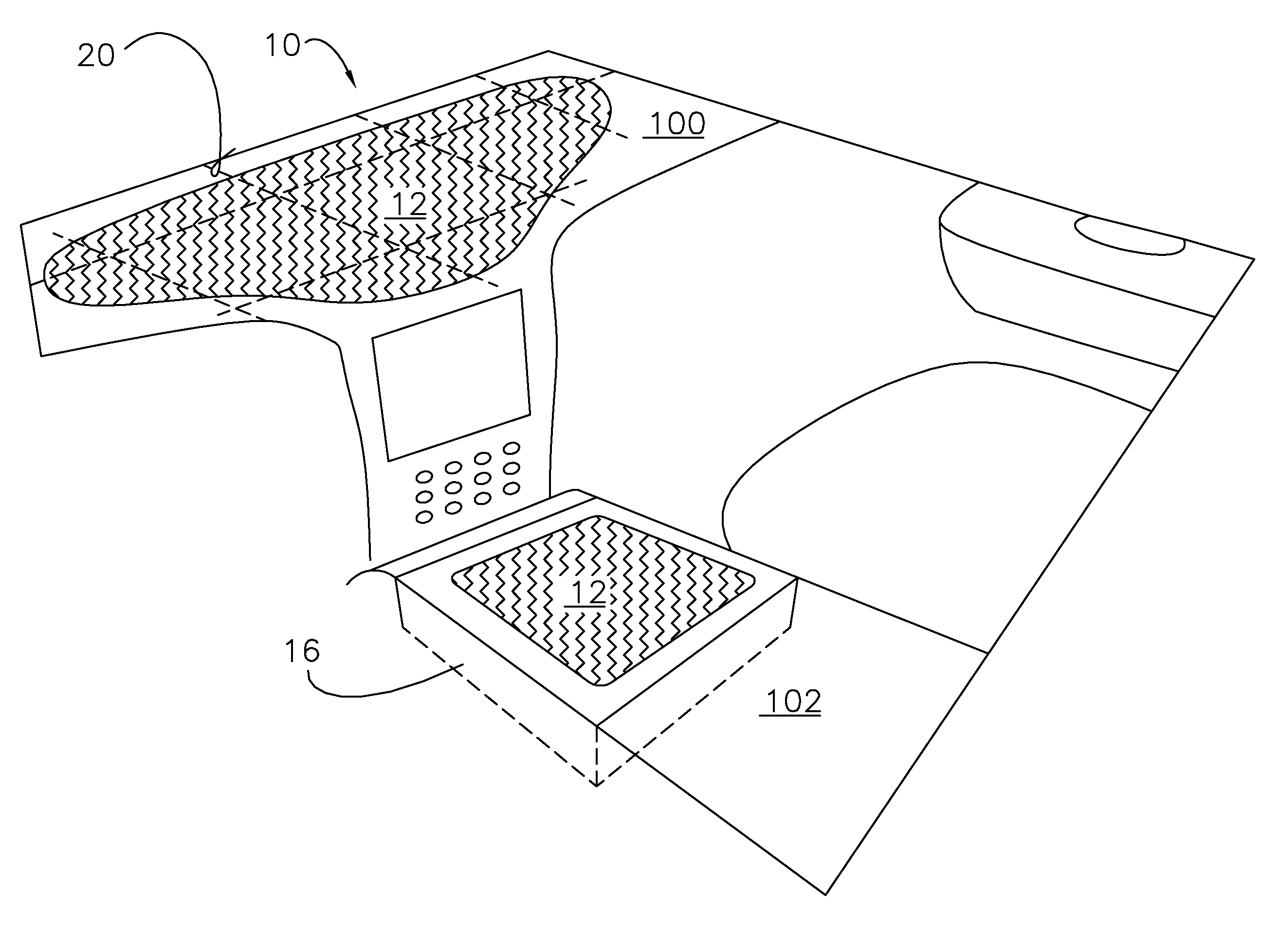

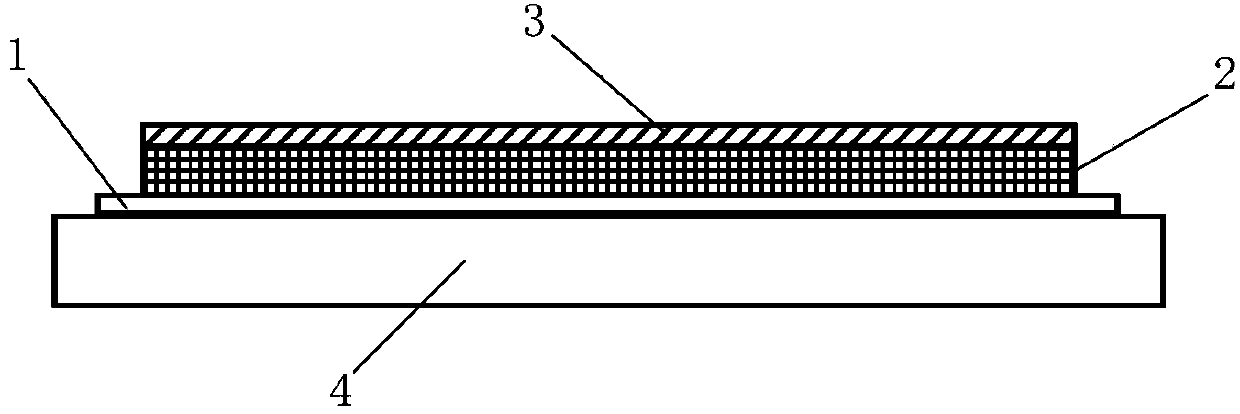

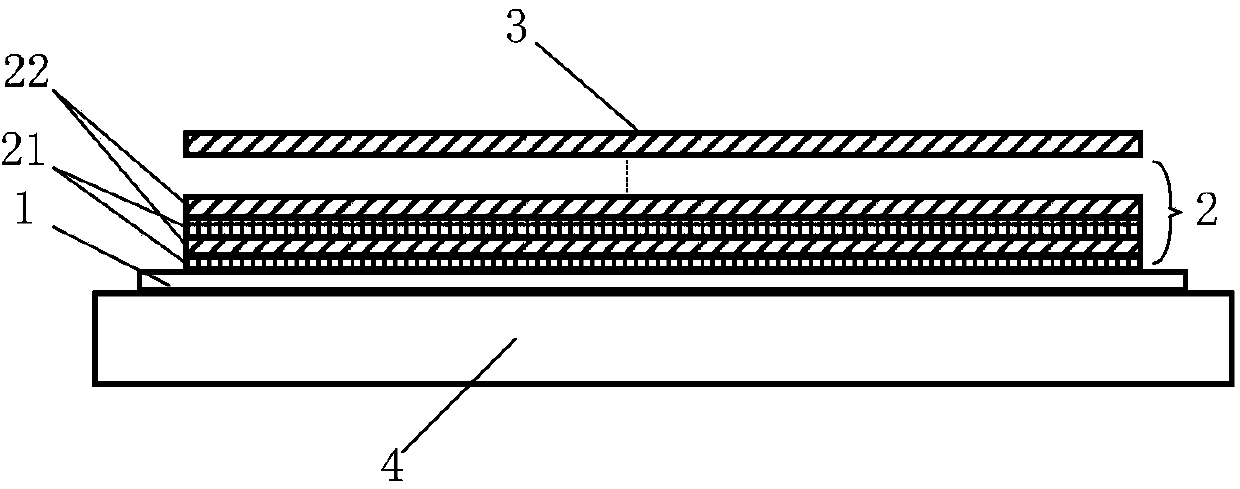

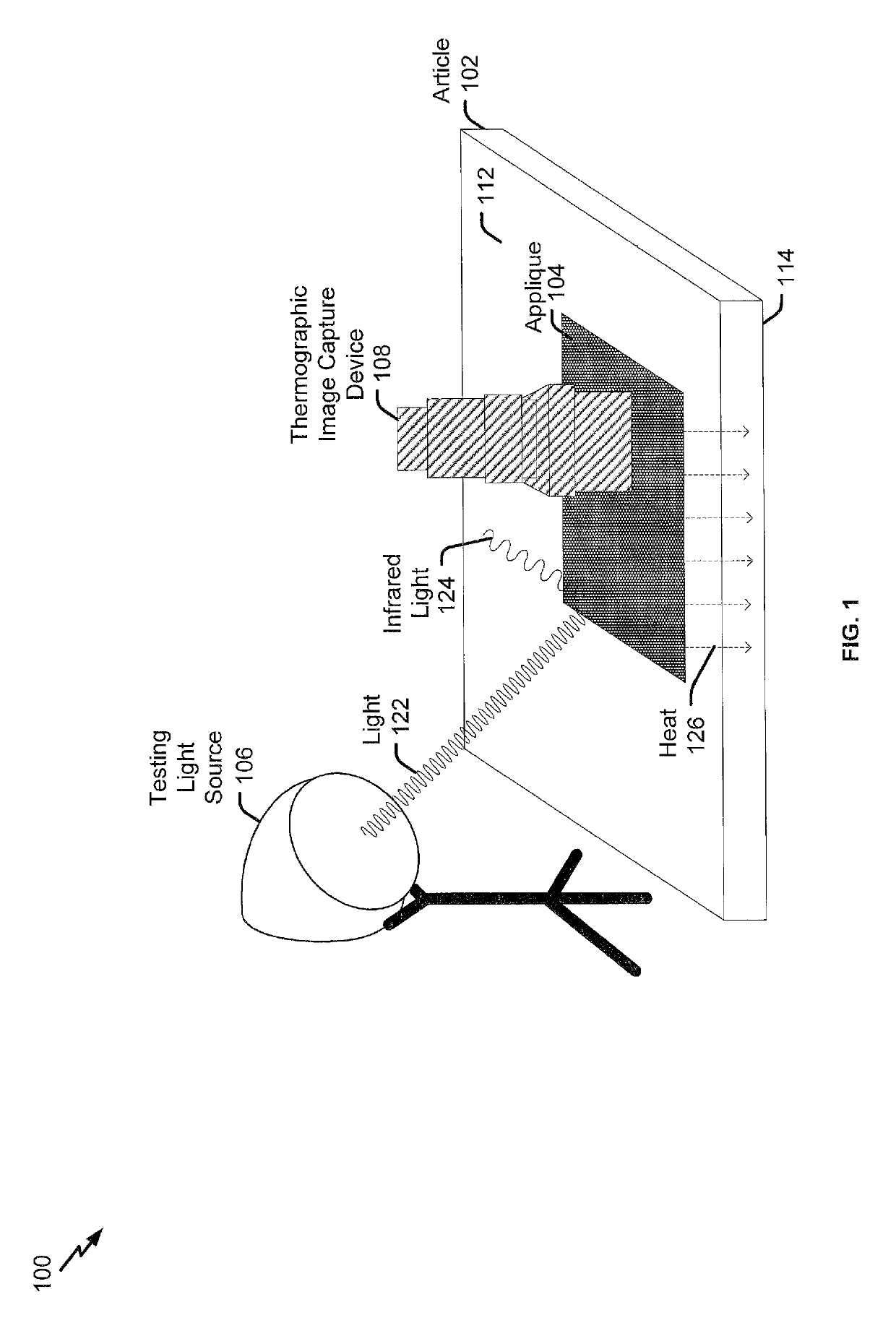

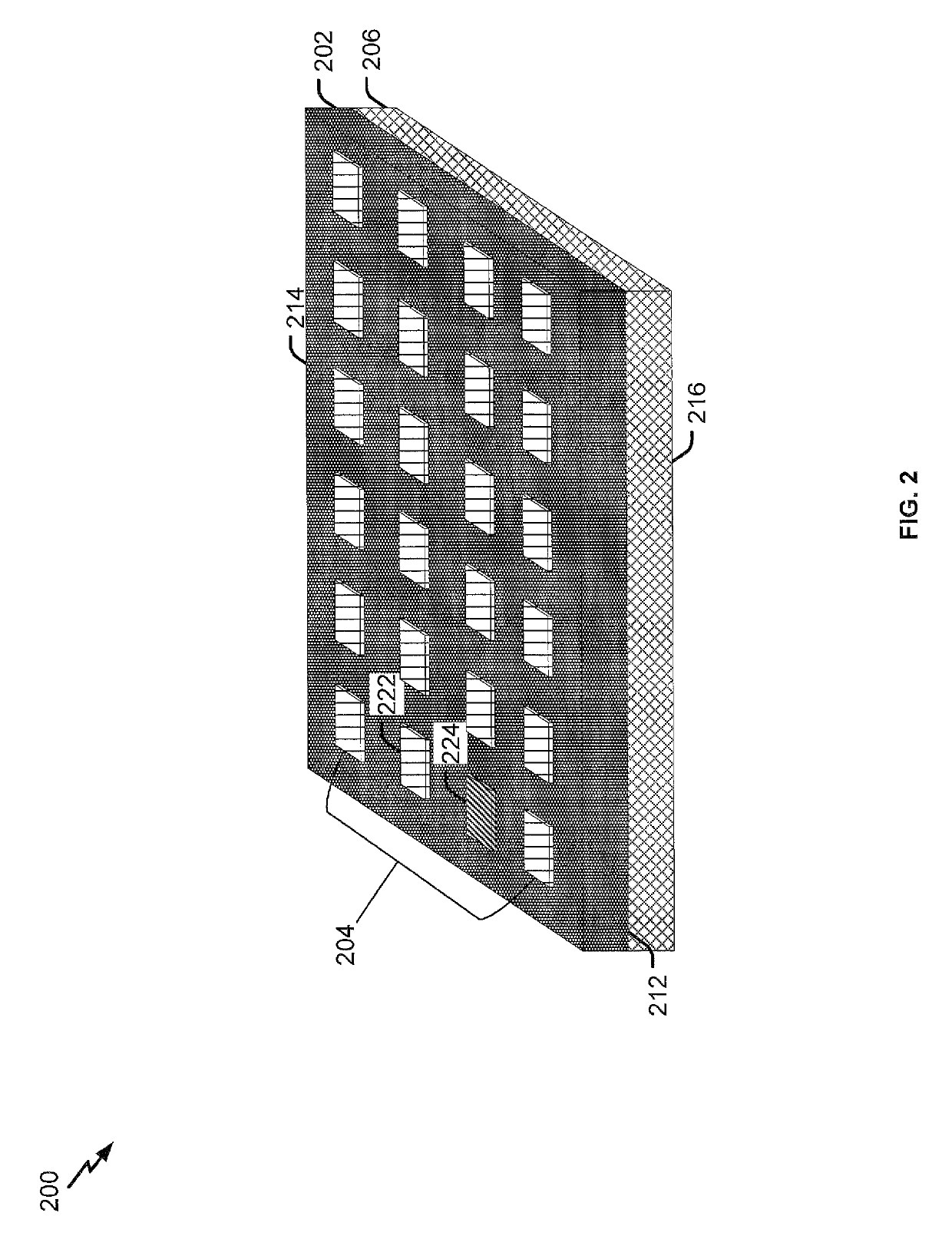

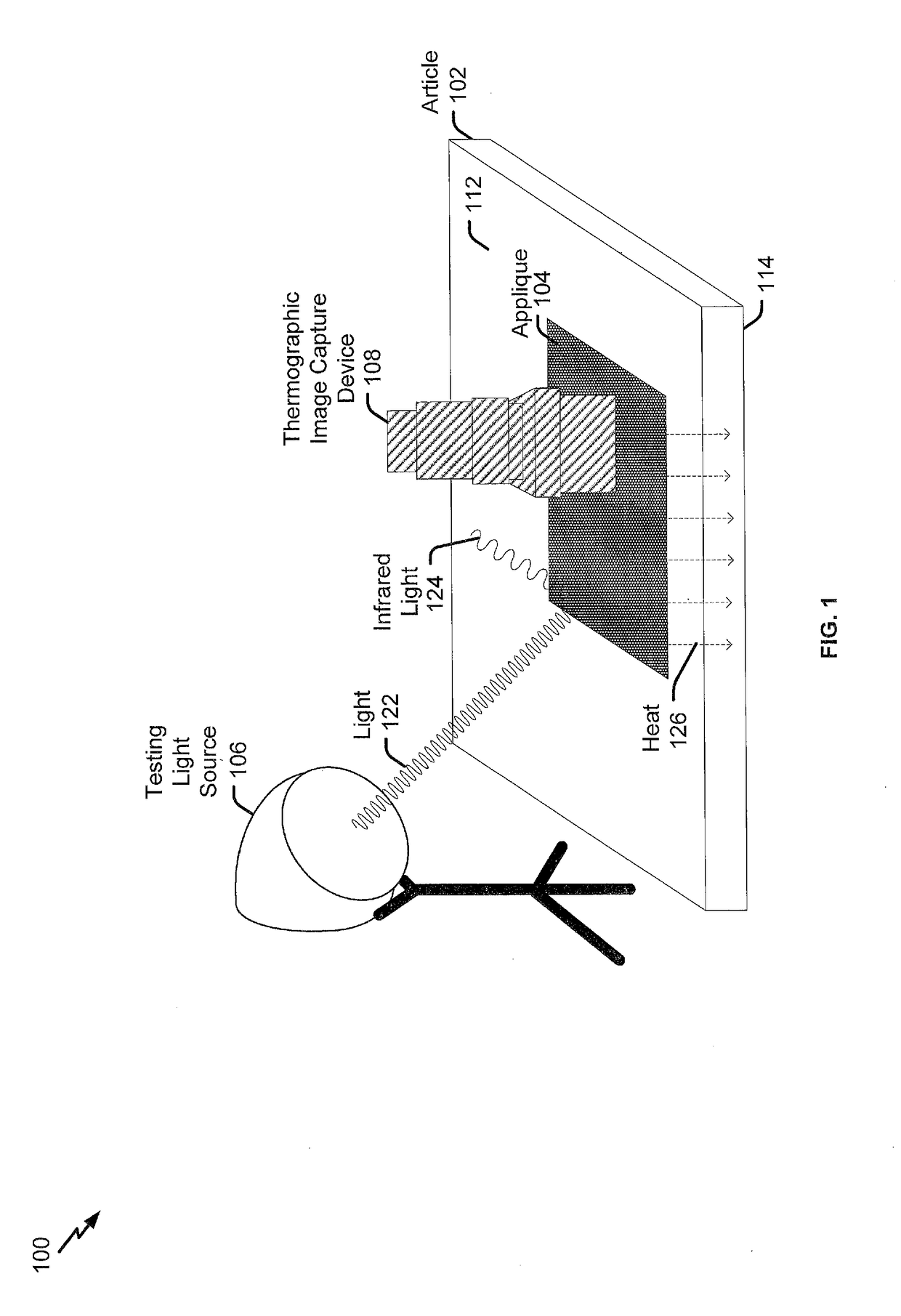

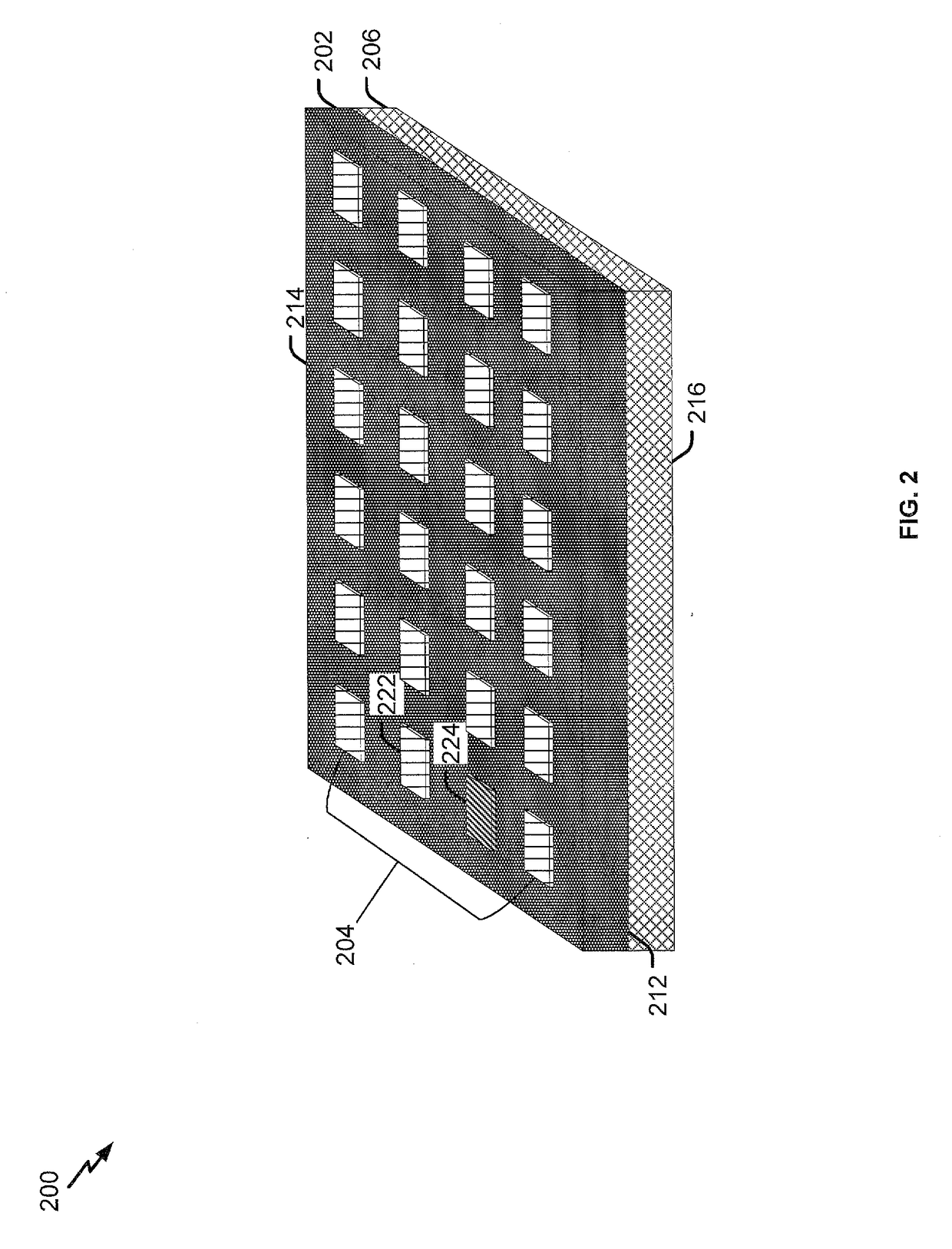

Applique and method for thermographic inspection

ActiveUS10260953B2High quality thermographic imageIncrease absorptivityOptically investigating flaws/contaminationMaterial flaws investigationOptoelectronicsThermal radiation

A method of thermographic inspection includes absorbing, at an applique applied to a test area of an article, light from a testing light source. The method further includes emitting, by the applique, thermal radiation directed to a capture device, the thermal radiation corresponding to at least a portion of the light absorbed by the applique.

Owner:THE BOEING CO

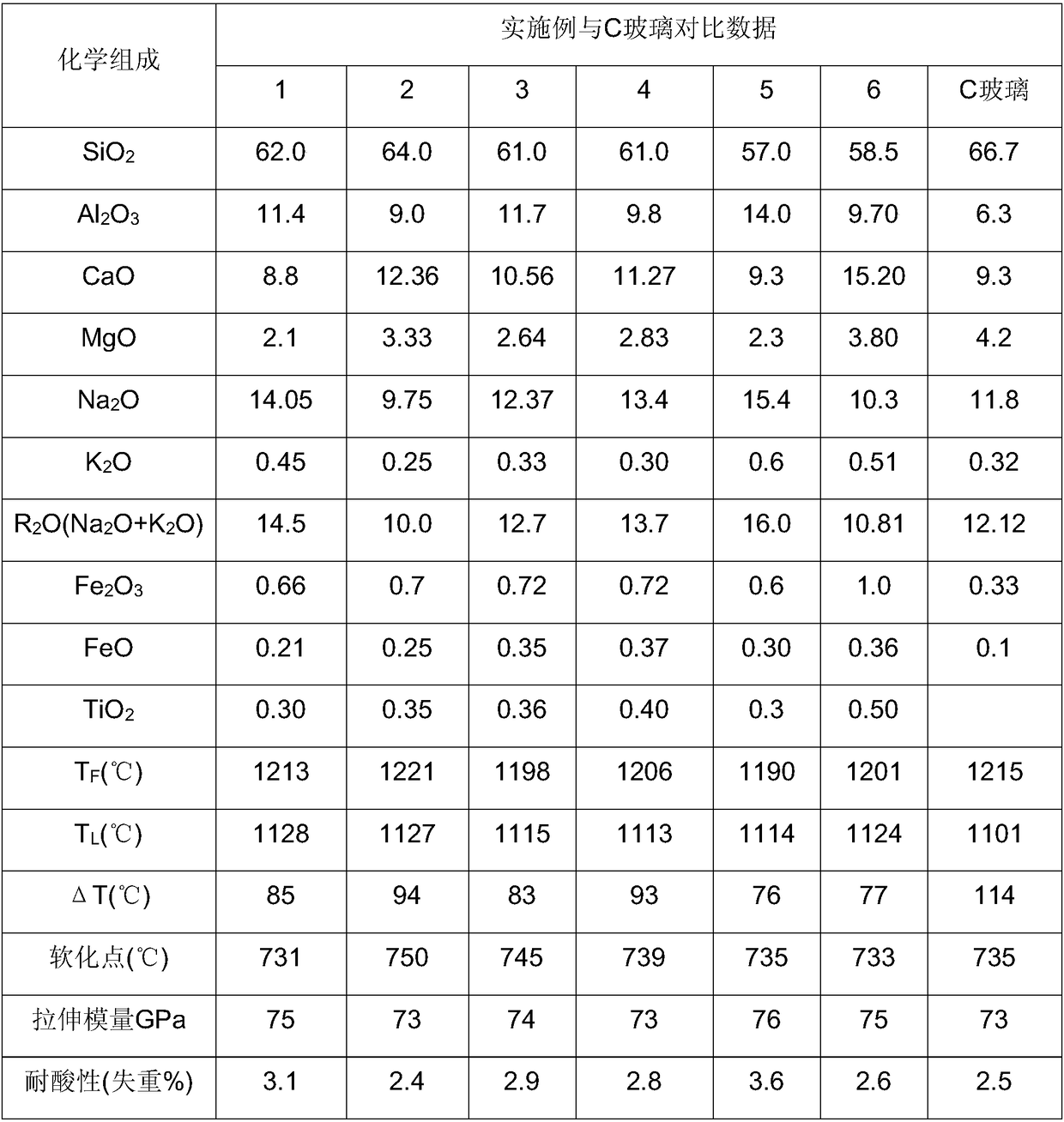

Fiberizable glass composition and preparation method

ActiveCN108545949AReduce the use of soda ashReduce formulation costsGlass making apparatusInorganic ChemicalMaterials science

