High temperature and high radiation resistant powder, its preparation, coating slurry containing it, coating and application

A high-radiation coating and high-temperature-resistant technology, which is applied in the coating protection field of high-temperature structural materials, can solve problems such as difficult implementation, incompatibility of ceramic matrix composite materials, and complicated preparation process of high-radiation coatings, and achieve bond strength Effect of high, low temperature, high radiation coefficient in high temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

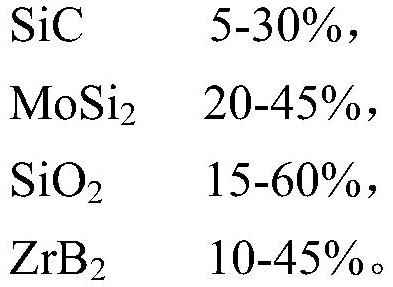

[0050] (1) SiC, MoSi 2 , SiO 2 , ZrB 2 The powder is mixed according to the mass percentage of 10%, 20%, 60%, and 10%, and ground in a ball mill for 2 hours; the powder is taken out and sieved to obtain a high-temperature and high-radiation-resistant powder with a particle size of about 200 mesh;

[0051] (2) Mix the powder prepared in the above steps with absolute alcohol in a mass ratio of 1:1, place in a stirring container, and stir for 20 minutes to obtain a mixed slurry;

[0052] (3) Mix the dispersed mixed slurry with the liquid polycarbosilane (PCS) polymer in a mass ratio of 2:1.5, and stir the mixture evenly with a stirrer;

[0053](4) Mix the slurry uniformly stirred in step (3) with the novolac epoxy resin (F51) in a mass ratio of 1:1, and mix evenly with a stirrer to prepare a high temperature resistant high radiation coating slurry;

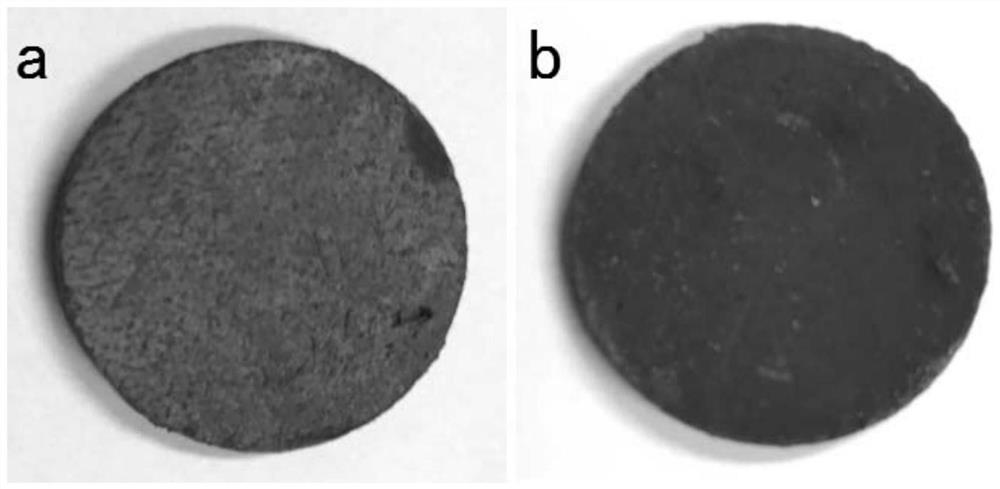

[0054] (5) Coating the above-mentioned coating slurry on the surface of the C / SiC composite material by spraying, and the coatin...

Embodiment 2

[0059] (1) SiC, MoSi 2 , SiO 2 , ZrB 2 The powder is mixed according to the mass percentage of 15%, 20%, 45%, and 20%, and ground in a ball mill for 3 hours; the powder is taken out, and after sieving, a high-temperature and high-radiation-resistant powder with a particle size of about 300 meshes is obtained;

[0060] (2) Mix the powder prepared in the above steps with absolute alcohol in a mass ratio of 1:0.7, place in a stirring container, and stir for 20 minutes to obtain a mixed slurry;

[0061] (3) Mix the dispersed mixed slurry with the liquid polycarbosilane (PCS) polymer in a mass ratio of 1:1.5, and stir the mixture evenly with a stirrer;

[0062] (4) Mix the uniformly stirred slurry in step (3) with the novolak epoxy resin (F-51) at a mass ratio of 1:1.5, and mix evenly with a stirrer to prepare a high temperature resistant high radiation coating slurry ;

[0063] (5) Apply the above-mentioned coating slurry on the surface of the C / SiC composite material by spray...

Embodiment 3

[0068] (1) SiC, MoSi 2 , SiO 2 , ZrB 2 The powders were mixed in proportions of 5%, 25%, 25%, and 45% by mass, and were ground in a ball mill for 3.5 hours. Take out the powder and sieve to obtain a high temperature and high radiation powder with a particle size of about 400 mesh;

[0069] (2) Mix the powder prepared in the above steps with absolute alcohol at a ratio of 1:2, place in a stirring container, and stir for 40 minutes.

[0070] (3) Mix the dispersed mixed slurry with the liquid polycarbosilane (PCS) polymer, the mass ratio is 1:2.5, and stir the mixture evenly with a stirrer;

[0071] (4) Mix the uniformly stirred slurry in step (3) with the novolak epoxy resin (F-51) at a mass ratio of 1:2, and mix evenly with a stirrer to prepare a high temperature resistant high radiation coating slurry ;

[0072] (5) Apply the above-mentioned coating slurry on the surface of the C / SiC composite material by spraying, and the coating thickness is controlled at 0.3mm;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com