Preparation method of secondary-electron emission thin film

A secondary electron emission and thin film technology, which is applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problem of reducing the conductivity of the film, poor applicability of magnesium oxide film, and reducing the secondary electron emission of magnesium oxide Coefficient and other issues, to achieve the effect of flexible film forming process and easy control of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

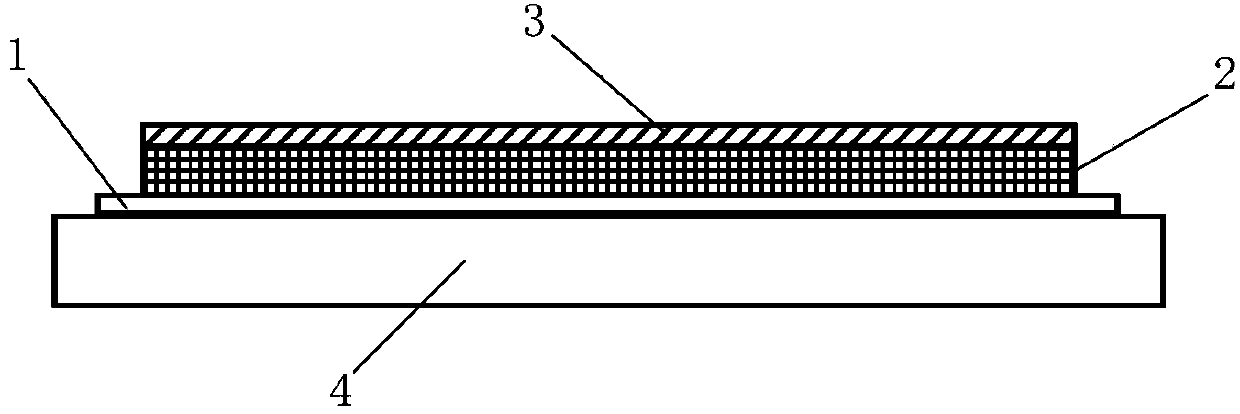

[0039] refer to figure 1 As shown, the secondary electron emission film has a multi-layer structure, including a buffer layer 1 , a mixed layer of magnesium oxide and metal 2 and a layer of magnesium oxide 3 arranged on a metal substrate 4 in sequence.

[0040] A kind of preparation method of secondary electron emission thin film of the present invention, comprises the following steps:

[0041] Firstly, a buffer layer 1 is deposited on the metal substrate 4 by sputtering a target made of one material among titanium, nickel, chromium, gold, silver, platinum or a composite target made of several of them, with a thickness of 3-100nm ;

[0042] Next, a magnesium oxide and metal mixed layer 2 is deposited on the buffer layer 1, which is a magnesium oxide cermet formed by simultaneously depositing magnesium oxide and metals by co-sputtering a magnesium target (or magnesium oxide target) and other metal targets layer, in which the other metal target is a target material of gold, si...

