Dark-color reflective and heat insulation varnish and preparation method thereof

A dark color, hot water technology, applied in the field of coatings, can solve the problems of light pollution decoration, reduced reflection efficiency, poor stain resistance, etc., and achieve the effect of saving labor costs and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

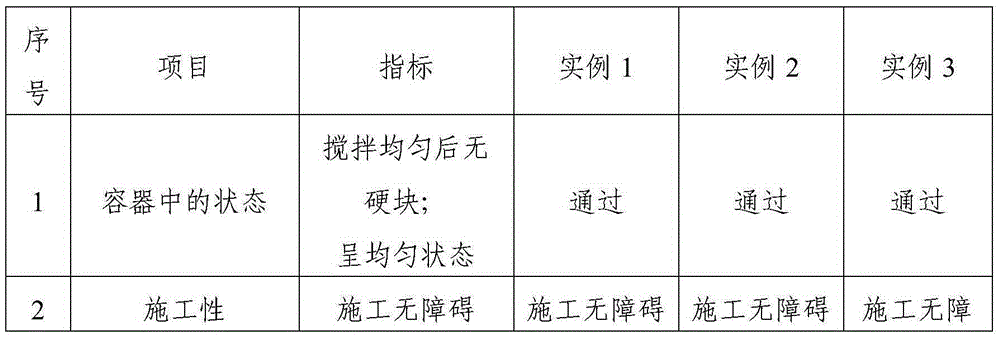

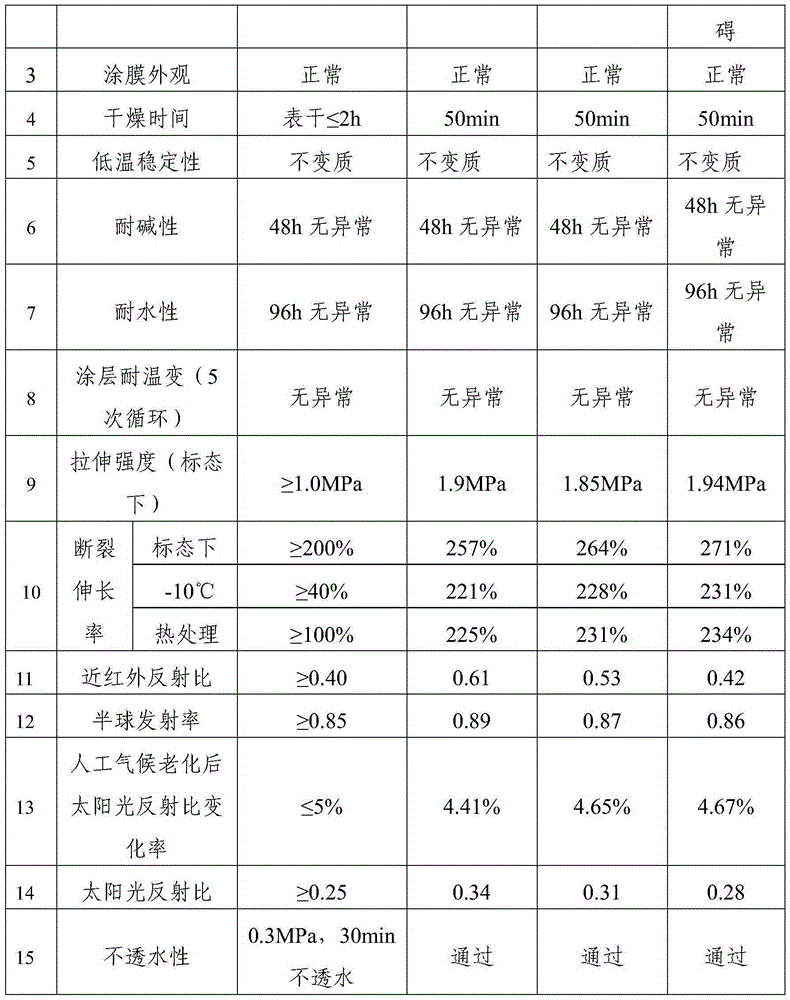

Examples

Embodiment 1

[0036] The dark reflective thermal insulation paint provided in this embodiment comprises:

[0037] 320 parts of elastic emulsion, 80 parts of fluorocarbon emulsion, 240 parts of filler (120 parts of functional filler composed of hollow glass microspheres: reflective filler = 1:1.5, 120 parts of other fillers), 90 parts of toner, 50 parts of titanium dioxide , 4 parts of dispersant, 5 parts of defoamer, 10 parts of film-forming aid, 3 parts of leveling agent, 8 parts of thickener, 2 parts of anti-mold and anti-algae agent, 2 parts of fungicide, 3 parts of wetting agent, 200 parts of deionized water and an appropriate amount of pH regulator, the appropriate amount shown is based on adjusting the pH value of the dark reflective thermal insulation paint to 9.

[0038] Among them, the elastic emulsion is BLJ-9468, the fluorocarbon emulsion is BLJ-9988, the reflective filler is TK501W, the other filler is heavy calcium 800, the toner is (Black30C938, Brown157), the titanium dioxide...

Embodiment 2

[0042] The dark reflective thermal insulation paint provided in this embodiment comprises according to the proportion by weight:

[0043] 360 parts of elastic emulsion, 60 parts of fluorocarbon emulsion, 110 parts of filler (hollow glass microspheres: reflective filler = 1:1.5), 130 parts of other fillers, 50 parts of toner, 30 parts of titanium dioxide, 5 parts of dispersant, defoaming 4 parts of agent, 7 parts of film-forming aid, 4 parts of leveling agent, 6 parts of thickener, 2 parts of anti-mildew and anti-algae agent, 2 parts of fungicide, 4 parts of wetting agent, 230 parts of deionized water, pH adjustment An appropriate amount of agent, the appropriate amount shown is based on adjusting the pH value of the dark reflective thermal insulation paint to 9.

[0044] Among them, the elastic emulsion is BLJ-9468, the fluorocarbon emulsion is BLJ-9988, the reflective filler is TK501W, the other filler is heavy calcium 800, the titanium dioxide is LR996, the dispersant is 963...

Embodiment 3

[0048] The dark reflective thermal insulation paint provided in this embodiment comprises according to the proportion by weight:

[0049] 380 parts of elastic emulsion, 40 parts of fluorocarbon emulsion, filler (hollow glass microspheres: reflective filler = 1:1.590 parts, 180 parts of other fillers), 30 parts of toner, 10 parts of titanium dioxide, 6 parts of dispersant, defoamer 3 parts, 5 parts of film-forming aid, 5 parts of leveling agent, 8 parts of thickener, 2 parts of anti-mildew and anti-algae agent, 2 parts of fungicide, 4 parts of wetting agent, 220 parts of deionized water, PH regulator Appropriate amount, the appropriate amount shown is based on adjusting the pH value of the dark reflective thermal insulation paint to 9.

[0050] Among them, the elastic emulsion is BLJ-9468, the fluorocarbon emulsion is BLJ-9988, the reflective filler is TK501W, the other filler is heavy calcium 800, the titanium dioxide is LR996, the dispersant is 963, the defoamer is A10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com