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

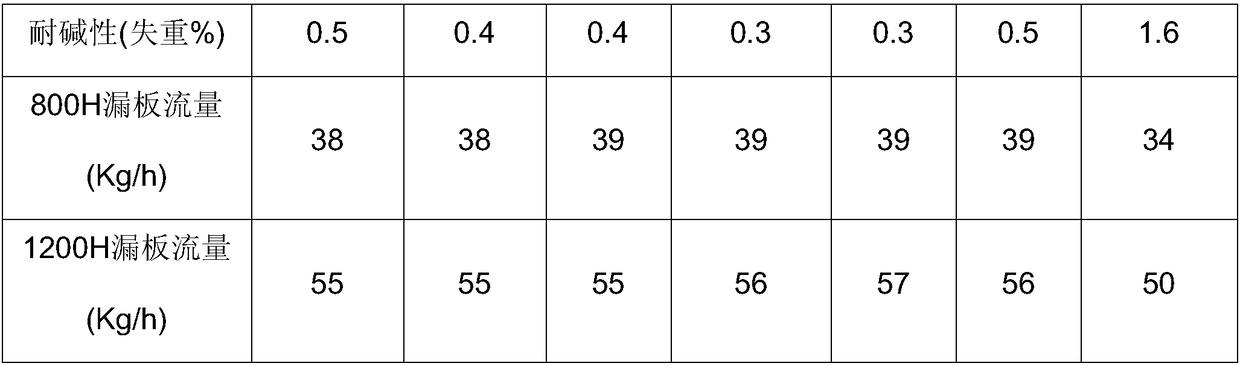

Composite oxidation method for metallic products

InactiveCN101376999AHigh hardnessImprove wear resistanceAnodisationMetallic material coating processesMetal

The invention provides a composite oxidization method of a metal product, which comprises the following steps: the metal product to be treated receives conductive oxidization treatment; an area on the metal product after conductive oxidization treatment to be conducted is shielded; the shielded metal product receives anode oxidization treatment; the shielding of the area is removed. The method can prepare the metal product with low cost and high yield according to the intention of the designer.

Owner:新奇点智能科技集团有限公司

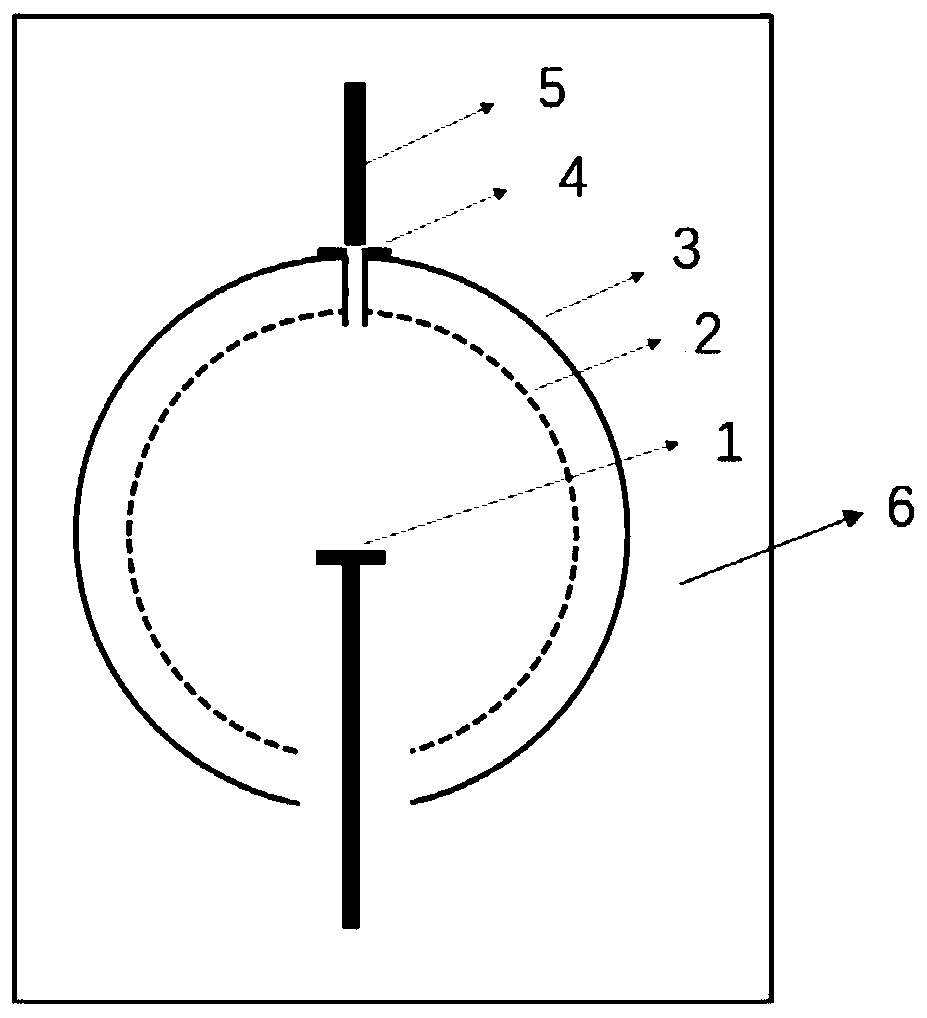

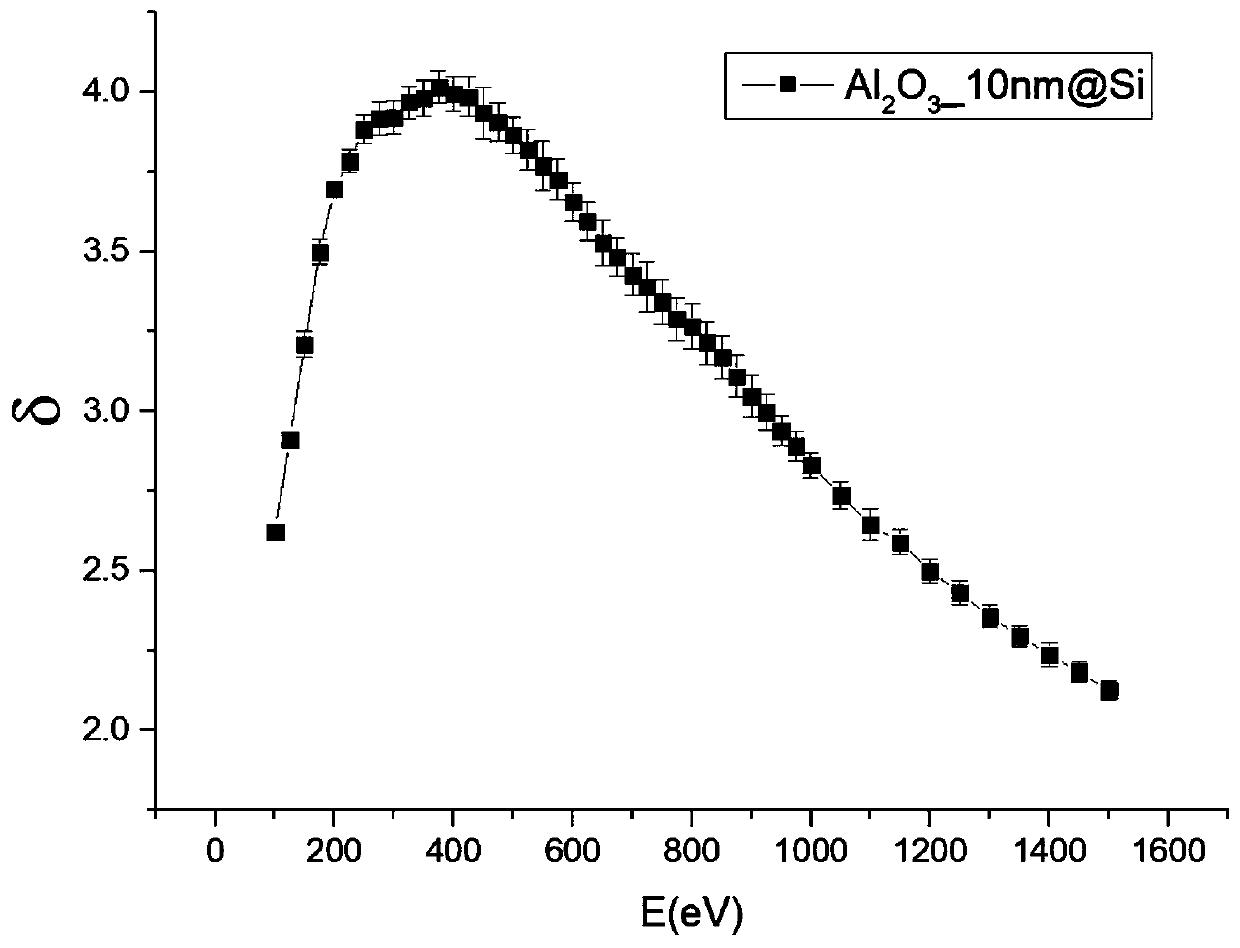

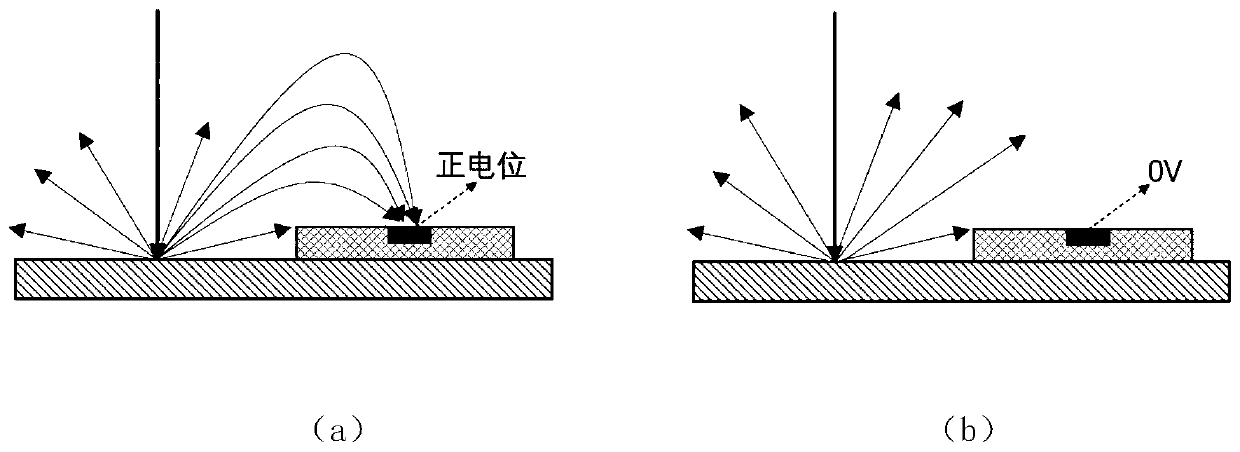

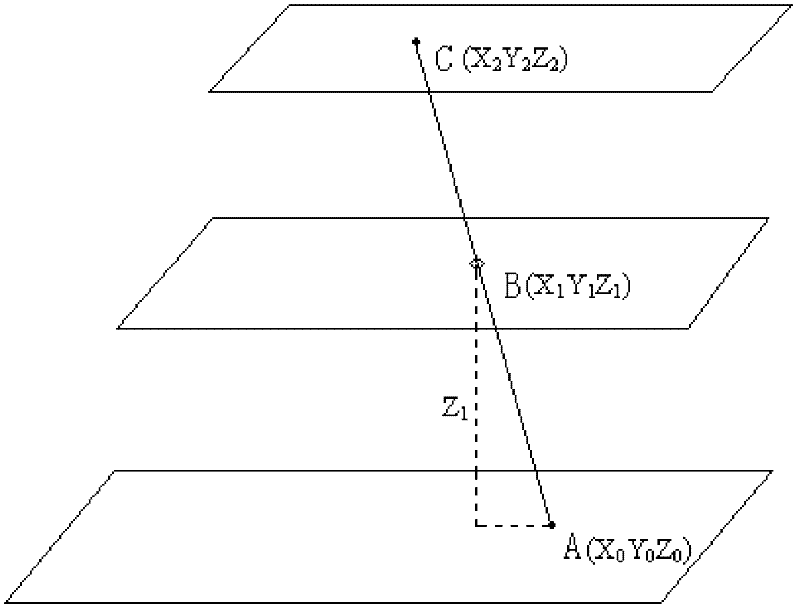

Method for measuring secondary electron emission coefficient of dielectric material

