Vacuum cavity embedded aerogel type heat preservation shell for thermal battery and application of vacuum cavity embedded aerogel type heat preservation shell

A technology of vacuum insulation and aerogel, which is applied in the direction of electrical components, battery boxes/coats, battery pack components, etc., which can solve the development requirements of unfavorable thermal batteries to save space, unsatisfactory long-life thermal batteries, and unsatisfactory thermal insulation effects, etc. problem, to achieve the effect of improving thermal insulation effect, low solid thermal conductivity, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

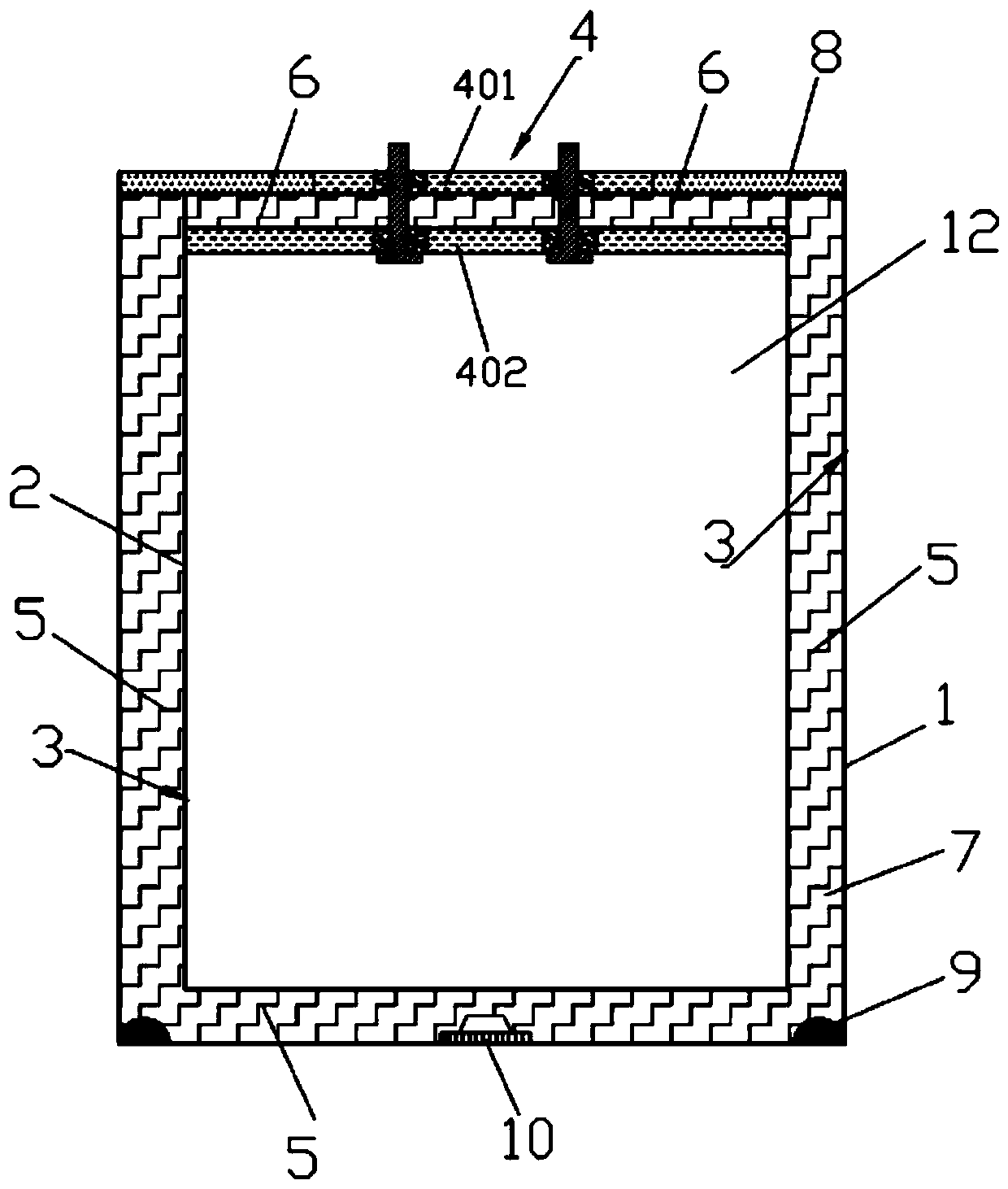

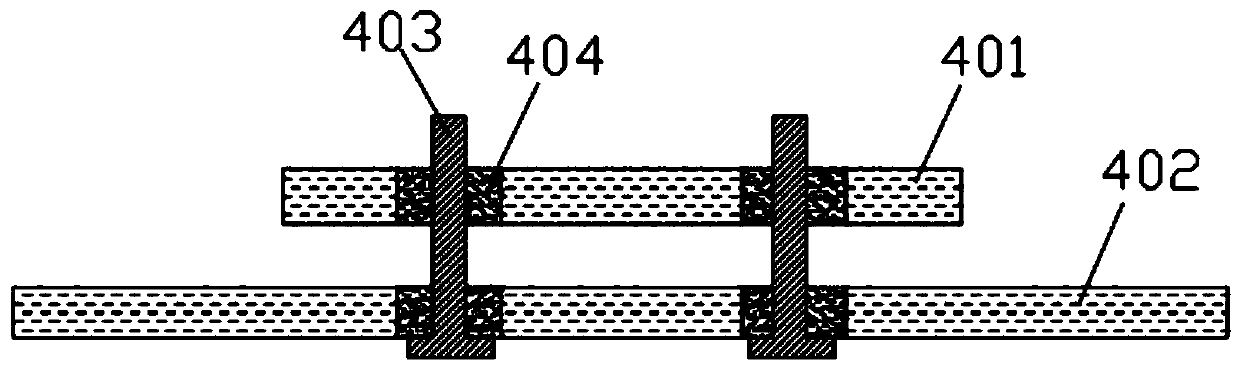

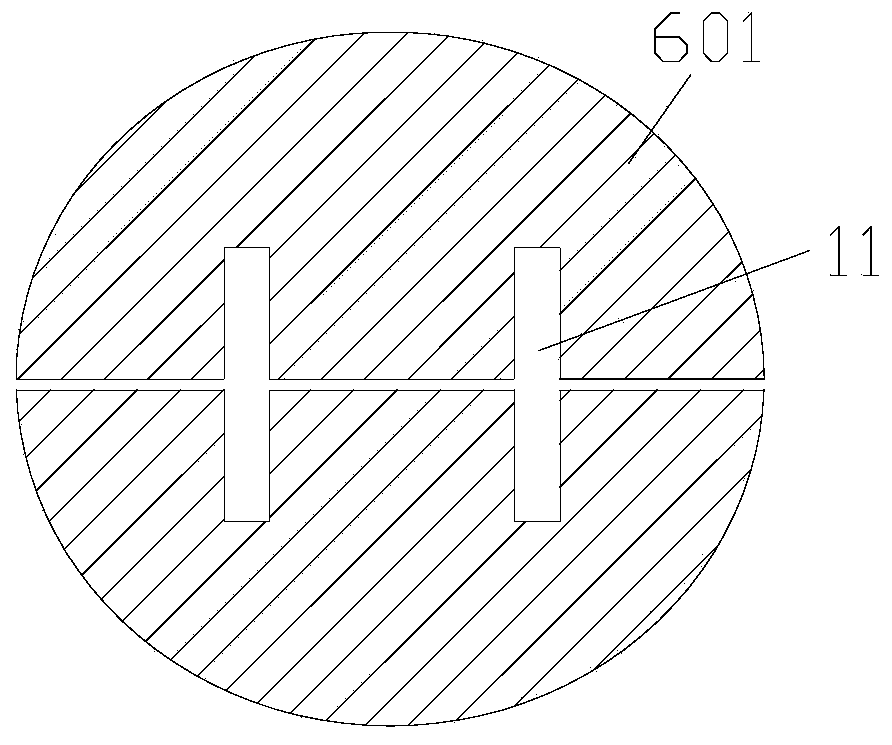

[0056] The battery case 1 and the battery inner case 2 are made of stainless steel 304, the reflective material aluminum is plated on the inner wall of the battery case 1 and the outer wall of the battery inner case 2, the thickness is 100 μm, and the getter material 9 barium is fixed inside the vacuum cavity aluminum alloy, and then the nano-silica airgel insulation tube 5 is packed into the battery casing 1. After the assembled battery cell stack 12 is put into the battery inner case 2, cover the battery cover 4, weld the lower cover 402 of the battery cover 4 with the battery inner case 2, and then install the airgel insulation block 6 between the upper and lower layers of the battery cover 4, then weld the upper cover 401 of the battery cover 4 to the inner edge of the outer ring 8 of the cover, and then weld the welded battery inner case 2 and battery cover 4 , nano-silica airgel insulation block 6, the combination of four parts of the outer ring 8 of the cover plate are ...

Embodiment 2

