Discharge lamp

A technology for discharge lamps and discharge capacitors, which is applied to discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of difficult processing and expensive tungsten, and achieve low cost, small heat load, and high emissivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] With the aid of xenon short-arc lamps or mercury vapor short-arc lamps (OSRAM XBO or OSRAM HBO ) to illustrate the present invention. In a xenon short-arc lamp, the discharge arc burns in an atmosphere of pure xenon gas (or gas mixture) at high pressure. In mercury vapor short arc lamps, the atmosphere is mercury vapor and one or more inert gases. XBO lamps are used, for example, in conventional and digital movie projection and HBO lamps in the electronics industry, eg in microchip and LCD production.

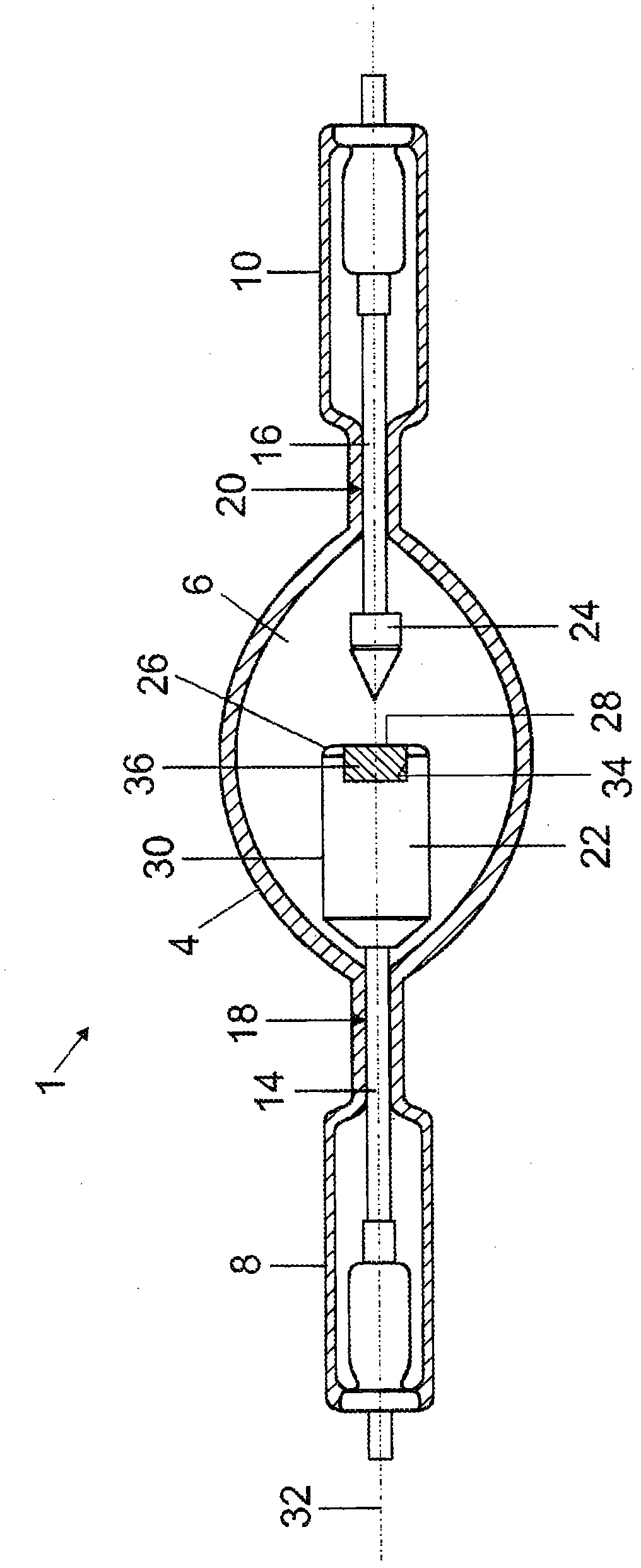

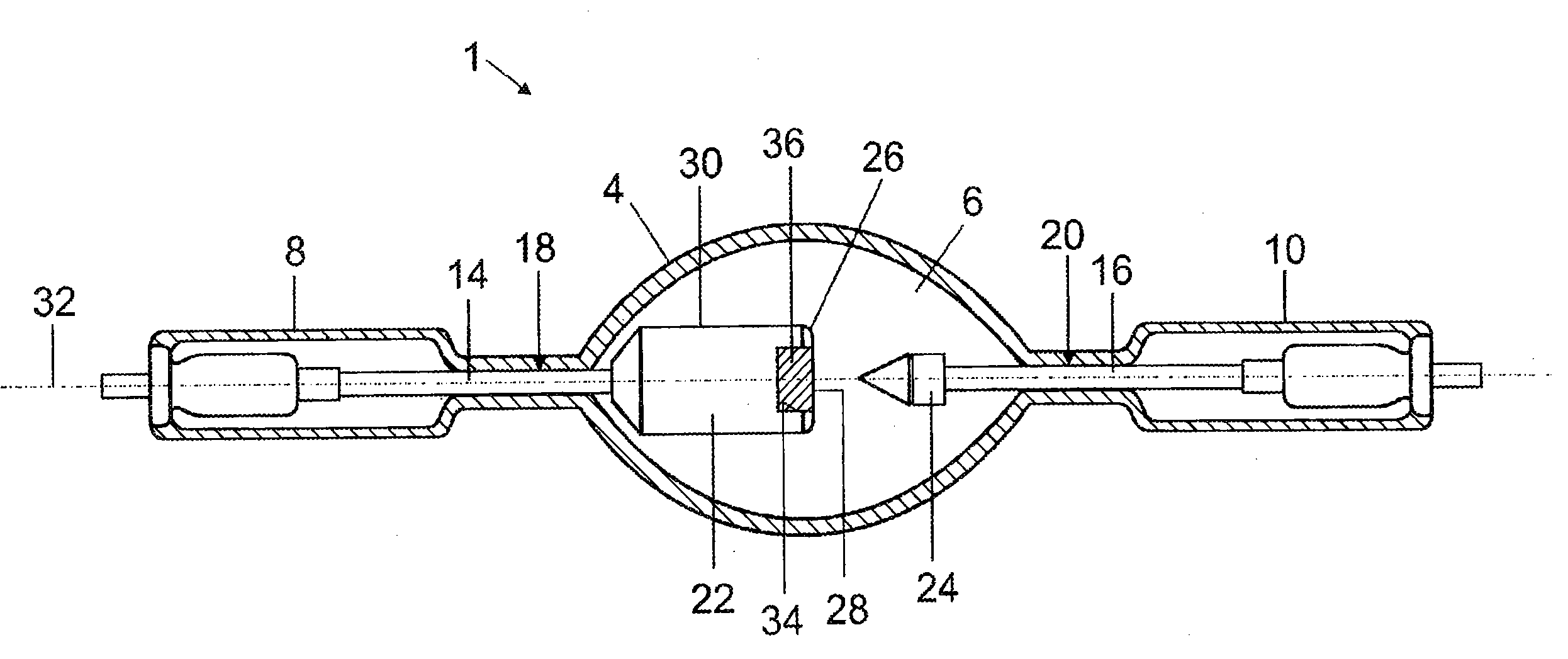

[0016] This figure shows a schematic view of a high-pressure discharge lamp 1 with bases on both sides designed for DC operation in short-arc technology. The high-pressure discharge lamp has a discharge vessel 4 made of quartz glass with a discharge space 6 and two sealed bulb stems 8 , 10 arranged radially on the discharge vessel 4 , the free end sections of which can be A base sleeve (not shown) is provided in each case. Two electrode systems 14 , 16 running in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com