Kiwi brandy

A technology of brandy and kiwi fruit, applied in the direction of preparation of alcoholic beverages, microorganisms, biochemical equipment and methods, etc., can solve the problems of increasing the bitter taste and unpleasant smell of kiwi fruit wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

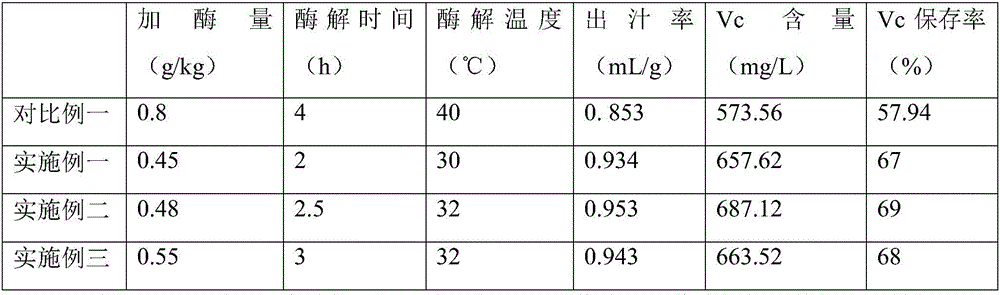

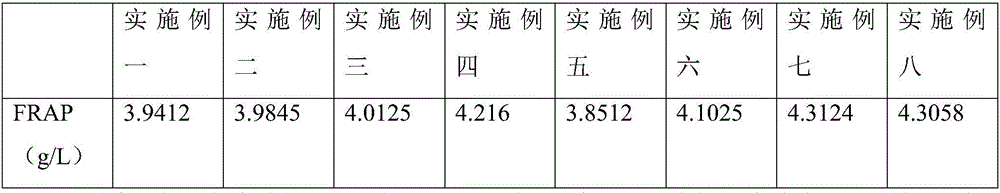

Embodiment 1

[0018] A. Select 8000g of naturally mature kiwi fruit, clean it, dry the skin of kiwi fruit, break it into paste kiwi fruit pulp for later use, dissolve 10g of Saccharomyces cerevisiae evenly with 80g of white wine to make Saccharomyces cerevisiae solution for later use, and then crush 8000g of kiwi fruit The kiwifruit pulp, 6g pulp enzyme, 50g brewer's yeast lysate, 3g sodium bisulfite, 20g antioxidant and 5g bacteriostatic agent are placed in the mixing drum of the double-helix mixer and stirred evenly to obtain the kiwifruit mixture;

[0019] B, adding 1800g salt of wormwood, 500g honey, 4g fruit pulp enzyme, 30g saccharomyces cerevisiae lysate, 3g sodium bisulfite, 20g antioxidant and 3g bacteriostatic agent in the kiwifruit mixture prepared by step A and pressing to get the juice, making to clarify the juice;

[0020] C, adding the sodium bisulfite of 10g brewer's yeast lysate, 2g, 10g antioxidant and 2g antibacterial agent fermentation 10-15 days in the clarified fruit j...

Embodiment 2

[0026] The difference between this example and Example 1 is that in step A, 9000g of kiwifruit is selected, 15g of Saccharomyces cerevisiae is uniformly dissolved into a Saccharomyces cerevisiae solution with 100g of white wine, and then 9000g of broken kiwifruit pulp, 12g of fruit pulp enzyme, and 50g of brewing yeast Yeast lysate, 3.6g sodium bisulfite, 40g antioxidant and 7.5g antibacterial agent are placed in the mixing drum of the double-helix mixer and stirred evenly; 2200g potassium carbonate, 750g honey, 8g fruit pulp enzyme are added to the kiwifruit mixture in step B , 40g Saccharomyces lysate, 3.6g sodium bisulfite, 40g antioxidant and 4.5g bacteriostatic agent and squeeze the juice; add 25g Saccharomyces lysis solution, 2.4g sodium bisulfite, 20g antioxidant and 3g bacteriostatic agent; Add the sodium bisulfite of 2.4g in step D; Add ammonium sulfate 50g and filter aid 250g in step E.

Embodiment 3

[0028]The difference between this example and Example 1 is that in step A, 10000g of kiwifruit is selected, 20g of Saccharomyces cerevisiae is uniformly dissolved into a Saccharomyces cerevisiae solution with 120g of white wine, and then 10000g of crushed kiwifruit pulp, 18g of fruit pulp enzyme, and 60g of brewing yeast Yeast lysate, 4.5g sodium bisulfite, 45g antioxidant and 10g bacteriostatic agent are placed in the mixing drum of the double-helix mixer and stirred evenly; in the kiwi fruit mixture, add 3000g potassium carbonate, 1000g honey, 12g fruit pulp enzyme, 50g of Saccharomyces cerevisiae solution, 4.5g of sodium bisulfite, 45g of antioxidant and 6g of bacteriostatic agent, and squeeze the juice; add 30g of Saccharomyces cerevisiae solution, 3g of sodium bisulfite, 30g of antioxidant Agent and 4g antibacterial agent; Add the sodium bisulfite of 3g in step D; Add ammonium sulfate 70g and filter aid 300g in step E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com