E-beam bombardment resistant secondary electron emission composite film and preparation method thereof

A technology of secondary electron emission and electron beam bombardment, used in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of poor resistance to electron/ion beam bombardment and unstable secondary electron emission performance and other problems, to achieve the effect of high secondary electron emission coefficient, excellent resistance to electron beam bombardment, and good crystallinity of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

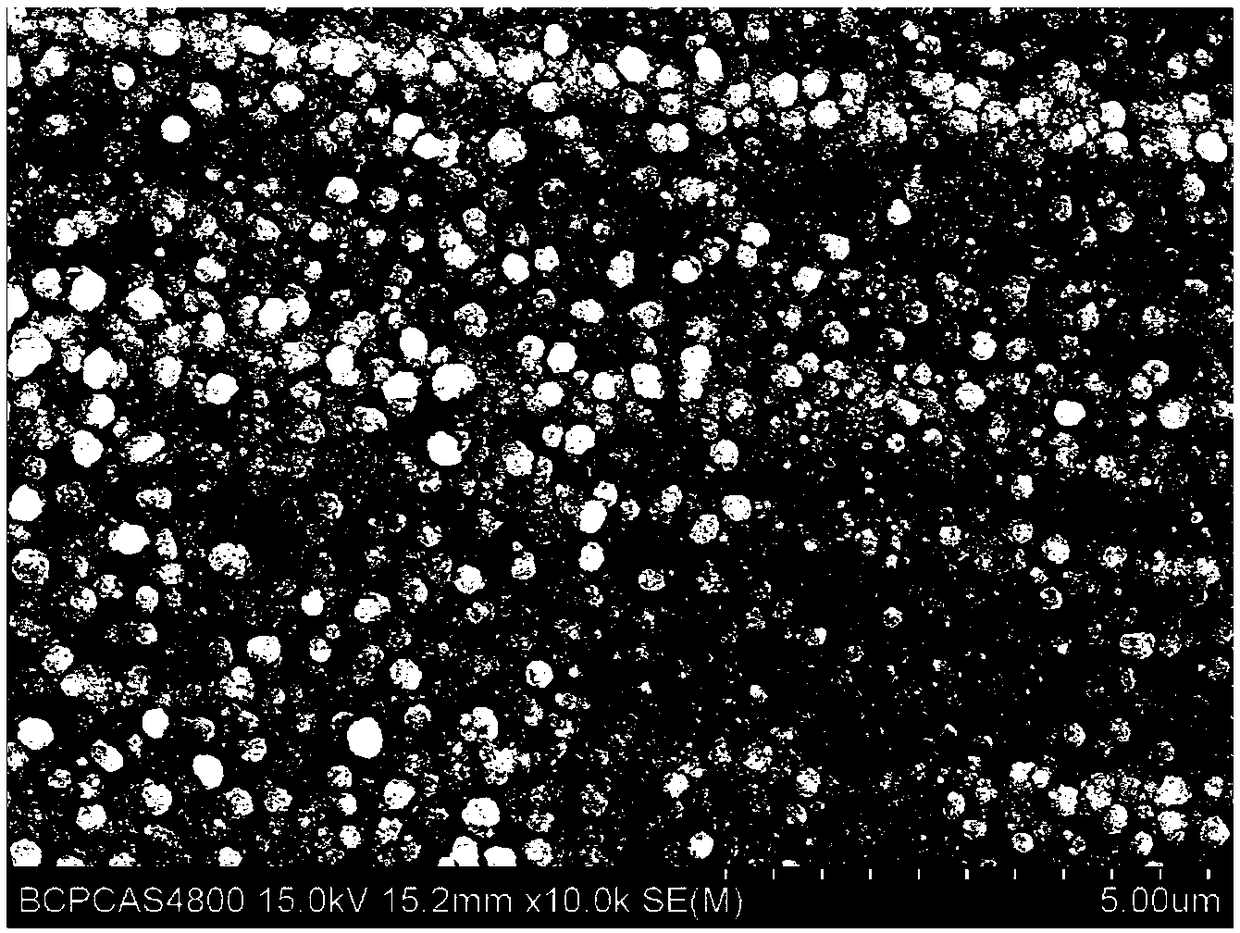

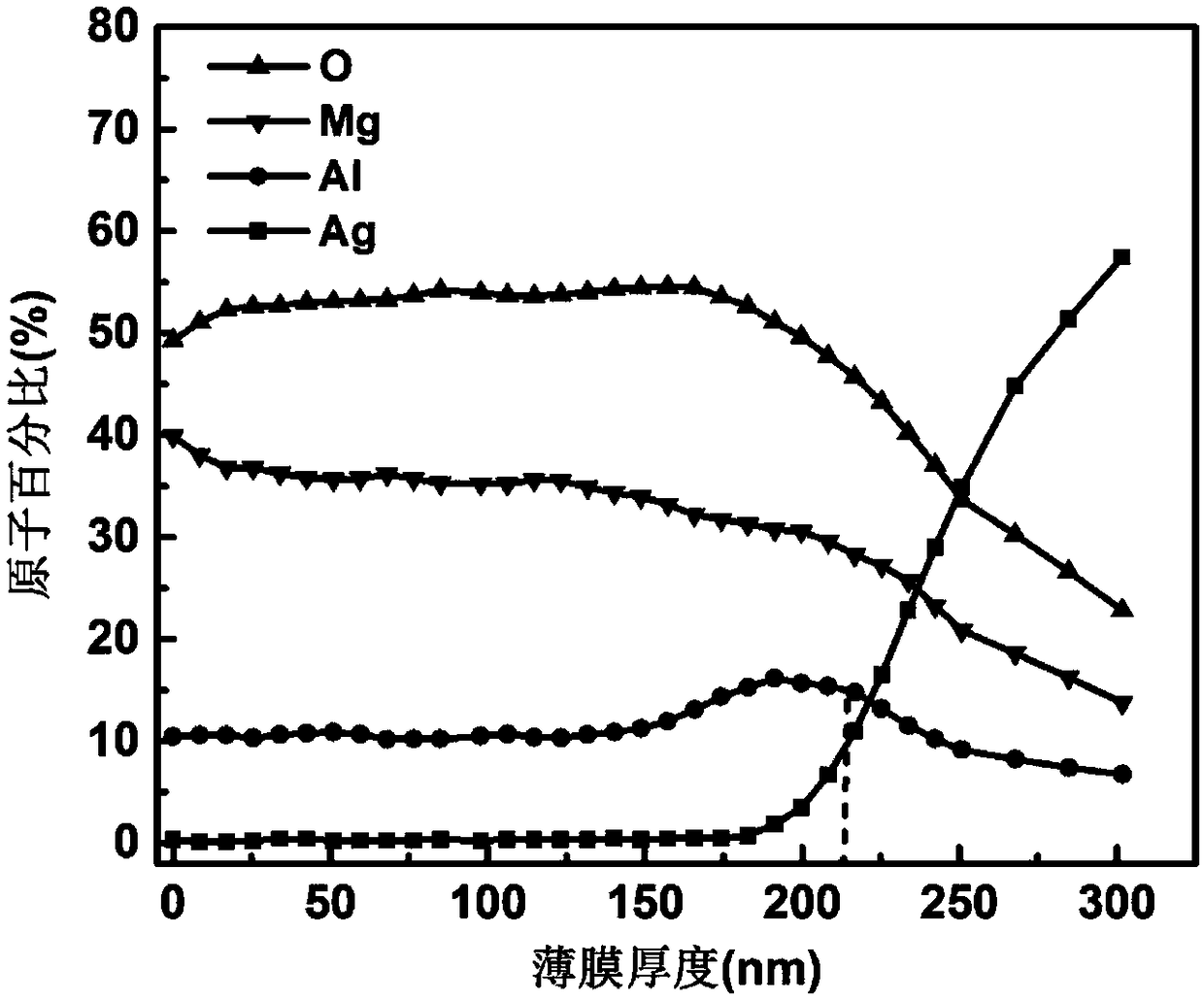

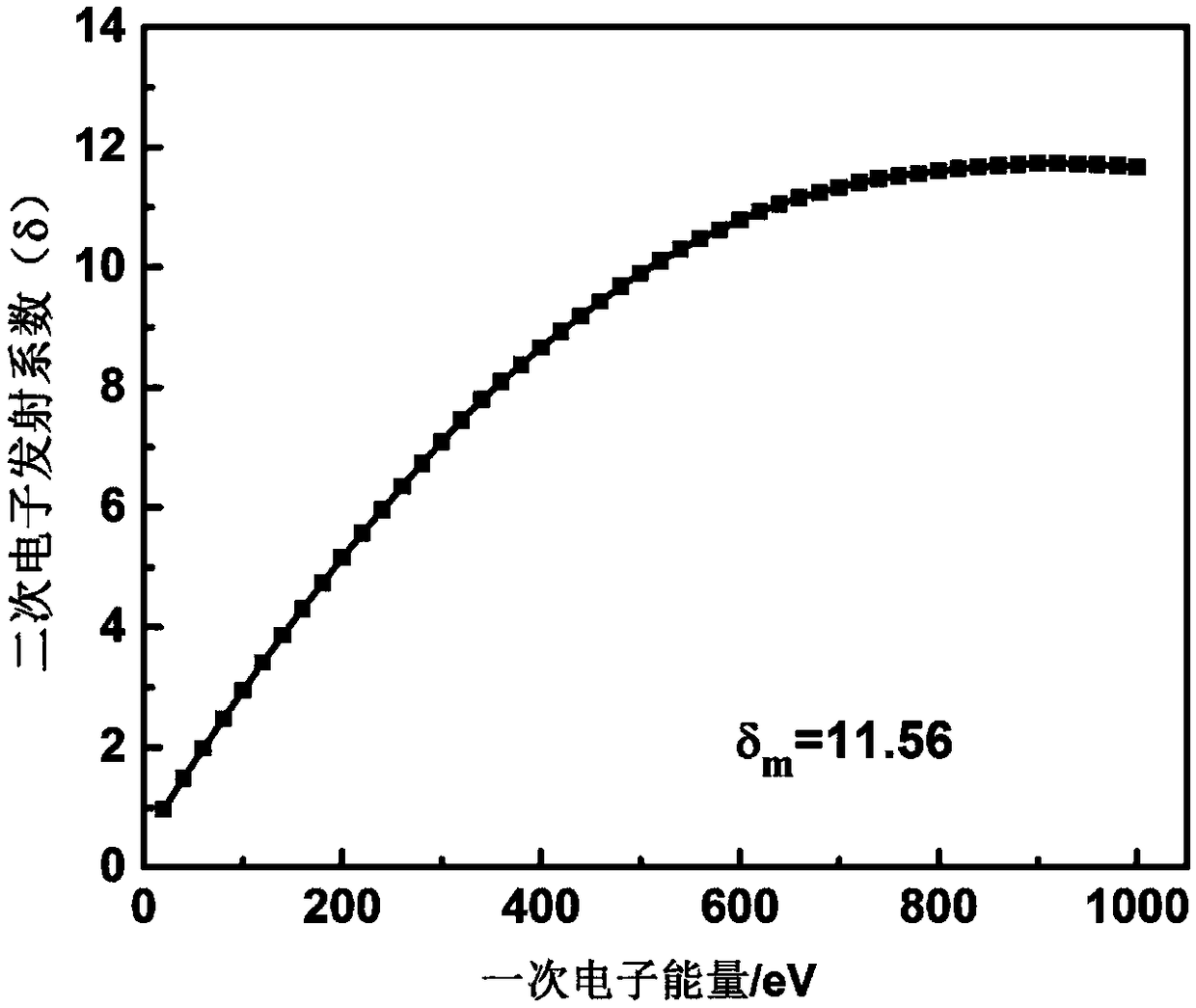

Embodiment 1

[0036] Install the prepared magnesium-aluminum alloy (magnesium:aluminum=5:1 molar ratio) target on the DC target position. Fix the cleaned and dried high-purity silver sheet on the sample stage with a 400°C high-temperature-resistant tape, and place it in the sample chamber of the magnetron sputtering coating system together with the sample stage. The silver sheet was cleaned by argon ion glow discharge under the condition of radio frequency power of 50W in the sampling chamber, and then the silver sheet was sent into the reaction chamber together