ActiveCN110146529AAvoid accumulationAccurate measurementMaterial analysis by measuring secondary emissionIncident energySecondary electron emission coefficient

The invention discloses a method for measuring the secondary electron emission coefficient of a dielectric material. The method comprises the following steps that: 1) a to-be-measured dielectric material is arranged on a metal sample table; the output ports of the metal sample table, a grid mesh and a collector are connected with the input ports of an acquisition device, voltages applied by the metal sample table and the grid mesh are the same as the voltage of the emission opening of an electron gun, and the potential of the collector is higher than the potential of the metal sample table; 2)the parameters of the electron gun are adjusted, so that an electron beam spot irradiates the surface of the metal sample table and continuously irradiates the surface of the metal sample table for set time; 3) electron energy emitted by the electron gun is adjusted to be energy required to be tested, and the irradiation position of a primary electron beam is adjusted to the surface of the dielectric material, the electron gun is made to emit a pulse electron beam, pulse current I1, pulse current I2 and pulse current I3 of the closed circuits of the metal sample table, the grid mesh and the collector are measured and calculated, and the secondary electron emission coefficient delta of the dielectric material under current electron incident energy is calculated according to the formula that delta=(I2+I3) ) / (I1+I2+I3).

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Dark-color reflective and heat insulation varnish and preparation method thereof

InactiveCN105295624AReduce labor costsSave time and costReflecting/signal paintsIonReflection coefficient

The invention discloses a dark-color reflective and heat insulation varnish and a preparation method thereof, relating to the field of coatings. The dark-color reflective and heat insulation varnish comprises the following components in parts by weight: 320-380 parts of an elastic emulsion, 40-80 parts of a fluorocarbon emulsion, 220-270 parts of filler, 4-6 parts of a dispersing agent, 3-5 parts of a defoaming agent, 5-10 parts of a film-forming additive, 3-5 parts of a flatting agent, 5-8 parts of a thickening agent, 2 parts of a mildew-proof and alga-proof agent, 2 parts of a bactericide, 3-5 parts of a wetting agent and 200-250 parts of deionized water. The varnish belongs to an environment-friendly coating, not only is high in reflection coefficient and radiation coefficient, free of grinding and good in decoration property, but also does not contain APEO and cannot generate hazards to the environment and human health.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Applique and method for thermographic inspection

ActiveUS20180045574A1Surface preparation and cleaning time be reduceInspection time be shortenOptically investigating flaws/contaminationMaterial flaws investigationThermal radiationLight source

A method of thermographic inspection includes absorbing, at an applique applied to a test area of an article, light from a testing light source. The method further includes emitting, by the applique, thermal radiation directed to a capture device, the thermal radiation corresponding to at least a portion of the light absorbed by the applique.

Owner:THE BOEING CO

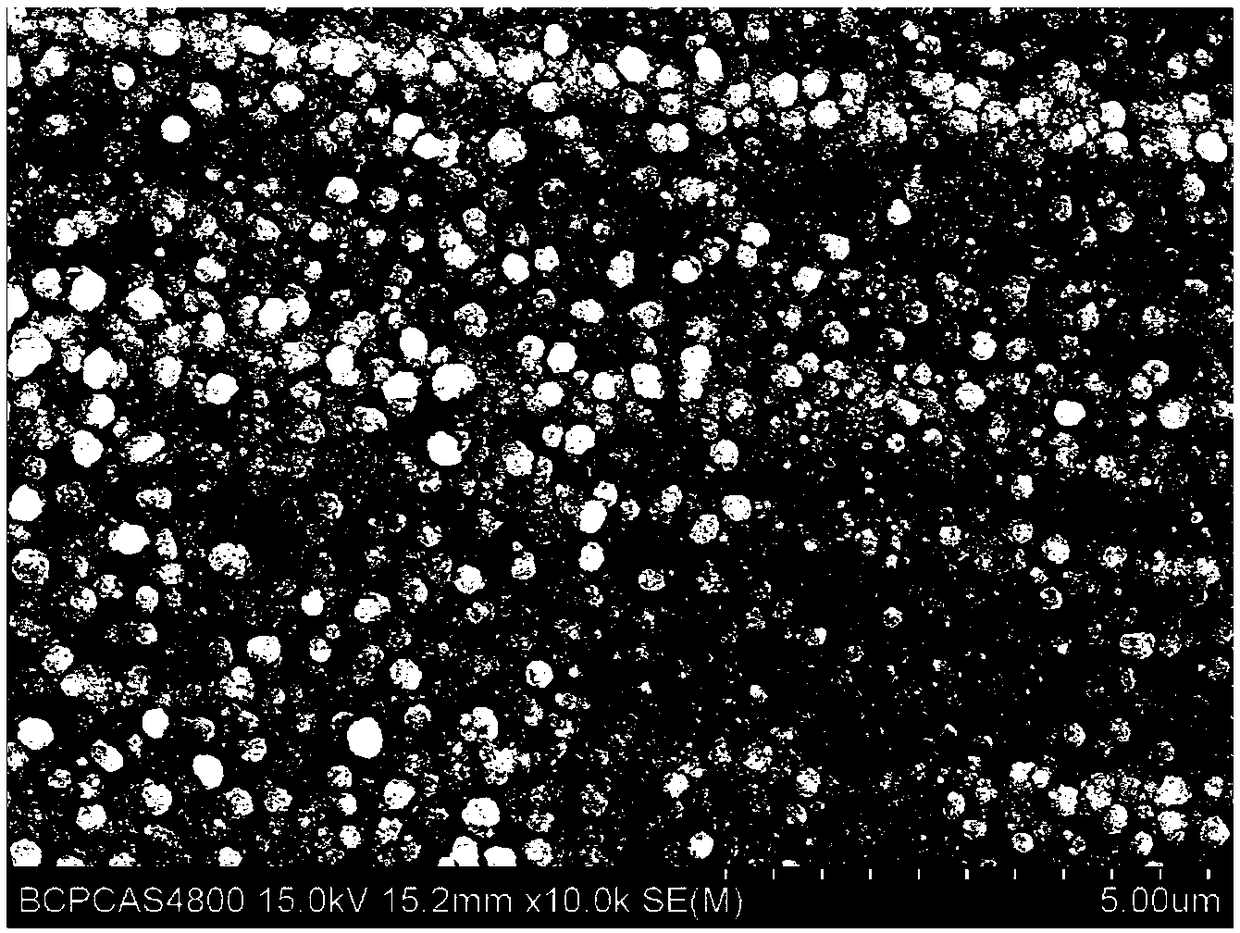

E-beam bombardment resistant secondary electron emission composite film and preparation method thereof

ActiveCN108085651AThickness is easy to controlUniform compositionVacuum evaporation coatingSputtering coatingComposite filmSource material

The invention discloses an e-beam bombardment resistant secondary electron emission composite film and a preparation method thereof, and belongs to the technical field of preparation of functional film materials. By using high-pure metal silver as a substrate material, a magnesium aluminum alloy in a certain atomic ratio as a sputtering source material and high-pure argon-oxygen mixed gas as working and reaction gas, a direct-current reaction magnetron sputtering coating technology is adopted under a certain temperature condition, by adjusting parameters such as sputtering power, sedimentationtime, gas flow ratio and the like, the prepared MgO / Al2O3 composite film has higher secondary electron emission coefficients and better e-beam bombardment resistance performance. By adopting the method, the prepared MgO / Al2O3 composite film has the advantages of controlled thickness of the film, uniform components, high secondary electron emission coefficients, excellent e-beam bombardment resistant performance and the like.

Owner:BEIJING UNIV OF TECH

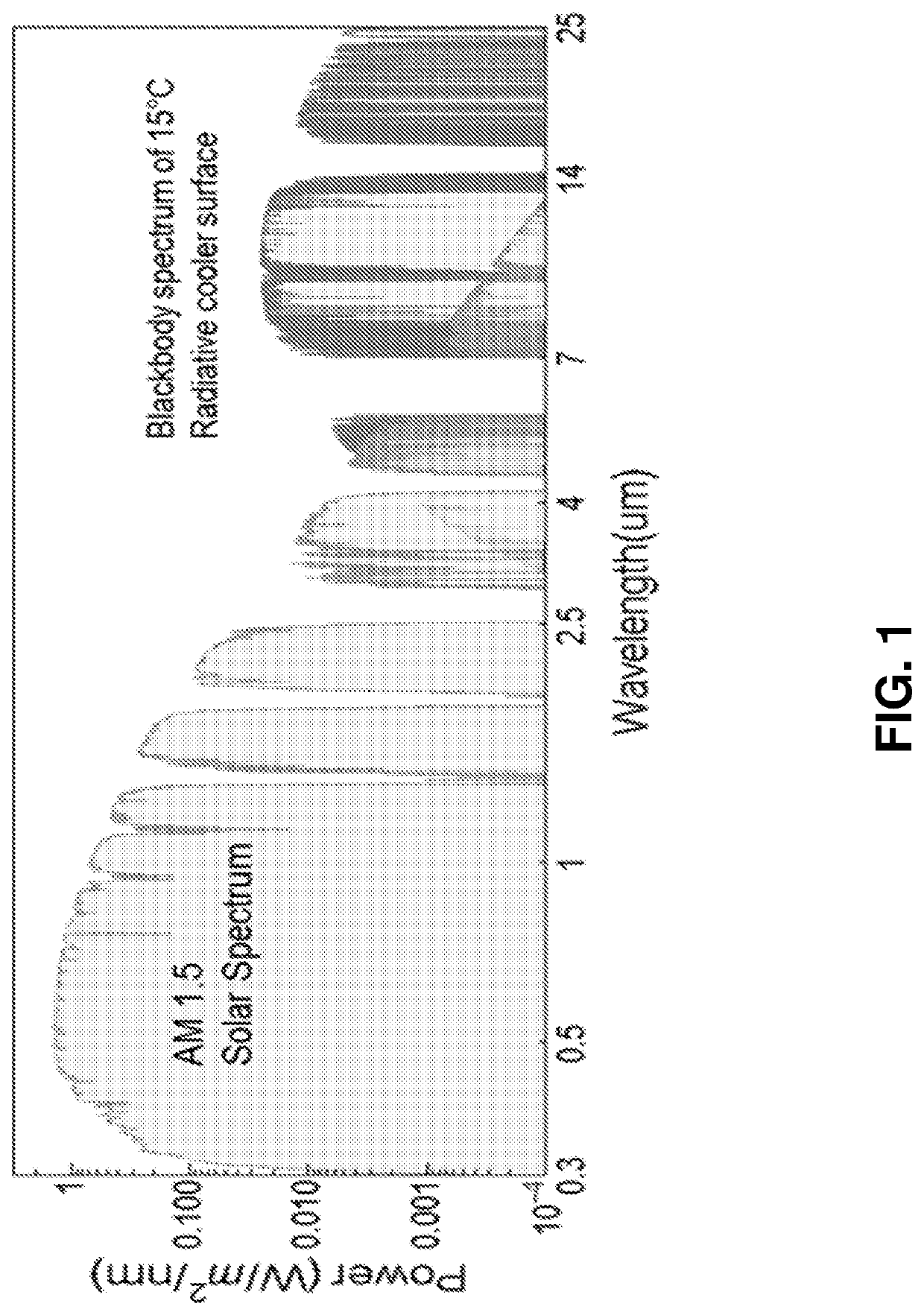

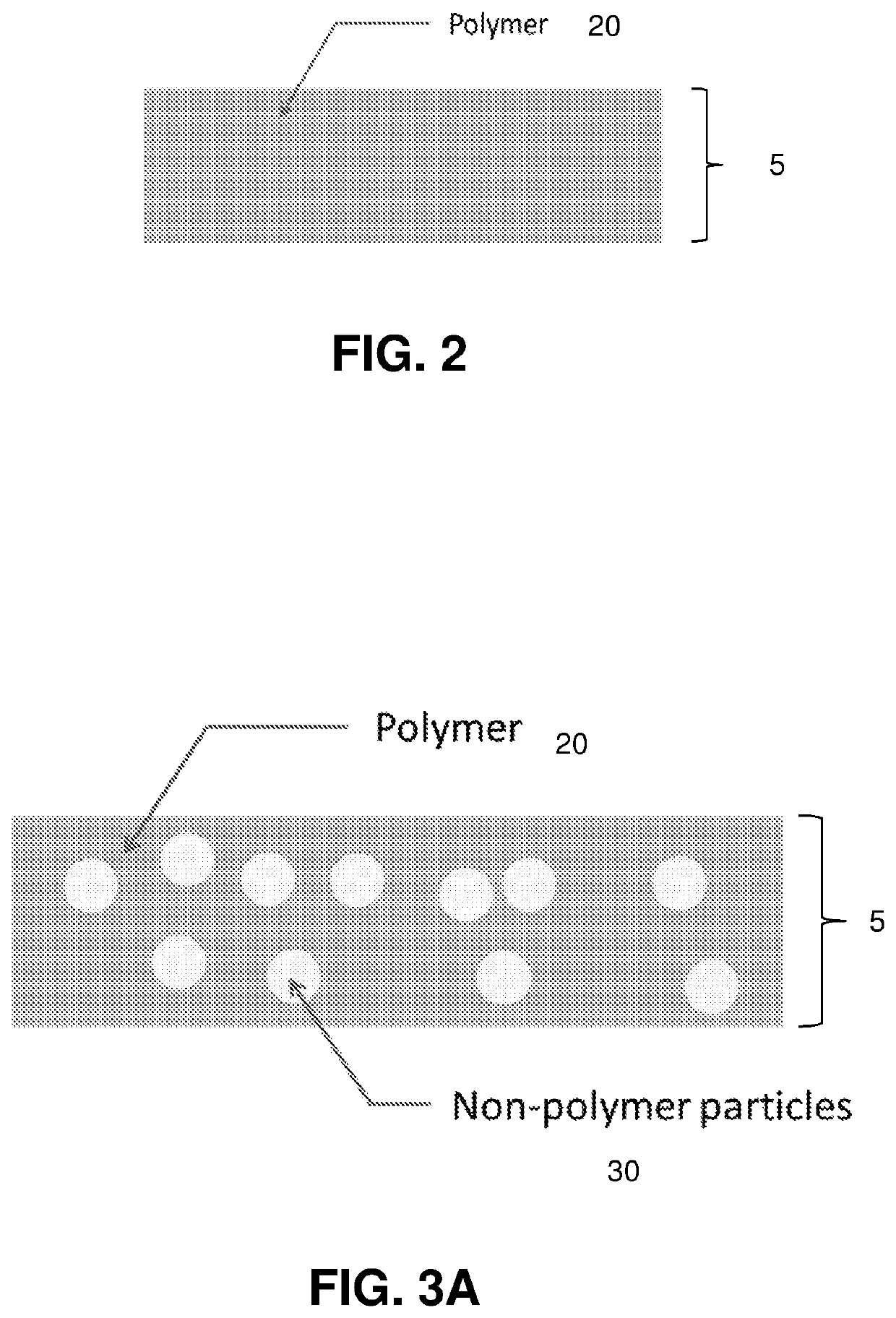

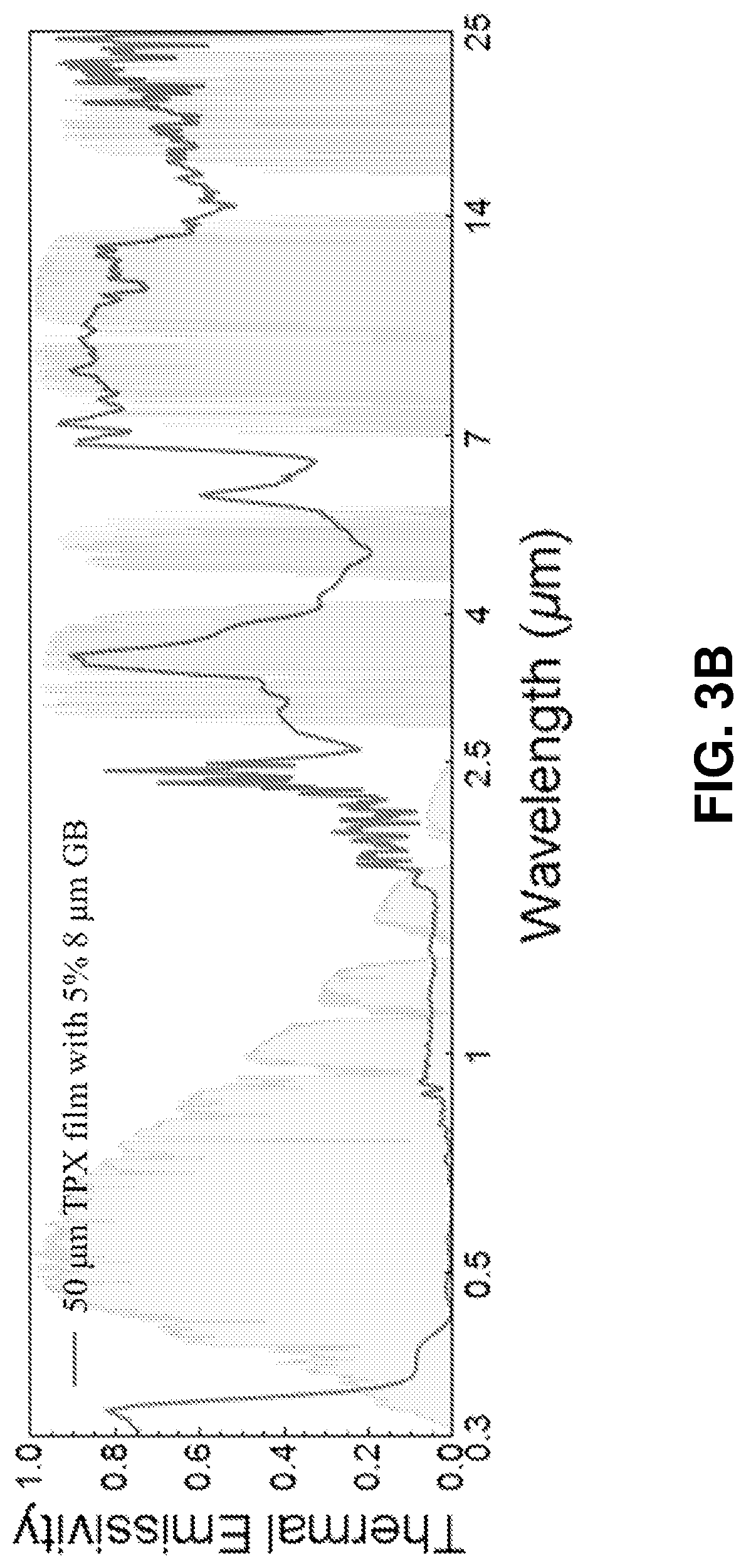

Radiative cooling structures and systems

ActiveUS10724809B2Low costEasy to integrateHeat storage plantsClimate change adaptationPhysical chemistryThermal radiation

Polymer-based selective radiative cooling structures are provided which include a selectively emissive layer of a polymer or a polymer matrix composite material. Exemplary selective radiative cooling structures are in the form of a sheet, film or coating. Also provided are methods for removing heat from a body by selective thermal radiation using polymer-based selective radiative cooling structures.

