A heat-storing black body cement and its preparation method

A technology of black body and cement, which is applied in the field of black body cement and its preparation, can solve the problems of insufficient heat storage and difficulty in increasing the volume of ceramic regenerators, and achieve good thermal conductivity, stable heat storage capacity and radiation capacity, and enhanced heat. The effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

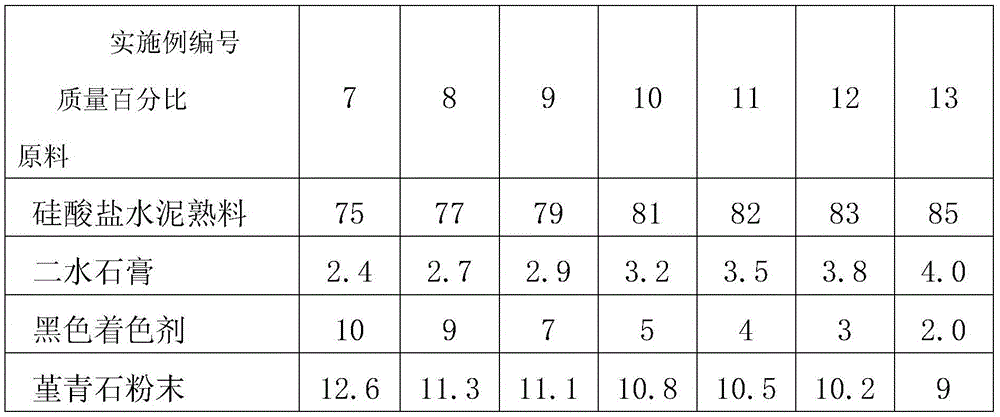

Examples

Embodiment 1

[0038] A heat-storing blackbody cement and a preparation method thereof:

[0039] A. Black body cement ingredients: Portland cement clinker, dihydrate gypsum, ferrite powder, and cordierite powder are mixed according to the mass percentage of Portland cement clinker 75%, dihydrate gypsum 2.4%, and ferrite powder 10% %, cordierite powder 12.6% metering.

[0040] B. Add each raw material into the ball mill according to the metering ratio and grind at a speed of 45r / min. The specific surface area of the prepared cement is 3560m 2 / kg.

[0041] C. Through the above-mentioned batching scheme and grinding process, the setting time of the prepared black body cement is normal, among which the initial setting time is 243min, the final setting time is 294min, the water consumption of standard consistency is about 28%, and the compressive strength for 3 days is 27.3MPa, 28 The daily strength is 43.2MPa, and the stability is qualified.

[0042] D, the clean slurry of the black body ...

Embodiment 2

[0044] A. Black body cement ingredients: Portland cement clinker, dihydrate gypsum, ferrite powder, and cordierite powder are mixed according to mass percentage Portland cement clinker 80%, dihydrate gypsum 3%, ferrite powder 8 %, cordierite powder 9% metering.

[0045] B. Add each raw material into the ball mill according to the metering ratio and grind at a speed of 45r / min. The specific surface area of the prepared cement is 3650m 2 / kg.

[0046] C. Through the above-mentioned batching scheme and grinding process, the setting time of the prepared blackbody cement is normal, the standard consistency water consumption is about 28%, the initial setting time is 238min, the final setting time is 274min, the strength of 3 days is 28.2MPa, and the strength of 28 days is 44.3 MPa, the stability is qualified.

[0047] D, the clean slurry of the black body cement prepared by the above process. After preparing the sample according to the requirements of the vacuum blackbody radi...

Embodiment 3

[0049] A. Blackbody cement ingredients: Portland cement clinker, dihydrate gypsum, graphite powder, and cordierite powder are prepared according to the mass percentage of Portland cement clinker 80%, dihydrate gypsum 3%, ferrite powder 3%, Cordierite powder 14% metered.

[0050] B. Add each raw material into the ball mill according to the metering ratio and grind at a speed of 45r / min. The specific surface area of the prepared cement is 3680m 2 / kg.

[0051] C. Through the above-mentioned batching scheme and grinding process, the setting time of the prepared black body cement is normal, the water consumption of the standard consistency is about 29%, the initial setting time is 247min, the final setting time is 286min, the strength of 3 days is 29.2MPa, and the strength of 28 days is 45.4 MPa, the stability is qualified.

[0052] D, the clean slurry of the black body cement prepared by the above process. After sample preparation according to the requirements of the vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com