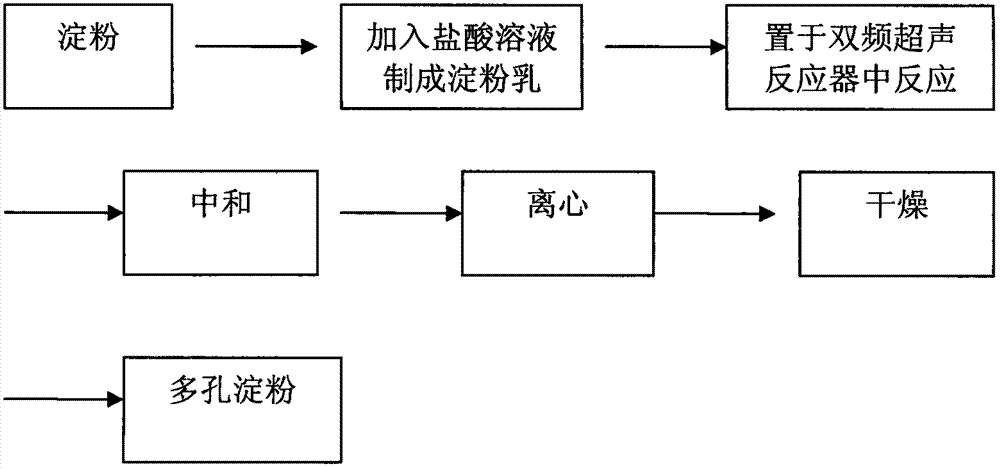

Method for processing porous starch through dual-frequency ultrasonic assisted acid hydrolysis

A dual-frequency ultrasonic, porous starch technology is applied in the processing field of modified starch, which can solve the problems of easy generation of standing waves and reduction of cavitation events, and achieve the effects of reducing dead angles, efficient utilization, and lowering production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 300g of cornstarch, make 30% starch milk solution with 700ml of 4% hydrochloric acid solution, place it in a dual-frequency ultrasonic reactor, and continuously stir it in a water bath at 35°C, with ultrasonic power of 800W, and ultrasonic frequencies of 25kHz and 50kHz. 3h, after the reaction, neutralize with saturated sodium carbonate solution, adjust the pH value to neutral, centrifuge at 3000r / min for 20min, separate the supernatant from the precipitate, wash the precipitate repeatedly with water to remove residual sodium chloride and sodium carbonate, Centrifuge again, take the precipitate, dry it in an oven at 40°C, and grind it into powder to obtain a porous starch product.

Embodiment 2

[0028] Weigh 350g of sweet potato starch, use 650ml of 3% hydrochloric acid solution to make a 35% starch milk solution, place it in a dual-frequency ultrasonic reactor, and keep stirring for 4 hours in a water bath at 40°C, with ultrasonic power of 700W, and ultrasonic frequencies of 25kHz and 70kHz. , after the reaction, neutralize with saturated sodium carbonate solution, adjust the pH value to neutral, centrifuge at 3000r / min for 20min, separate the supernatant from the precipitate, wash the precipitate with water repeatedly to remove residual sodium chloride and sodium carbonate, and again Centrifuge, take the precipitate, dry it in an oven at 40°C, and grind it into powder to obtain a porous starch product.

Embodiment 3

[0030] Weigh 400g of mung bean starch, use 600ml of 2% hydrochloric acid solution to make 40% starch milk solution, place it in a dual-frequency ultrasonic reactor, and keep stirring for 5 hours in a water bath at 45°C, with ultrasonic power of 600W, and ultrasonic frequencies of 50kHz and 70kHz. , after the reaction, neutralize with saturated sodium carbonate solution, adjust the pH value to neutral, centrifuge at 3000r / min for 20min, separate the supernatant from the precipitate, wash the precipitate with water repeatedly to remove residual sodium chloride and sodium carbonate, and again Centrifuge, take the precipitate, dry it in an oven at 40°C, and grind it into powder to obtain a porous starch product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com