[0058] The battery case 1 and the battery inner case 2 are made of industrial pure titanium materials, and the reflective material aluminum is evaporated on the inner wall of the battery case 1 and the outer wall of the battery inner case 2, with a thickness of 50 μm, and the getter material is fixed inside the vacuum cavity 9 barium-titanium alloys, and then the nano-zirconia airgel insulation tube 5 is packed into the battery casing 1. After the assembled battery cell stack 12 is loaded into the battery inner shell 2, cover the battery cover plate 4, weld the lower cover plate 402 of the battery cover plate 4 with the battery inner shell 2, and then apply the nano zirconia airgel The insulation block 6 is put between the upper and lower layers of the battery cover plate 4, and then the upper layer cover plate 401 of the battery cover plate 4 is welded to the inner edge of the outer ring 8 of the cover plate, and then the welded battery inner shell 2, The battery cover plate ...

Embodiment 3

[0060] The battery case 1 and the battery inner case 2 are made of stainless steel 304 material, the reflective material aluminum is electroplated on the inner wall of the battery case 1 and the outer wall of the battery inner case 2, the thickness is 20 μm, and the getter material 9 zirconium is fixed inside the vacuum chamber aluminum alloy, and then the nano zirconia airgel insulation tube 5 is packed into the battery casing 1. After the assembled battery cell stack 12 is loaded into the battery inner shell 2, cover the battery cover plate 4, weld the lower cover plate 402 of the battery cover plate 4 with the battery inner shell 2, and then apply the nano-silica airgel The insulation block 6 is put between the upper and lower layers of the battery cover plate 4, and then the upper layer cover plate 401 of the battery cover plate 4 is welded to the inner edge of the outer ring 8 of the cover plate, and then the welded battery inner shell 2, The battery cover plate 4, the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com