Calcium-based compound catalyst and loading method thereof

A composite catalyst, calcium-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low reaction activity and low methane content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

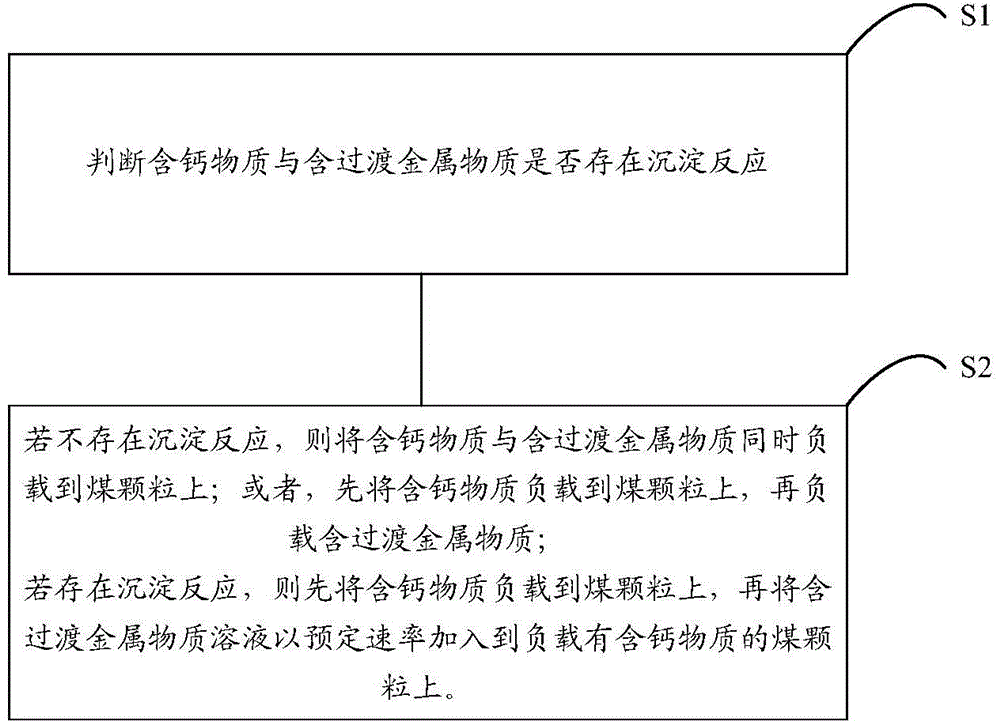

Method used

Image

Examples

Embodiment 1

[0111](1) Raw materials: lignite is used as coal particles and crushed to less than 1mm; the calcium-containing substance is Ca(NO 3 ) 2 , Ca(AC) 2 At least one of them, based on the quality of coal particles, the loading of calcium in the calcium-containing substance is 3%; the iron-containing substance is Fe(NO 3 ) 2 、Fe(AC) 2 At least one of them, the loading of iron element in the iron-containing substance is 1%; the nickel-containing substance is Ni(NO 3 ) 2 、Ni(AC) 2 At least one of them, the loading amount of nickel element in the nickel-containing substance is 1%.

[0112] (2) Loading method: Any one of the following methods can be used to load the catalyst:

[0113] a) Mix calcium-containing substances and coal particles evenly, add water and stir, impregnate, then mix iron-containing substances or nickel-containing substances with coal particles loaded with calcium-containing substances, add water and stir, and impregnate; add water, stir and impregnate, in or...

Embodiment 2

[0118] (1) Raw materials: Coal particles are blended with lignite, sub-bituminous coal, bituminous coal or anthracite, crushed to less than 1mm; calcium-containing substances are CaO, Ca(OH) 2 , Ca(AC) 2 , Ca(NO 3 ) 2 At least one of them, based on the mass of coal particles, the loading of calcium in the calcium-containing substances is 4.5%, and the iron-containing substances are FeO, Fe 2 o 3 , Fe 3 o 4 At least one of them, the loading of iron element in the iron-containing substance is 0.5%; or the nickel-containing substance is NiO, the loading of nickel element in the nickel-containing substance is 0.5%, and the iron-containing substance and the nickel-containing substance are pre-broken to 0.1mm the following.

[0119] (2) Loading method: the catalyst comprising calcium-containing substance and iron-containing substance, i.e. Ca-Fe catalyst, and the catalyst comprising calcium-containing substance and nickel-containing substance, i.e. Ca-Ni catalyst, are loaded a...

Embodiment 3

[0125] (1) Raw materials: lignite is used as coal particles, crushed to less than 1mm; calcium-containing substances and iron-containing substances or nickel-containing substances are precipitated and reacted to form other products. Among them, calcium-containing substances can be selected from CaO, Ca(OH) 2 , CaSO 4 , Ca(AC) 2 , Ca(NO 3 ) 2 At least one of them, based on the quality of coal particles, the load of calcium in the calcium-containing material is 3.5%; the iron-containing material can be selected from Fe(NO 3 ) 2 、Fe(AC) 2 、FeCO 3 , FeSO 4 At least one of them, the loading of iron element in the iron-containing substance is 1.3%, and the nickel-containing substance can be selected from Ni(NO 3 ) 2 、Ni(AC) 2 、NiCO 3 、NiSO 4 In at least one of them, the loading amount of nickel element in the nickel-containing substance is 0.2%.

[0126] (2) Loading method: first mix calcium-containing substances with coal particles evenly, add water to stir, and impregn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com