Multilayer fluidized bed gasification furnace for preparing methane-rich gas by coal gasification

A fluidized bed gasifier and multi-layer fluidized bed technology, applied in the field of gasifiers, can solve the problems of low reaction volume utilization rate, prolong the residence time of pulverized coal, affect solid phase processing, etc., and achieve the realization of logistics coupling, The effect of prolonging the average residence time and increasing the gas production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

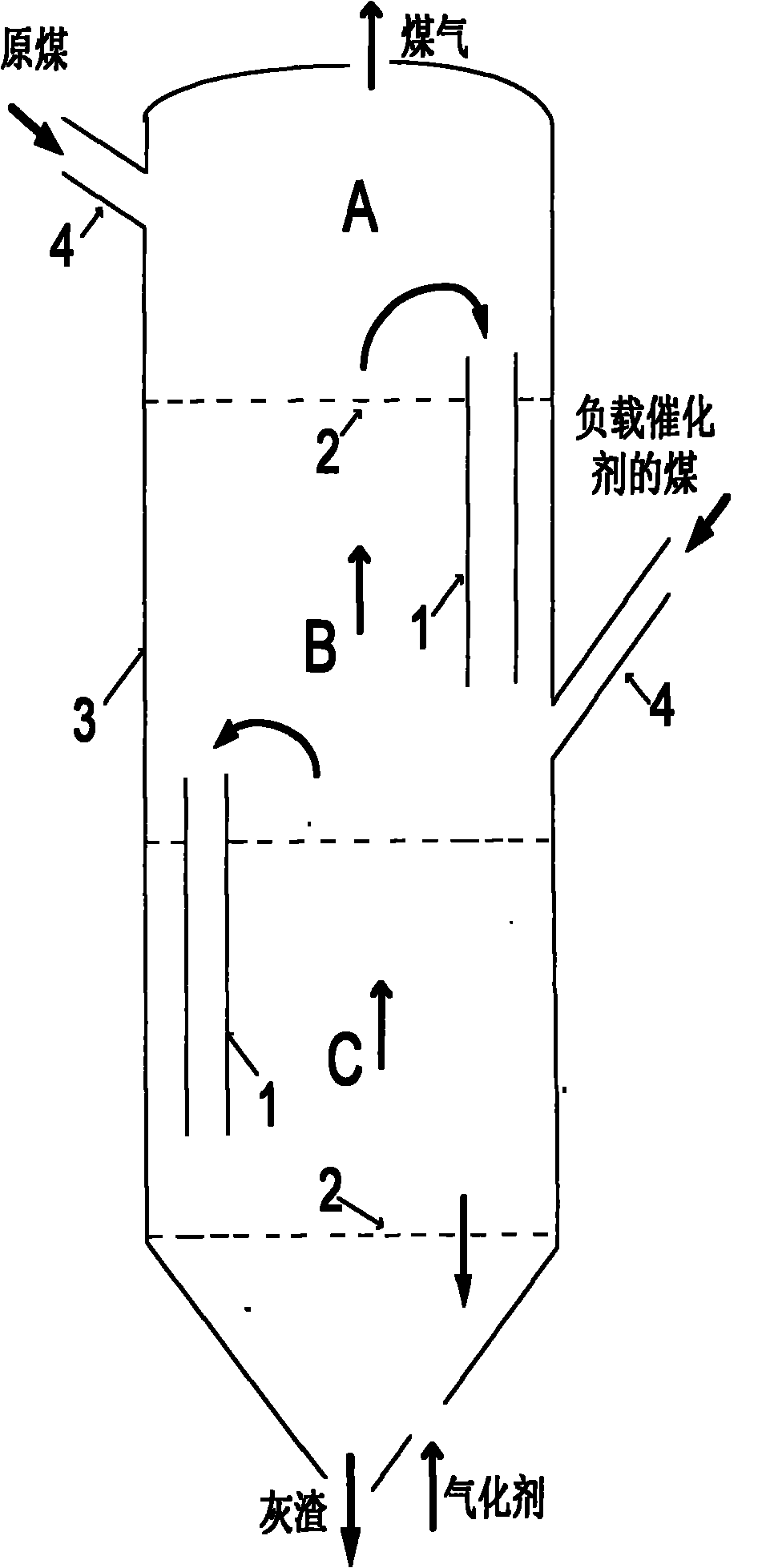

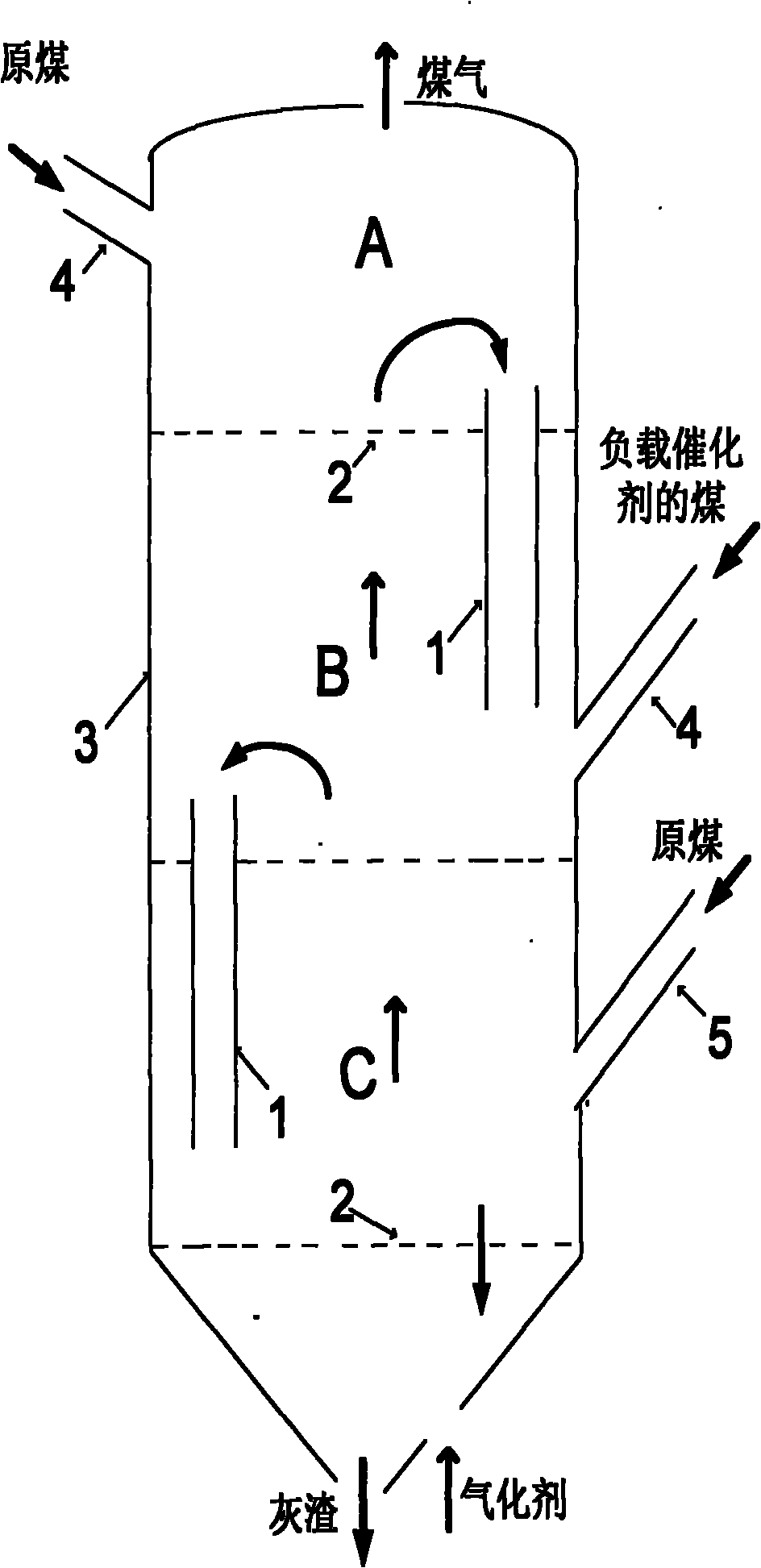

[0108] see figure 2 , in the structure figure 1 If the heat generated by the gasification of residues alone is difficult to meet the temperature requirements for catalytic gasification, a feed inlet 5 can be set on the furnace body 3 of the lowermost layer C of the multi-layer fluidized bed, through which the feed Add a small amount of raw coal to the residue gasification zone.

