Energy saving measure and construction method for producing andesite continuous fiber flame furnace

A technology of continuous fiber and construction method, applied in the field of energy-saving measures, can solve problems such as insufficient flame kiln, and achieve the effects of good thermal insulation effect, high crystallization temperature and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

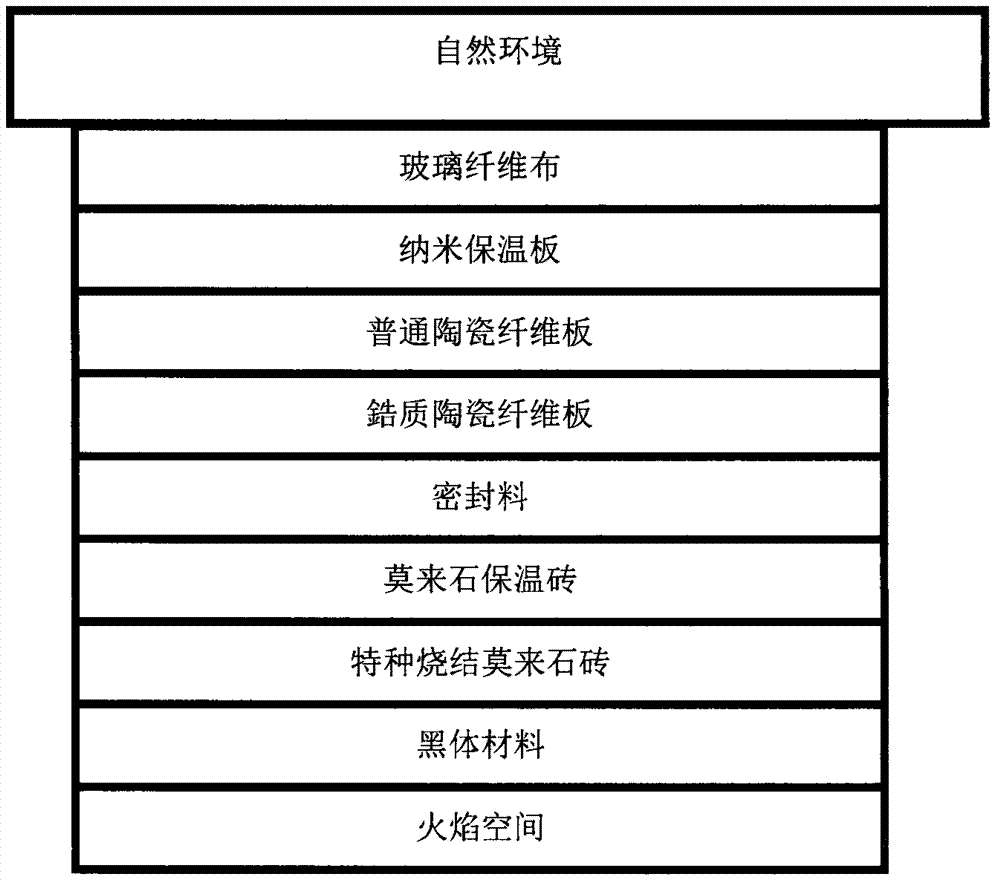

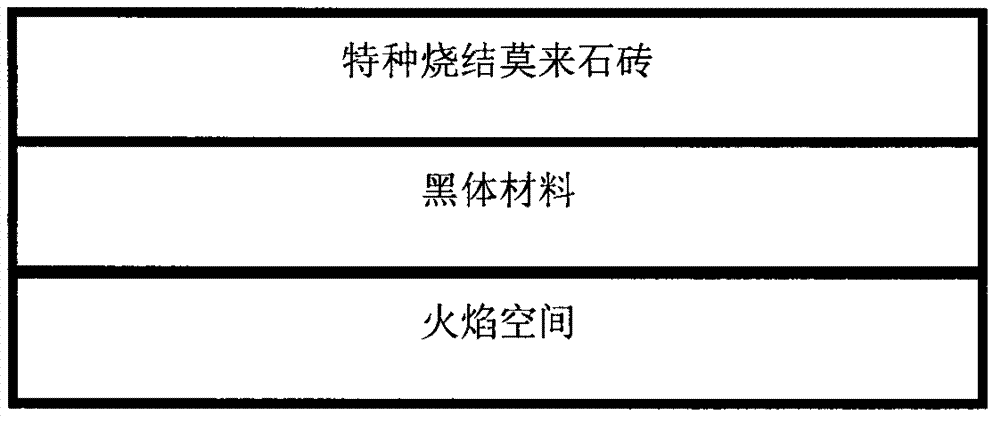

[0018] The energy-saving measures and construction method of a continuous flame kiln for producing andesite according to the present invention will be further described in detail below in conjunction with Fig. 1 and Fig. 2 .

[0019] Please refer to Figure 1 for an energy-saving measure and construction method of a flame kiln for producing andesite continuous fiber according to the present invention, which includes external insulation of the large wall of the melting part of the flame kiln, spraying black body materials on the large wall of the melting part of the flame kiln, and the parapet and flame contact parts. The details are as follows, the external insulation of the large wall of the melting part of the flame kiln: the special sintered mullite bricks are built by wet masonry, and the special sintered mullite bricks are mainly resistant to high temperature, small creep, and good volume stability, ensuring that the kiln lasts for one kiln life. run requirements. On the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com