Supercritical water treatment device and method

A technology of supercritical water and treatment device, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of increasing the difficulty of liquid discharge and increasing the energy consumption of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

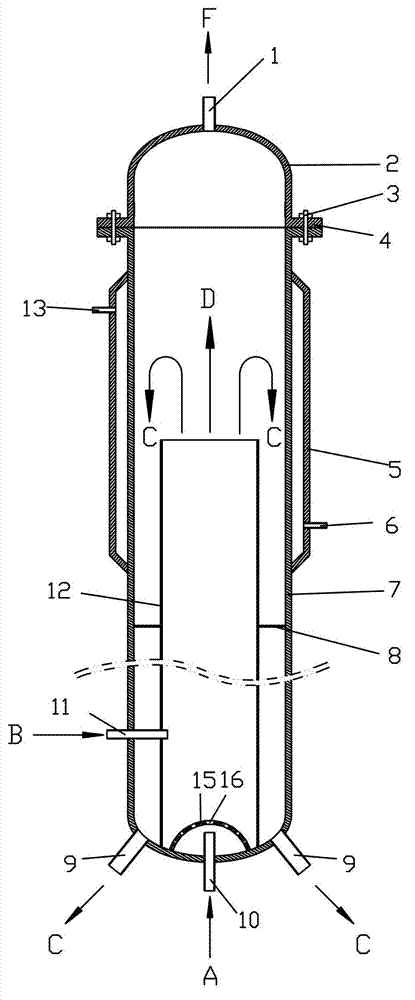

[0079] like figure 1 Shown, a kind of supercritical water treatment device, described device comprises:

[0080] Housing 7, made of pressure-resistant material, has an upwardly facing open end;

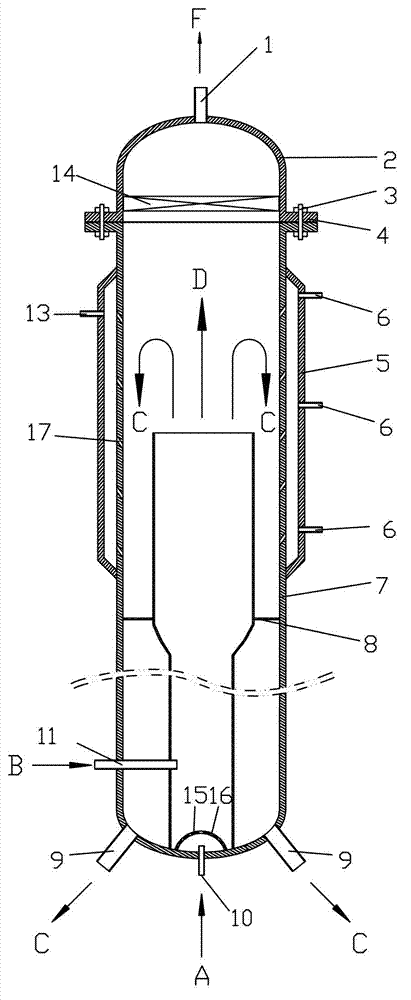

[0081] The top cover 2 is arranged on the top of the housing 7 and is flanged to the top to form a chamber with the inner wall of the housing 7; the flange connection is composed of fastening bolts 3 and connecting flanges 4 Assembled;

[0082] The inner sleeve 12 is made of temperature-resistant material, and is fixedly sleeved on the bottom of the chamber. There is an annular chamber between the inner sleeve 12 and the housing 7, and the annular chamber and the The chamber is in fluid communication; the inner sleeve 12 is fixed on the inner wall of the housing 7 through the bracket 8;

[0083] The oxidant inlet 10 is arranged through the bottom of the housing 7 and is in fluid communication with the chamber for allowing the oxidant to enter the inner sleeve 12; an oxidant distrib...

Embodiment 2

[0092] The present embodiment device is the same as embodiment 1, as figure 1 shown.

[0093] Use attached figure 1 The device performs supercritical treatment on waste water. Wastewater with a COD of 30258mg / L preheated to 250°C is used as raw material A and enters the inner sleeve 12 from the raw material inlet 11, and the inlet pressure of the waste water is 24~25MPa. The air with an inlet pressure of 22.5~25MPa and a temperature of 240°C is used as the oxidant B and enters the inner sleeve 12 through the oxidant inlet 10, and forms a spray state through the oxidant distribution hole 16 on the oxidant distributor 15, and the oxygen consumption is 120% of the COD value of the raw wastewater. %. After the air and waste water are mixed, a violent oxidation reaction releases heat, so that the temperature inside the inner sleeve 12 reaches 420° C., making the mixture a supercritical water state, and a supercritical water oxidation reaction occurs. The reaction product is in ...

Embodiment 3

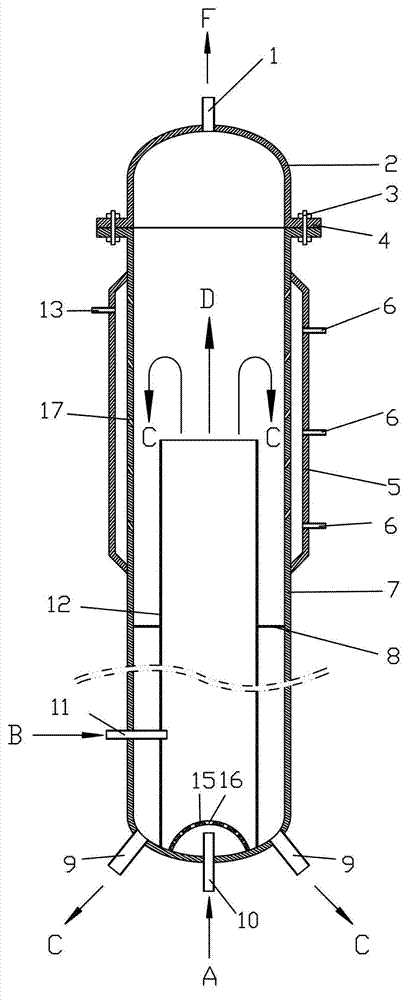

[0096] The difference between the device in this embodiment and the device in Embodiment 1 is that the part of the outer wall of the housing 7 surrounded by the cooling system is provided with a penetration hole 17 for the cooling medium to enter the chamber. The cooling medium inlets 6 are arranged as three inlets on the same side, and one cooling medium outlet 13 is arranged on the other side. like figure 2 shown.

[0097] Use attached figure 2 The device performs supercritical treatment on the coal-water slurry. Waste water with a concentration of 35% preheated to 500°C is used as raw material A and enters the inner sleeve 12 from the raw material inlet 11, and the inlet pressure of the coal-water slurry is 28-30 MPa. The oxidant B is a mixture of supercritical water and oxygen with a ratio of 5:1, the inlet pressure is 30~34MPa, and the temperature is 380°C. In the injection state, the amount of oxidant used is 7% of the oxygen demand for the complete combustion of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com