Inorganic oxidability high molecular ferro-silicon coagulant, preparation process thereof and applications

An oxidizing and polymer technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem that the inorganic polymer ferrosilicon coagulant and its oxidative modifier have not formed a market scale, and the pollution removal performance has not been improved. Break through the problems of progress and poor product stability, and achieve the effects of low price, short production cycle and short stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

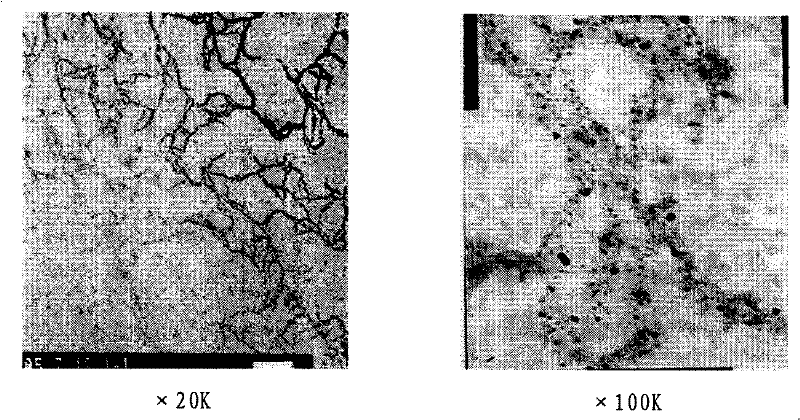

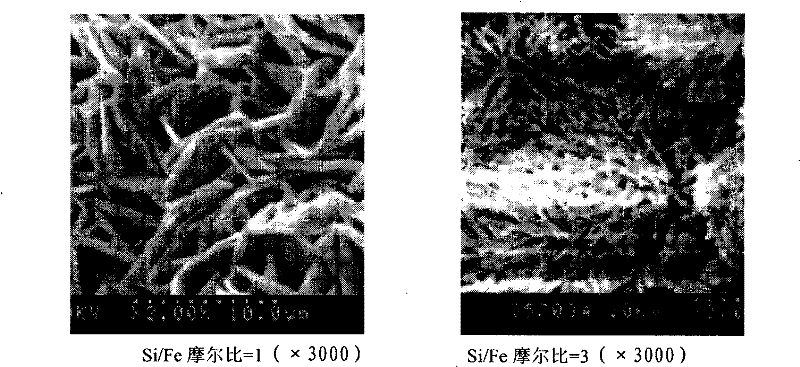

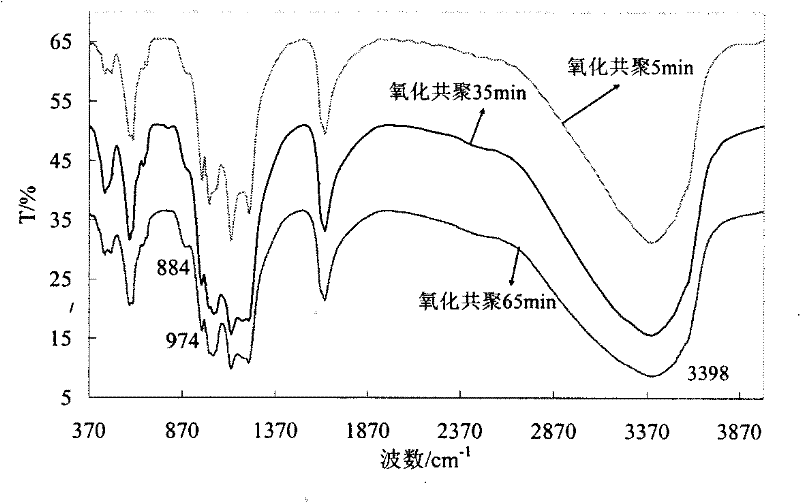

Image

Examples

Embodiment 1

[0031] Dilute 20L of water glass with 71L of water. At a temperature of 20°C to 40°C and a stirring speed of 300 to 500 rpm, add the diluted water glass to 5L of dilute sulfuric acid solution with a mass fraction of 40%, and control the pH value to 3.5 , stop after stirring for 4 minutes, and let it stand for 1 hour to obtain polysilicic acid, which is ready for use. At a temperature of 25°C to 55°C, add 60kg of ferrous sulfate heptahydrate into 31L of dilute sulfuric acid solution with a mass fraction of 40%, and stir for 10 minutes at a speed of 150 to 300 rpm to prepare Obtain ferrous sulfate solution. Under the condition that the temperature is 25°C-55°C and the stirring speed is 200rpm-400rpm, the polysilicic acid to be used is added to the above-mentioned ferrous sulfate solution, and 3.5kg of sodium chlorate is added at the same time, After 5 minutes, the stirring was stopped, and the semi-finished product of the inorganic oxidizing polymer ferrosilicon coagulant was ...

Embodiment 2

[0033] Dilute 20L of water glass with 68L of water. At a temperature of 20°C to 40°C and a stirring speed of 300 to 500 rpm, add the diluted water glass to 5L of dilute sulfuric acid solution with a mass fraction of 40%, and control the pH value to 3 , stop after stirring for 4 minutes, and let it stand for 2 hours to obtain polysilicic acid, which is ready for use. At a temperature of 25°C to 55°C, add 30kg of ferrous sulfate heptahydrate into 18L of dilute sulfuric acid solution with a mass fraction of 40%, and stir for 10 minutes at a speed of 150 to 300 rpm to prepare Obtain ferrous sulfate solution. Under the condition that the temperature is 25°C-55°C and the stirring speed is 200rpm-400rpm, the polysilicic acid to be used is added to the above ferrous sulfate solution, and 1.7kg of sodium chlorate is added at the same time, After 5 minutes, the stirring was stopped, and the semi-finished product of the inorganic oxidizing polymer ferrosilicon coagulant was obtained. ...

Embodiment 3

[0035] Dilute 20L of water glass with 65L of water. At a temperature of 20°C to 40°C and a stirring speed of 300 rpm to 500 rpm, add the diluted water glass to 5L of dilute sulfuric acid solution with a mass fraction of 40%, and control the pH value to 2 , stop after stirring for 4 minutes, and let it stand for 3 hours to obtain polysilicic acid, which is ready for use. At a temperature of 25°C to 55°C, add 16kg of ferrous sulfate heptahydrate to 8.5L of dilute sulfuric acid solution with a mass fraction of 40%, and stir for 10 minutes at a speed of 150 to 300 rpm. Prepare ferrous sulfate solution. Under the condition that the temperature is 25°C-55°C and the stirring speed is 200rpm-400rpm, the polysilicic acid to be used is added to the above-mentioned ferrous sulfate solution, and 0.9kg of sodium chlorate is added at the same time, After 5 minutes, the stirring was stopped, and the semi-finished product of the inorganic oxidizing polymer ferrosilicon coagulant was obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com