Metal and zinc oxide doped magnesium oxide secondary electron emission film and preparation method thereof

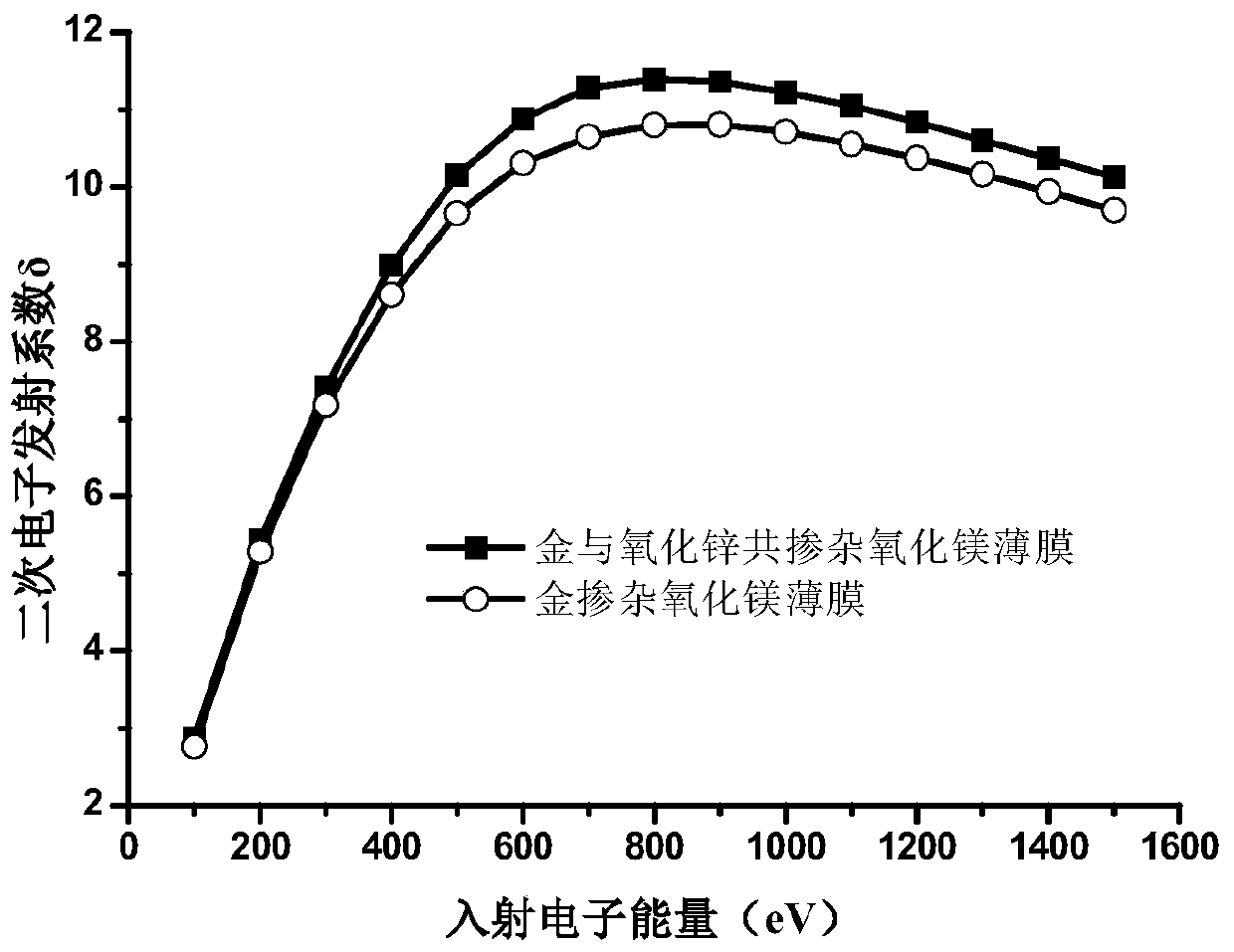

A technology of secondary electron emission and metal doping, applied in metal material coating process, sputtering coating, vacuum evaporation coating, etc. The problem of secondary electron emission attenuation, etc., can improve the secondary electron emission coefficient, improve the electron transport characteristics, and reduce the forbidden band width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