Owner:UNIV OF COLORADO THE REGENTS OF +1

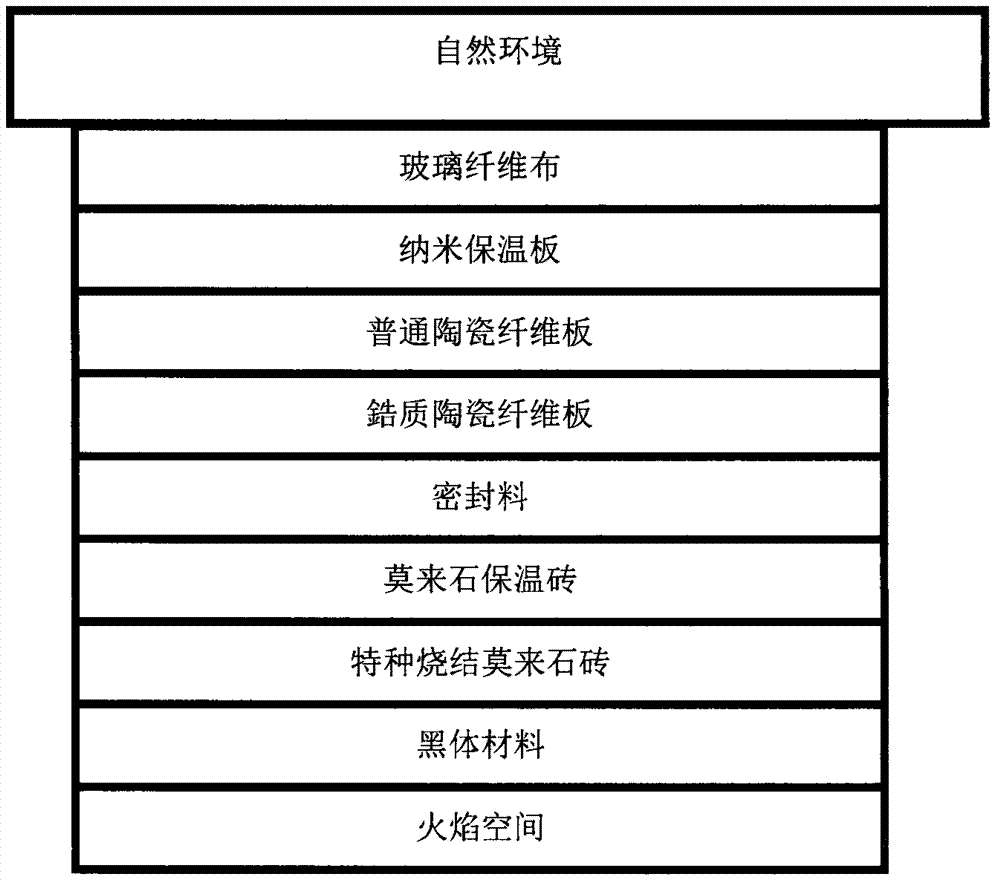

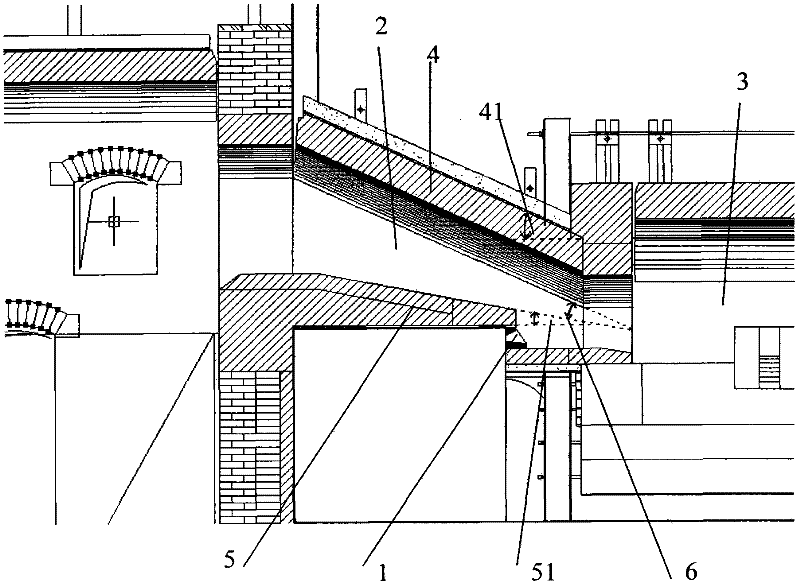

Energy saving measure and construction method for producing andesite continuous fiber flame furnace

InactiveCN104843986AImprove thermal stabilityImprove volume stabilityGlass making apparatusGlass productionGlass fiberFiber

The invention discloses an energy saving measure and construction method for producing andesite continuous fiber flame furnace. The method comprises two parts. The first part comprises a flame furnace crown exterior (air contact part) energy saving measure and construction method. The first part comprises building mullite insulating bricks on flame furnace crown special mullite sintered bricks, coating the mullite insulating bricks with a seal material, orderly laying a zirconium ceramic fiber board, a common ceramic fiber board and a nano-material insulating board on the mullite insulating bricks and carrying out fixing by a glass fiber cloth. The second part comprises a flame furnace breast wall and crown (flame contact part) energy saving measure and construction method. The second part comprises building special mullite sintered bricks at breast wall and crown parts contacting with flame, and spray-coating the surfaces of the mullite sintered bricks with a black material so that the breast wall and crown parts contacting with flame have hemispherical radiation coefficients improved to 0.9 or more from 0.3-0.4 and heat reflection is reinforced. The energy saving measure has the advantages of simple processes, fast construction rate, low cost, more glass liquid fused in unit time, energy consumption at least reduced by 25% and production efficiency improved by 30% or more.

Owner:SHANGDE RUIGU BEIJING TECH CO LTD

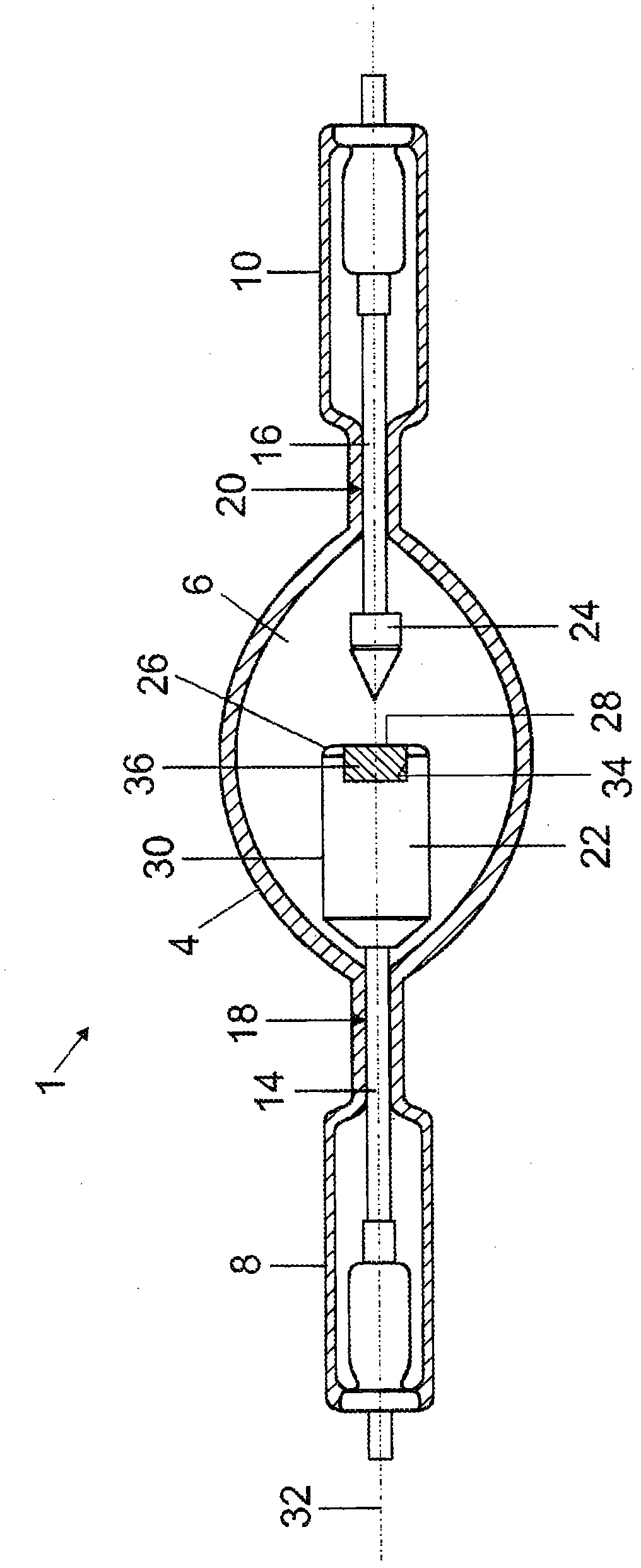

Discharge lamp

InactiveCN102257594ALow densityImprove emissivityGas discharge lamp detailsGas-discharge lampEngineering

The invention relates to a discharge lamp (1), particularly a xenon or mercury vapor short arc lamp, comprising electrodes (22, 24) arranged in an interior of a discharge vessel (4). At least one of the electrodes (22) is designed in two parts, wherein a first part on the connection side is made of carbon and a second part (36) facing the discharge arc during operation is made of tungsten.

Owner:OSRAM GMBH

A method of making microchannel plate functional layer by atomic layer deposition technology

ActiveCN104152868BEasy to adjustMeet surface precision requirementsChemical vapor deposition coatingWorking lifeAtomic layer deposition

The invention provides a method for making a functional layer of a microchannel plate by using atomic layer deposition technology, so as to overcome the inherent defects of the functional layer prepared by the traditional hydrogen reduction technology of the microchannel plate, and solve the problem of complex manufacturing of the functional layer of the microchannel plate, unstable performance, and short lifespan. Not long and other problems, to manufacture a resistance layer and emission layer with strong adhesion, smooth surface, uniform thickness, and high purity of composition, improve the performance stability of the micro-channel plate, and prolong its working life.

