A kind of high secondary electron emission coefficient cold cathode material and its preparation method

A technology of secondary electron emission and electron emission materials, which is applied in the field of secondary electron cold cathode materials and its preparation, can solve the problems of unsatisfactory, long-term use, and limited application occasions, and achieve stable performance and long service life Long-lasting, highly chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of cold cathode material of the present invention is as follows:

[0029] (1) Pt with a purity of 99.95% and Ba with a purity of 99.9% are mixed according to 1.5% by weight of Ba and the rest is Pt, and are smelted in a vacuum induction melting furnace at a melting temperature of 1750-1900°C.

[0030] (2) After melting, the alloy is poured directly into the metal mold, and the pouring temperature is about 1750-1800°C;

[0031] (3) hot-rolling the cast ingot, the hot-rolling temperature is 900° C., the pass deformation is 10%, and when the total deformation reaches 60%, it is annealed at 800° C. for 60 minutes;

[0032] (4) Carry out cold rolling and annealing subsequently, cold rolling deformation amount 50%, carry out vacuum annealing, vacuum degree 10 -1 Pa, the annealing time is 1h, the annealing temperature is 700°C, and finally a cold cathode strip with a thickness of 0.1mm is obtained.

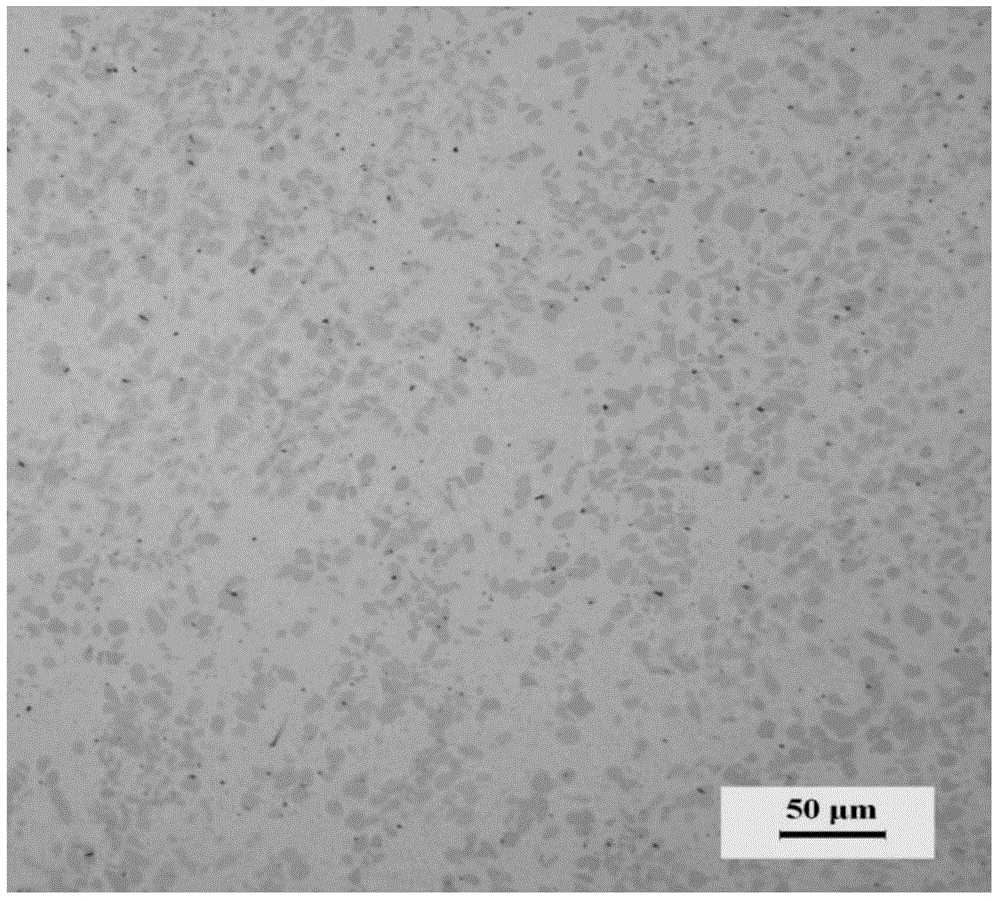

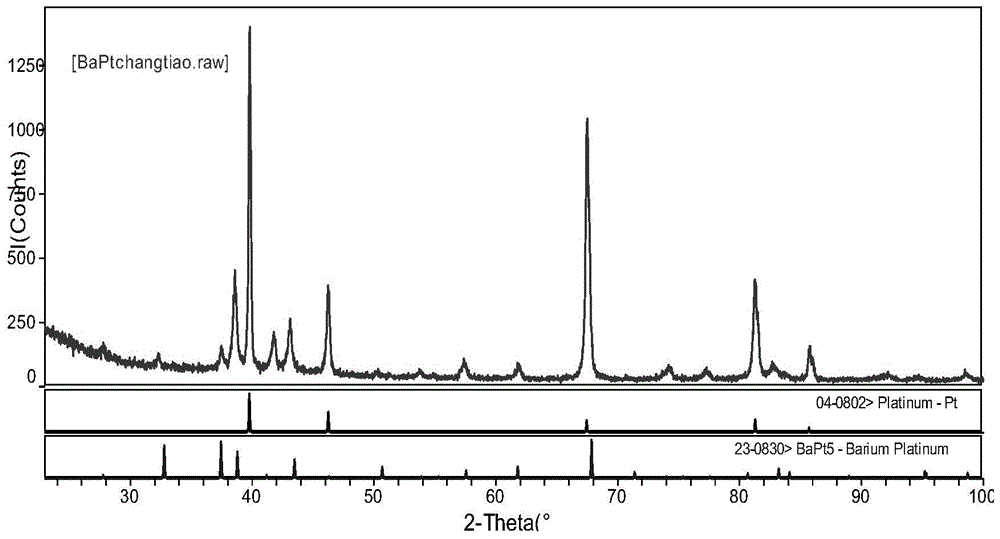

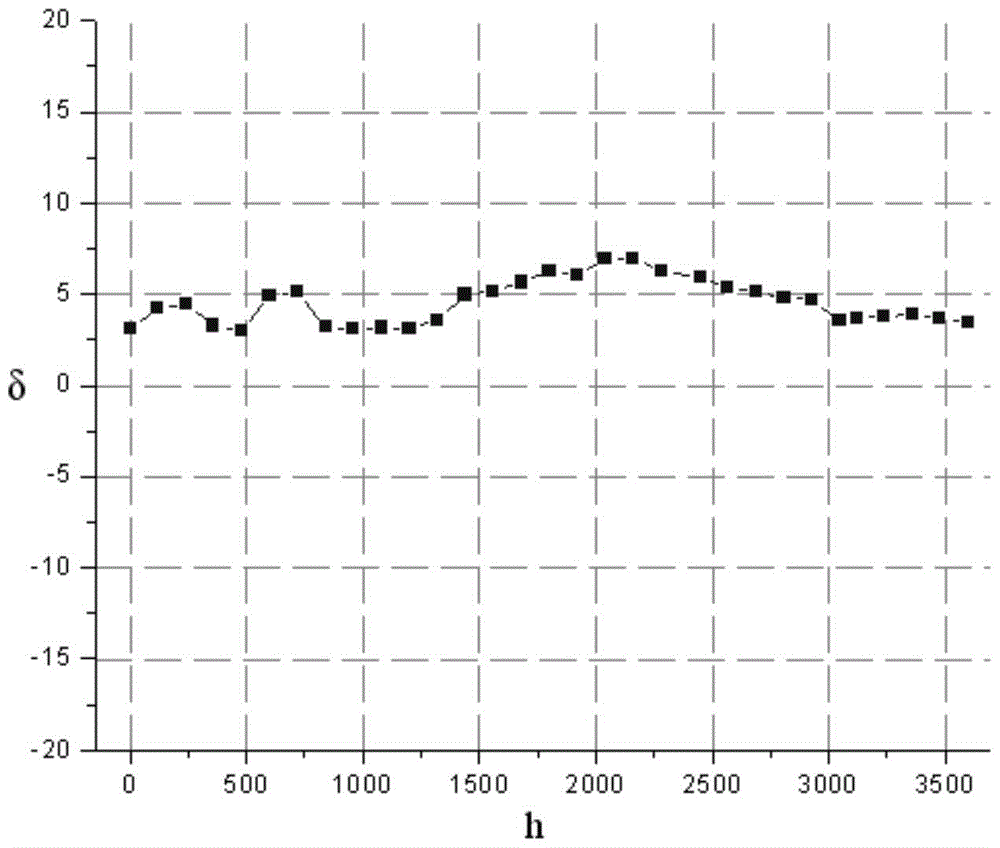

[0033] The metallographic structure of the cold cath...

Embodiment 2

[0038] This example describes a possible composition of the cold cathode material of the present invention and its preparation method, and characterizes its microstructure and properties.

[0039] The preparation method of the cold cathode material described in this embodiment is as follows:

[0040] (1) Pt with a purity of 99.95% and Ba with a purity of 99.9% are mixed according to the Ba content of 3wt.% and the rest is Pt, and placed in a vacuum induction melting furnace for melting at a melting temperature of 1750-1900°C.

[0041] (2) After melting, the alloy is poured directly into the metal mold, and the pouring temperature is about 1750-1800°C;

[0042] (3) hot-rolling the cast ingot, the hot-rolling temperature is 1100° C., and the pass deformation is 7%. When the total deformation reaches 60%, it is annealed at 900° C. for 50 minutes;

[0043] (4) Carry out cold rolling and annealing subsequently, cold rolling deformation amount 30%, carry out vacuum annealing, vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com