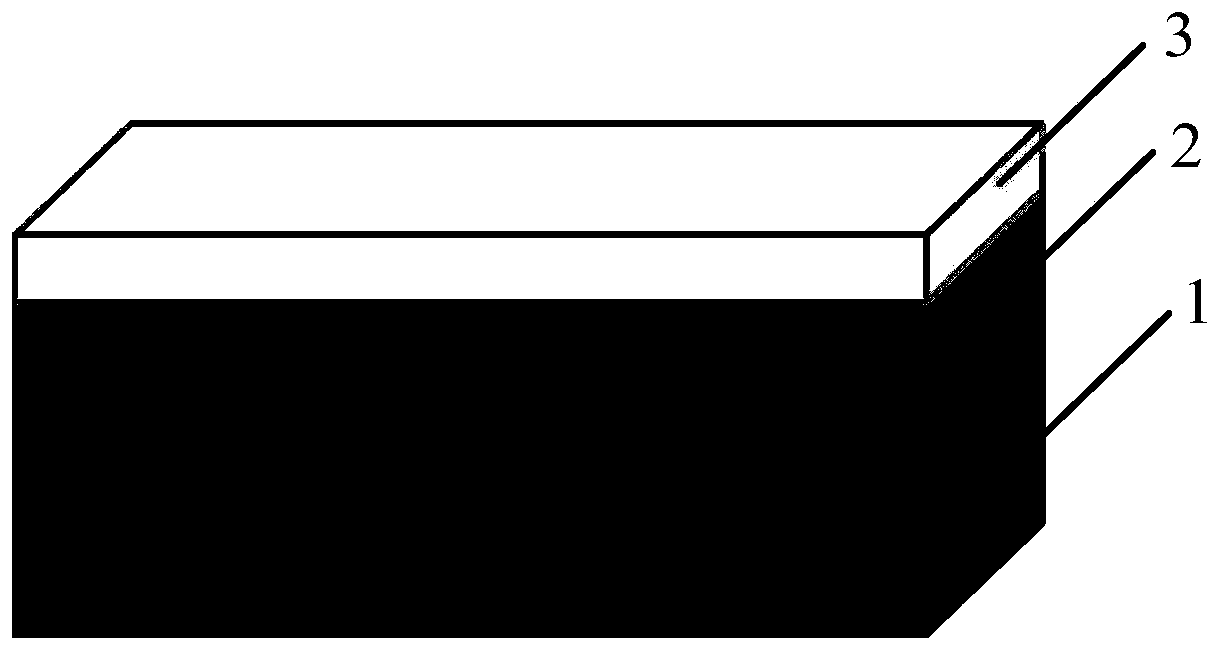

[0026] see figure 1When the metal buffer layer 4 is not provided in the present invention, it consists of a gold-doped magnesium oxide film layer on the surface of the substrate 1 and a zinc oxide-doped magnesium oxide film layer 3 on the top layer. Each film layer is prepared by a sputtering method, specifically Include the following steps:

[0027] 1) A gold-doped magnesium oxide film layer is deposited on the substrate 1 by means of radio frequency sputtering magnesium target and direct current sputtering gold target. During the deposition process, the temperature of the substrate 1 is kept at 300° C. Inject argon and oxygen, the flow ratio of argon to oxygen is 5:1, the total pressure in the coating chamber is 0.2Pa, the thickness of the deposited gold-doped magnesium oxide film is 100nm, the gold-doped magnesium oxide film layer The atomic percentage of gold is 30%.

[0028] 2) The zinc oxide-doped magnesium oxide film layer 3 is deposited on the gold-doped magnesium ox...

Embodiment 2

[0030] see figure 1 , when the metal buffer layer 4 is not provided in the present invention, it consists of a gold and zinc oxide co-doped magnesium oxide film layer on the surface of the substrate 1 and a zinc oxide-doped magnesium oxide film layer 3 on the top layer, and each film layer is sputtered Method preparation;

[0031] Specifically include the following steps:

[0032] 1) A gold and zinc oxide co-doped magnesium oxide film layer is deposited on the substrate 1 by radio frequency sputtering magnesium oxide target, zinc oxide target and direct current sputtering gold target. During the deposition process, the substrate temperature is maintained at 400°C. Argon and oxygen are fed into the coating chamber at the same time, the flow ratio of argon and oxygen is 10:1, the total pressure in the coating chamber is 0.25Pa, and the thickness of the deposited gold and zinc oxide co-doped magnesium oxide film is 50nm , the atomic percentage content of gold is 15%, and the at...