Embodiment 2

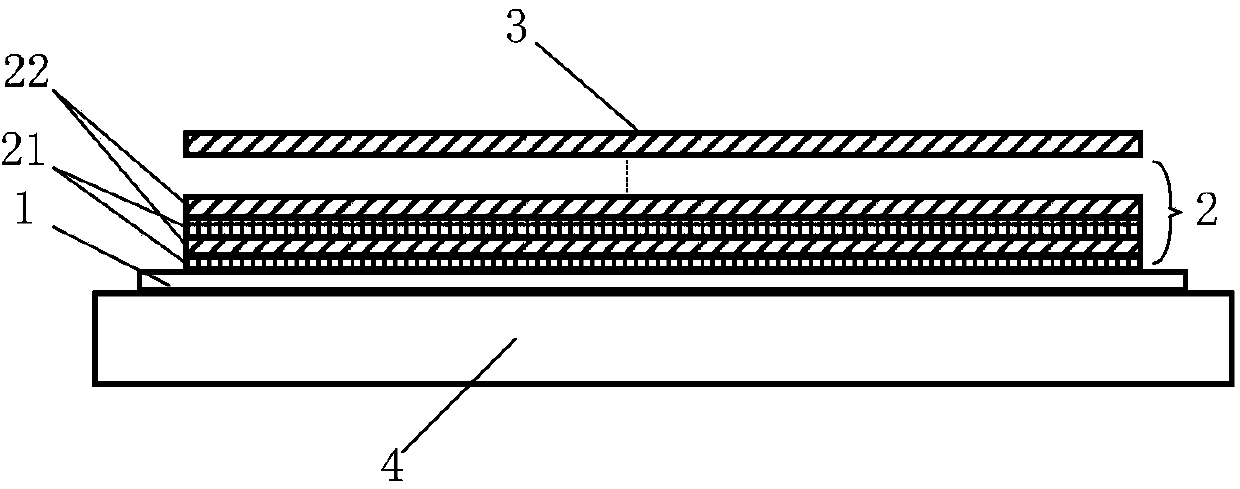

[0045] refer to figure 2 As shown, the secondary electron emission film has a multi-layer structure, including a buffer layer 1 , a mixed layer of magnesium oxide and metal 2 and a layer of magnesium oxide 3 arranged on a metal substrate 4 in sequence.

[0046] A kind of preparation method of secondary electron emission thin film of the present invention, comprises the following steps:

[0047] First, deposit a buffer layer 1 on the metal substrate 4 by sputtering a target made of one of titanium, nickel, chromium, gold, silver, and platinum, or a composite target consisting of several of these materials, with a thickness of 3-100nm between;

[0048] Next, the mixed layer 2 of magnesium oxide and metal is deposited on the buffer layer 1. The mixed layer 2 of magnesium oxide and metal is deposited by continuous sputtering of magnesium target (or magnesium oxide target) and intermittent sputtering of other metal targets. Magnesium oxide cermet layer 21 and magnesium oxide lay...

Embodiment 3

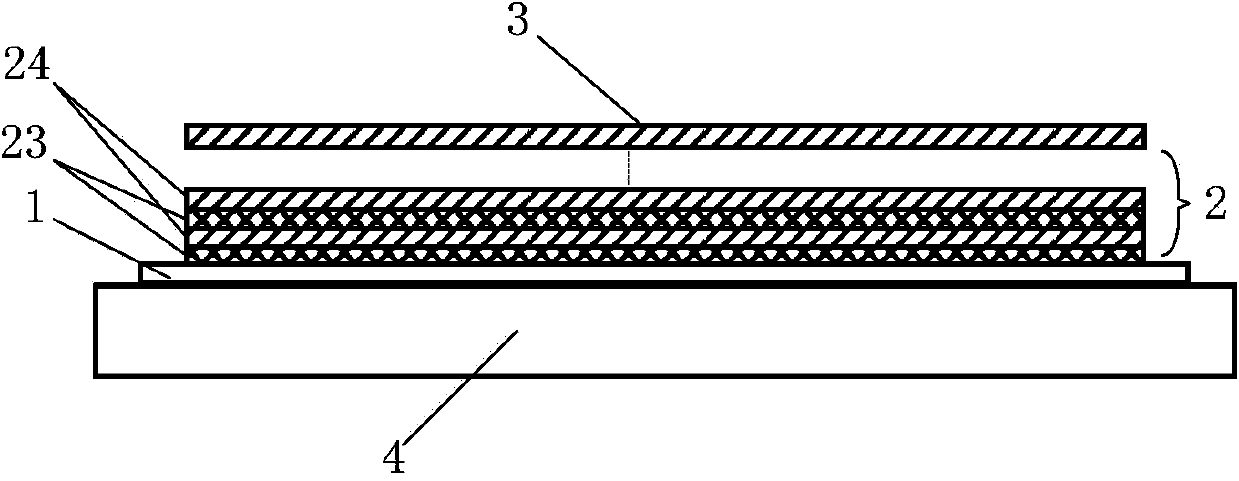

[0051] refer to image 3 As shown, the secondary electron emission film has a multi-layer structure, including a buffer layer 1 , a mixed layer of magnesium oxide and metal 2 and a layer of magnesium oxide 3 arranged on a metal substrate 4 in sequence.

[0052] A kind of preparation method of secondary electron emission thin film of the present invention, comprises the following steps:

[0053] Firstly, a buffer layer 1 is deposited on the metal substrate 4 by sputtering a target made of one material among titanium, nickel, chromium, gold, silver, platinum or a composite target made of several of them, with a thickness of 3-100nm ;

[0054] Next, a mixed layer 2 of magnesium oxide and metal is deposited on the buffer layer 1. The mixed layer 2 of magnesium oxide and metal is deposited by alternately sputtering a magnesium target (or magnesium oxide target) and other metal targets to deposit multiple alternating metal layers 23 and Magnesium oxide layer 24, wherein other meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com