with the sample table by the manipulator, and the mechanical pump and the molecular pump baffle valve were turned on to start vacuuming. Wait until the vacuum degree of the reaction chamber reaches the set background vacuum degree of 5×10 -4At Pa, start the resistance heating system and start heating the sample stage. When the temperature of the sample stage reaches the set temperature of 400°C, start to feed the mixed gas of oxygen...

Embodiment 2

[0040] Install the prepared magnesium-aluminum alloy (magnesium:aluminum=5:1 (molar ratio)) target on the DC target position. Fix the cleaned and dried high-purity silver sheet on the sample stage with a 400°C high-temperature-resistant tape, and place it in the sample chamber of the magnetron sputtering coating system together with the sample stage. The silver sheet was cleaned by argon ion glow discharge under the condition of radio frequency power of 50W in the sampling chamber, and then the silver sheet was sent into the reaction chamber together with the sample table by the manipulator, and the mechanical pump and the molecular pump baffle valve were turned on to start vacuuming. Wait until the vacuum degree of the reaction chamber reaches the set background vacuum degree of 5×10 -4 At Pa, start the resistance heating system and start heating the sample stage. When the temperature of the sample stage reaches the set temperature of 400°C, start to feed the mixed gas of oxy...

Embodiment 3

[0043] Install the prepared magnesium-aluminum alloy (magnesium:aluminum=5:1 (molar ratio)) target on the DC target position. Fix the cleaned and dried high-purity silver sheet on the sample stage with a 400°C high-temperature-resistant tape, and place it in the sample chamber of the magnetron sputtering coating system together with the sample stage. The silver sheet was cleaned by argon ion glow discharge under the condition of radio frequency power of 50W in the sampling chamber, and then the silver sheet was sent into the reaction chamber together with the sample table by the manipulator, and the mechanical pump and the molecular pump baffle valve were turned on to start vacuuming. Wait until the vacuum degree of the reaction chamber reaches the set background vacuum degree of 5×10 -4 At Pa, start the resistance heating system and start heating the sample stage. When the temperature of the sample stage reaches the set temperature of 400°C, start to feed the mixed gas of oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com