Owner:东莞市中科原子精密制造科技有限公司

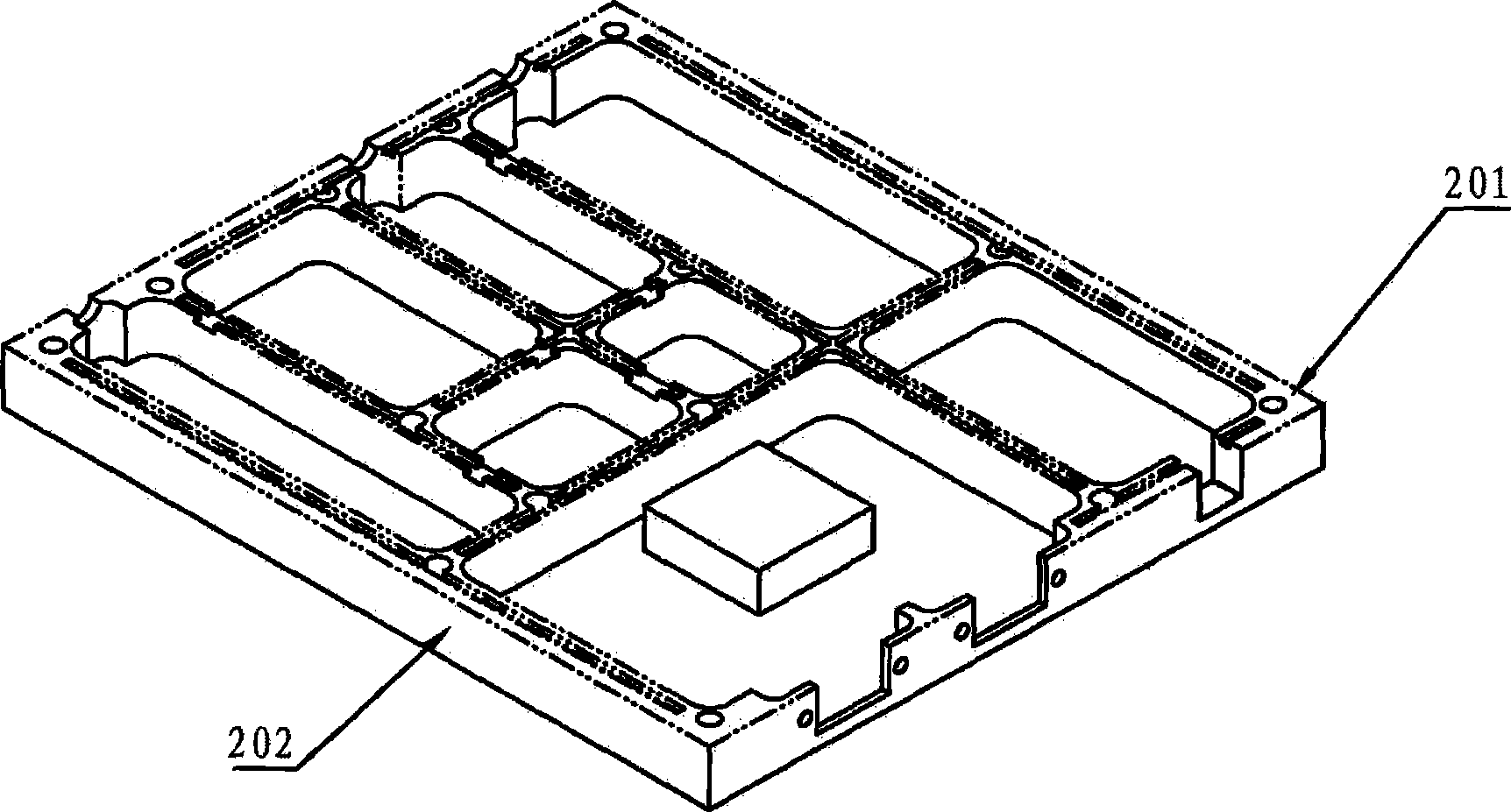

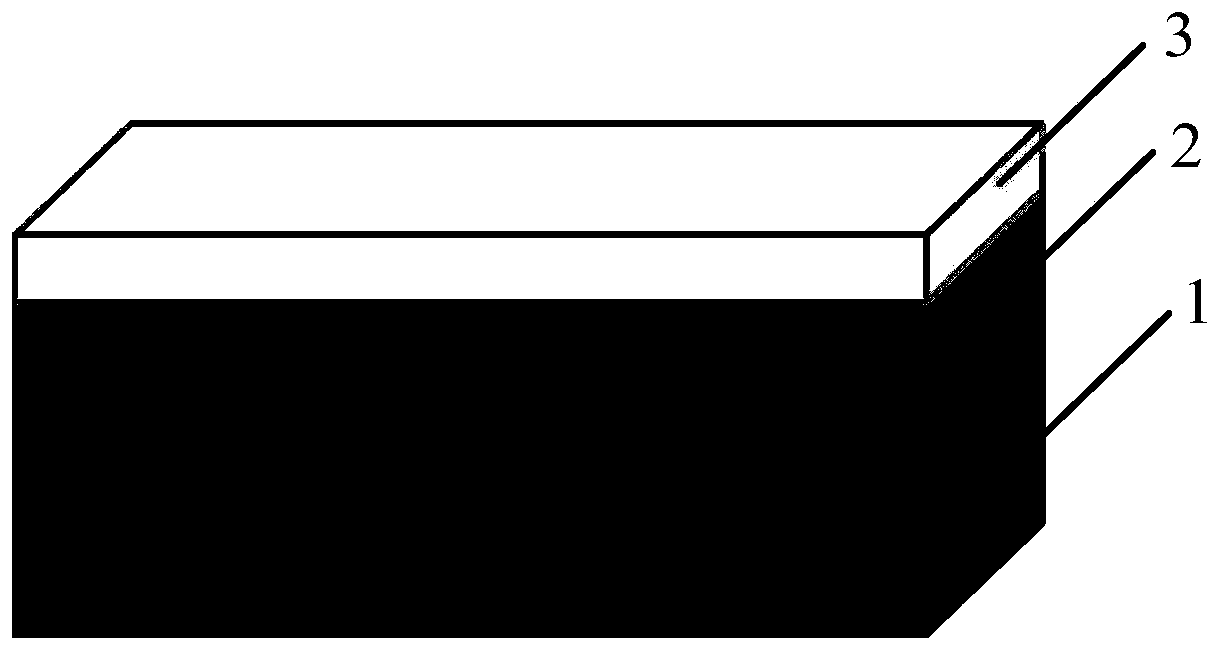

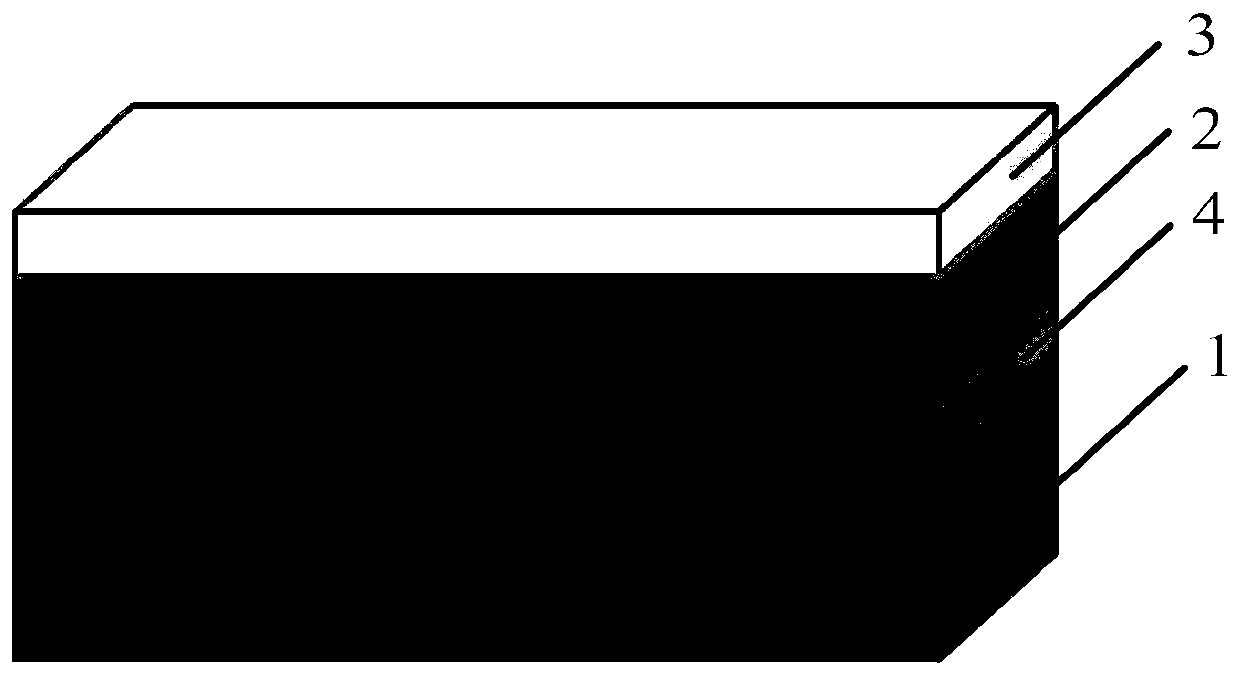

Vacuum cavity embedded aerogel type heat preservation shell for thermal battery and application of vacuum cavity embedded aerogel type heat preservation shell

ActiveCN111525049AReduce volumeSmall footprintDeferred-action cellsSpecific condition cell workingElectrical batteryThermal insulation

The invention discloses a vacuum cavity embedded aerogel type heat preservation shell for a thermal battery and application of the vacuum cavity embedded aerogel type heat preservation shell. The shell comprises a battery outer shell, a battery inner shell, a reflection infrared radiation layer, a battery cover plate, an aerogel heat preservation cylinder and an aerogel heat preservation block, the battery inner shell is mounted in the middle in the battery outer shell; the reflection infrared radiation layer is arranged on the inner wall of the battery outer shell and the outer wall of the battery inner shell, the battery outer shell surrounds the battery inner shell to form a vacuum heat preservation cavity, and the aerogel heat preservation cylinder is embedded in the cavity of the vacuum heat preservation cavity and located between the reflection infrared radiation layer on the inner wall of the battery outer shell and the reflection infrared radiation layer on the outer wall of the battery inner shell; the aerogel heat preservation block is arranged between the upper layer and the lower layer of the battery cover plate, and the aerogel layer and the vacuum layer are combined into a whole in space, so that the size of the thermal battery is reduced. The heat preservation shell provided by the invention has good thermal insulation performance, and can significantly prolong the thermal life of the thermal battery and reduce the surface temperature of the thermal battery.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

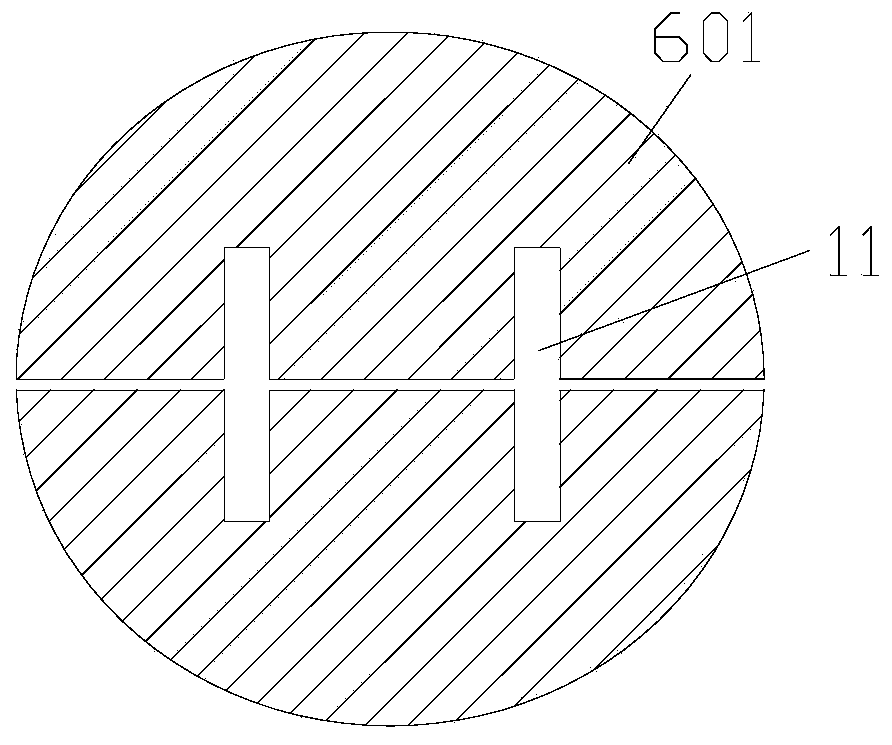

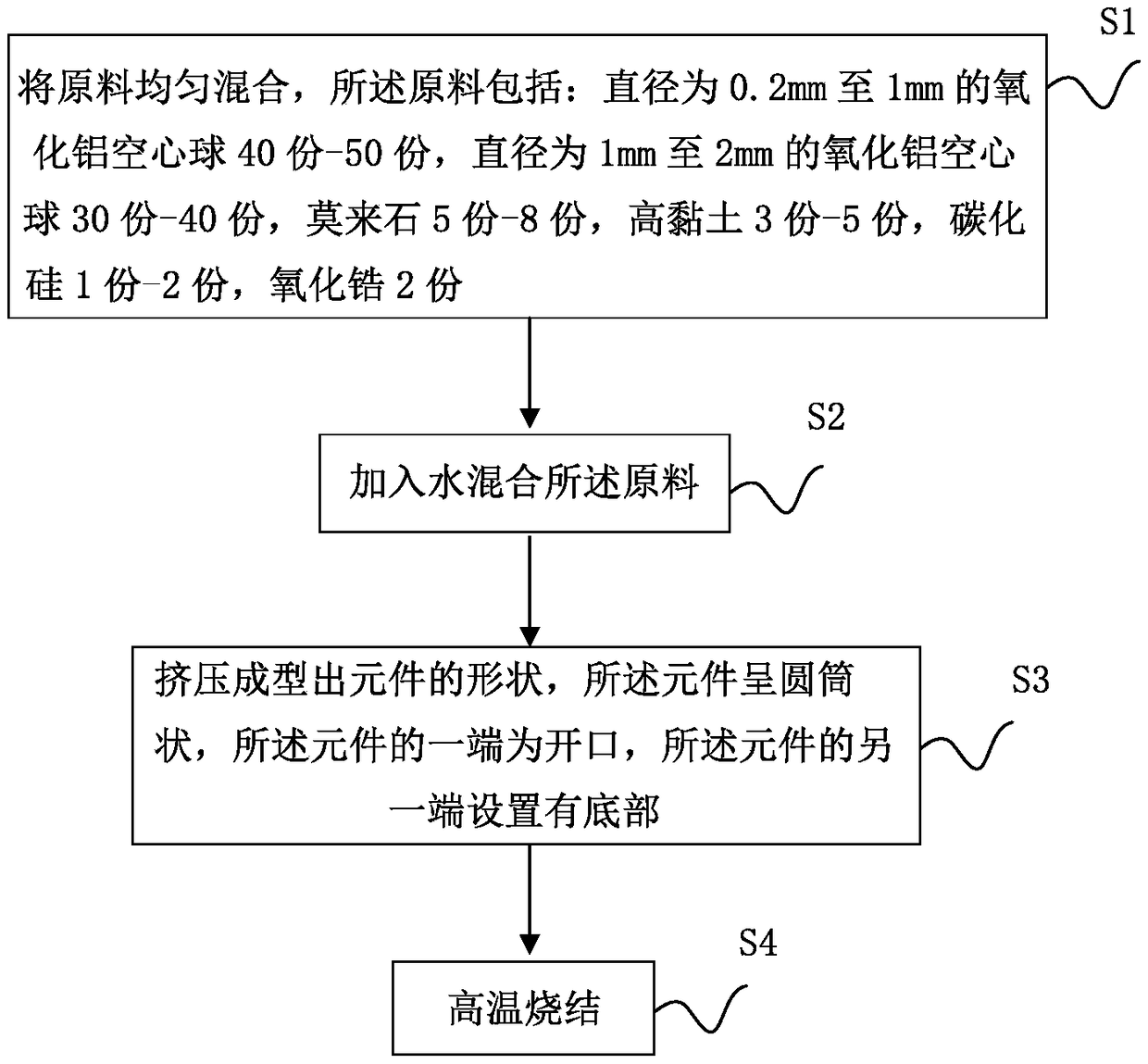

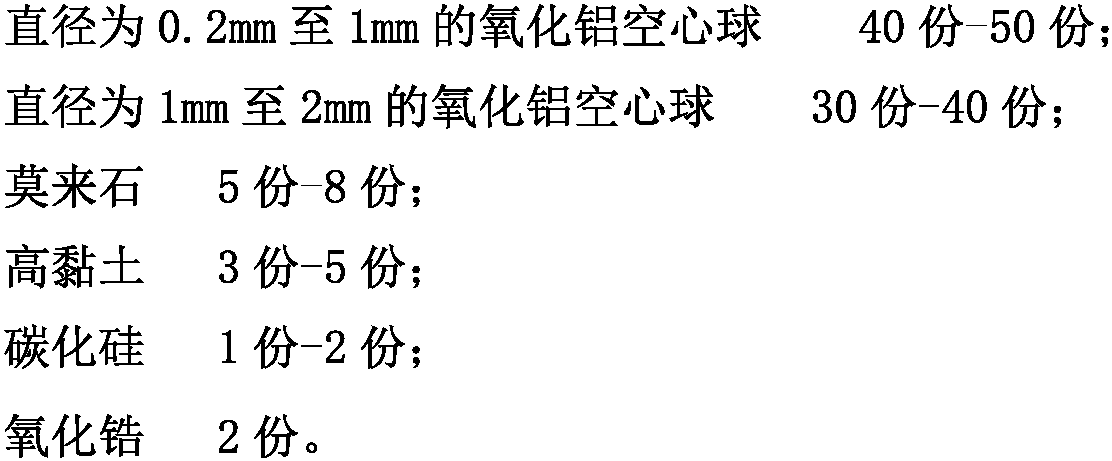

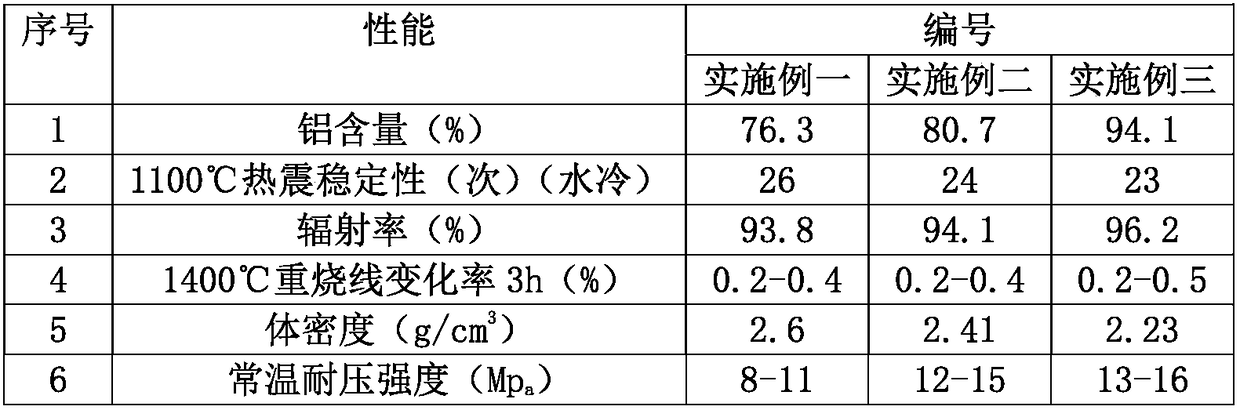

Element capable of enhancing radiation and preparation method

The invention discloses an element capable of enhancing radiation, which comprises the following materials in parts by weight: 40-50 parts of alumina hollow balls with a diameter of 0.2 mm to 1 mm; 30-40 parts of alumina hollow balls with a diameter of 1 mm to 2 mm; 5-8 parts of mullite; 3-5 parts of high viscosity clay; 1-2 parts of silicon carbide; 2 parts of zirconia. The heat radiation absorption efficiency of a workpiece in a heating furnace can be greatly improved by the element. The invention also provides a preparation method of the element capable of enhancing radiation.