Embodiment 3

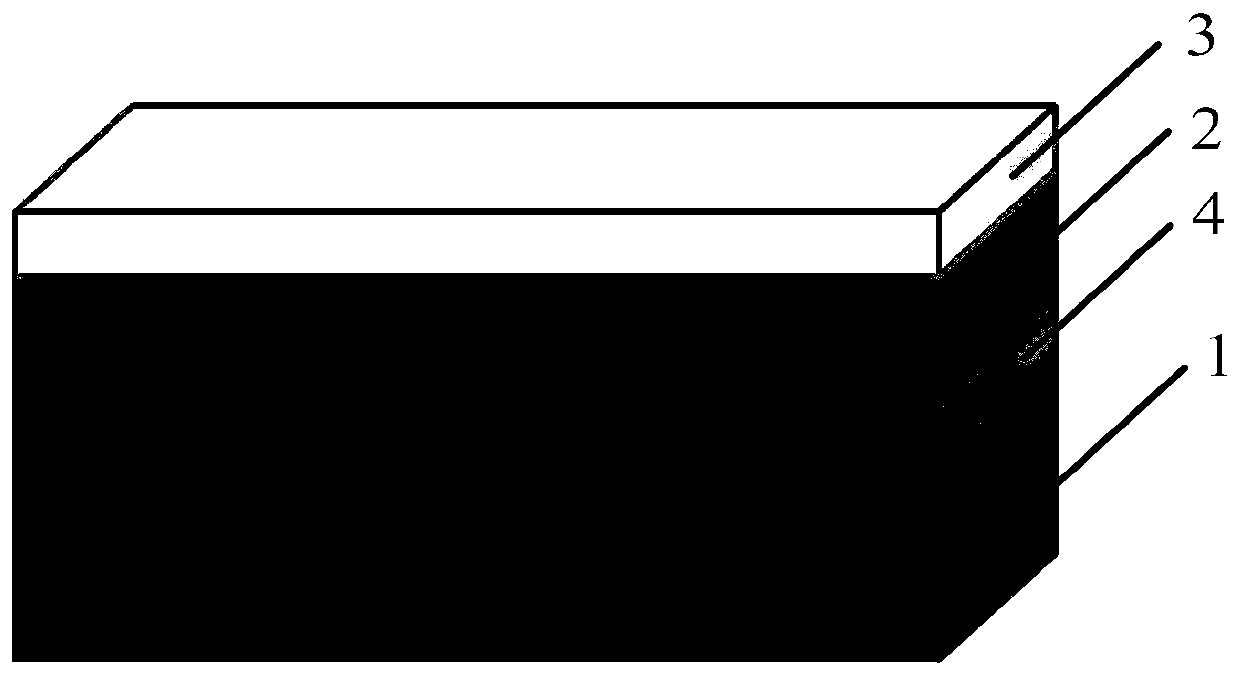

[0035] see figure 2 , the present invention increases the film structure of the metal buffer layer 4, which is composed of a gold buffer layer positioned on the surface of the substrate 1, a gold-doped magnesium oxide film layer and a zinc oxide-doped magnesium oxide film layer 3 on the top layer, and each film layer is sputtered shot preparation.

[0036] The preparation method specifically includes the following steps:

[0037] 1) A gold buffer layer was deposited on the substrate 1 by means of direct current sputtering gold target. During the deposition process, the temperature of the substrate was kept at 100° C., argon gas was introduced into the coating chamber, and the total pressure in the coating chamber was 0.5 Pa. The thickness of the deposited gold buffer layer is 10 nm.

[0038] 2) The gold-doped magnesium oxide film layer was deposited on the gold buffer layer by radio frequency sputtering magnesium target and DC sputtering gold target. During the deposition p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com