Method for deoxidizing and concentrating mine gas

A gas and mine technology, which is applied in the field of mine gas deoxygenation and concentration production, can solve the problems of poor temperature resistance of catalyst, high cost of deoxidation operation, inapplicability of low-concentration gas deoxidation, etc., and achieve the goal of ensuring product quality and safe production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be illustrated by the following description of specific embodiments. For ease of illustration, the following description of the present invention is a separate description of each process for engineering the present invention. Each disclosed process is not strictly performed in the order described here, and the order of the processes can be changed as needed.

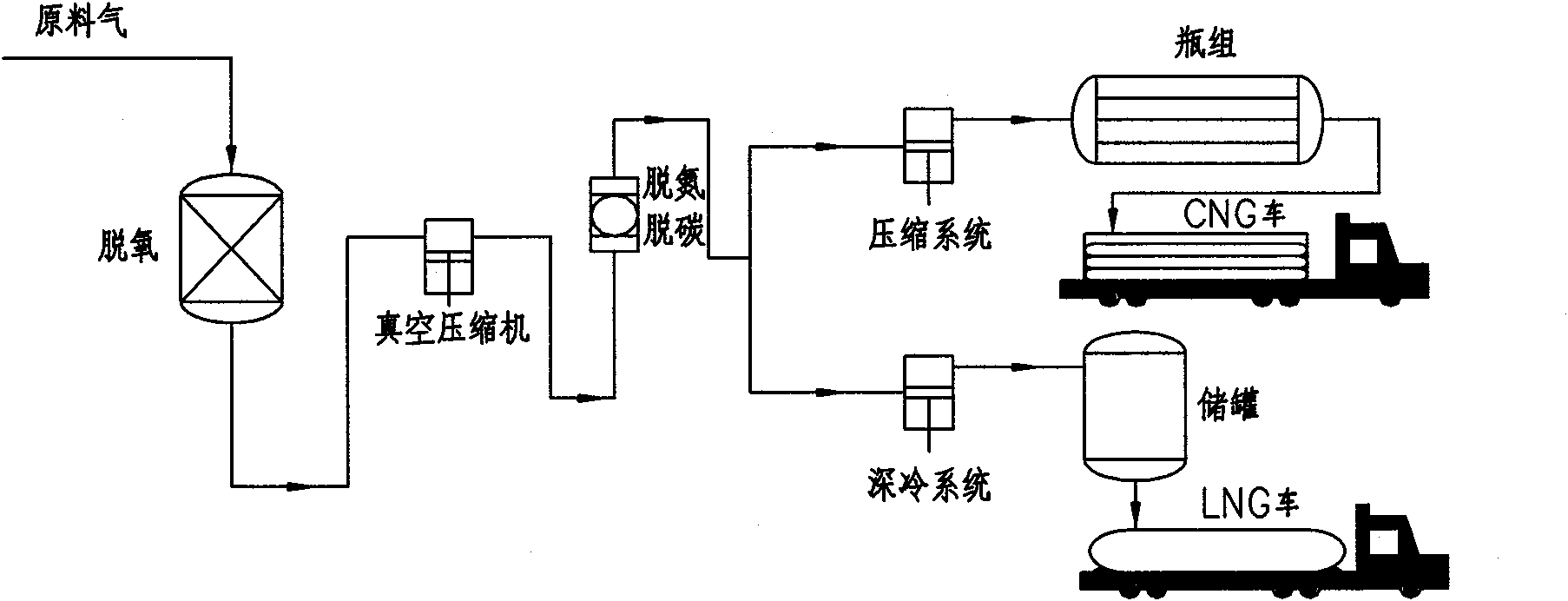

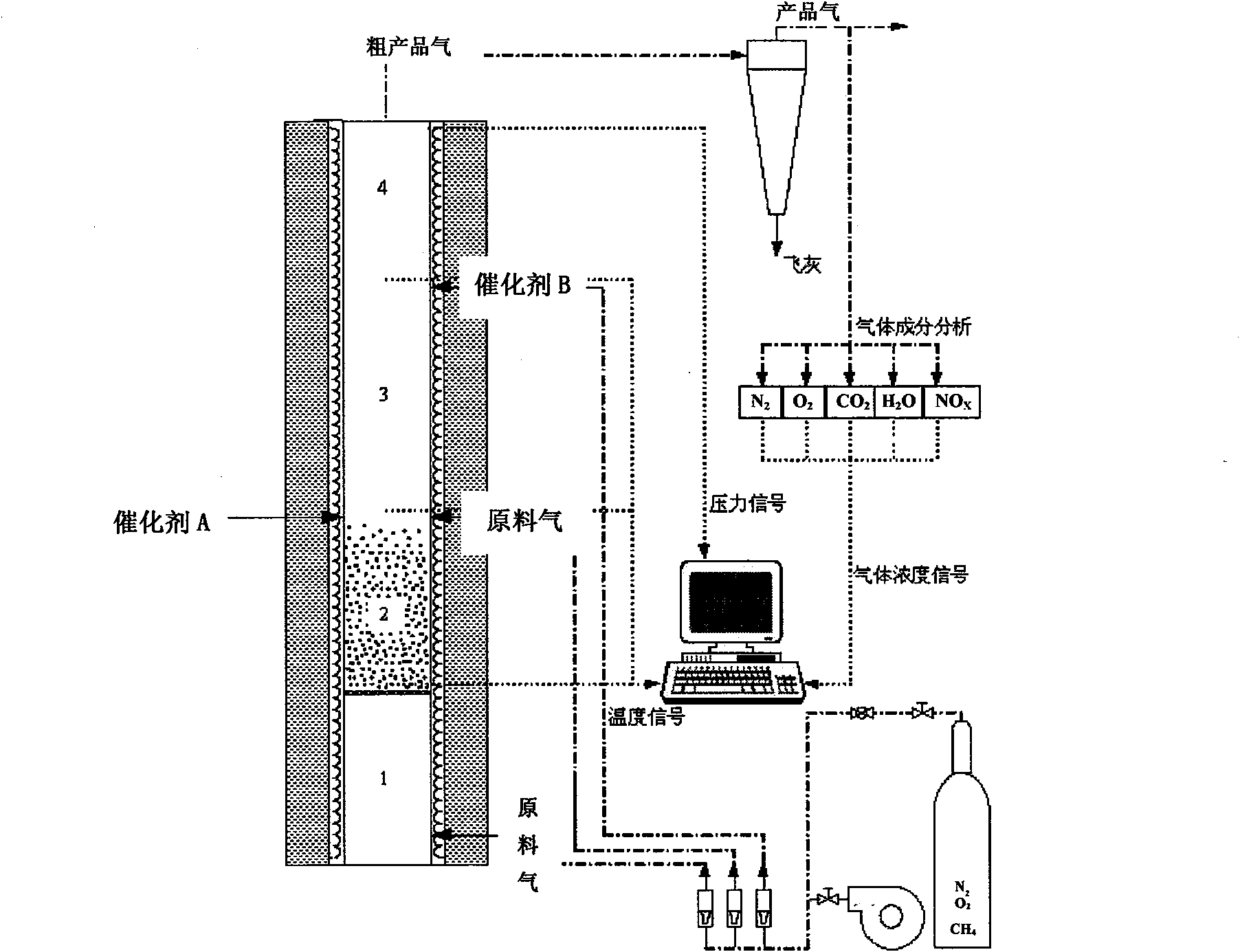

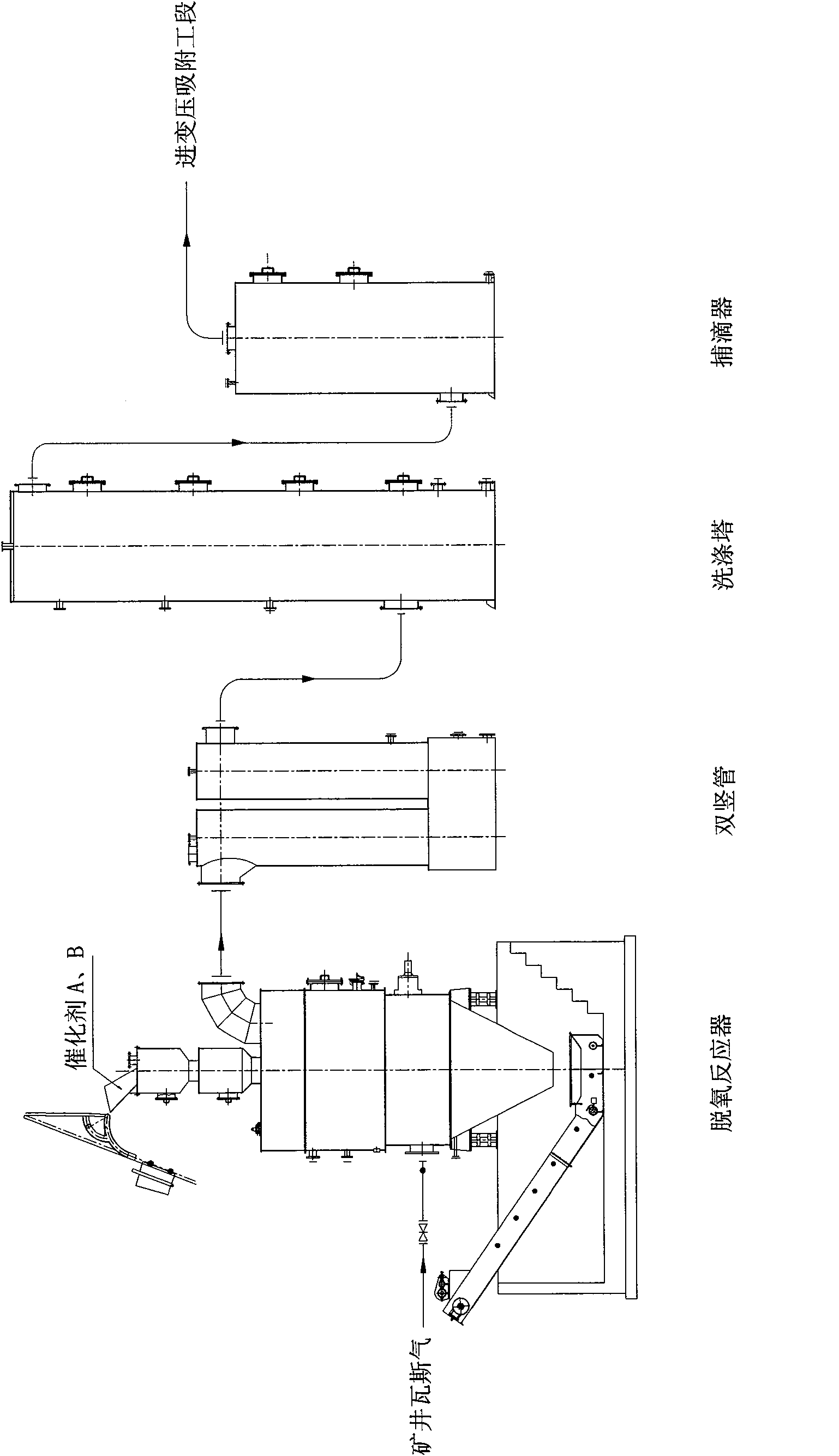

[0073] 1. Catalytic deoxidation

[0074] The purpose of deoxidation: to reduce the 10% (volume percentage) of oxygen in the mine gas to below 1% (volume percentage), which can improve the quality of the raw material gas and improve the operation safety of the downstream section.

[0075] This project successfully uses two kinds of catalysts for deoxygenation operation through dense-phase catalysis and dilute-phase catalysis two-stage catalysis process.

[0076] Catalyst A is in contact with the raw material gas in dense phase operation. This type of catalyst can remove most of the oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com