Owner:亚创环能科技集团有限公司

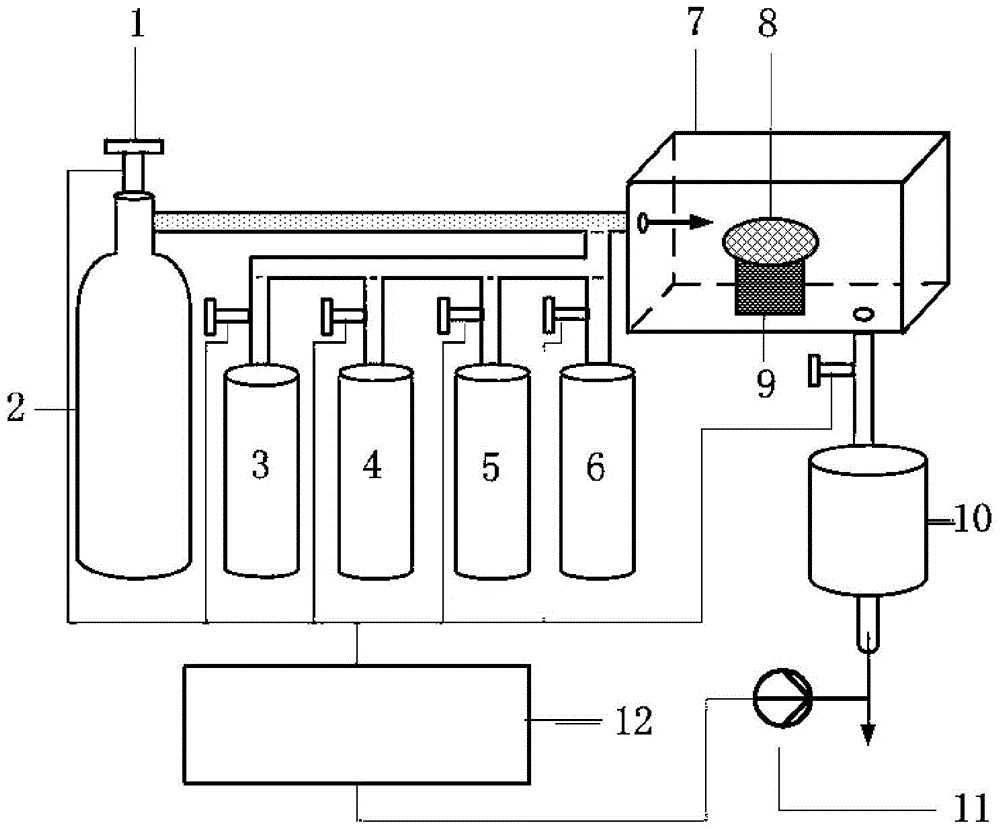

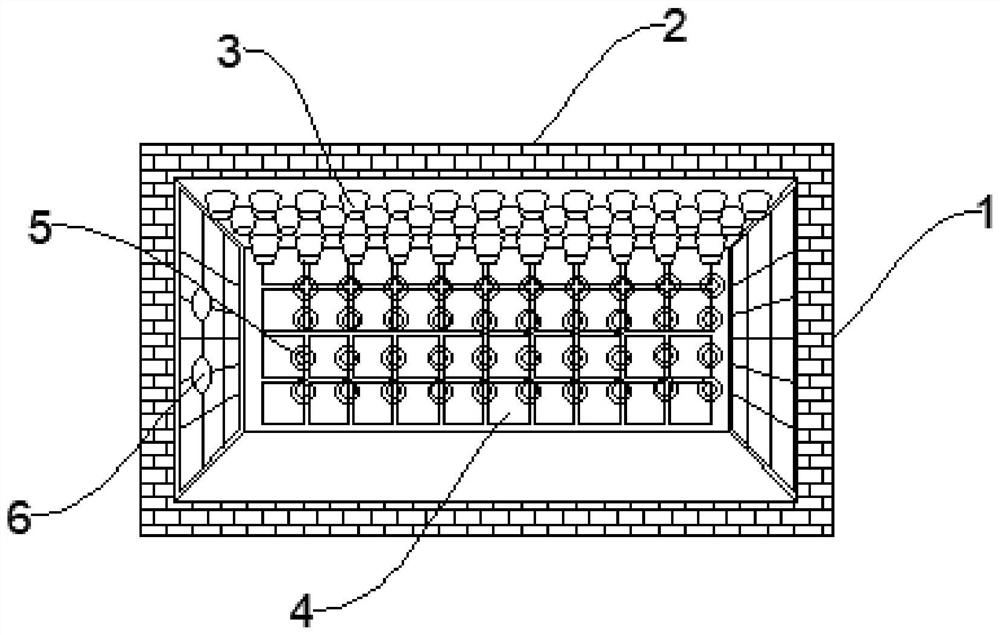

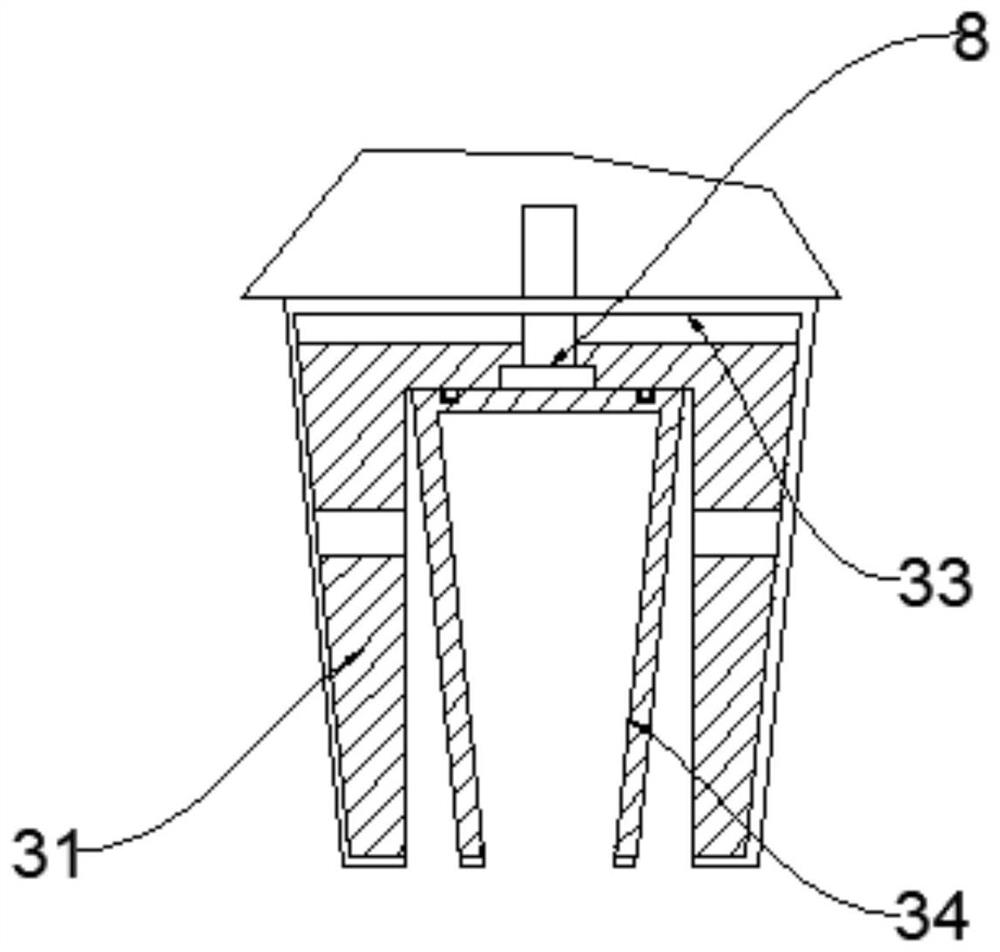

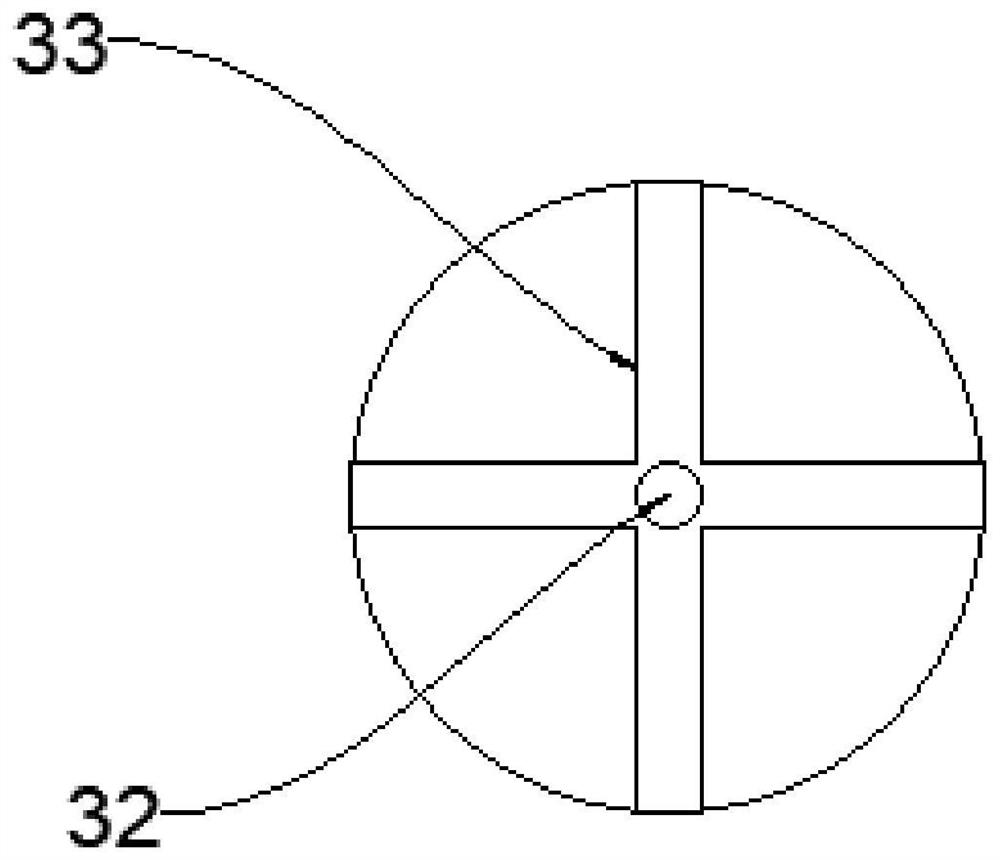

Energy-saving heating furnace with black bodies and fibers arranged on furnace lining, and construction method thereof

InactiveCN112229223AImprove emissivityAchieve energy saving effectLinings repairFurnace typesFiberFurnace temperature

The invention relates to the technical field of industrial furnaces, and specifically relates to an energy-saving heating furnace. The energy-saving heating furnace comprises a furnace body end wall and a furnace top, wherein a first black body energy-saving element is arranged on the furnace top, and a refractory fiber module and a second black body energy-saving element are arranged on the furnace body end wall; the diameter ratio of the first black body energy-saving element to the second black body energy-saving element is (1 to 3): 1, and the second black body energy-saving element arranged on the furnace body end wall penetrates through the refractory fiber module arranged on the furnace body end wall. According to the energy-saving heating furnace, the refractory fiber module is arranged on the furnace body end wall of the heating furnace and matched with the first black body energy-saving element arranged on the furnace top, so that the effect of comprehensively saving energy in the furnace body is achieved. When a furnace temperature is higher than 800 DEG C, heat transfer is mainly based on radiation, and radiation heat transfer is more than 15 times of convection heat transfer and accounts for more than 80% of total heat; and the first black body energy-saving element has a high radiation coefficient and plays a role in fully reflecting radiation downwards at the furnace top, so that efficient recycling for the radiation heat of a workpiece is achieved.

Owner:四川科达节能技术有限公司

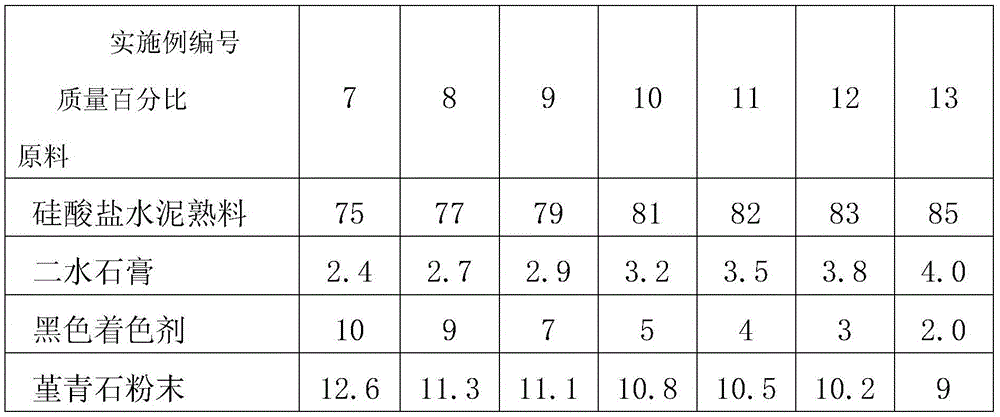

A heat-storing black body cement and its preparation method

The invention discloses a heat-storing blackbody cement and a preparation method thereof, which are characterized in that: 75.0-85.0% Portland cement clinker, 2.4-4.0% dihydrate gypsum, 2.0-10.0% black colorant, and 5.0-15.0% cordierite powder composition and mass percentage ratio to take each raw material; adopt dry ball milling process, put the raw material into the ball mill, the rotating speed of the ball mill drum is 43-47r / min, and the residence time of the raw material in the ball mill is 29 ~31 minutes, after the raw materials are mixed by ball milling, the heat-storing black body cement can be obtained. The prepared blackbody cement has high color blackness, high blackbody radiation coefficient and large heat storage coefficient, and can be used as a material for large-scale heat storage engineering after being poured into a large-volume block solid; the blackbody cement prepared by the present invention is a kind of heat storage Cement material with good performance, heat radiation and heat diffusion.

