Plasma display panel and manufacturing method thereof

A technology of a plasma display screen and a manufacturing method, which is applied to the field of plasma display screen and manufacturing, can solve the problems of increasing the number of lines, reducing the discharge space, and failing to meet the quality requirements of the full high-definition PDP display screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

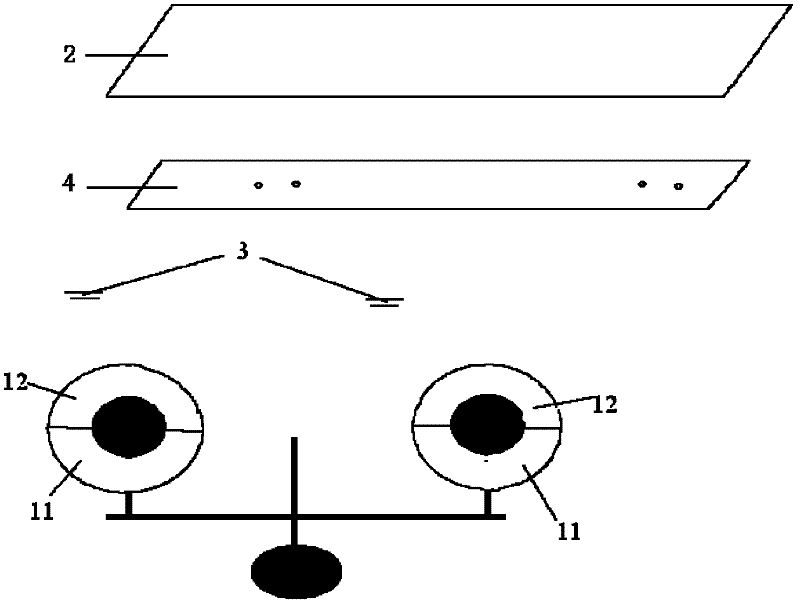

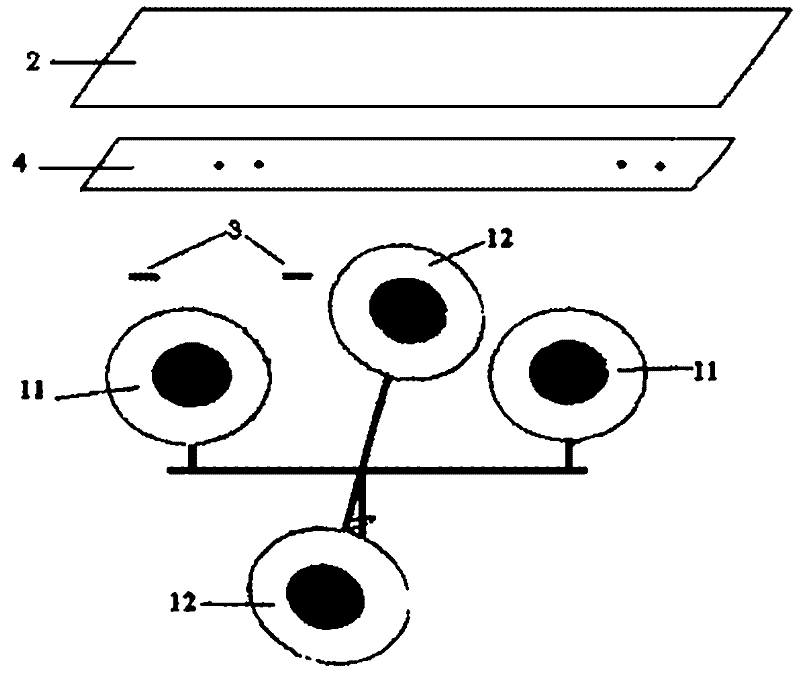

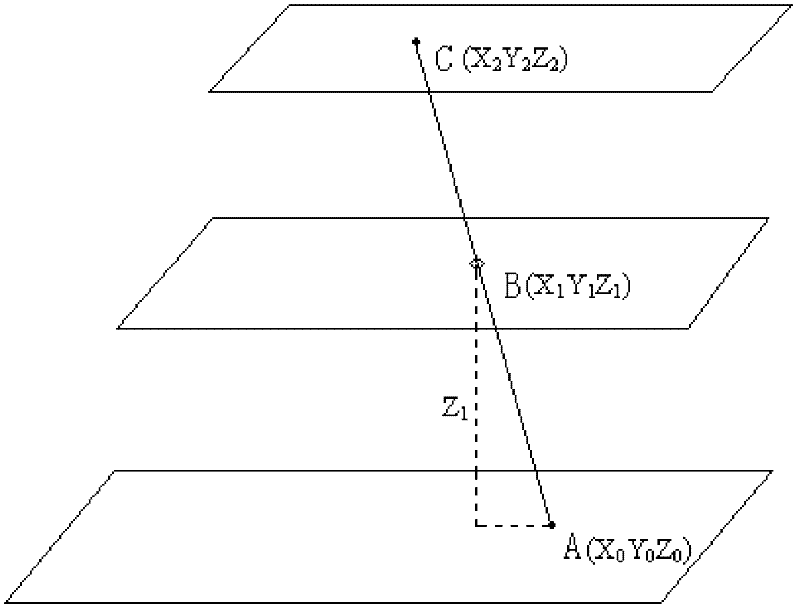

Image

Examples

Embodiment 1

[0040] Embodiment 1 technological step

[0041] The pre-order steps are the same as those of the prior art, and the process steps for forming the second protective layer: firstly, vacuum the chamber so that the degree of vacuum is 1.9×10 -4 Pa, the temperature was raised to 290°C while evacuating; after that, oxygen was passed into the chamber to reduce the vacuum to 2.8×10 -2 Pa, and then steam to reduce the vacuum to 5.1×10 -2 Pa; keep the moving speed of the substrate at 420 mm / sec during evaporation; finally control the thickness of the second protective layer to be 3700 angstroms.

Embodiment 2

[0042] Embodiment 2 technological steps

[0043] The steps are the same as in Example 1, the difference is: first vacuumize the chamber so that the degree of vacuum is 5.0×10 -4 Pa, the temperature was raised to 300°C while evacuating.

Embodiment 3

[0044] Embodiment 3 technological steps

[0045] The steps are the same as in Example 1, the difference is: first vacuumize the chamber so that the degree of vacuum is 7.6 × 10 -4 Pa, the temperature was raised to 310°C while evacuating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com