Embodiment 2

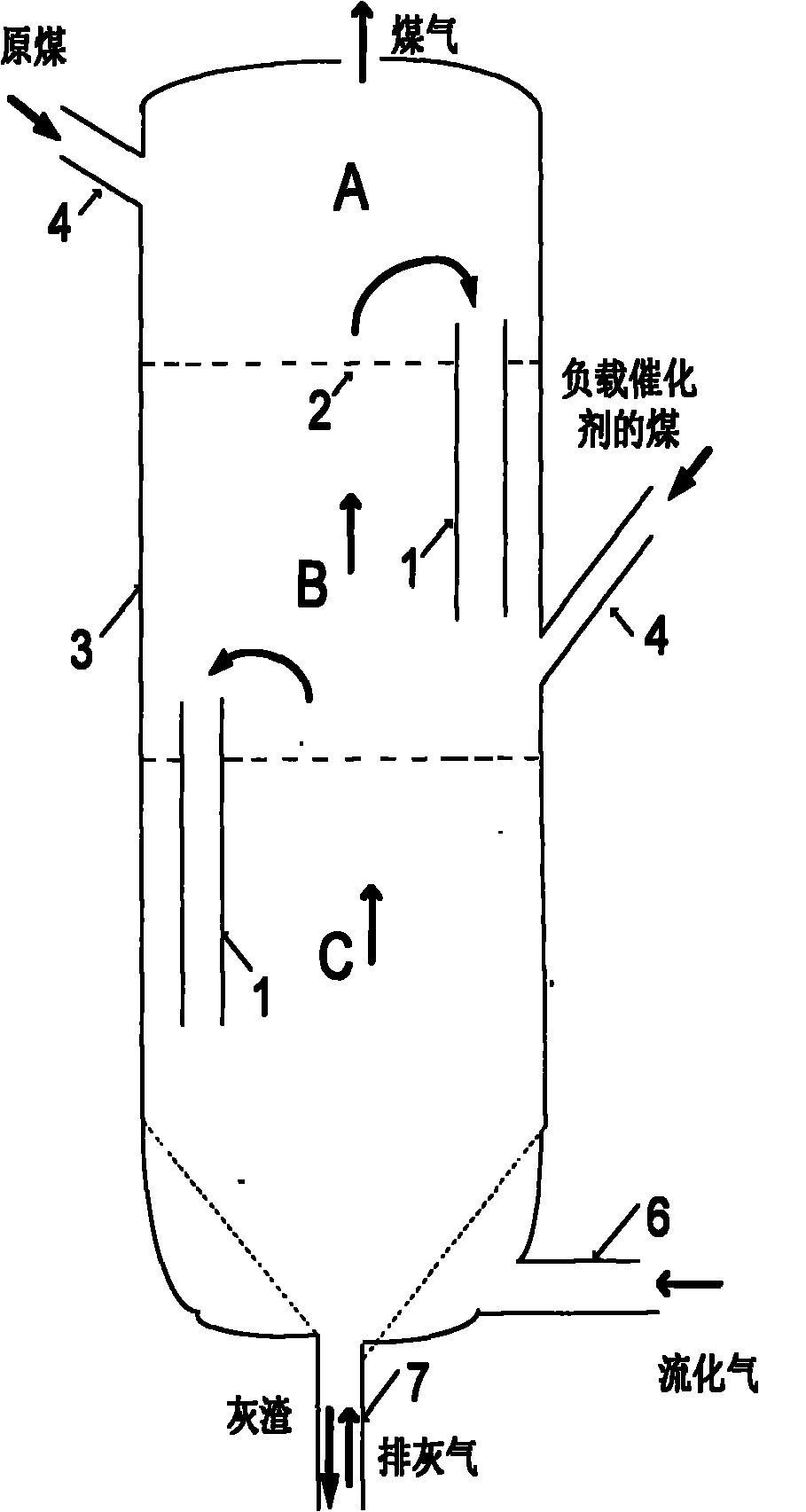

[0110] see image 3 , in the structure figure 1 In order to meet the needs of ash discharge or process operation conditions, the distribution plate of the lowest layer C of the multi-layer fluidized bed can be replaced, and the funnel-shaped distribution plate can be used to control the ash discharge gas velocity and flow through the air inlets 6 and 7 respectively. gasification speed.

Embodiment 3

[0112] see Figure 4 , in the structure figure 1 In order to avoid the reverse series of gas, to achieve continuous and stable overflow between the beds, and to facilitate the control of the overflow flow of the material, other forms of overflow pipes can be used, such as plug-type overflow pipes with mechanical transmission devices . Adjust the position of the plug 8 through the mechanical transmission device, change the direction of the gas and the size of the cross-section of the discharge port, and realize a smooth overflow.

[0113] Regarding the relative position of the overflow device and the gas distributor:

[0114] 1. The overflow pipe can be installed at any horizontal section of the gas distributor 2. It can be installed vertically or obliquely, and the angle with the horizontal plane is greater than or equal to 30°; in order to prevent solid particles from flowing between the two overflow pipes Short circuit, the outlet of the upper overflow pipe should keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com