Owner:新疆天山水泥有限责任公司

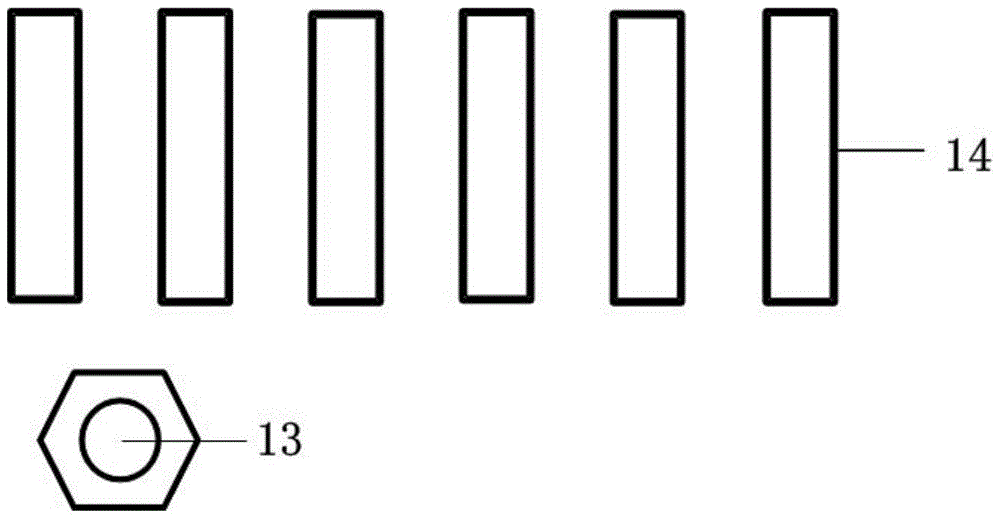

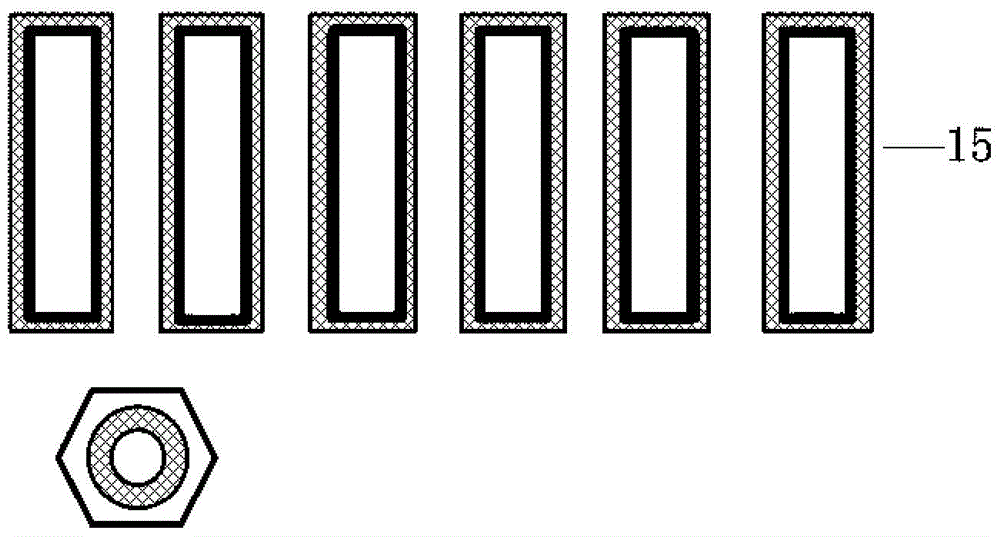

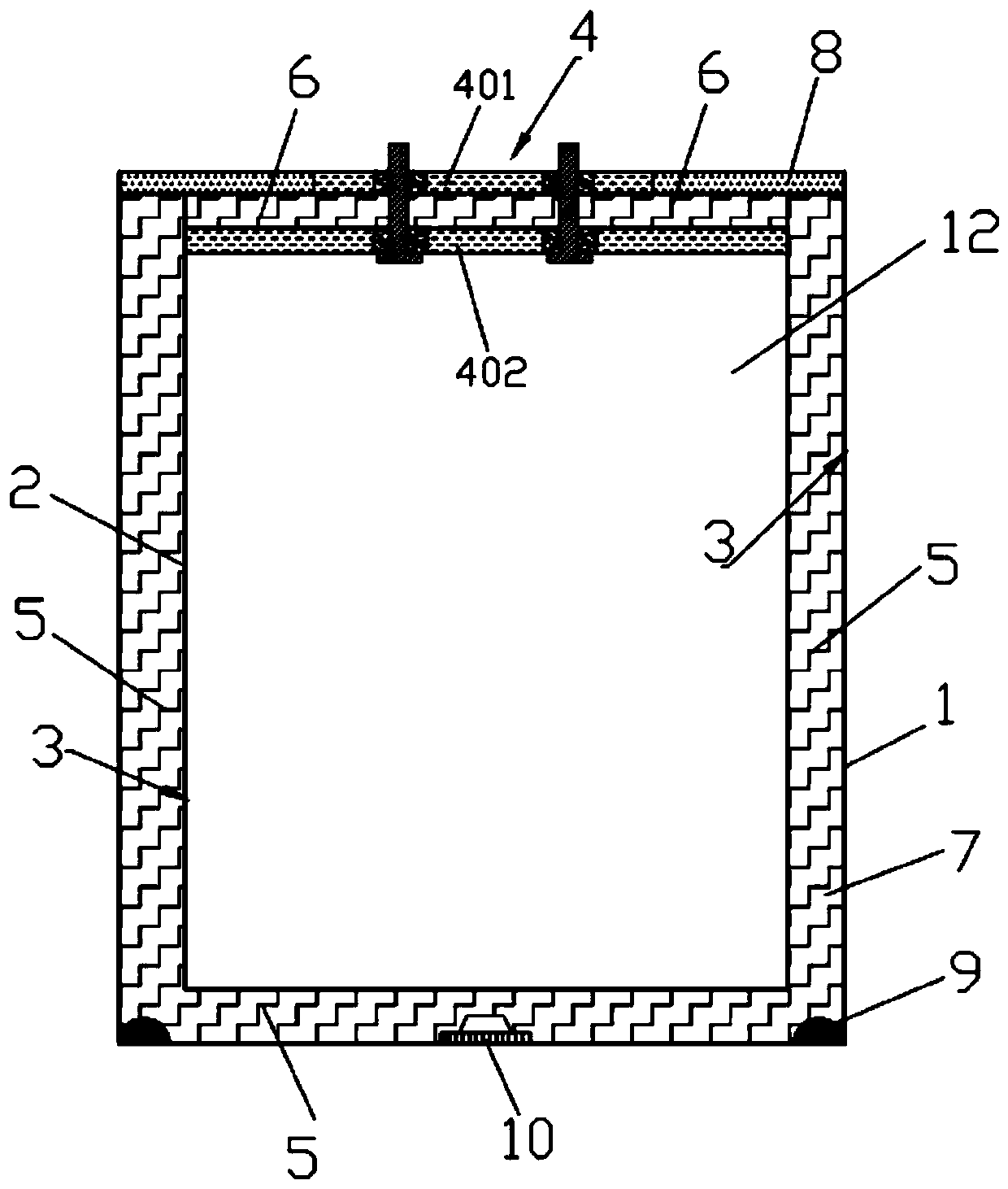

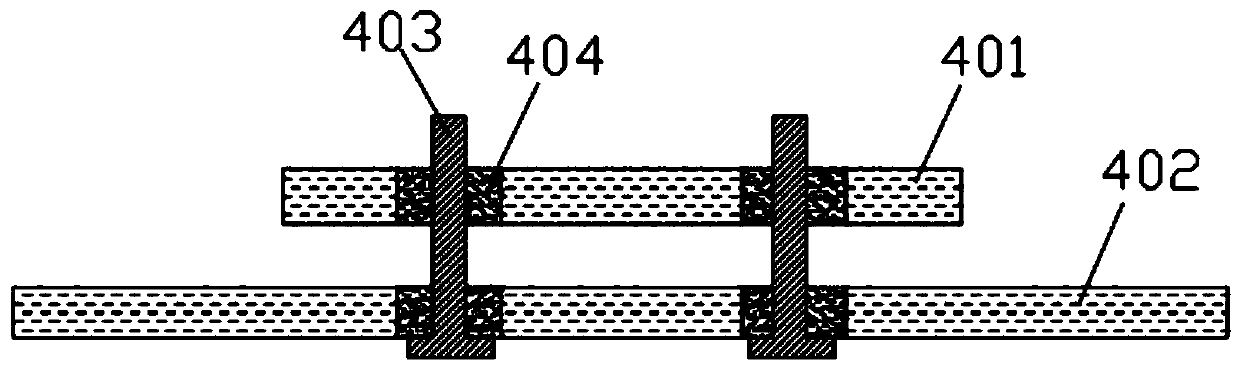

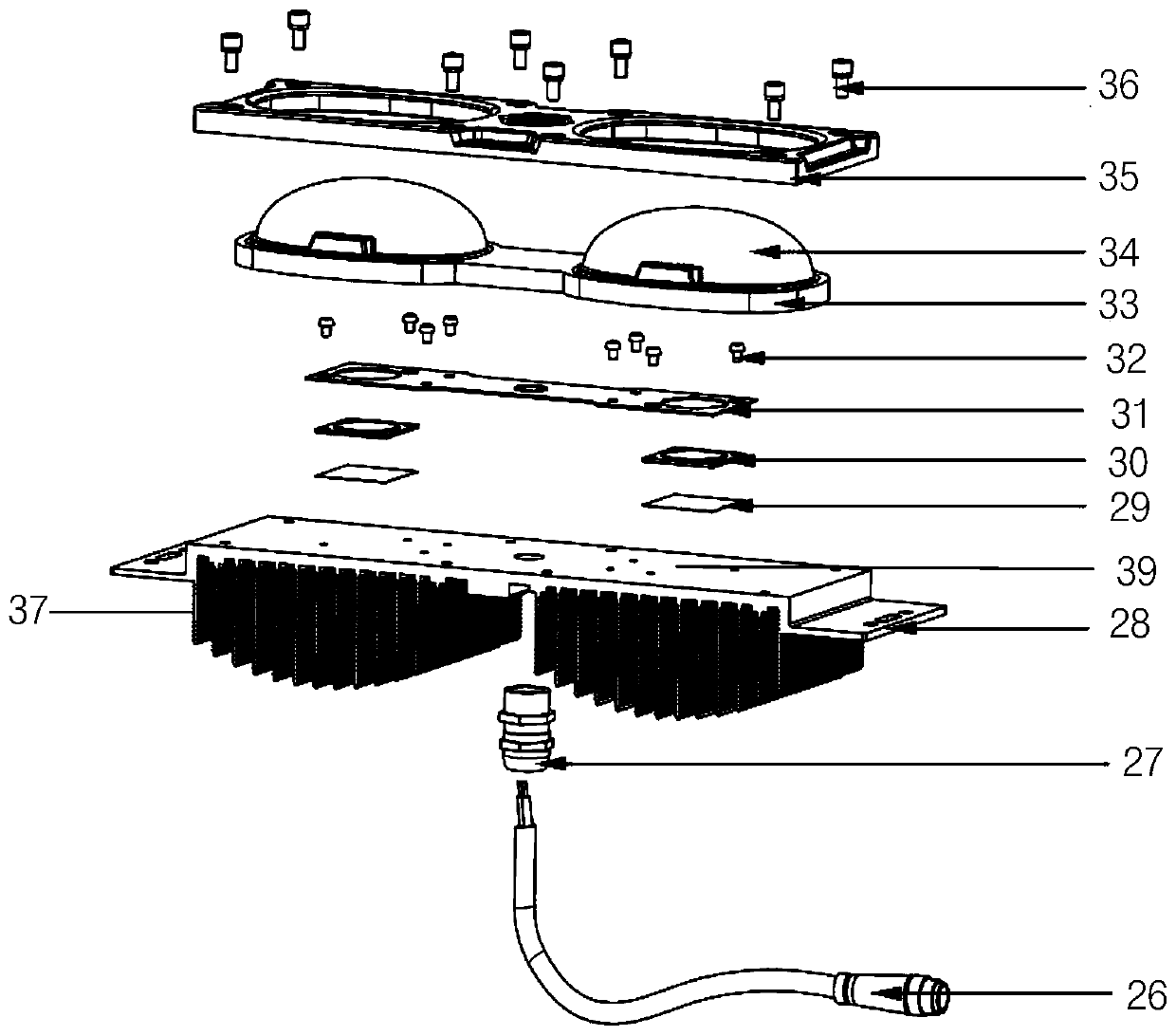

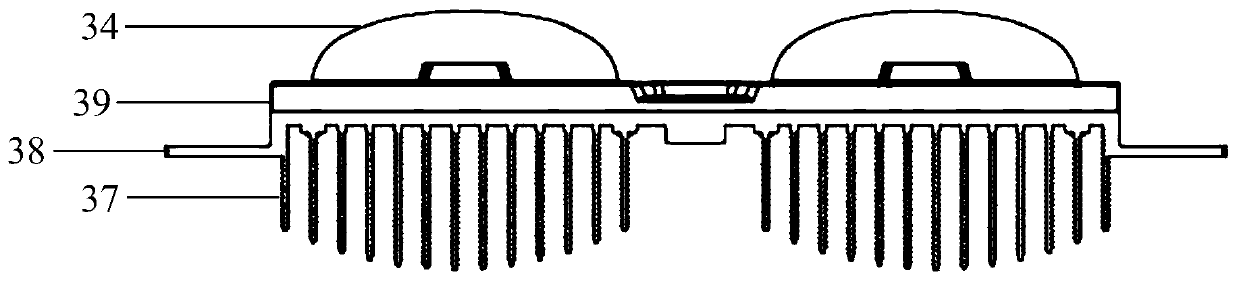

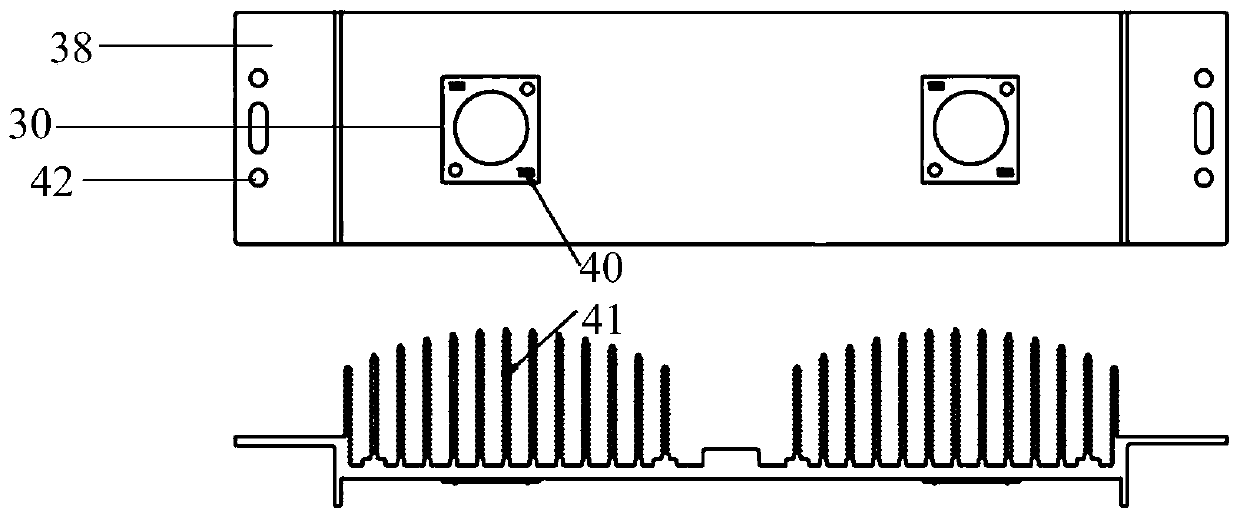

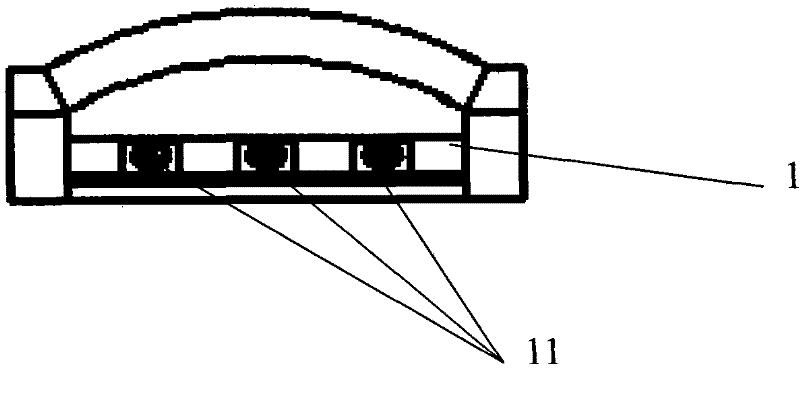

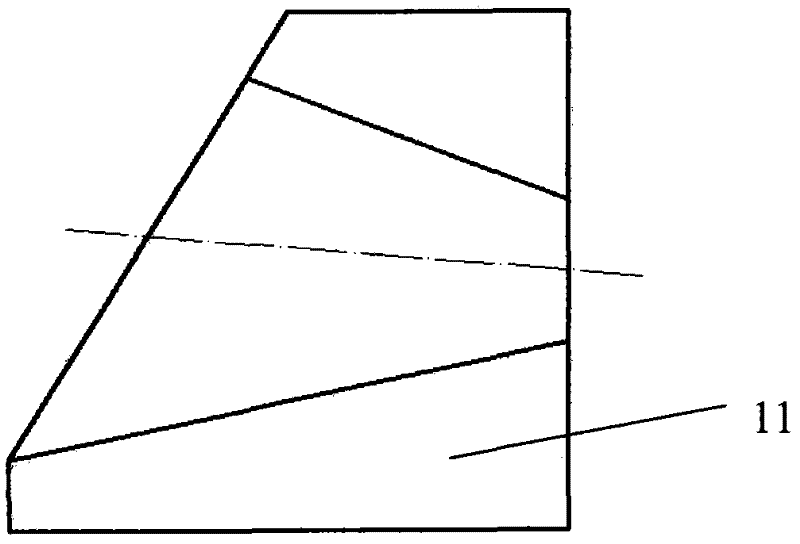

LED light source module and intelligent lamp cap

InactiveCN110319384AExtended service lifeImprove cooling effectElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringHeat spreader

The invention discloses an LED light source module. The LED light source module comprises a radiator, one or more light source chips, glass lenses with the number being equal to that of the light source chips, a PCB connecting board and a pressing cover, wherein the radiator comprises a heat dissipation base plate and at least one group of heat dissipation fins; the heat dissipation fins are positioned on the same side of the heat dissipation base plate and are vertical to the heat dissipation base plate; each group of heat dissipation fins comprises three or more heat dissipation fins; in each group of heat dissipation fins, the heat dissipation fins are arranged in parallel; in each group of heat dissipation fins, in the direction vertical to the heat dissipation base plate, the lengthsof the different heat dissipation fins are gradually reduced towards two ends from the middle; and the light source chips are connected with the radiator, the PCB connecting board is connected with the light source chips and the radiator, and the glass lenses are fixed on the PCB connecting board. The invention further discloses an intelligent lamp cap comprising the LED light source module. The LED light source module provided by the invention is uniform in heat dissipation, good in heat dissipation effect, little in used material, small in integral weight and size, low in cost, and convenient to replace.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD +1

Furnace combustion structure having function of oxygen-supporting combustion

InactiveCN102418935AGuaranteed to meltReduce consumptionNon-combustible gases/liquids supplyCombustorPollutant emissions

The invention relates to a furnace combustion structure having the function of oxygen-supporting combustion, which comprises a combustion nozzle, a combustion supporting air nozzle and a furnace body space, wherein the combustion supporting air nozzle is composed of an upper skew arch above, a lower bottom plate and sidewalls at two sides, the combustion nozzle which is disposed below the combustion supporting air nozzle is provided with 3 horn-shaped oxygen-supporting combustion nozzles (combustor flame is transversely distributed) and is 0.5 to 1 meter away from the furnace body space, and an included angle of 14 degrees is formed between the combustion supporting air nozzle and the combustion nozzle. When a furnace having this structure is in used, fuel is mixed with low-temperature combustion supporting air entering from a heat accumulation chamber so as to result in a carbon separation process and then enters into the high-temperature furnace body for combustion. The structure can improve the uniformity of temperature field in the furnace, enhance the radiation coefficient of fuel-combusting flame and the production quality of metallurgical accessories, and intensify the heat exchange capability of combustion flame and metallurgical accessories, thus fuel consumption, pollutant emission and production cost of metallurgical accessories are all reduced.

