Element capable of enhancing radiation and preparation method

A component, silicon carbide technology, applied in the field of components and preparations that can enhance radiation, can solve the problems of energy waste and increase the processing cost of enterprises, and achieve the effect of increasing the emissivity and improving the efficiency of thermal radiation absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

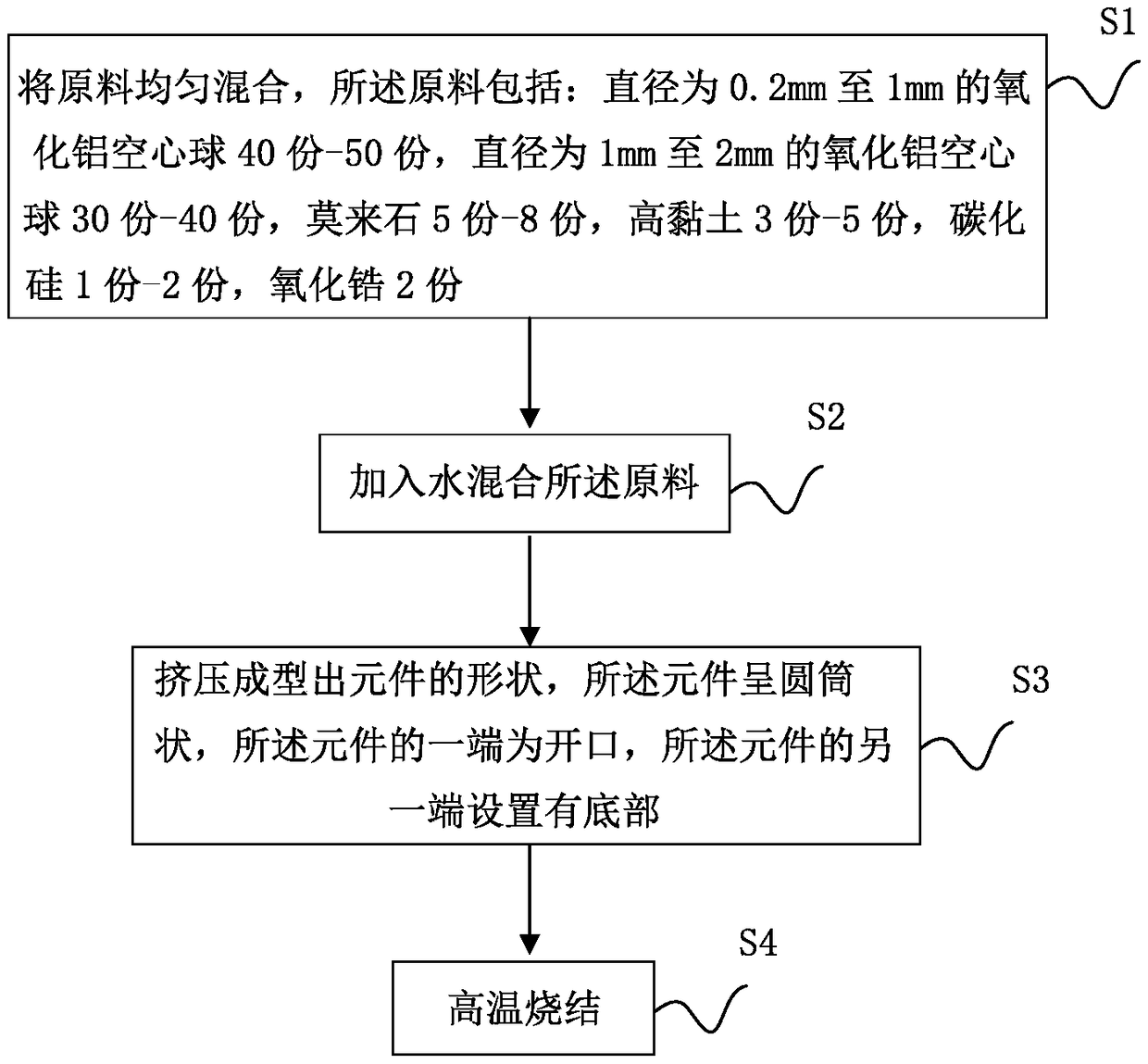

[0026] The invention provides a method for preparing a component capable of enhancing radiation, the method comprising:

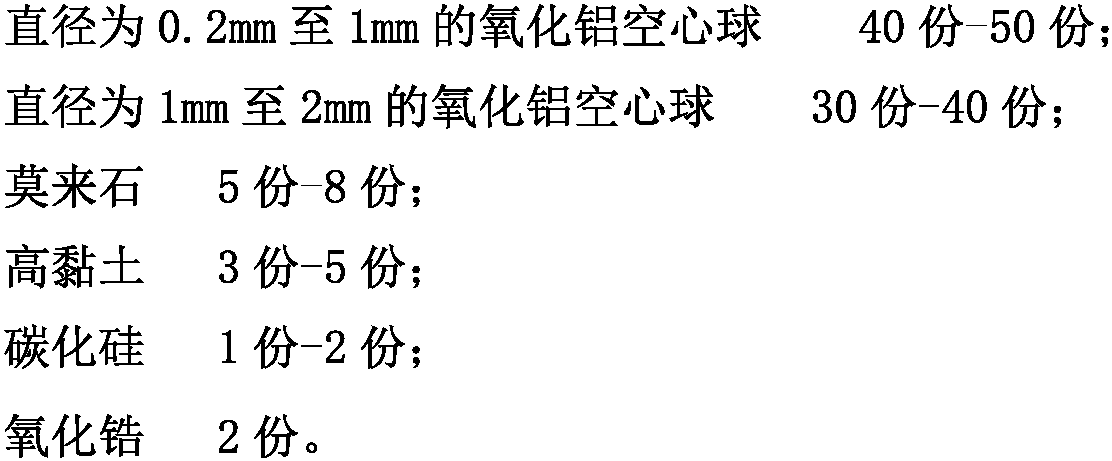

[0027] S1. Mix the raw materials evenly. The raw materials include: 40-50 parts of alumina hollow spheres with a diameter of 0.2mm to 1mm, 30-40 parts of alumina hollow spheres with a diameter of 1mm to 2mm, and 5 parts of mullite -8 parts, 3-5 parts of high clay, 1-2 parts of silicon carbide, 2 parts of zirconia;

[0028] S2, adding water to mix the raw materials;

[0029] S3. Extruding the shape of the element, the element is cylindrical, one end of the element is an opening, and the other end of the element is provided with a bottom;

[0030] S4, high temperature sintering.

[0031] In some embodiments, step S1 in the method provided by the present invention includes the following sub-steps:

[0032] S11, stirring the aluminum oxide hollow balls of two specifications evenly;

[0033] S12. Grinding mullite and high clay to nanoscale;

[0034] S13, un...

Embodiment 1

[0047] In this embodiment, the components provided by the present invention include, by weight: 40 parts of alumina hollow spheres with a diameter of 0.2 mm to 1 mm, 30 parts of alumina hollow spheres with a diameter of 1 mm to 2 mm, 8 parts of mullite, and 3 parts of clay, 1 part of silicon carbide, 2 parts of zirconia.

Embodiment 2

[0049] In this embodiment, the components provided by the present invention include, in parts by weight: 45 parts of alumina hollow spheres with a diameter of 0.2 mm to 1 mm, 35 parts of alumina hollow spheres with a diameter of 1 mm to 2 mm, 7 parts of mullite, and Clay 4 parts, silicon carbide 2 parts, zirconia 2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com