Owner:LIAONING TIANHE TECH

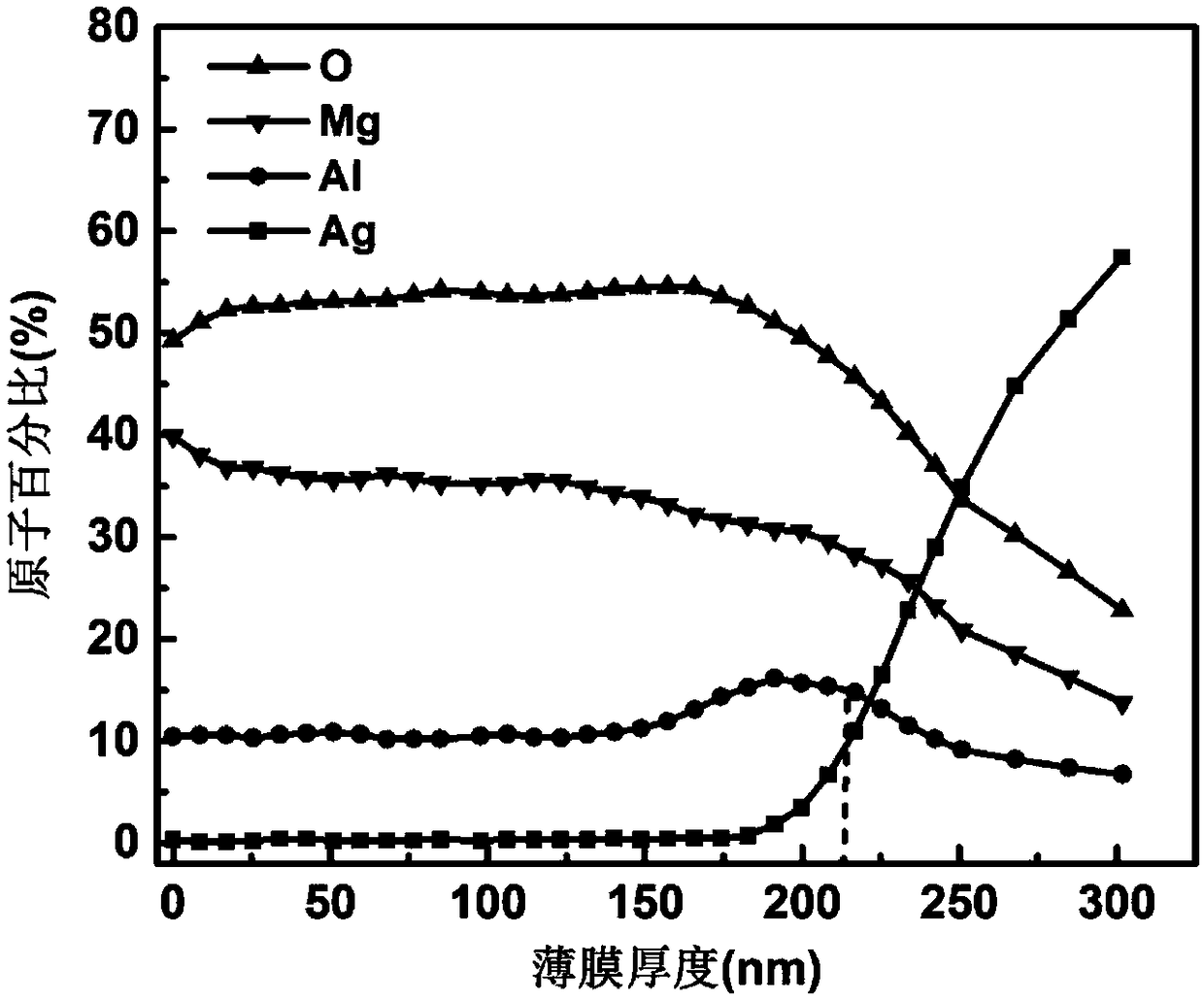

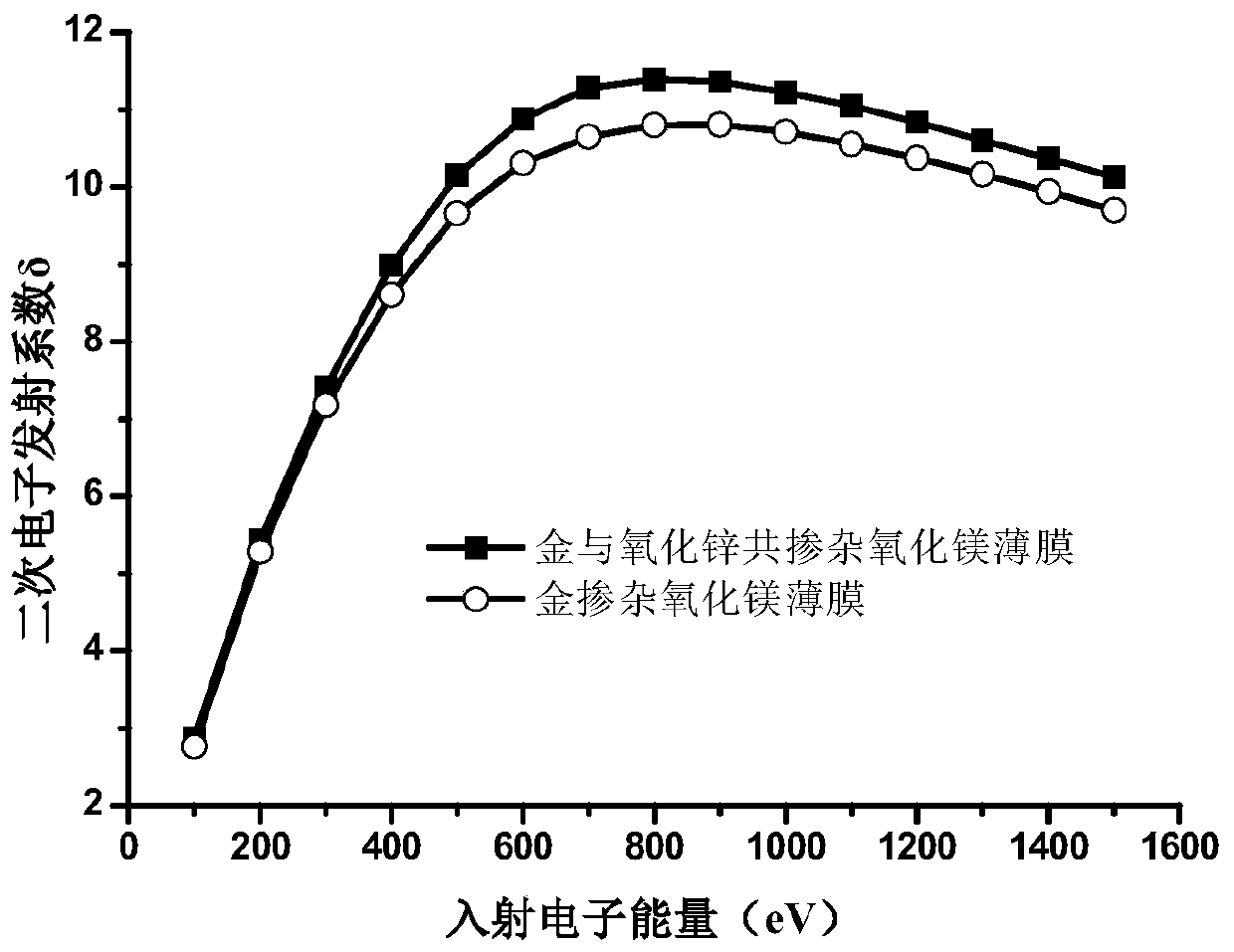

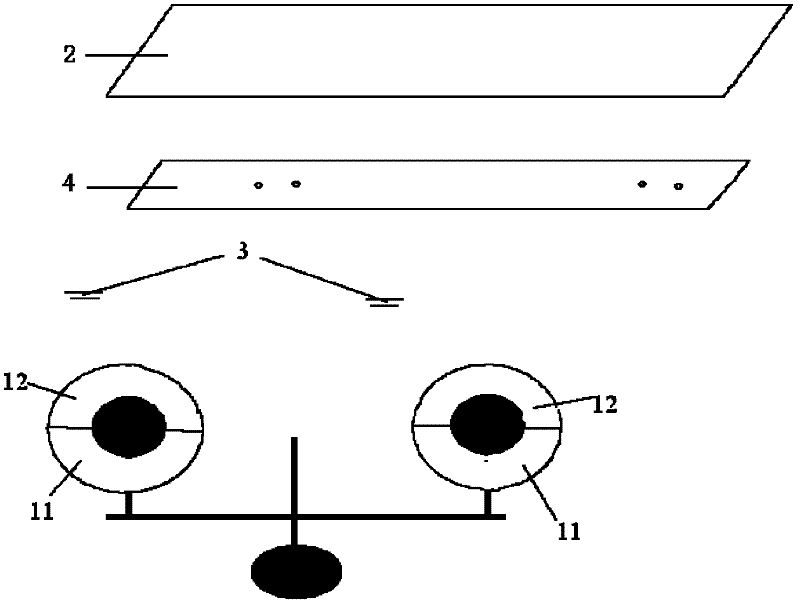

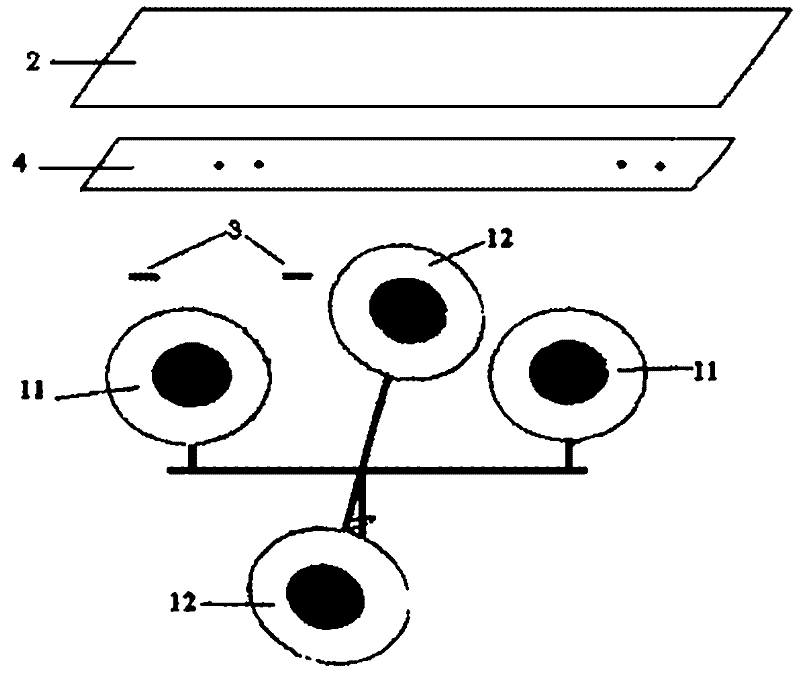

Metal and zinc oxide doped magnesium oxide secondary electron emission film and preparation method thereof

ActiveCN108374151BImprove conductivityImprove emissivityVacuum evaporation coatingSputtering coatingPhysical chemistryMetallic materials

The invention relates to a secondary-electron emission thin film containing metal and zinc oxide doped magnesium oxide, and a preparation method thereof. The secondary-electron emission thin film containing the metal and zinc oxide doped magnesium oxide comprises a substrate and a zinc oxide doped magnesium oxide film layer and a metal doped magnesium oxide film layer sequentially arranged on thesubstrate from top to bottom. In the metal doped magnesium oxide film layer, a metal material is singly doped or the metal material and zinc oxide are co-doped, the percentage content of the atomic number of the metal in the metal doped magnesium oxide film layer prepared from the singly doped metal material is 6 percent to 30 percent, the percentage content of the atomic number of the metal in the metal doped magnesium oxide film layer prepared from the co-doped metal material and zinc oxide is 5 percent to 25 percent, and the percentage content of the atomic number of zinc is not higher than5 percent; the size of an Mg-Zn-O composite grain formed in the zinc oxide doped magnesium oxide film layer is 8nm to 30nm, and the percentage content of the atomic number of the zinc is 0.2 percentto 8 percent. The secondary-electron emission thin film containing the metal and the zinc oxide doped magnesium oxide is prepared by adopting a sputtering method, the secondary-electron emission coefficient can be effectively improved, and the stability of electron emission is improved.

Owner:XI AN JIAOTONG UNIV

Plasma display panel and manufacturing method thereof

InactiveCN102368463AIncrease the diffusion coefficientIncrease the number ofTube/lamp screens manufactureDischarge tube luminescnet screensDelayed timeSecondary electrons

The invention discloses a plasma display panel and a manufacturing method of a protective layer. The display panel comprises an upper substrate and a lower substrate, wherein the upper substrate and the lower substrate are sealed oppositely. A discharge electrode, a dielectric layer and a protective layer are successively arranged on the upper substrate; and the protective layer includes: a first protective layer, which is formed by magnesium oxide; and a second protective layer, which is covered on the first protective layer; besides, the second protective layer consists of alkaline earth oxide and silica / titanium dioxide. According to a technical scheme provided in the invention, a second protective layer is evaporated and plated on a magnesium oxide film layer, so that a few doping atoms are mixed in a crystal structure of the magnesium oxide; after the doping atoms replace atoms in the magnesium oxide, a diffusion coefficient of the crystal is increased, so that the diffusion coefficient of the crystal structure containing the doping atoms is greater than a self-diffusion coefficient of a crystal only having a single atom; and therefore, an electron motion speed is accelerated and the electronic number is increased; an emission coefficient of a secondary electron is increased; a working voltage of a plasma display panel (PDP) is reduced; and discharge delay time is further reduced.

Owner:SICHUAN COC DISPLAY DEVICES

A kind of high secondary electron emission coefficient cold cathode material and its preparation method

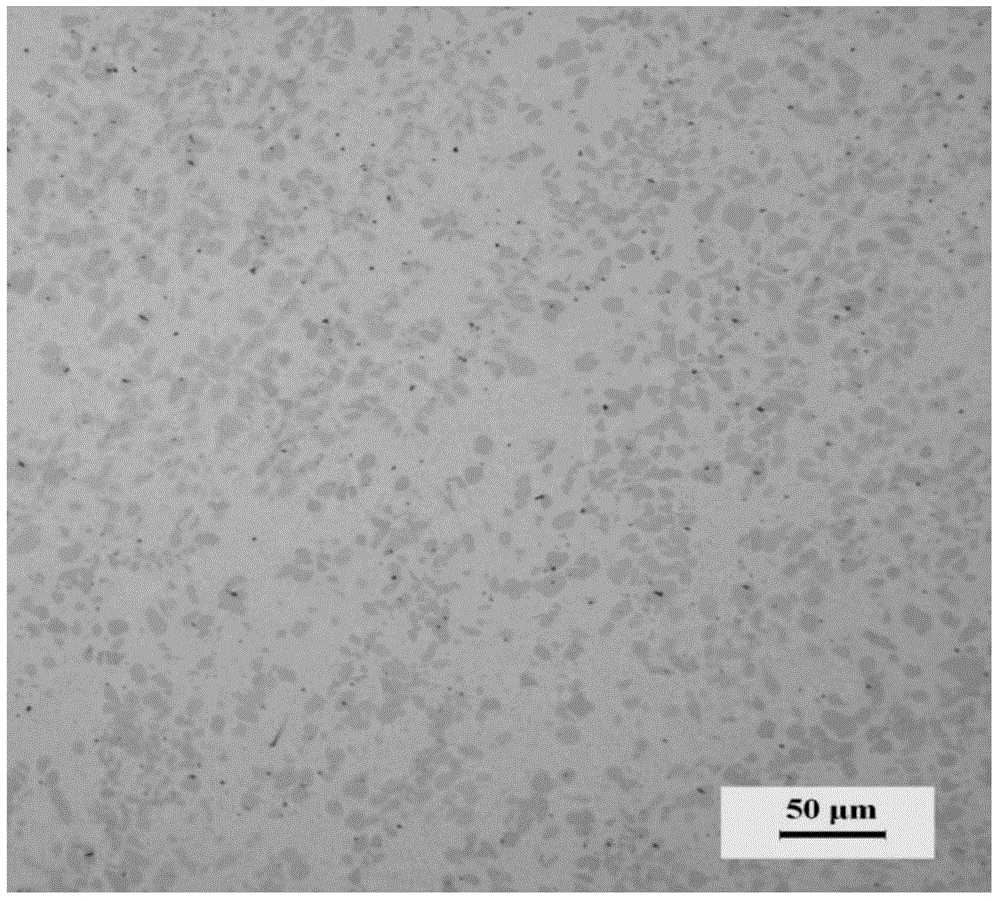

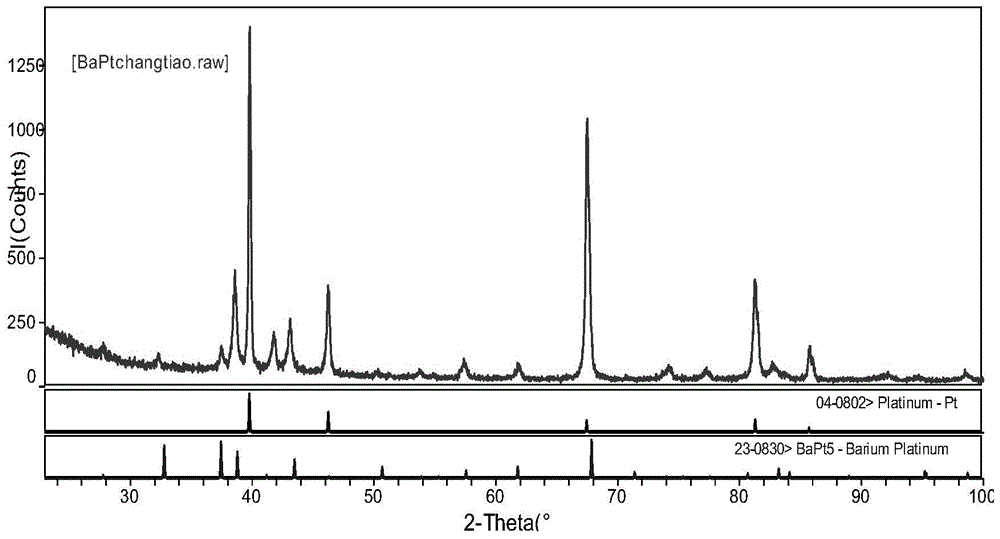

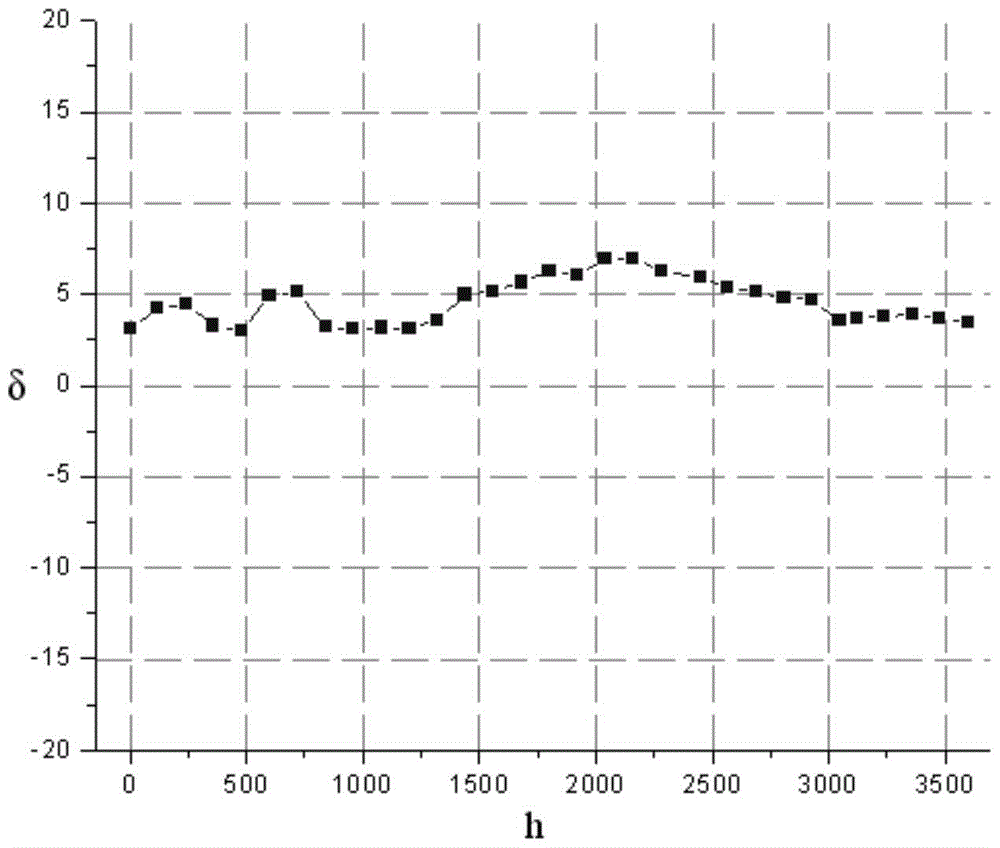

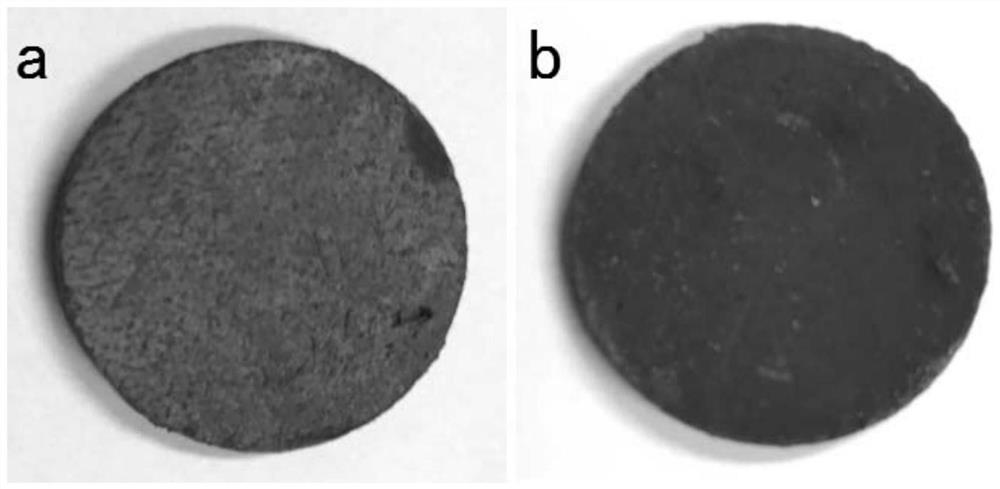

ActiveCN104342572BImprove emissivityImprove performanceDischarge tube cold cathodesSecondary electron emitting electrodesPlatinumCold cathode

The invention belongs to the technical field of negative electrode-material preparation and relates to a cold negative electrode material with high secondary-electron emission coefficient and a preparation method thereof. The cold negative electrode material comprises the following components in percentage by weight: 1.5%-4.5% of barium and 95.5%-98.5% of platinum; and the microstructure of the material is as follows: the platinum is used as a basal body and Pt5Ba is a second phase which is distributed in the basal body. The cold negative electrode material is continuously bombarded for 3600 hours under the condition that the power of primary electron bombardment is 200W / cm<2>, and the secondary-electron emission coefficient delta is more than 3.0. The cold negative electrode material is prepared by a series of processes such as casting, hot rolling, cold rolling and heat treatment. The cold negative electrode material has the advantages of high secondary-electron emission coefficient, long service life, stable performance and the like.

Owner:GRIKIN ADVANCED MATERIALS

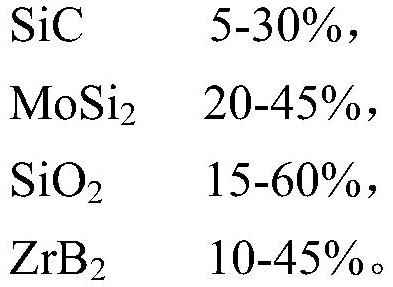

High temperature and high radiation resistant powder, its preparation, coating slurry containing it, coating and application

The invention discloses a high-temperature and high-radiation resistant powder, which comprises the following raw materials in mass percentage: SiC5-30%, MoSi 2 20‑45%, SiO 2 15‑60%, ZrB 2 10‑45% The powder has high temperature and high radiation characteristics. The invention also discloses the preparation of the powder, the coating slurry containing the powder, the preparation of the coating slurry, the coating and the application of the coating. When the coating is applied to the protection of ceramic matrix composites, the coating has high bonding strength with the matrix of ceramic matrix composites, high radiation coefficient in high temperature environment, good anti-oxidation and self-healing ability, and has anti-corrosion properties for ceramic matrix composites. Oxidation, the function of reducing the temperature of the material body.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com